Silicone rubber insulation wind power cable

A silicone rubber insulation and wind power technology, applied in the direction of insulated cables, insulated conductors, power cables with shielding layer/conductive layer, etc., can solve the problems of poor insulation, susceptibility to weather temperature, economic loss of users, etc., to ensure round shape The effect of improving the degree of uniformity, improving the electrical insulation performance, and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

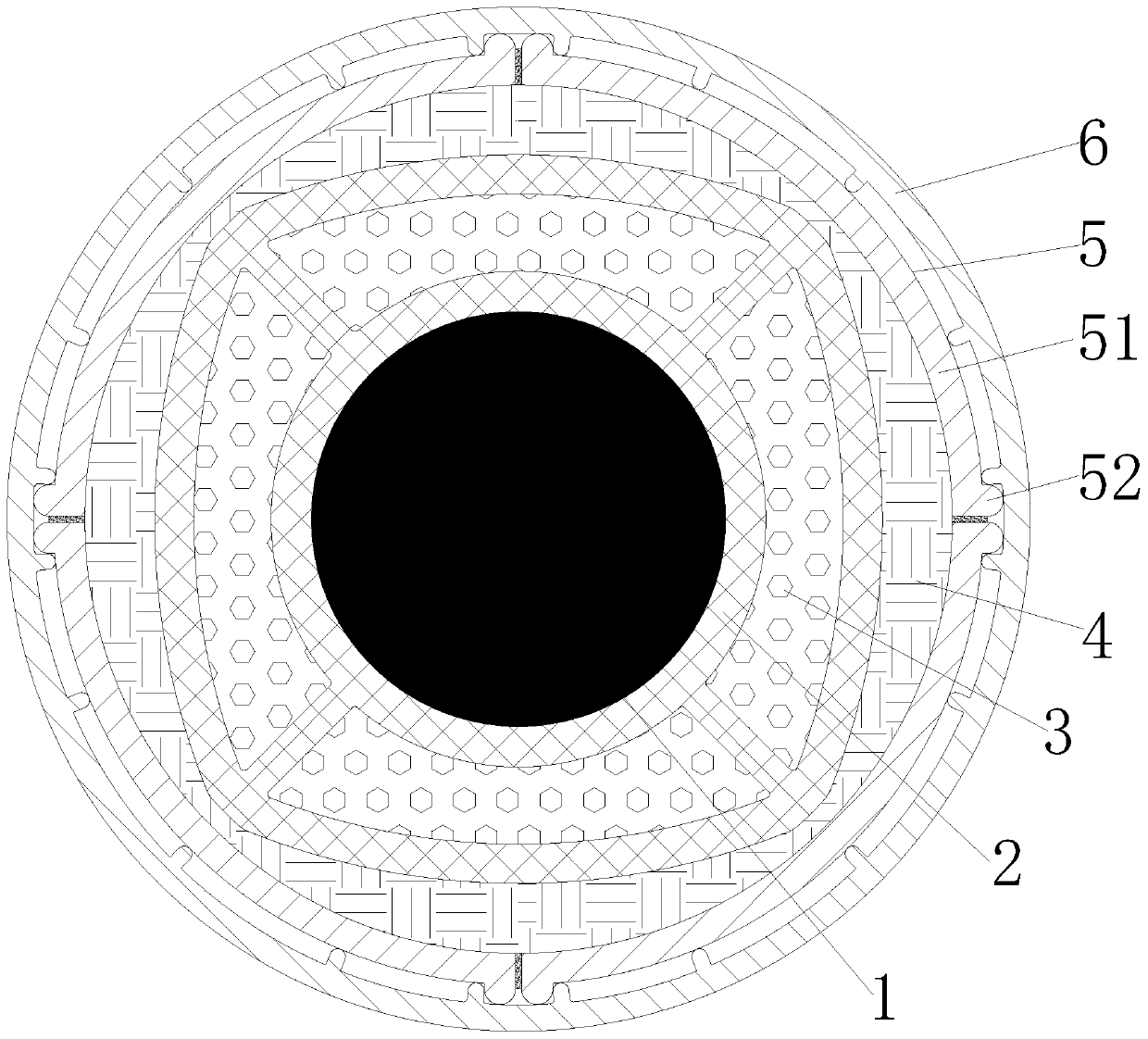

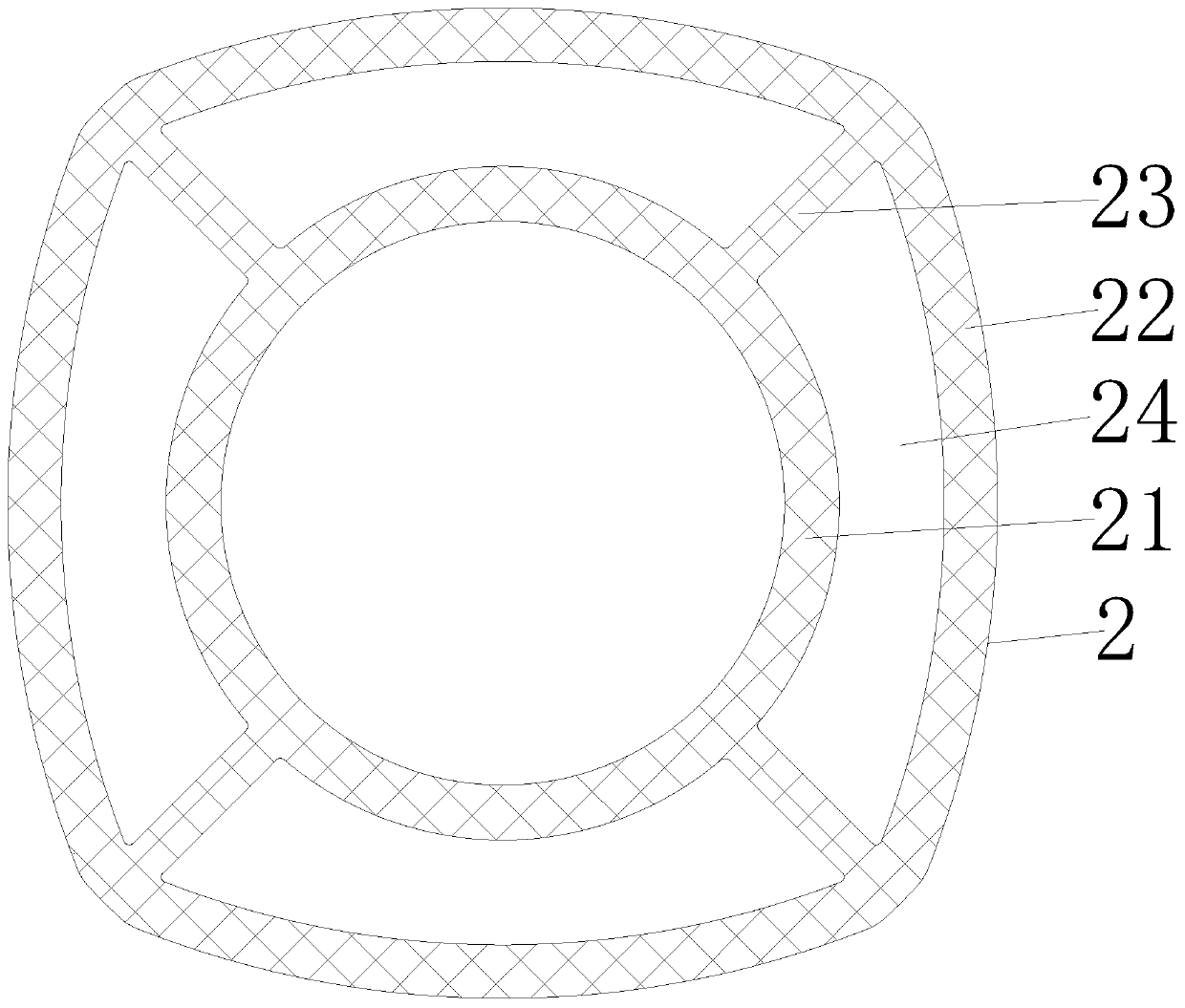

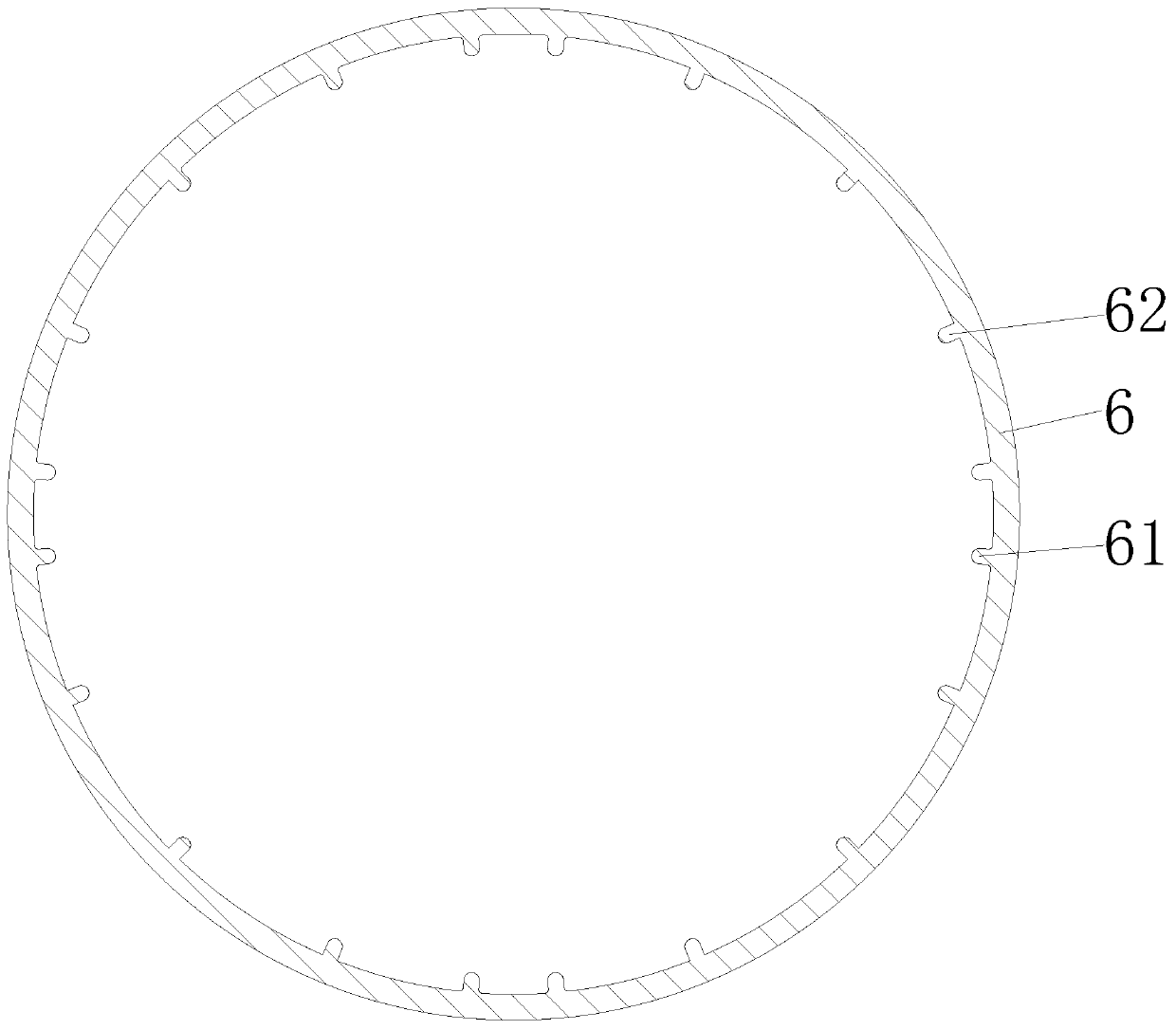

[0020] Such as figure 1 As shown, a silicon rubber insulated wind power cable includes a wire 1, an insulating inner cladding 2, a shielding layer 4, an insulating armor layer 5, and a protective layer 6 that are sequentially coated on the outside of the wire 1 from the inside to the outside.

[0021] Wherein the insulating inner cladding 2 and the insulating armor layer 5 are made of silicone rubber material, specifically silicone rubber, which has excellent electrical insulation performance, temperature resistance and weather resistance, and the electrical insulation performance can be guaranteed The cable avoids the occurrence of electric leakage caused by electrical breakdown. Most of the existing wind power cables are ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com