Film enclosed electric device and collector covering member for the film enclosed electric device

An electric device, film covering technology, applied to the field of collector covering parts, to achieve the effect of suppressing the increase in weight and improving the electrical insulation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0042] In the following, experiments on the embodiments of the present invention are given.

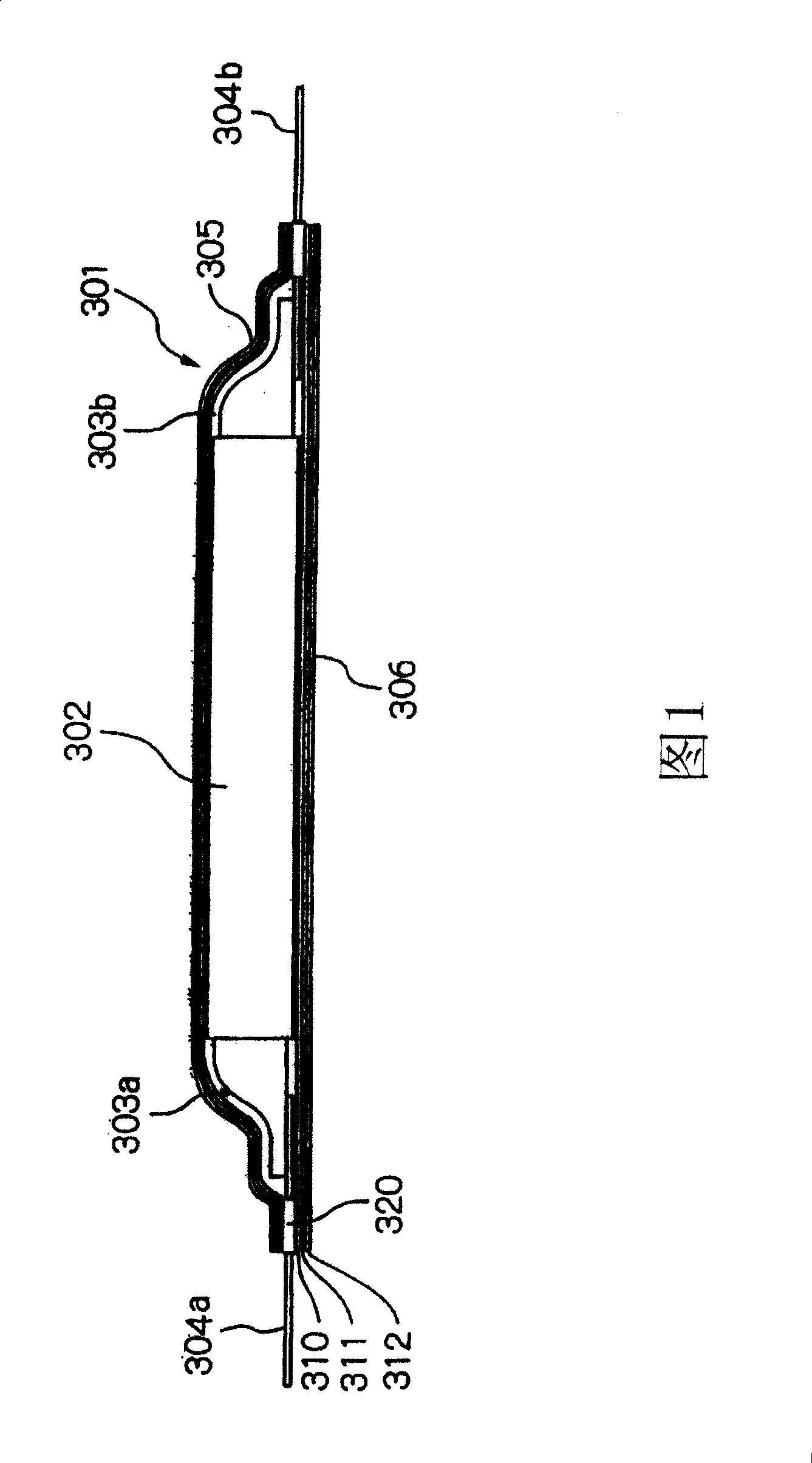

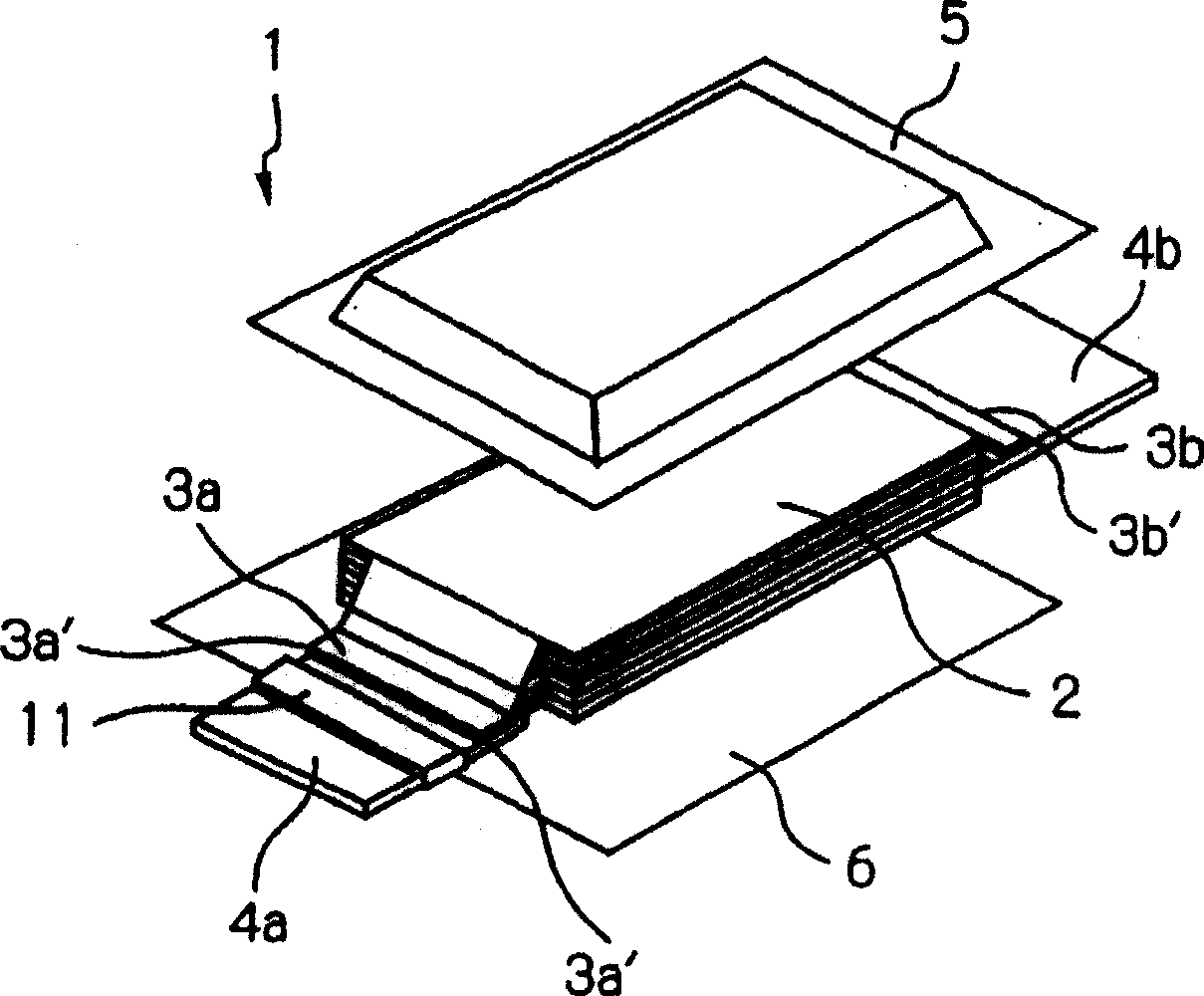

[0043] figure 2 An exploded perspective view of the battery covered by the film is shown. By the way, figure 2 The film covered battery is shown in which the collector protection member according to the first embodiment is removed.

[0044] The thin-film-covered battery 1 has a battery element 2, an anode collector 3a and a cathode collector 3b arranged for the battery element 2, an encapsulation component that houses the battery element 2 and the electrolytic solution together and includes two laminates 5, 6, An anode tab 4a connected to the anode collector 3a, and a cathode tab 4b connected to the cathode collector 3b.

[0045] The battery element 2 is formed by a plurality of anode plates and a plurality of cathode plates alternately stacked via separators.

[0046] Each anode plate is formed by coating an anode electrode on aluminum foil, and a cathode is formed by coating a cathod...

no. 2 example

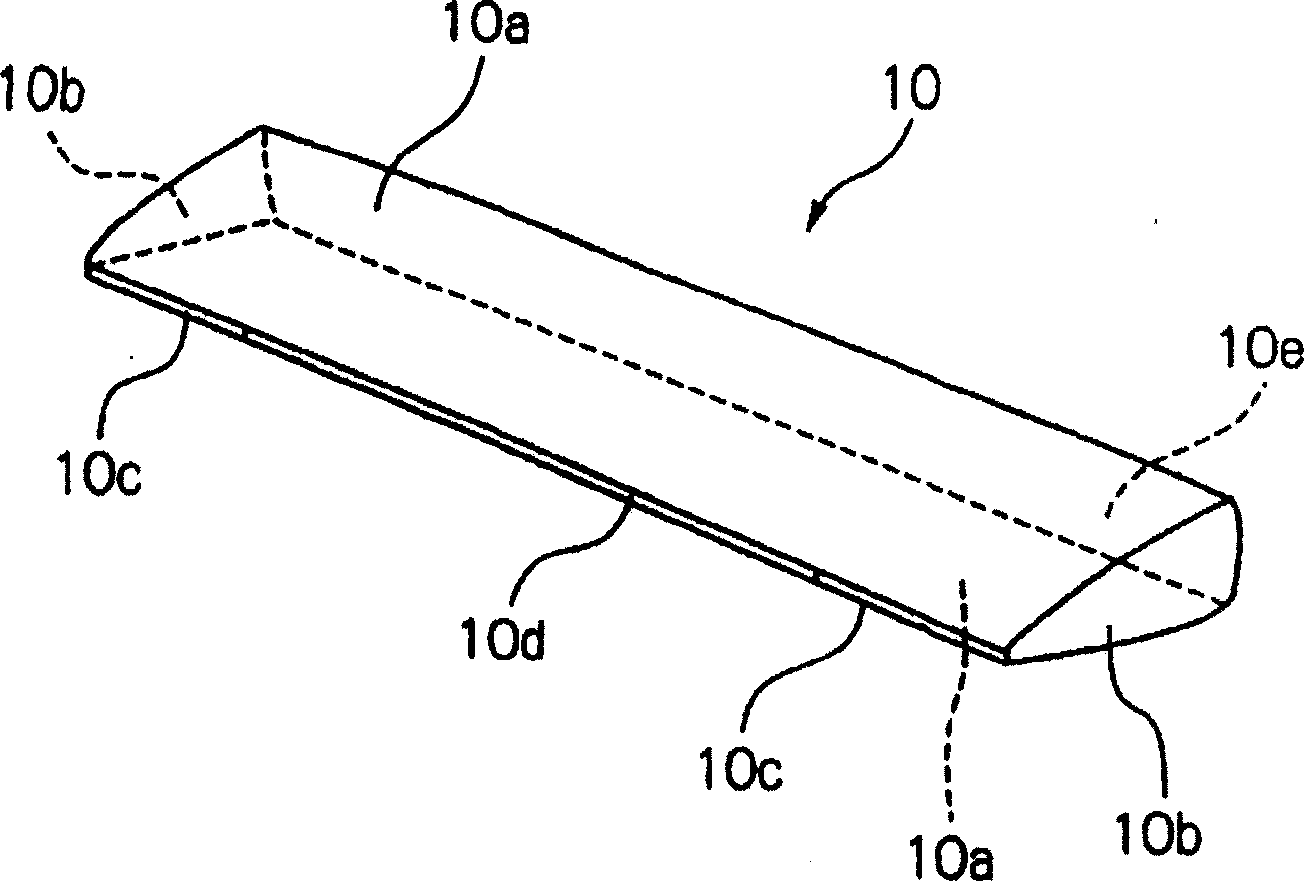

[0073] According to the collector protection member 10 of the first embodiment, the side portion 10b having a three-dimensional shape is formed before bonding and is set in a bag shape in advance, in which the insertion hole 10 and the insertion hole 10e are formed. Such as Picture 9 As shown, the collector protection member 110 according to the present embodiment is formed by bonding two films 112a and 112b together.

[0074] According to the collector protection member 110 of this embodiment, two films 112 are welded only at the side portion 110b and the front portion 110c (by Picture 9 The middle shaded part indicates the welding part 111) and is formed so as to form the insertion hole 110d and the insertion hole 110e. The collector protection member 110 is in a planar shape before being combined.

[0075] Similar to the collector protection member 10 according to the first embodiment, the size of each part is determined so as to achieve the same purpose as the collector prot...

no. 3 example

[0077] The collector protection member 110 according to the second embodiment is formed by bonding two films 112 together. Such as Picture 10 As shown, unlike the second embodiment, the collector protection member 210 according to the present embodiment is made of an inflation film 212.

[0078] According to the collector protection member 210 of this embodiment, the expansion film 212 is bent at the two bent portions 213a, 213b, and the part of the front part 210c is welded (by Picture 9 The middle shaded part indicates the welding part 211) and is formed so as to form the insertion hole 210d and the insertion hole 210e.

[0079] Similar to the collector protection member 10 according to the first embodiment, the size of each part is determined so as to achieve the same purpose as the collector protection member 10 according to the first embodiment. It is preferable to set the welding edge (margin) of the welding portion 211 to be wide so that the current path can be set as lon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com