Lithium ion battery composite diaphragm and preparation method thereof

A lithium-ion battery and composite diaphragm technology, which is applied in secondary batteries, battery pack components, secondary battery repair/maintenance, etc., can solve the problem of reducing the electrical insulation of lithium battery diaphragms, reducing the service life of lithium batteries, and damage to lithium batteries and other problems, to achieve the effect of improving electrical insulation and corrosion resistance, improving high temperature resistance, and improving electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

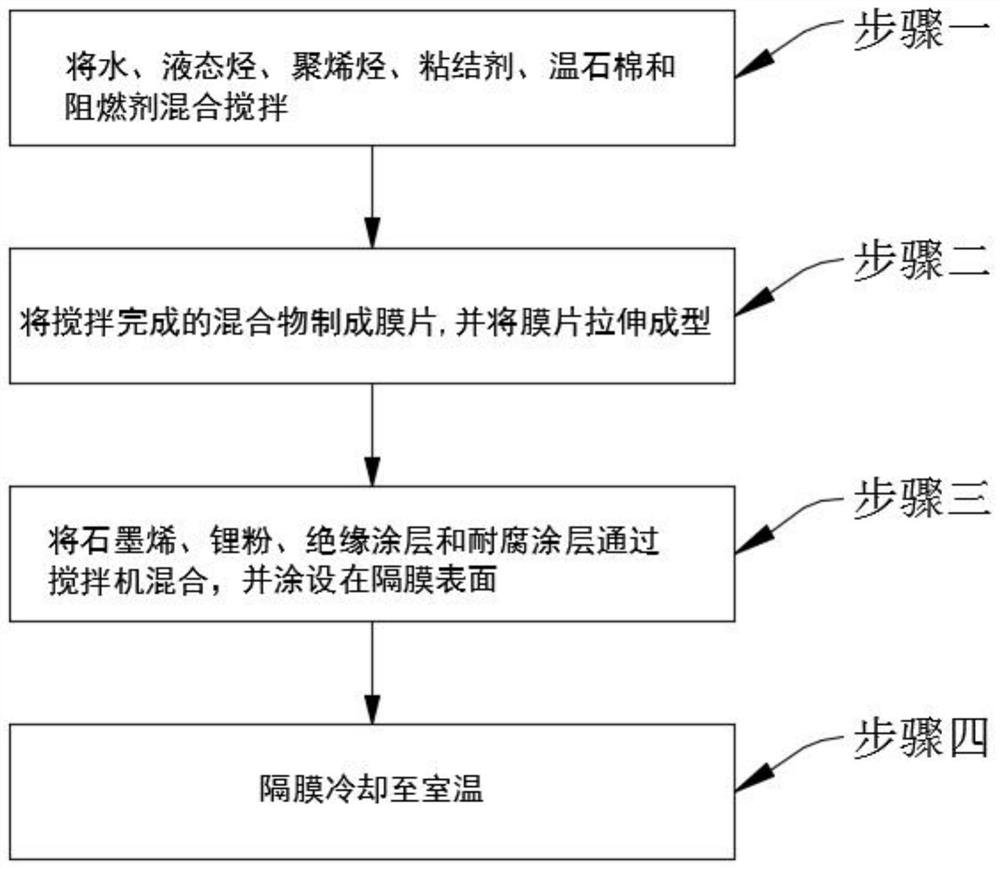

[0023] see figure 1 , the present invention provides a technical solution: a lithium-ion battery composite diaphragm prepared from the following raw materials:

[0024] The ratio of raw materials by weight is: 5 parts of water, 10 parts of liquid hydrocarbon, 10 parts of polyolefin, 2 parts of binder, 2 parts of high temperature resistant material, 2 parts of flame retardant, 4 parts of graphene, 4 parts of lithium powder, 2 parts of insulating coating, 2 parts of corrosion-resistant coating.

[0025] In this embodiment, specifically: the composition of the flame retardant is one or more of antimony trioxide, magnesium hydroxide and aluminum hydroxide; through the addition of the flame retardant, the flame retardant can absorb the The heat reduces the temperature of the diaphragm, and the flame retardant has a good affinity, which has little effect on the performance of the diaphragm, and the flame retardancy is long-lasting.

[0026] In this embodiment, specifically: the hi...

Embodiment 2

[0037] see figure 1 , the present invention provides a technical solution: a lithium-ion battery composite diaphragm prepared from the following raw materials:

[0038] The ratio of raw materials by weight is: 7 parts of water, 15 parts of liquid hydrocarbon, 15 parts of polyolefin, 3 parts of binder, 3 parts of high temperature resistant material, 3 parts of flame retardant, 5 parts of graphene, 5 parts of lithium powder, 3 parts of insulating coating, 3 parts of corrosion-resistant coating.

[0039] In this embodiment, specifically: the composition of the flame retardant is one or more of antimony trioxide, magnesium hydroxide and aluminum hydroxide; through the addition of the flame retardant, the flame retardant can absorb the The heat reduces the temperature of the diaphragm, and the flame retardant has a good affinity, which has little effect on the performance of the diaphragm, and the flame retardancy is long-lasting.

[0040] In this embodiment, specifically: the hi...

Embodiment 3

[0051] see figure 1 , the present invention provides a technical solution: a lithium-ion battery composite diaphragm prepared from the following raw materials:

[0052] The ratio of raw materials by weight is: 10 parts of water, 20 parts of liquid hydrocarbon, 20 parts of polyolefin, 4 parts of binder, 4 parts of high temperature resistant material, 4 parts of flame retardant, 6 parts of graphene, 6 parts of lithium powder, 4 parts of insulating coating, 4 parts of corrosion-resistant coating.

[0053] In this embodiment, specifically: the composition of the flame retardant is one or more of antimony trioxide, magnesium hydroxide and aluminum hydroxide; through the addition of the flame retardant, the flame retardant can absorb the The heat reduces the temperature of the diaphragm, and the flame retardant has a good affinity, which has little effect on the performance of the diaphragm, and the flame retardancy is long-lasting.

[0054] In this embodiment, specifically: the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com