Electronic component and production method thereof

A technology of electronic components and components, which is applied in the direction of capacitor components, electrical components, capacitor terminals, etc., and can solve the problems of electrolytic capacitors such as 1 large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0140] Hereinafter, the present invention will be described in detail with reference to embodiments as shown in the accompanying drawings.

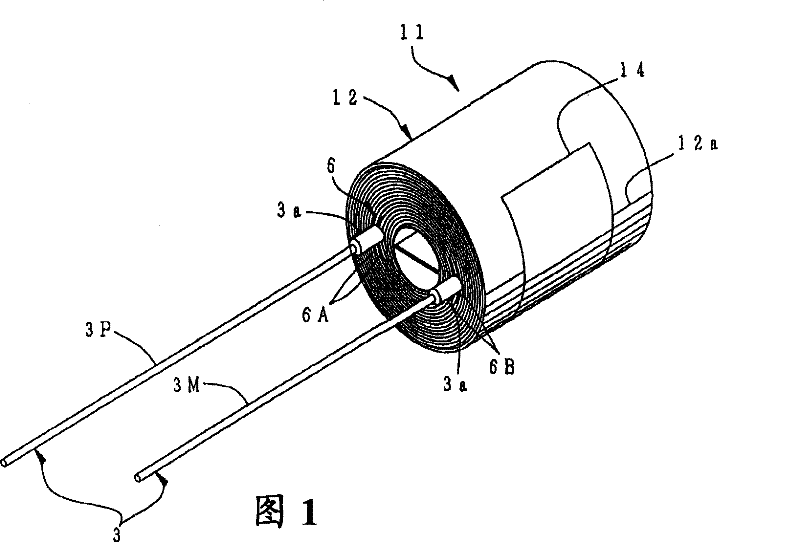

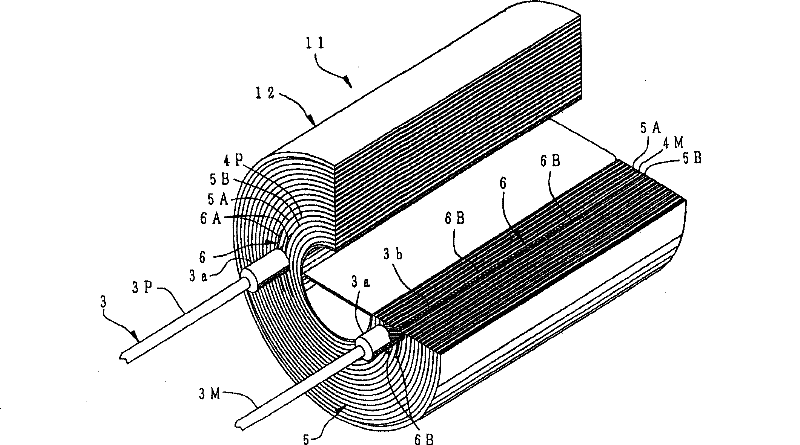

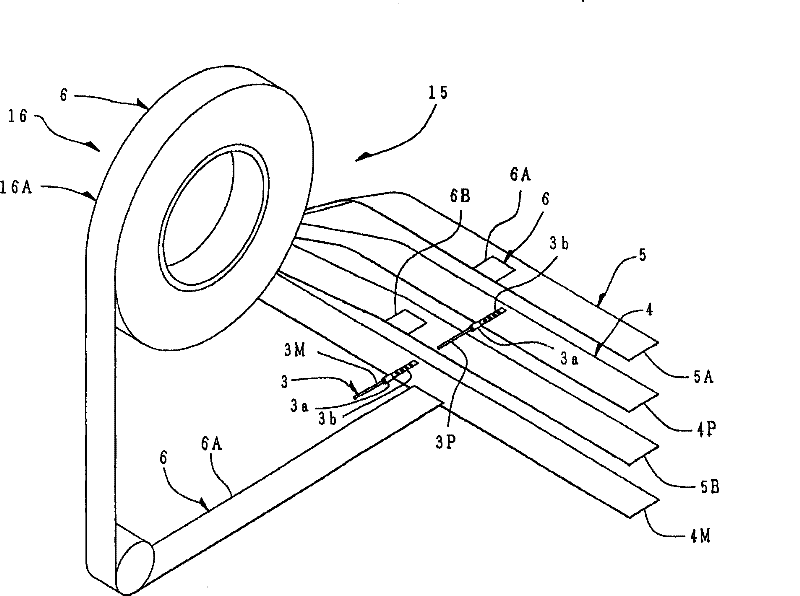

[0141] exist Figure 23 In, reference numeral 11 denotes an electrolytic capacitor 11, which is an example of an electrolytic component according to the present invention, and includes a capacitor element 12 formed with a plurality of electrode foils 4 rolled together with a plurality of insulating paper 5, the insulating paper 5 is interposed between electrode foils 4 including positive electrode foil 4P and negative electrode foil 4M, and insulating paper 5 including insulating papers 5A and 5B. The capacitor element 12 is also provided with a plurality of lead wires 3 including a positive electrode lead 3P and a negative electrode lead 3M each having a straight portion 3b having a predetermined width each fixed to the positive electrode foil 4P and the negative electrode foil 4M. Capacitor element 12 is also provided with protective p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com