Insulation silica gel material and silicon fabric used for new-energy vehicle battery heater

A technology of insulating silica gel and silica gel cloth, which is applied in the field of silica gel cloth for new energy vehicle battery heating sheets, can solve the problems of short circuit of heating wire and poor insulation, and achieve good flame retardant effect, good flexibility, compression performance, and outstanding thermal conductivity effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

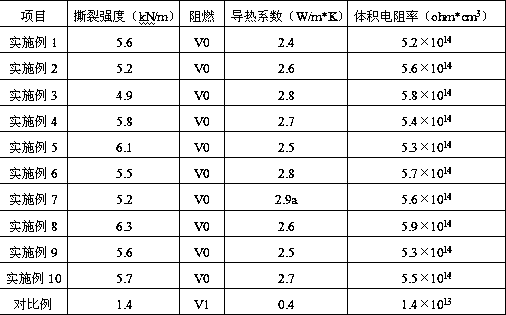

Examples

Embodiment 1

[0028] The insulating silicone material of this embodiment is prepared from raw materials including the following components and parts by weight: 100 parts of silicone rubber, 26 parts of composite flame retardant, 52 parts of filler, 4 parts of lubricant, 3 parts of accelerator and vulcanizing agent 3.5 servings.

[0029] Among them, the silicone rubber is methyl vinyl silicone rubber, the filler is silicon dioxide, calcium carbonate and silicon carbide mixed at a mass ratio of 1:1:1, the lubricant is calcium stearate, and the accelerator is 2-sulfur Alcohol benzothiazole, vulcanizing agent is thiuram vulcanizing agent.

[0030] In this example, the composite flame retardant includes the following components and weight percentages: 16% ammonium polyphosphate, 20% melamine, 8% magnesium hydroxide, 7% aluminum hydroxide, 5% zinc borate, antimony trioxide 18%, and the rest is graphite. The degree of polymerization of ammonium polyphosphate is 1300, and the graphite is expanded...

Embodiment 2

[0038] The insulating silicone material of this embodiment is prepared from raw materials including the following components and parts by weight: 105 parts of silicone rubber, 17 parts of composite flame retardant, 45 parts of filler, 3 parts of lubricant, 4 parts of accelerator and vulcanizing agent 5 servings.

[0039]Among them, the silicone rubber is methyl vinyl phenyl silicone rubber, the filler is silicon dioxide, calcium carbonate and alumina mixed in a mass ratio of 1:1:2, the lubricant is glyceryl tristearate, and the accelerator It is N, N'-bicyclohexyl-2-benzothiazole sulfenamide, and the vulcanizing agent is 2,2'-methyl diisocyanate.

[0040] In this example, the composite flame retardant includes the following components and weight percentages: 12% ammonium polyphosphate, 16% melamine, 7% magnesium hydroxide, 6% aluminum hydroxide, 4% zinc borate, antimony trioxide 14%, the rest is graphite. The degree of polymerization of ammonium polyphosphate is 1400, and th...

Embodiment 3

[0048] The insulating silicone material of this embodiment is prepared from raw materials including the following components and parts by weight: 110 parts of silicone rubber, 38 parts of composite flame retardant, 48 parts of filler, 5 parts of lubricant, 5 parts of accelerator and vulcanizing agent 8 servings.

[0049] Among them, the silicone rubber is nitrile silicone rubber, the filler is silicon dioxide, silicon nitride and alumina mixed in a mass ratio of 2:1:2, the lubricant is monoglyceride stearate, and the accelerator is dimethyl Zinc dithiocarbamate, vulcanizing agent is tetraethylenepentamine.

[0050] In this embodiment, the composite flame retardant includes the following components and weight percentages: 12% ammonium polyphosphate, 18% melamine, 21% magnesium hydroxide, 8% aluminum hydroxide, 5% zinc borate, antimony trioxide 8%, and the rest is graphite. The degree of polymerization of ammonium polyphosphate is 1500, and the graphite is expanded graphite. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com