Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Ensure welding stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

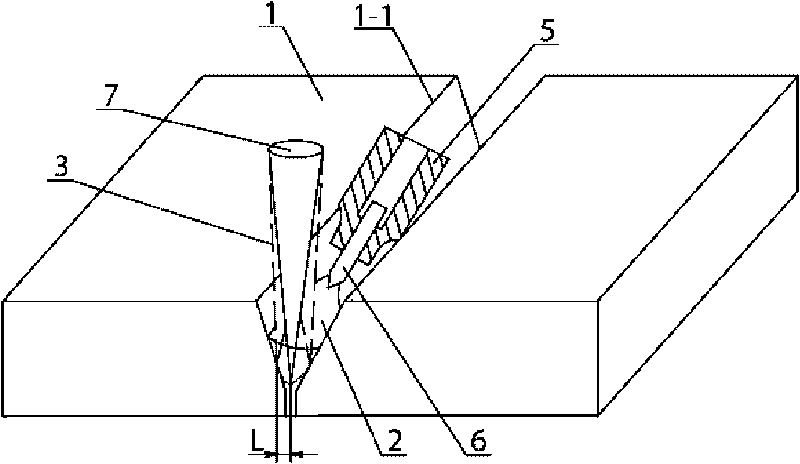

Method for realizing swing welding with laser-GMA electric arc hybrid welding device

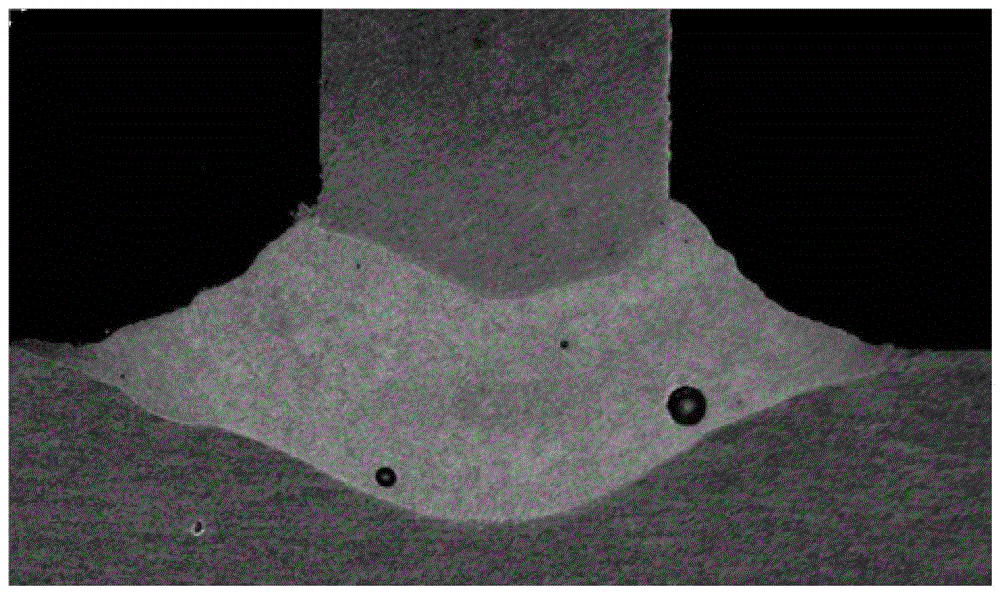

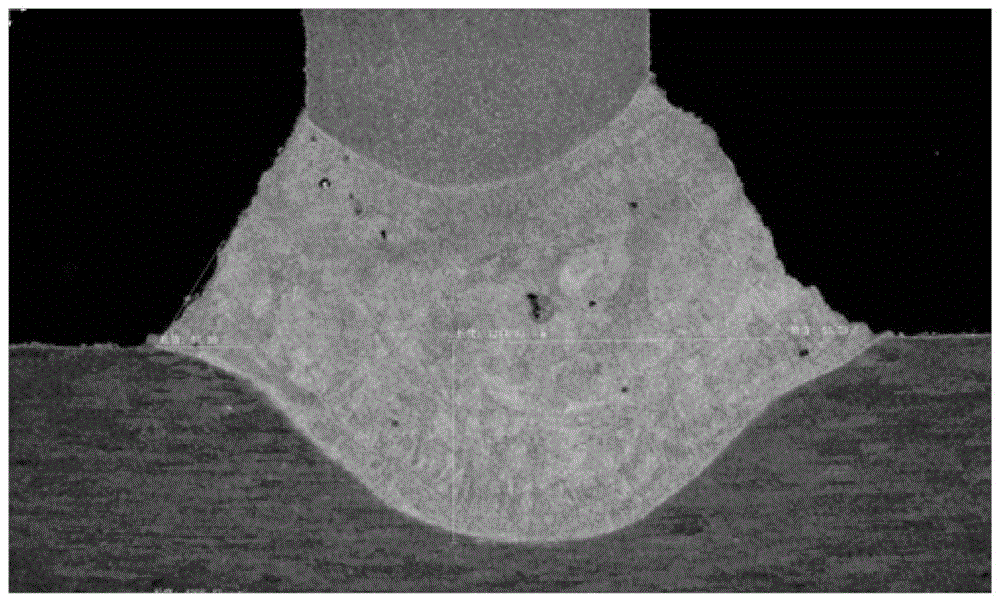

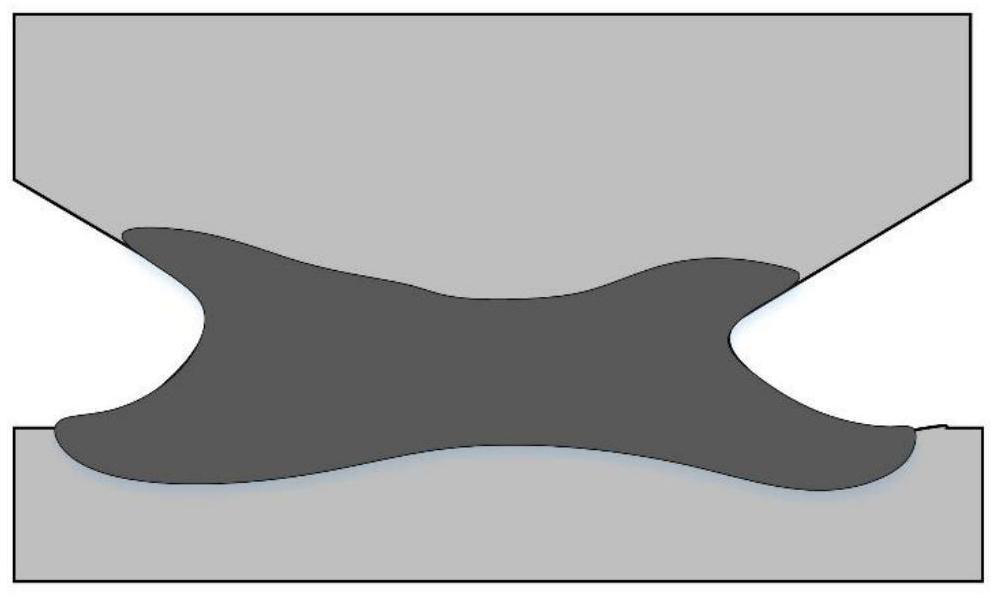

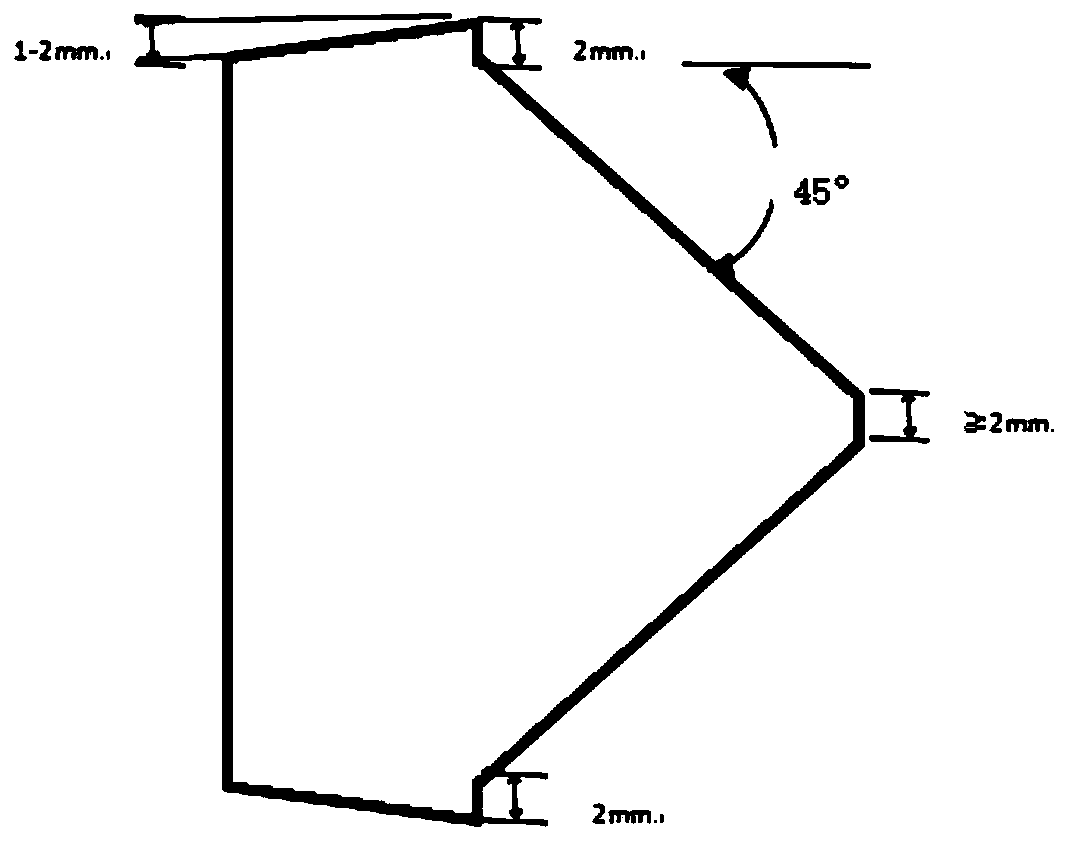

The invention discloses a method for realizing swing welding with a laser-GMA electric arc hybrid welding device, relating to a laser-melting electrode gas metal arc welding hybrid welding method. The method solves the problem that the defects such as incomplete fusion, gas hole and included slag, and the like, are easily existed between a side wall and a layer when welding a moderate plate and a thick plate with the laser-GMA electric arc hybrid welding device. The method comprises the following steps of: 1. chamfering; 2. clamping a work piece to be welded; 3. ensuring the positions of an electric arc and a laser beam, wherein the laser beam is perpendicularly irradiated to the surface of the work piece to be welded, an included angle between the electric arc and the laser beam is 15-60 DEG C, and the distance between the laser beam and the sharp end of a GMA electric arc welding wire is 2-6mm; 4. setting a welding technology parameter; and 5. performing the welding, wherein an electric arc welding gun is kept to be immovable when welding, and a laser beam-focused wielding gun swinging welds in the shape of 'S'. The method is used for butt welding of a thick plate more than 10mm in national defense and civil use fields of shipbuilding, petroleum pipe lines, high-pressure vessels, fighting vehicles and nuclear devices, etc.

Owner:HARBIN INST OF TECH

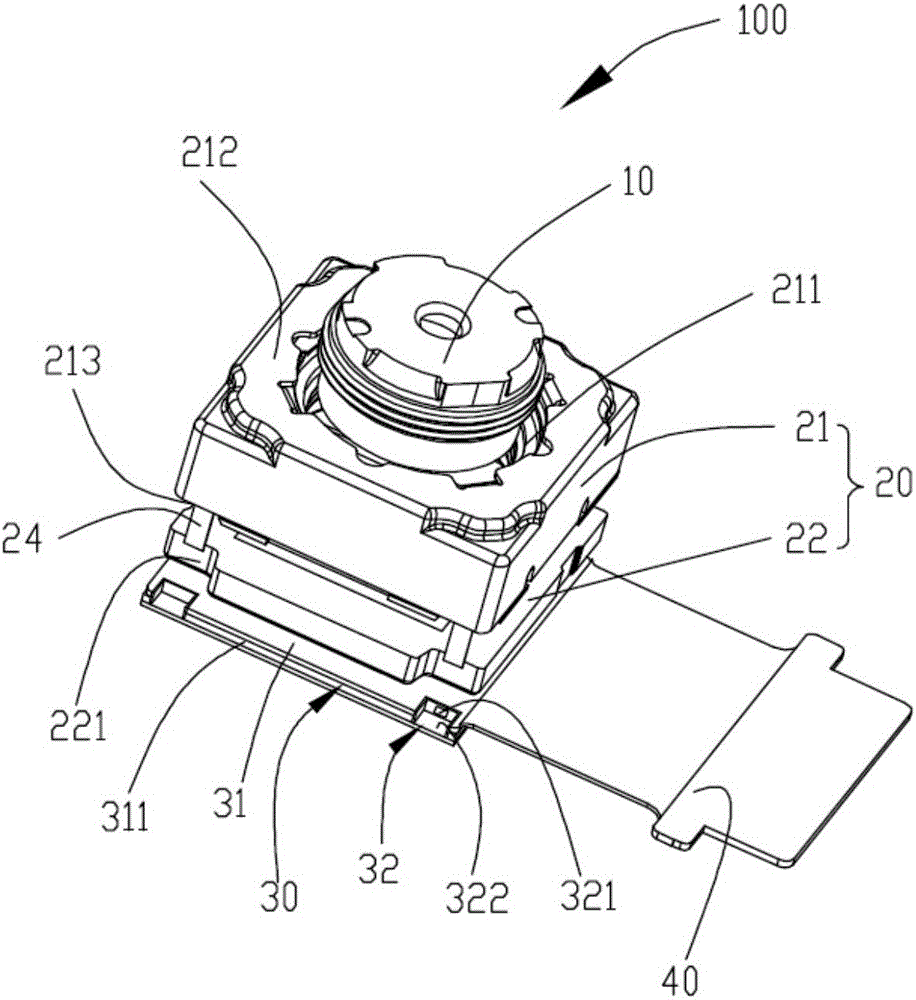

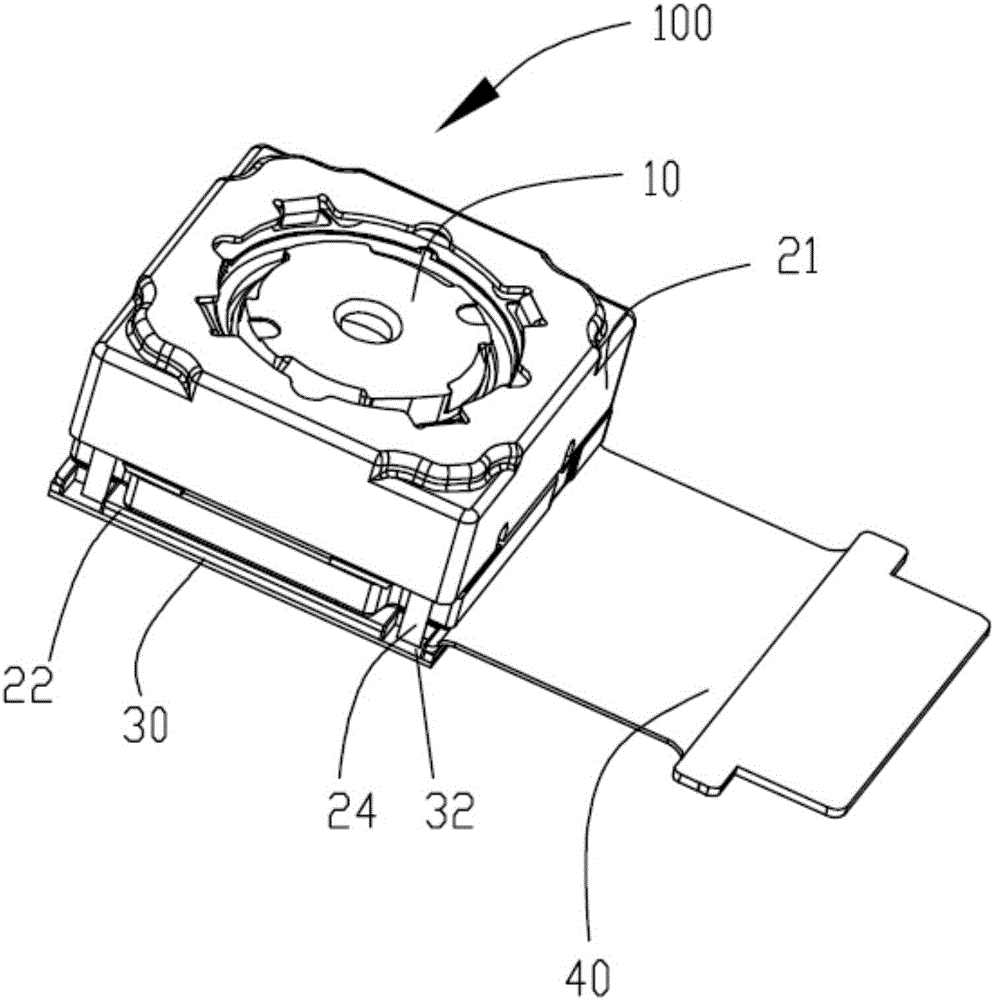

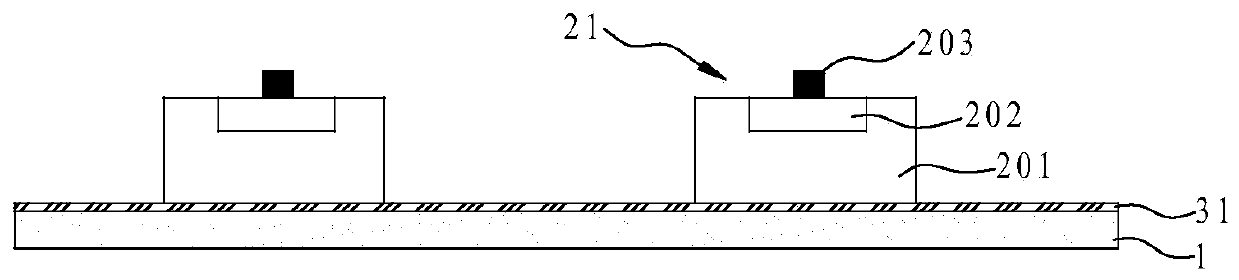

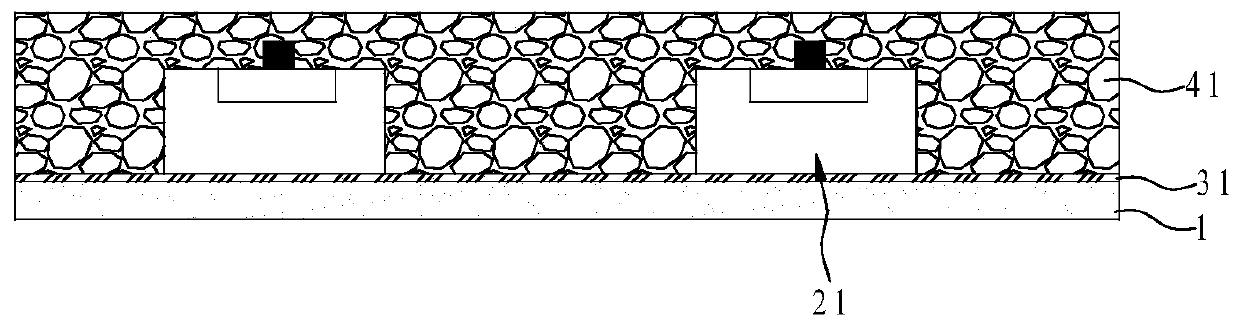

Camera module and electronic device having same

InactiveCN105100572APlay a supporting roleEnsure welding stabilityTelevision system detailsColor television detailsCamera lensEngineering

The invention provides a camera module. The camera module comprises a lens assembly, a driving member and a circuit board. The driving member comprises a main body and a base. The base is used for accommodating an infrared cut-off filter and an image sensor of the camera module. The main body comprises a top surface provided with a through hole and a bottom surface opposite to the top surface. The edge of the bottom surface is extended with welding legs. The circuit board comprises a first surface. The first surface is provided with grooves corresponding to the welding legs. The base is arranged on the first surface. The bottom surface of the main body is abutted against the base. The welding legs pass through the base and are inserted into and welded to the grooves. The lens assembly is arranged in the through hole of the main body. The invention also provides an electronic device.

Owner:NANCHANG O FILM OPTICAL ELECTRONICS TECH CO LTD +3

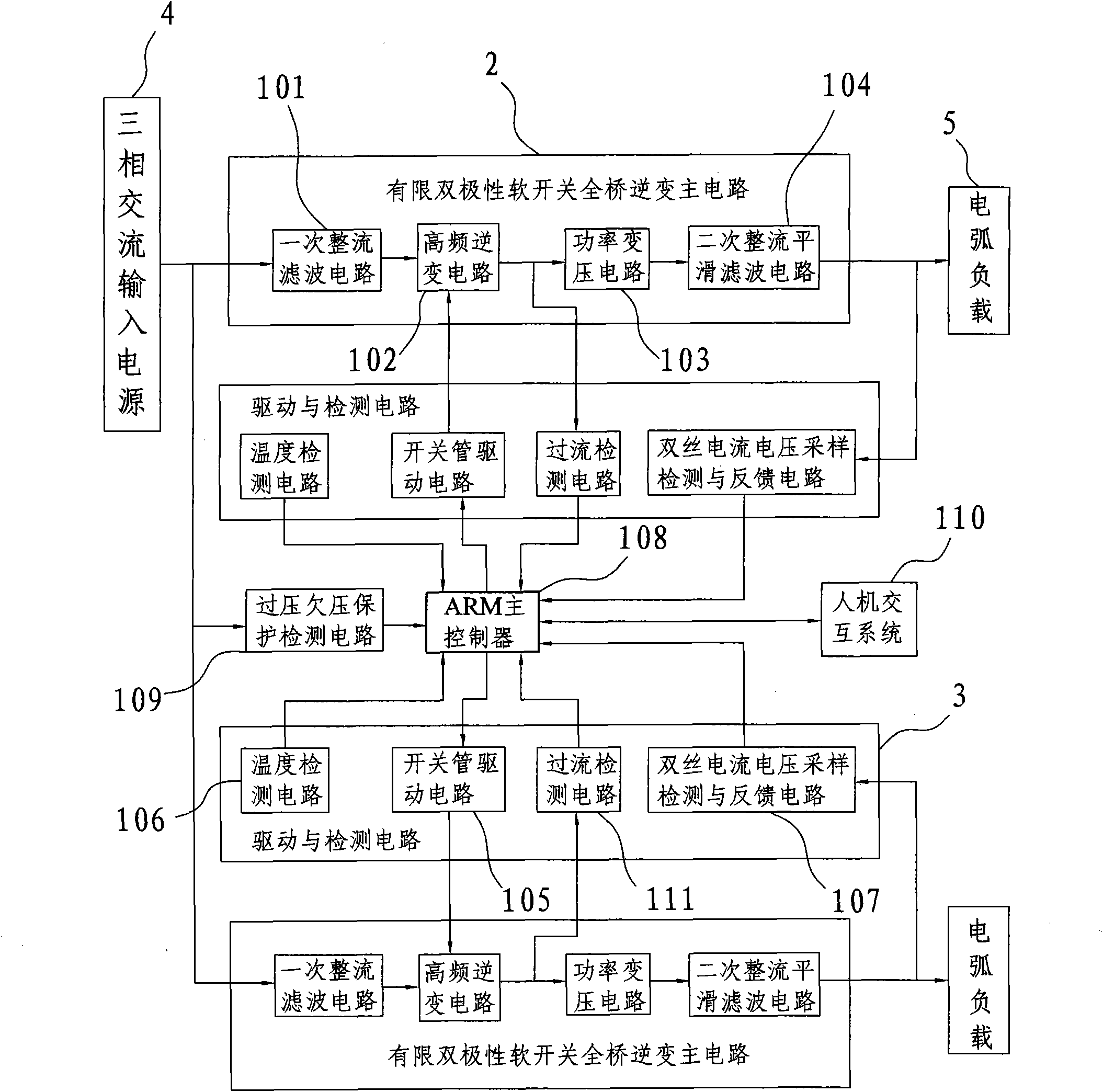

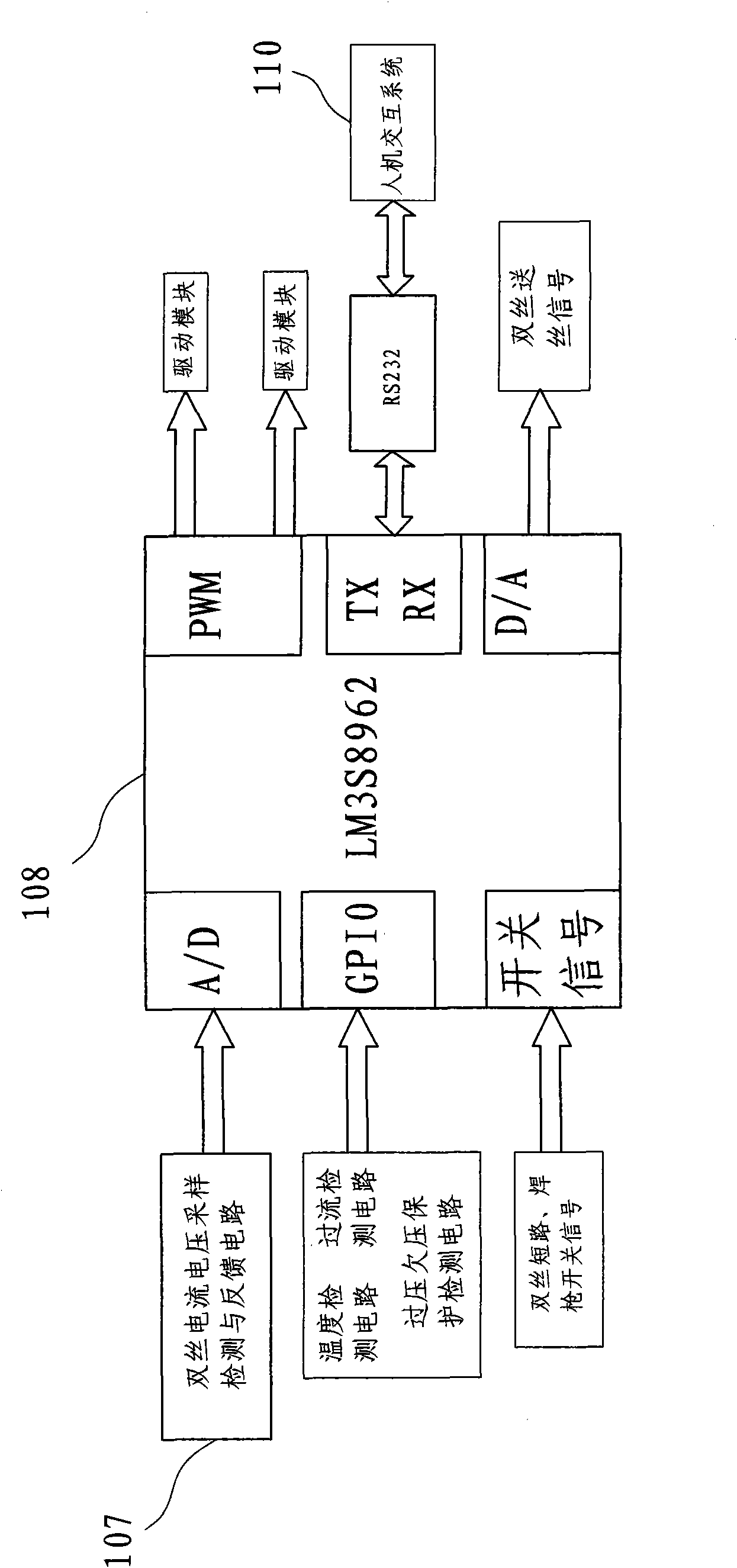

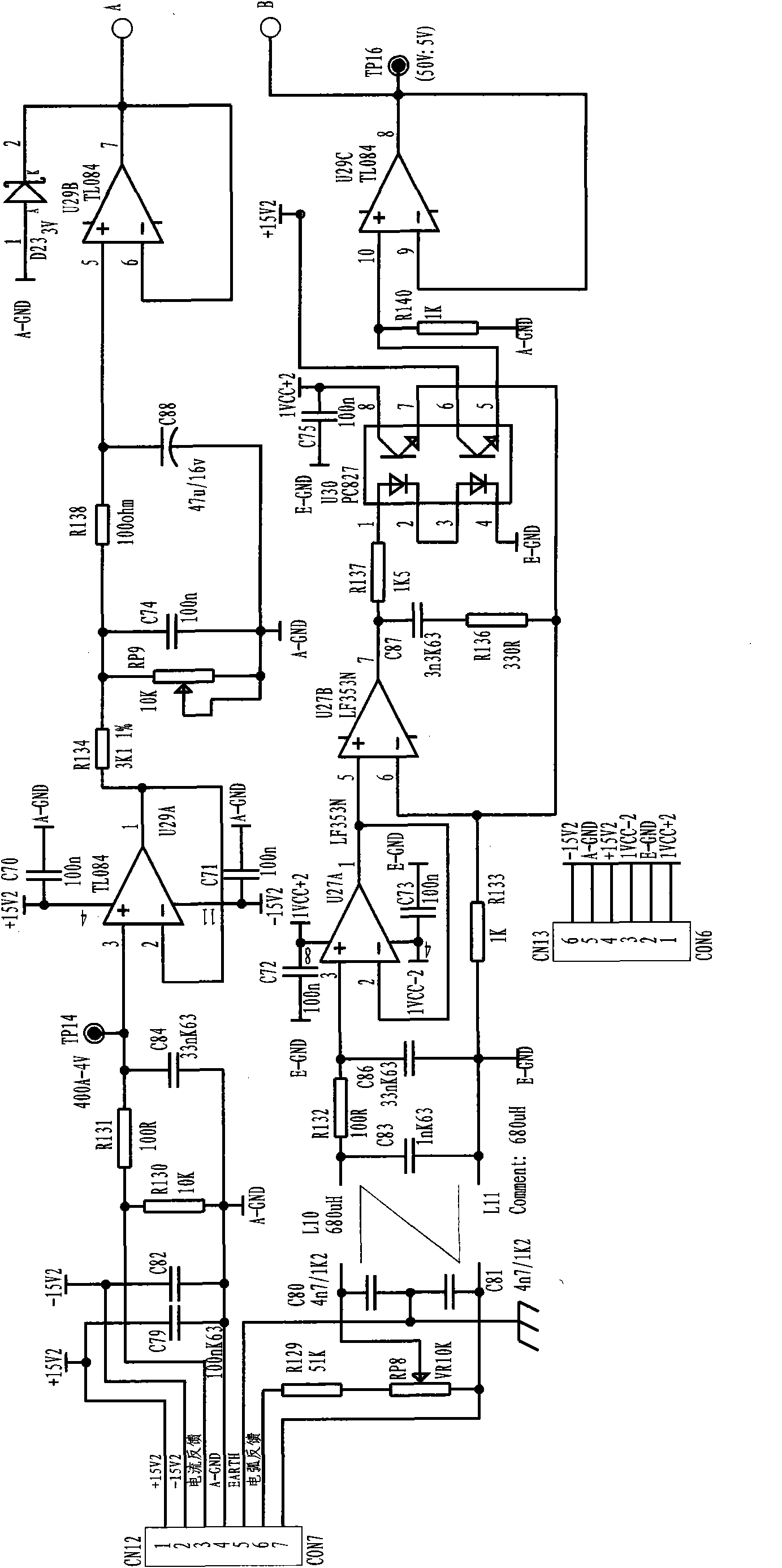

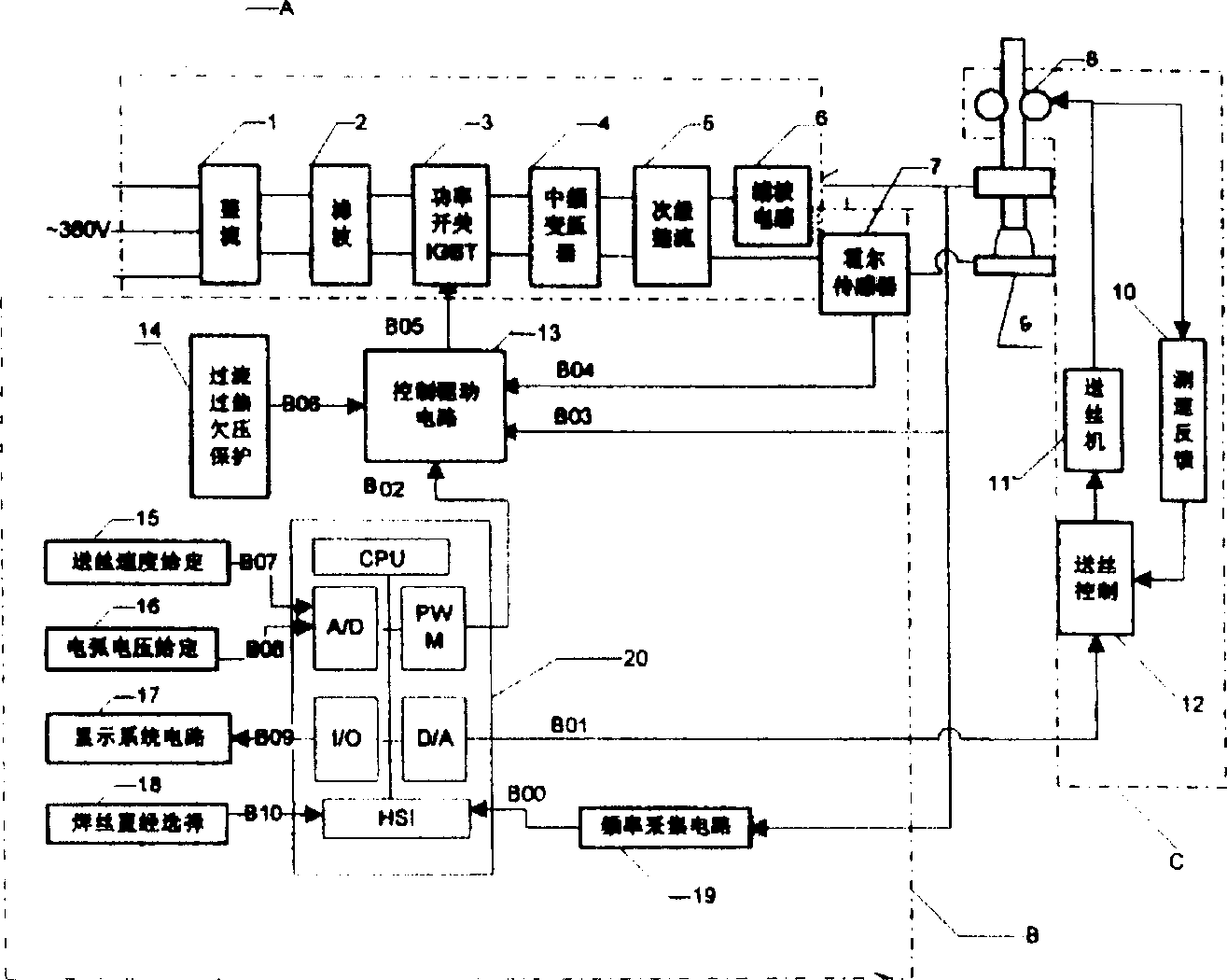

Thin double-wire digital soft switch inverter welding power source system and control method thereof

ActiveCN101913015AImprove consistencyImprove dynamic response performanceArc welding apparatusSoftware systemFull bridge

The invention relates to the technical field of welding equipment, in particular to a thin double-wire digital soft switch inverter welding power source system and a control method thereof. The system comprises over-voltage under-voltage protection and detection circuits placed in the same welding power source case by adopting an integrated structure, a man-machine interaction system, an ARM master controller in which a welding process expert database software system is placed, two limited bipolar soft switch full-bridge inverter main circuits with the same structure, and two drive and detection circuits with the same structure, wherein the limited bipolar soft switch full-bridge inverter main circuits take insulated gate bipolar transistors (IGBT) as switching elements. The system can improve the welding efficiency on the premise of ensuring the welding quality and the welding stability, effectively reduce the influence of electromagnetic interference of a welding site and eliminate mutual electromagnetic interference between two welding wires, has high safety performance, can reduce equipment volume and lower equipment cost, and is comparatively energy-saving.

Owner:EAST GRP CO LTD

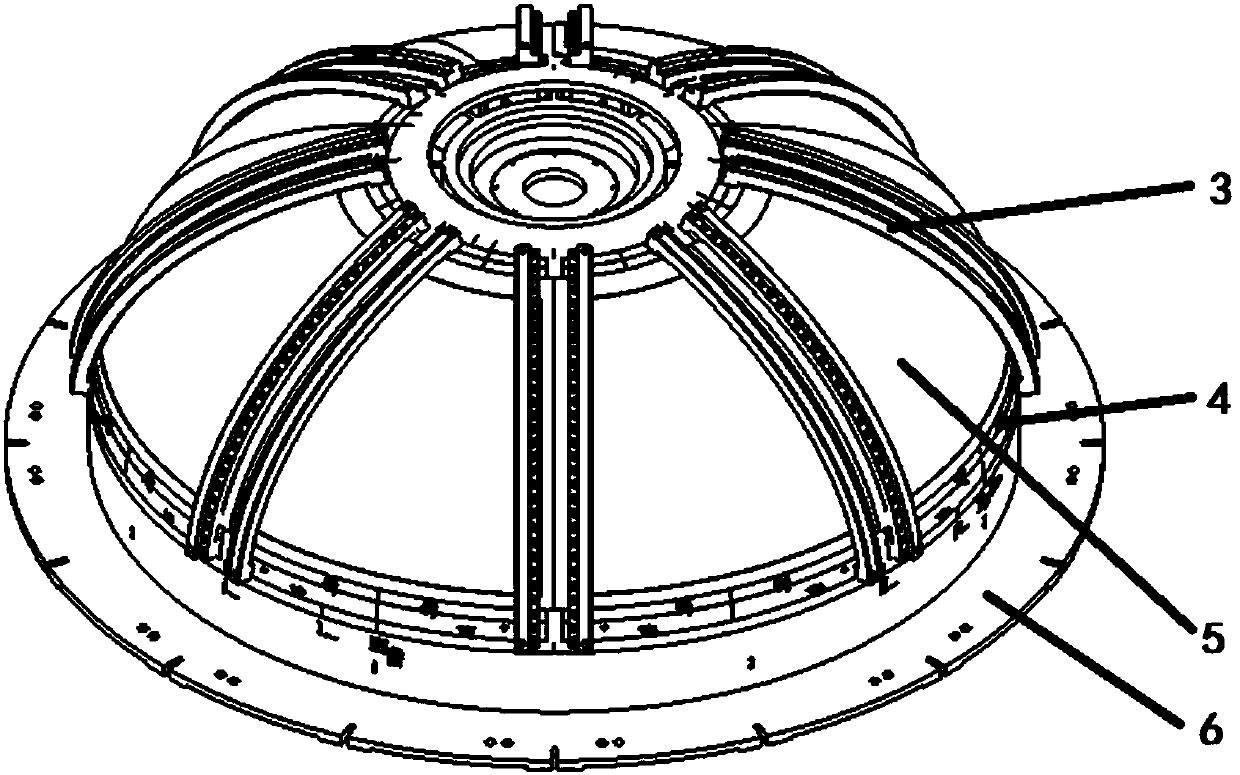

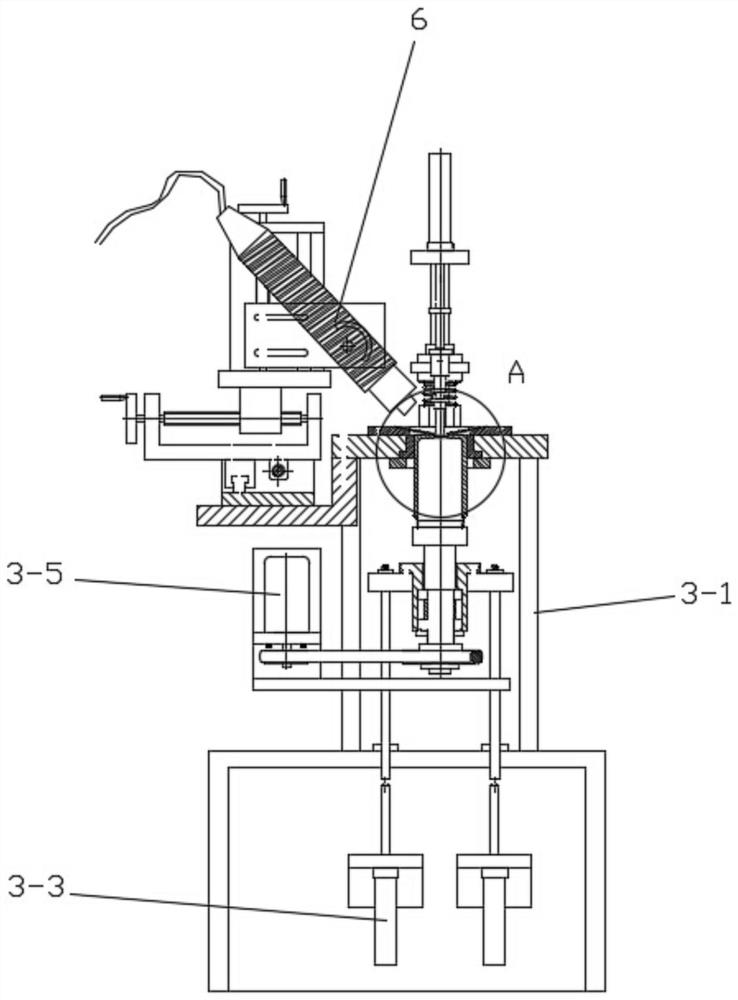

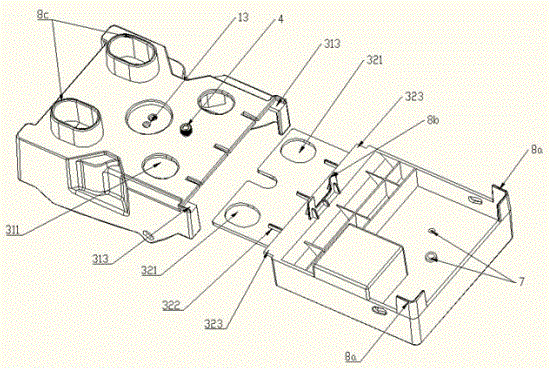

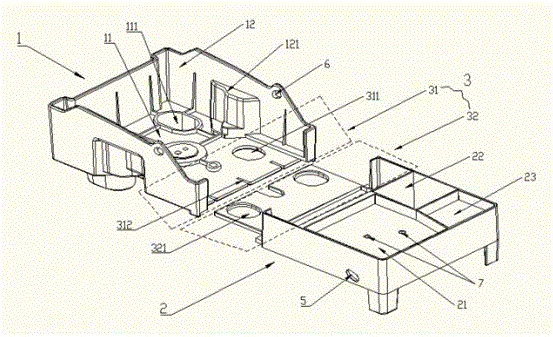

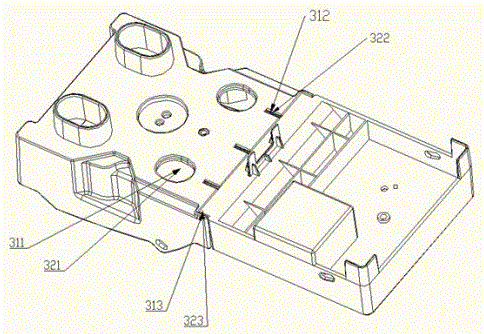

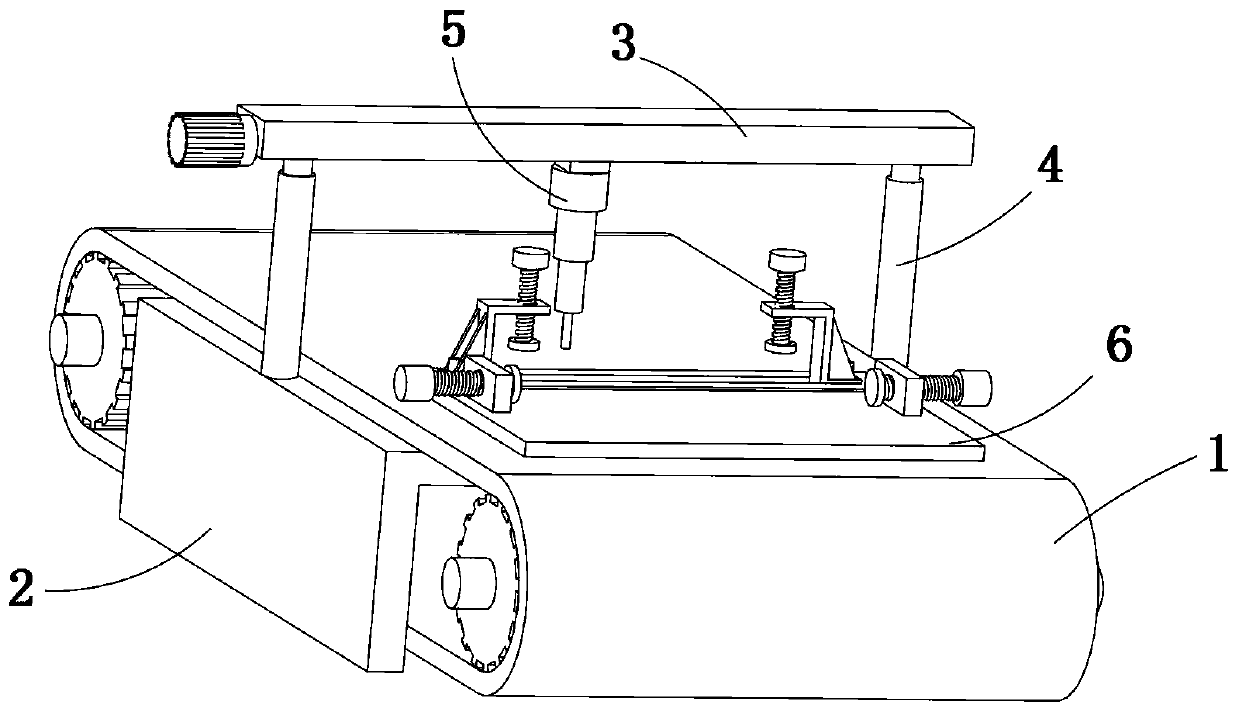

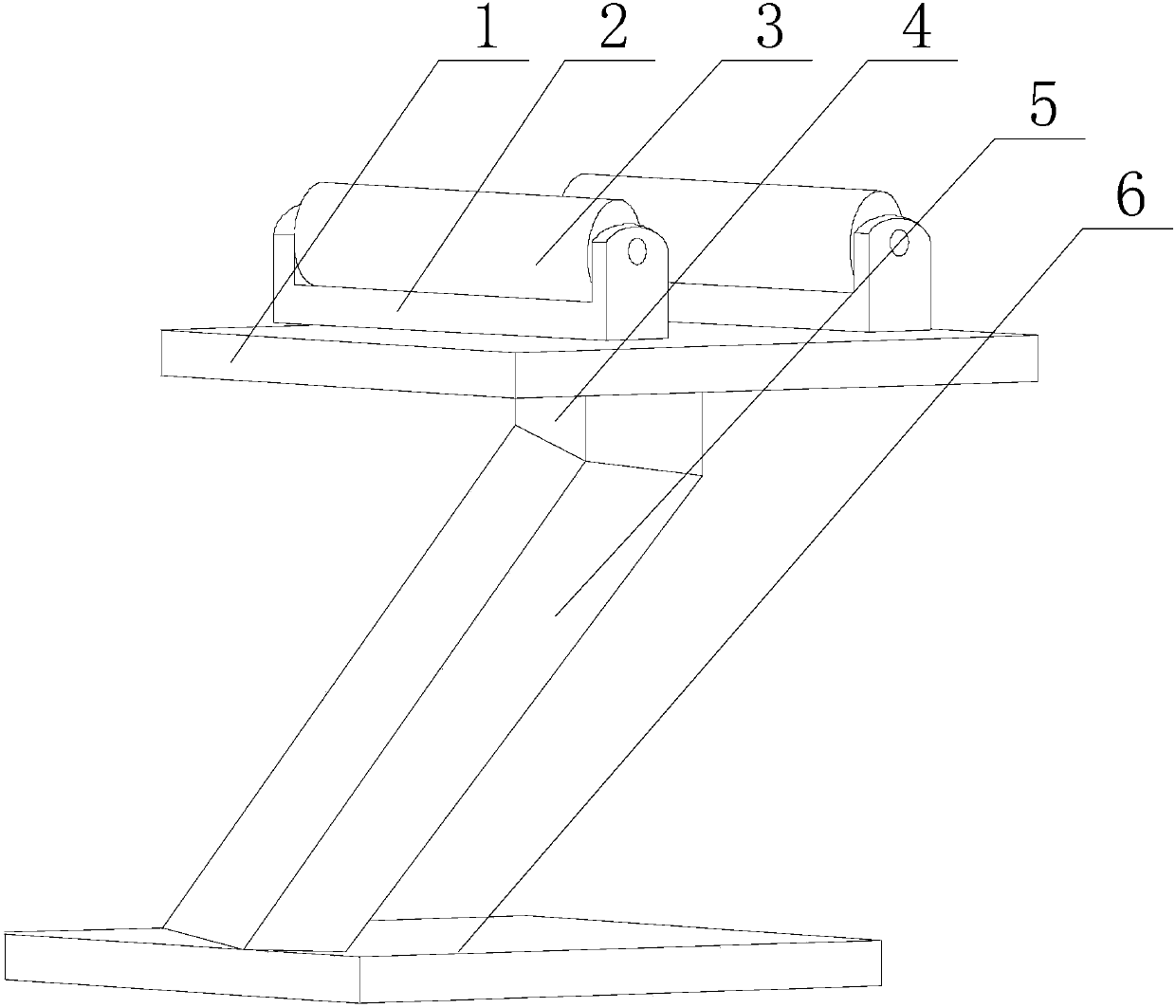

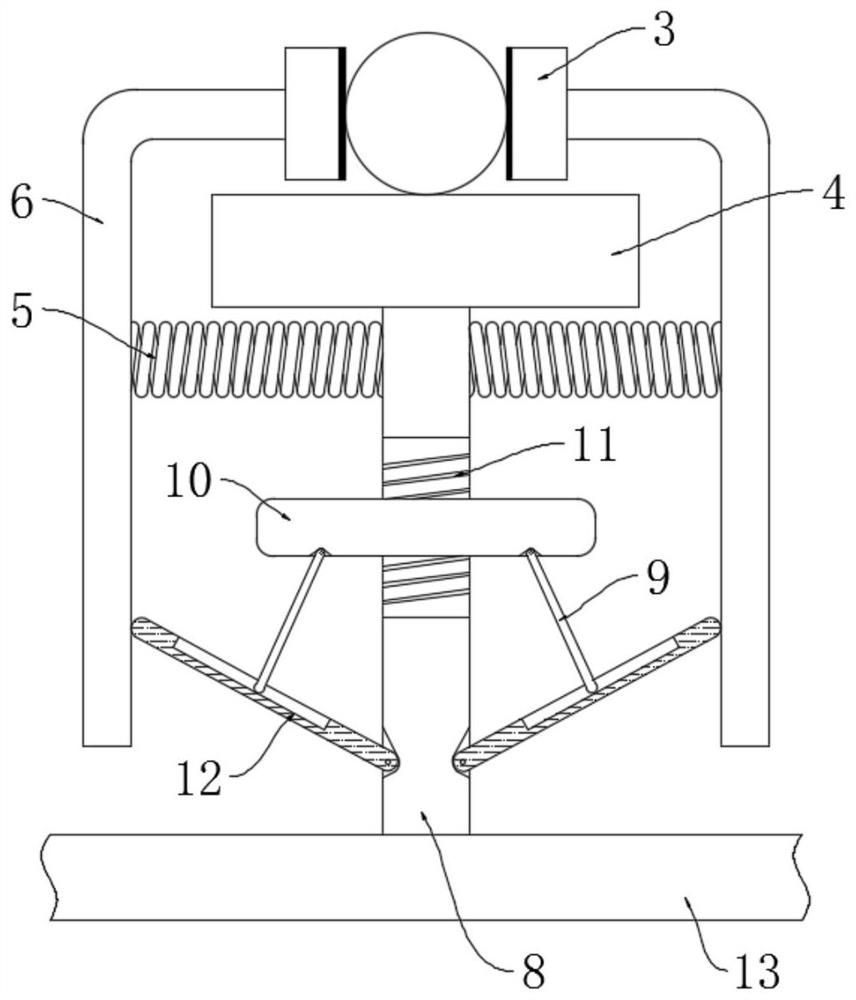

Friction stir welding assembling tool for large-scale ellipsoidal workpieces

ActiveCN107931825AIncrease productivityImproving the Accuracy of Friction Stir Welding Joint SurfaceWork clamping meansWelding/cutting auxillary devicesHydraulic cylinderEngineering

The invention provides a friction stir welding assembling tool for large-scale ellipsoidal workpieces. The friction stir welding assembling tool comprises a fixing base, a lifting die bed, adjusting mechanisms, mechanical pressing strips and lifting mechanisms, wherein the workpieces are attached to the lifting die bed, the positions of the workpieces on the lifting die bed are adjusted through the adjusting mechanisms fixed to the lifting die bed; the two ends of the mechanical pressing strips are fixed to the lifting die bed; each lifting mechanism comprises limiting stop blocks, a hydrauliccylinder, guide shafts and a hydraulic cylinder base, wherein the multiple guide shafts are fixedly arranged on the hydraulic cylinder base through threads, the hydraulic cylinder is fixed in the middle of the hydraulic cylinder base through threads, and the limiting stop blocks are arranged on the hydraulic cylinder base; a plurality of guide holes and a threaded hole are machined in the bottomof the lifting die bed and are connected to the guide shafts and the push rods of the hydraulic cylinders correspondingly; each adjusting mechanism consists of an adjusting base and an adjusting screw; and the positions of the workpieces can be finely adjusted by rotating the adjusting screws. According to the friction stir welding assembling tool, the friction stir welding production efficiency of the large-scale ellipsoidal workpieces can be improved, and in-situ edge milling and welding can be realized.

Owner:SHANGHAI TOPNC NUMERICAL CONTROL TECH CO LTD +1

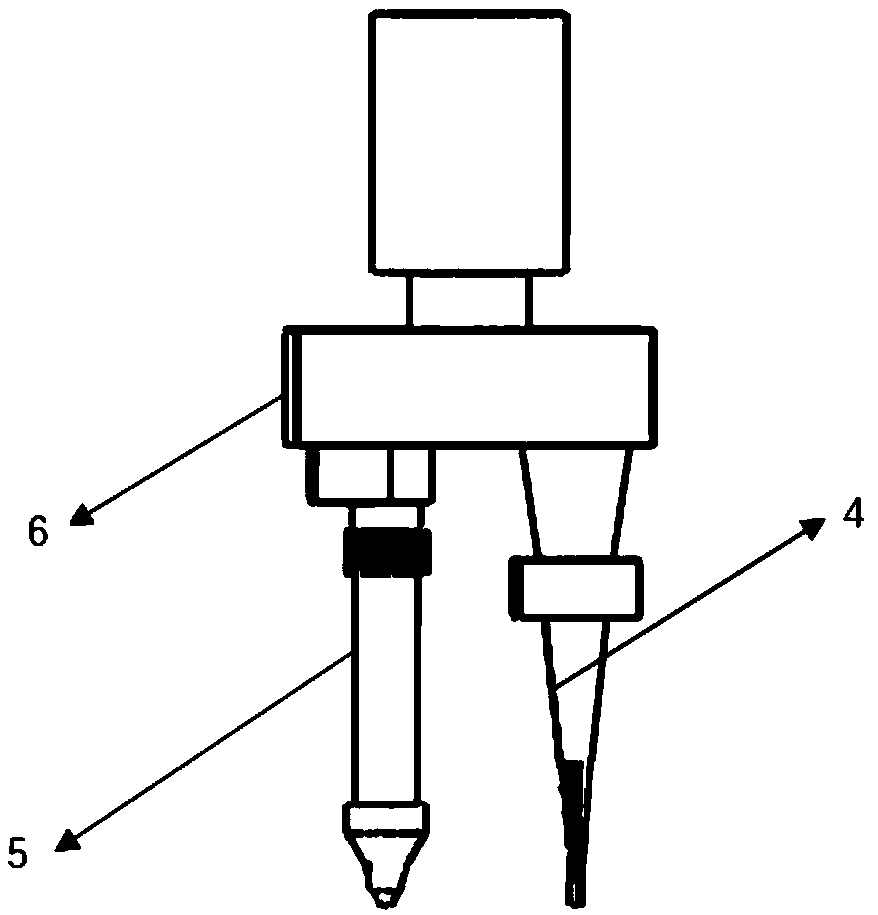

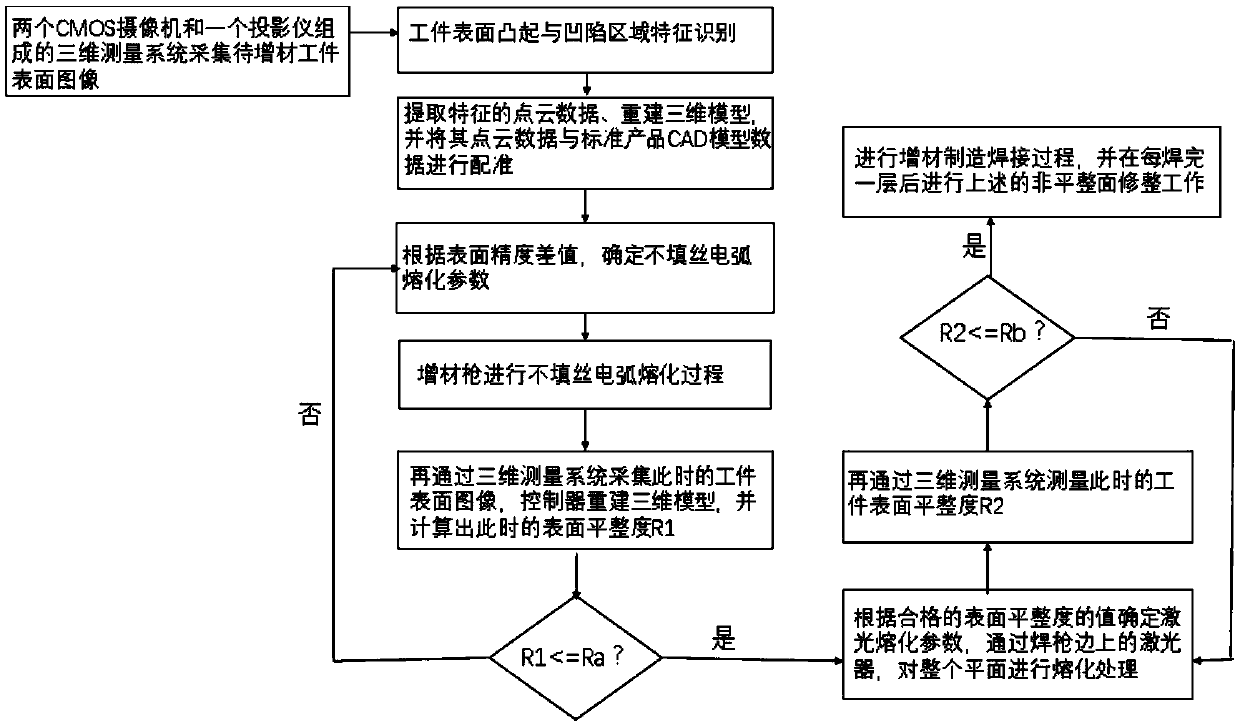

Non-leveling surface autonomous identification robot additive manufacturing forming precision control method

ActiveCN109648202AImprove surface accuracyQuality improvementLaser beam welding apparatusThree dimensional measurementVisual perception

The invention discloses a non-leveling surface autonomous identification robot additive manufacturing forming precision control method. A CMOS camera and a projector form a three-dimensional measuringsystem, the surface image of a workpiece is collected, the binocular vision based on structured light is combined, the characteristic data of the surface of the workpiece are extracted, and a controller is used for reconstructing a three-dimensional model and determining electric arc melting parameters; flat-peak valley filling operation of non-filler wire melting is carried out in a protective atmosphere by utilizing a TIG welding gun; the corresponding energy is set according to the measured value of the surface flatness, and a laser heat source is used for carrying out laser melting treatment on the surface through the laser; and the actual surface flatness is detected, and the actual surface flatness is compared with the standard surface flatness, if not, the process is repeated untilthe process is qualified. According to the non-leveling surface autonomous identification robot additive manufacturing forming precision control method, the surface precision of an arc additive partcan be effectively improved, welding quality and stability are guaranteed, and therefore the quality of the arc additive forming part can be effectively improved.

Owner:NANJING UNIV OF SCI & TECH

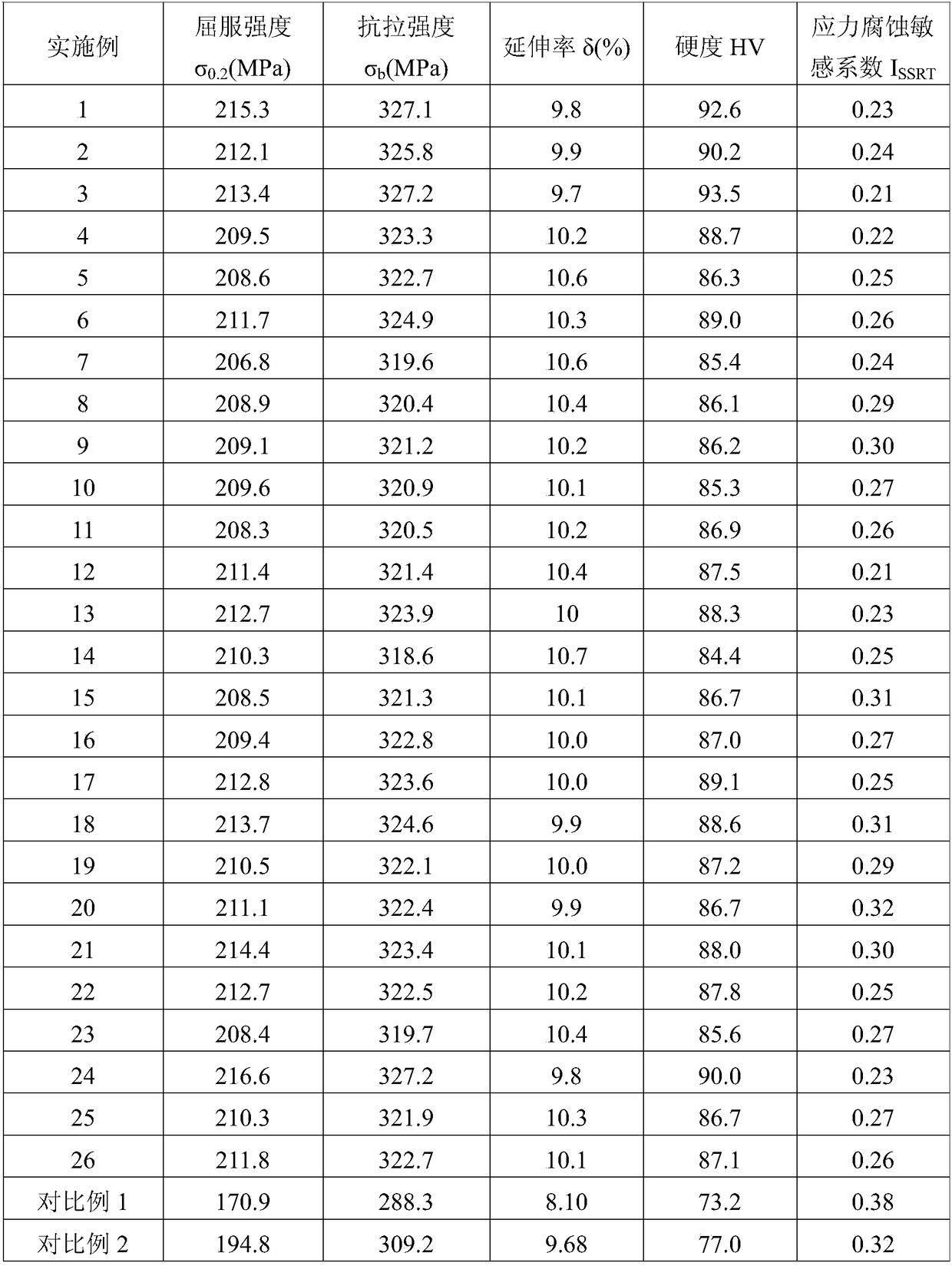

Al-Mg-Zn-Mn aluminum alloy welding wire and preparation method thereof

PendingCN108161273AShort production processReduce manufacturing costWelding/cutting media/materialsSoldering mediaMetal microstructureNatural aging

Disclosed are an Al-Mg-Zn-Mn aluminum alloy welding wire and a preparation method thereof. The welding wire and the method belong to the technical field of aluminum alloys. The welding wire comprises,by mass, 0.5-3.0% of Zn, 4.5-5.5% of Mg, 0.4-1.0% of Mn, 0-0.15% of Ti, 0-0.15% of Cr, 0-0.25% of Fe, 0-0.25% of Si, 0-0.15% of the total amount of other impurity elements, 0-0.05% of single impurityelement and the balance Al. The preparation method comprises the steps of smelting, casting, preprocessing after heating to 200-400 DEG C and performing heat preserving for 2-6 hours, extruding afterperforming heat preserving under the temperature of 440-470 DEG C for 2-4 hours, rolling after heating to 480-550 DEG C and performing heat preserving for 2-4 hours, in-process annealing and bright-cold drawing. According to the method, high-temperature and long-duration uniform processing is not needed, energy is saved, processing procedures of welding wire are shortened, wire braking during drawing is reduced, yield of drawing is improved, production cost is reduced, and metal microstructure can be refined, so that weld metal has natural aging strengthening capability to improve the performance of weld joints.

Owner:NORTHEASTERN UNIV

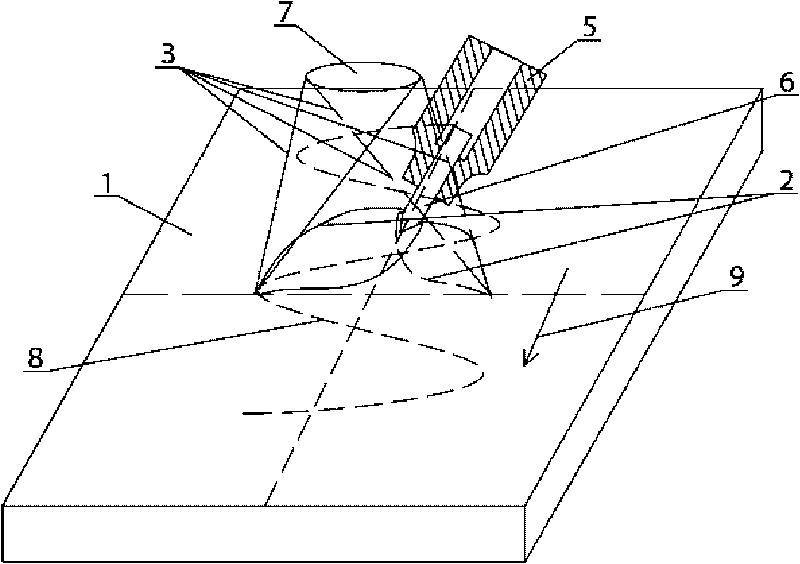

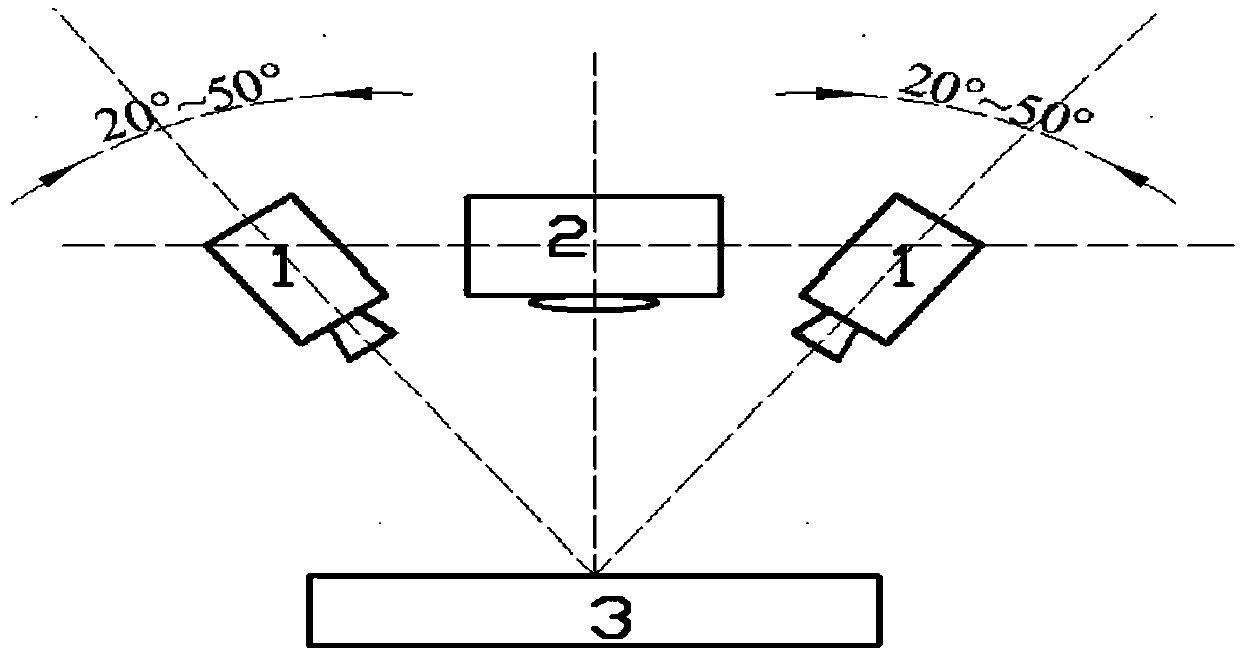

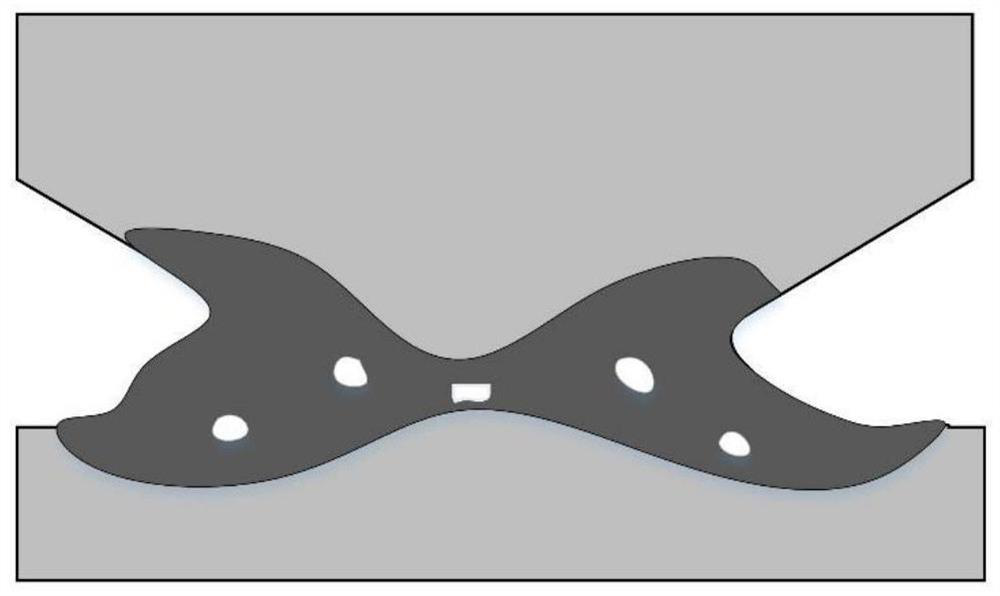

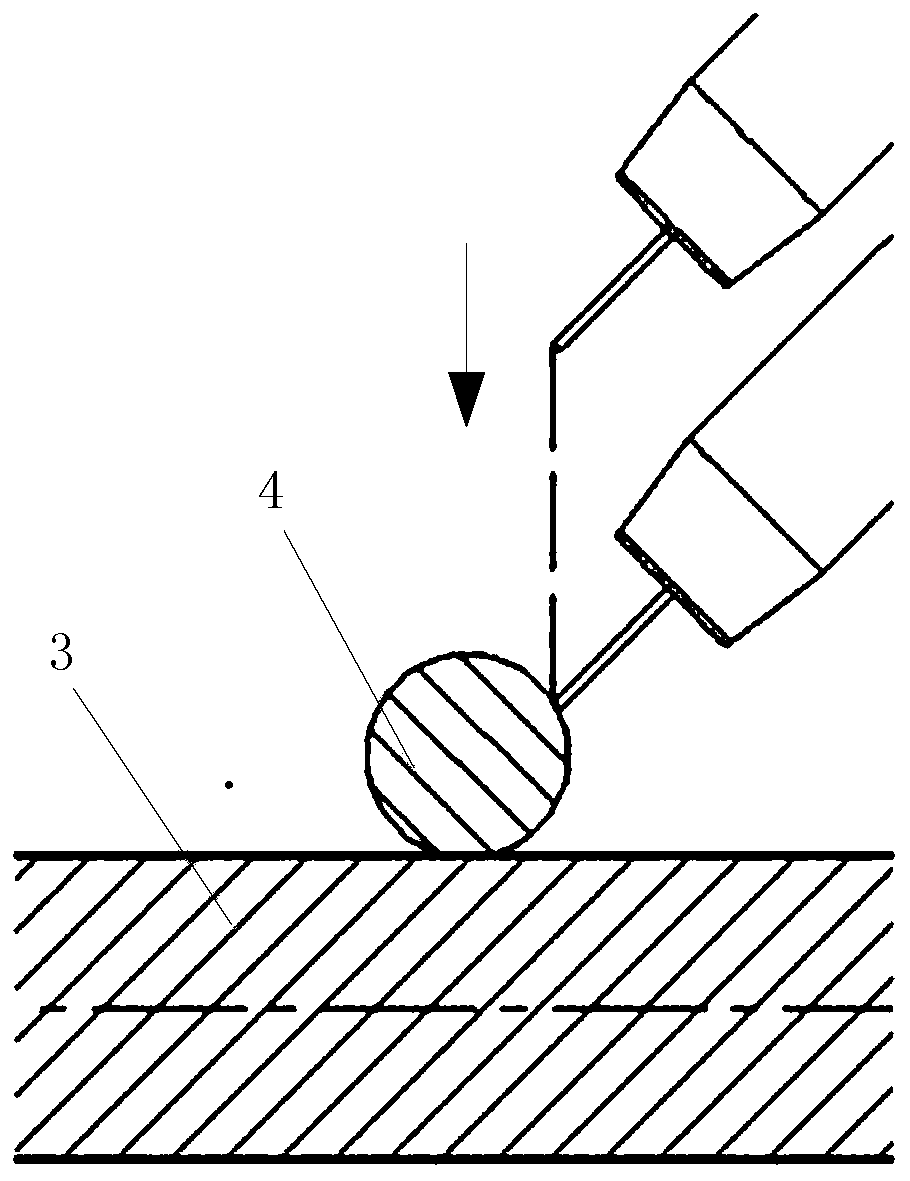

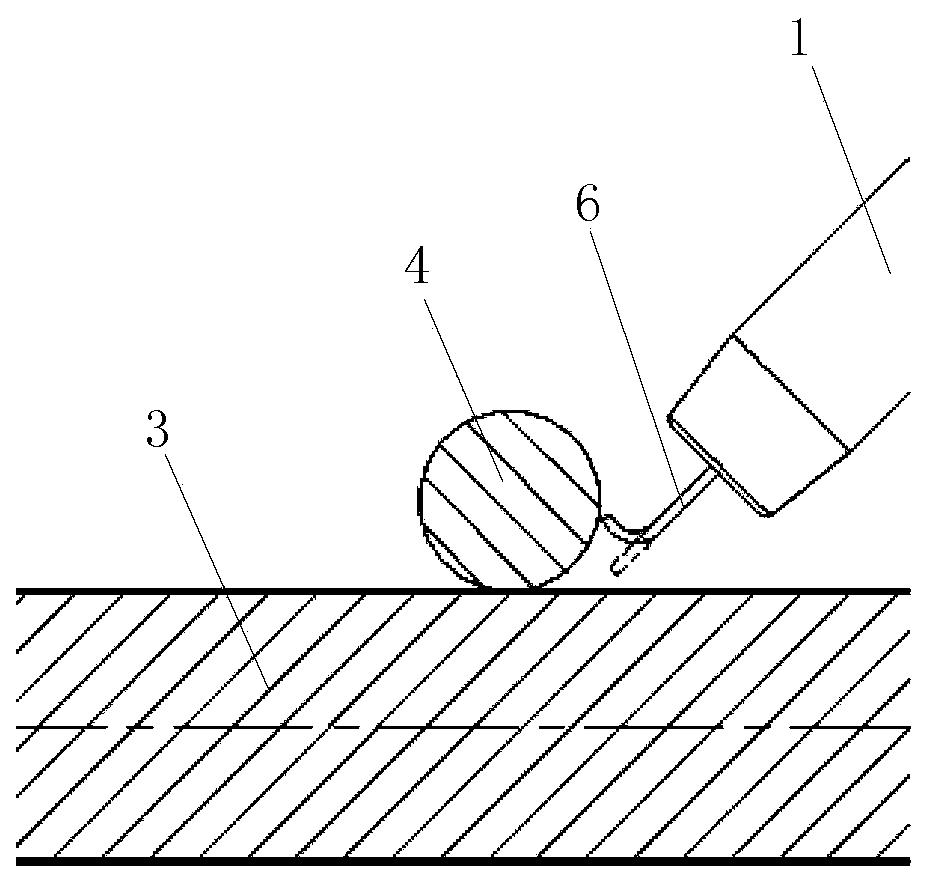

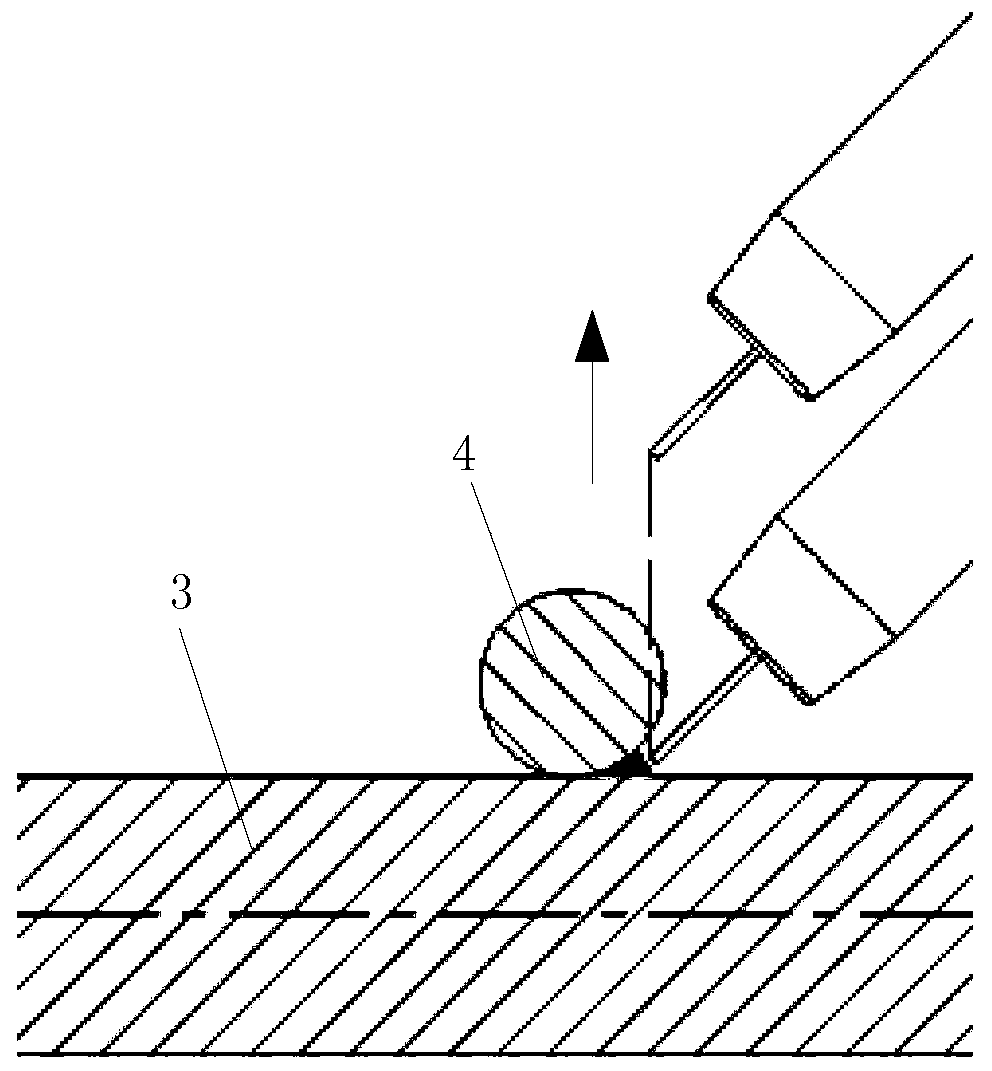

Double-heat-source collaborative welding method and device for large thermal conductivity mismatched metal materials

ActiveCN108436234AImprove welding qualityControl soldering temperatureArc welding apparatusWelding/soldering/cutting articlesThree-dimensional spaceHeat losses

The invention discloses a double-heat-source collaborative welding method and device for large thermal conductivity mismatched metal materials, and belongs to the field of metal material welding. Whenwelding the large thermal conductivity mismatched metal materials, the method adopts two heat sources to simultaneously heat the front and back sides of joints and optimizes energy distribution of the joints by controlling energy parameters and positional parameters of the two heat sources, side heat input of high thermal conductivity metal is increased, the heat loss caused by the higher thermalconductivity is compensated, the low thermal conductivity metal side welding temperature is controlled, and the problem of large thermal conductivity mismatched metal material welding forming is solved and the joint welding quality is improved. The preheating effect of the joints is obtained by tilting the two heat sources on the front and back sides at a certain angle in the welding direction, and the single-pass welding double-sided forming of the joints is realized under auxiliary measures such as no chamfering and pre-weld preheating. The welding device can effectively adjust and controlthe heat distribution of the joints by precisely controlling the position of the welding heat sources in the three-dimensional space, and efficient and reliable connection of the large thermal conductivity mismatched metal materials is realized.

Owner:UNIV OF SCI & TECH BEIJING

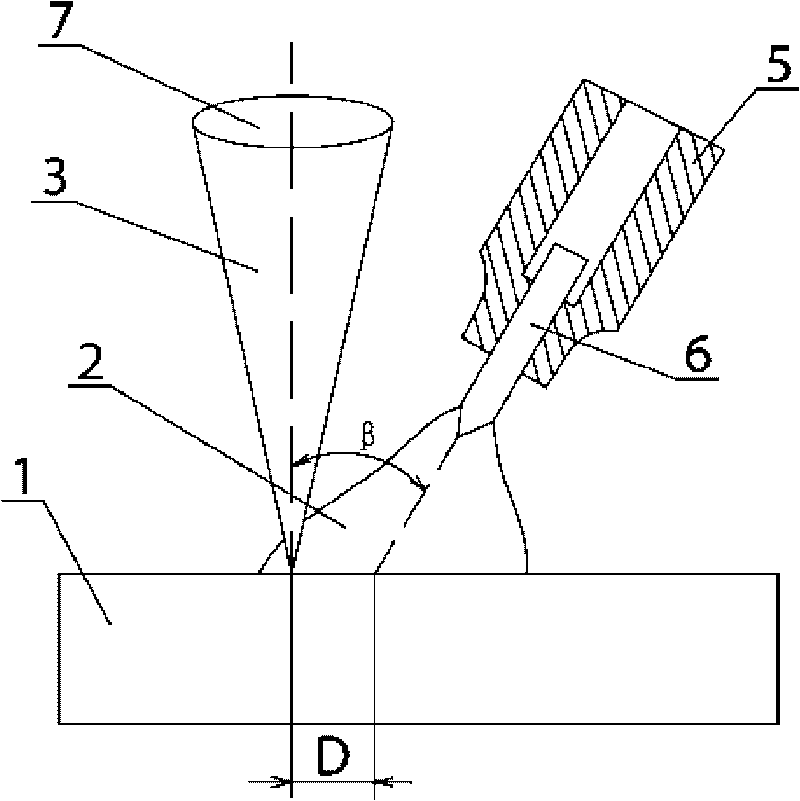

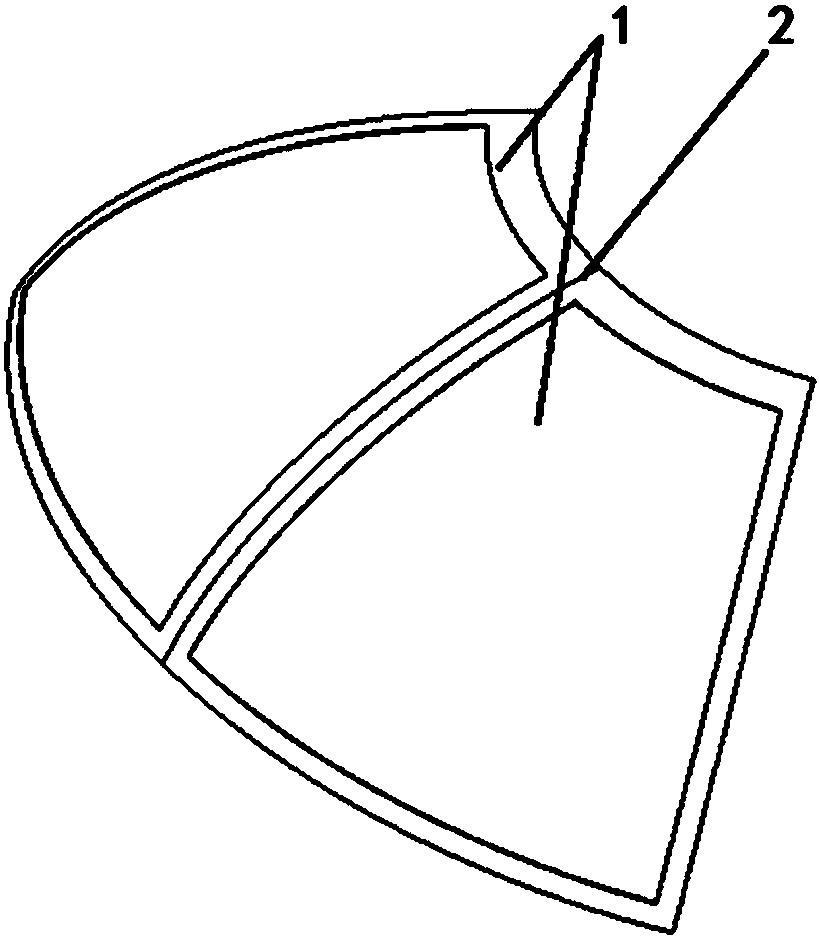

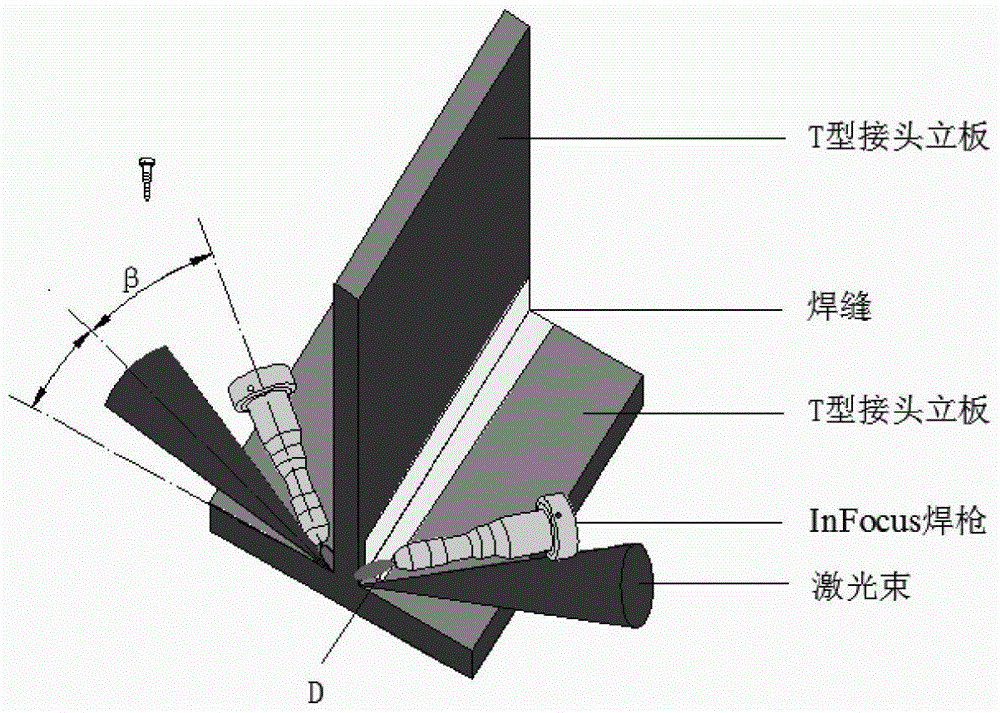

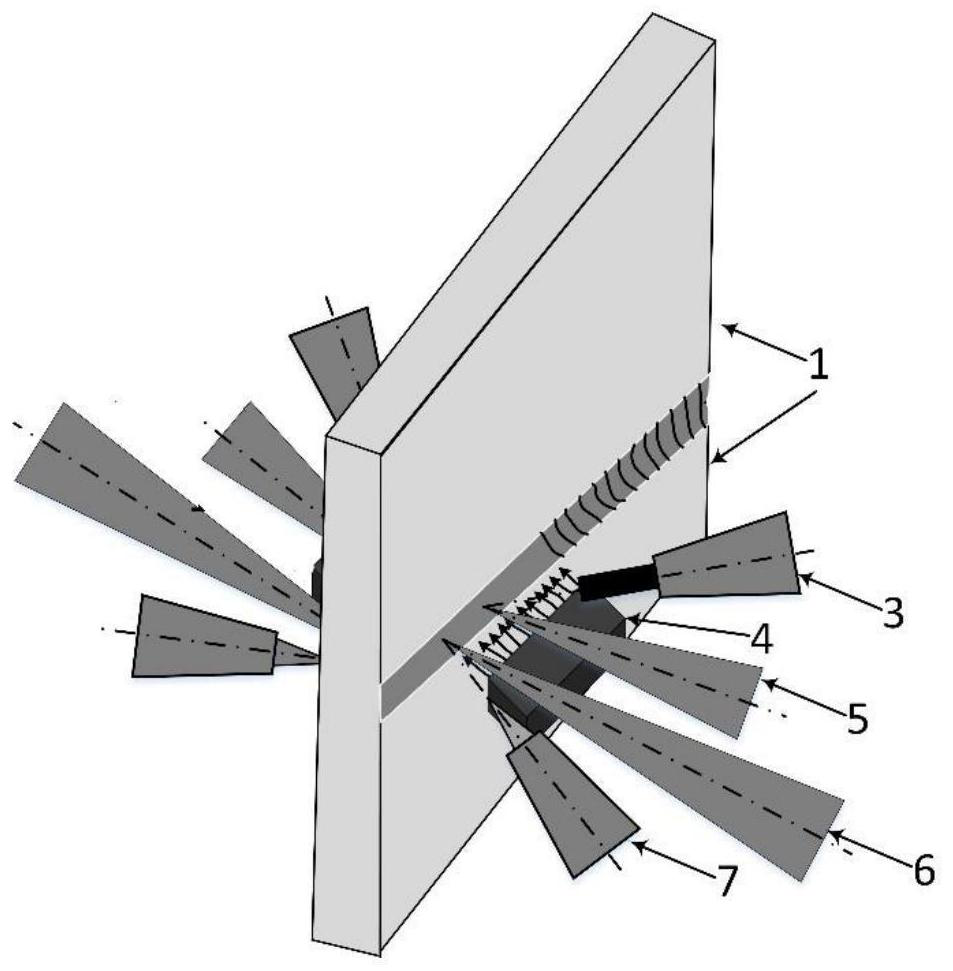

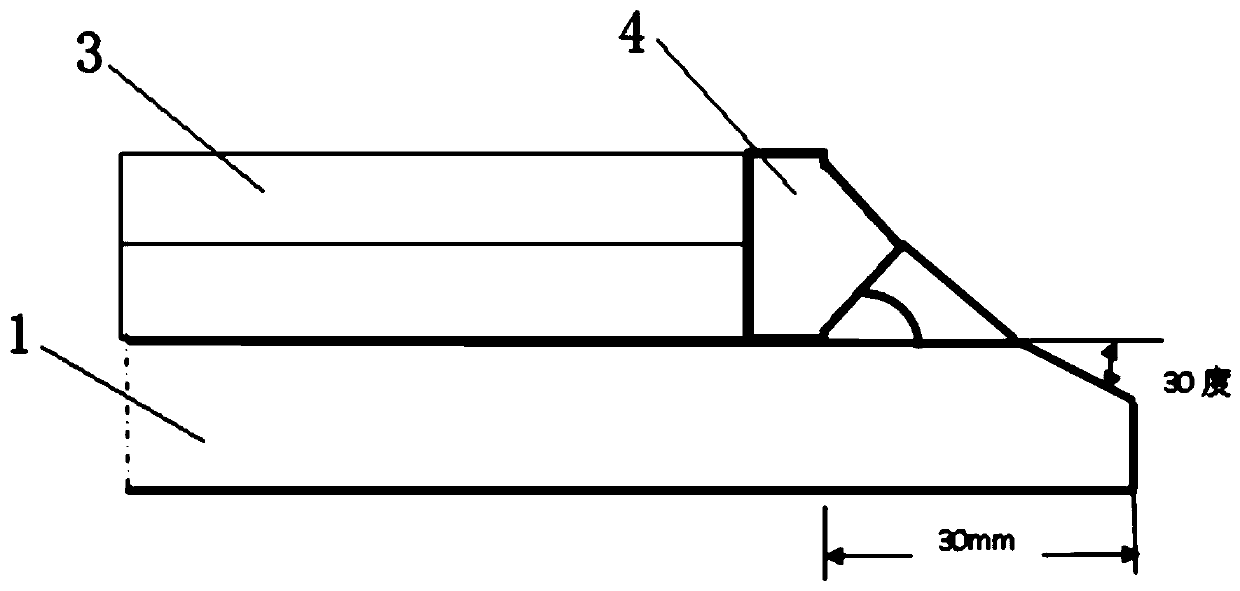

Bilateral laser-InFocus electric arc composite welding method for T-type joint

InactiveCN104985326AStrong penetrating powerFast welding speedLaser beam welding apparatusEngineeringPeak value

The invention discloses a bilateral laser-InFocus electric arc composite welding method for a T-type joint, and relates to a welding method. The method comprises: I, processing a to-be-welded part and fixing the to-be-welded part by a clamp; II, keeping an included angle alpha between an InFocus welding gun and a panel longitudinal surface of the T-type joint at 30 degrees to 45 degrees, and keeping an included angle beta between the InFocus welding gun and a T-type bottom plate at 30 degrees; III, setting bilateral laser power to 1000W-3000W, setting bilateral electric-arc current to 200A-900A, setting gas flow of an electric-arc welding gun to 15L / min to 30L / min, and setting welding speed to 1.0m / min to 5.0m / min; and IV, implementing welding. Compared with the peak value of conventional ITG electric arc 400A, current acting force and energy density are relatively large, key hole welding can be realized, depth of fusion is large, welding speed is high, and welding efficiency is improved; during welding of a medium-thickness plate, laser power is reduced by increasing welding current, so that the welding cost is reduced.

Owner:HARBIN INST OF TECH

Thick plate laser arc composite double-sided synchronous horizontal welding method and device

ActiveCN114012266AImprove liquidityImprove uniformityLaser beam welding apparatusThick plateEngineering

The invention discloses a thick plate laser arc composite double-sided synchronous horizontal welding method and device. The horizontal welding method comprises the following steps that 1, a welding workpiece is prepared; 2, two laser arc devices are arranged on the two sides of the welding workpiece correspondingly, and the positions are adjusted; 3, welding process parameters are set, a laser arc device is started, and a base layer is welded; and 4, welding process parameters are adjusted, a laser arc device is started, and filling layer welding is performed. The method reduces the porosity of the weld joint, solves the problems of incomplete penetration of the weld joint, incomplete fusion of the side wall, weld joint cracks and the like, and ensures the quality of the weld joint and the welding stability. The horizontal welding device comprises a TIG welding gun, a first laser device, a second laser device, a GMAW welding gun and an air injection assembly.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

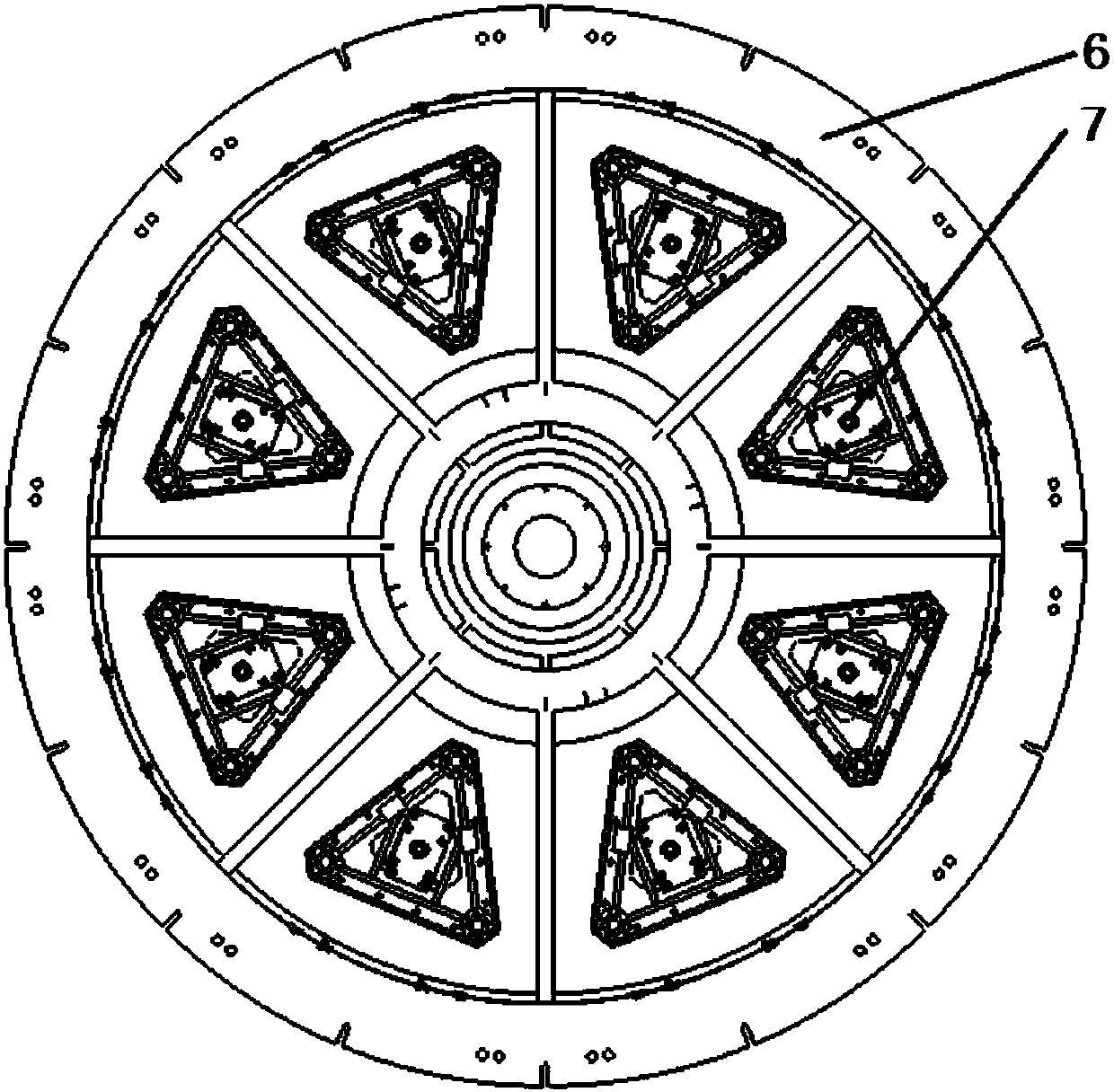

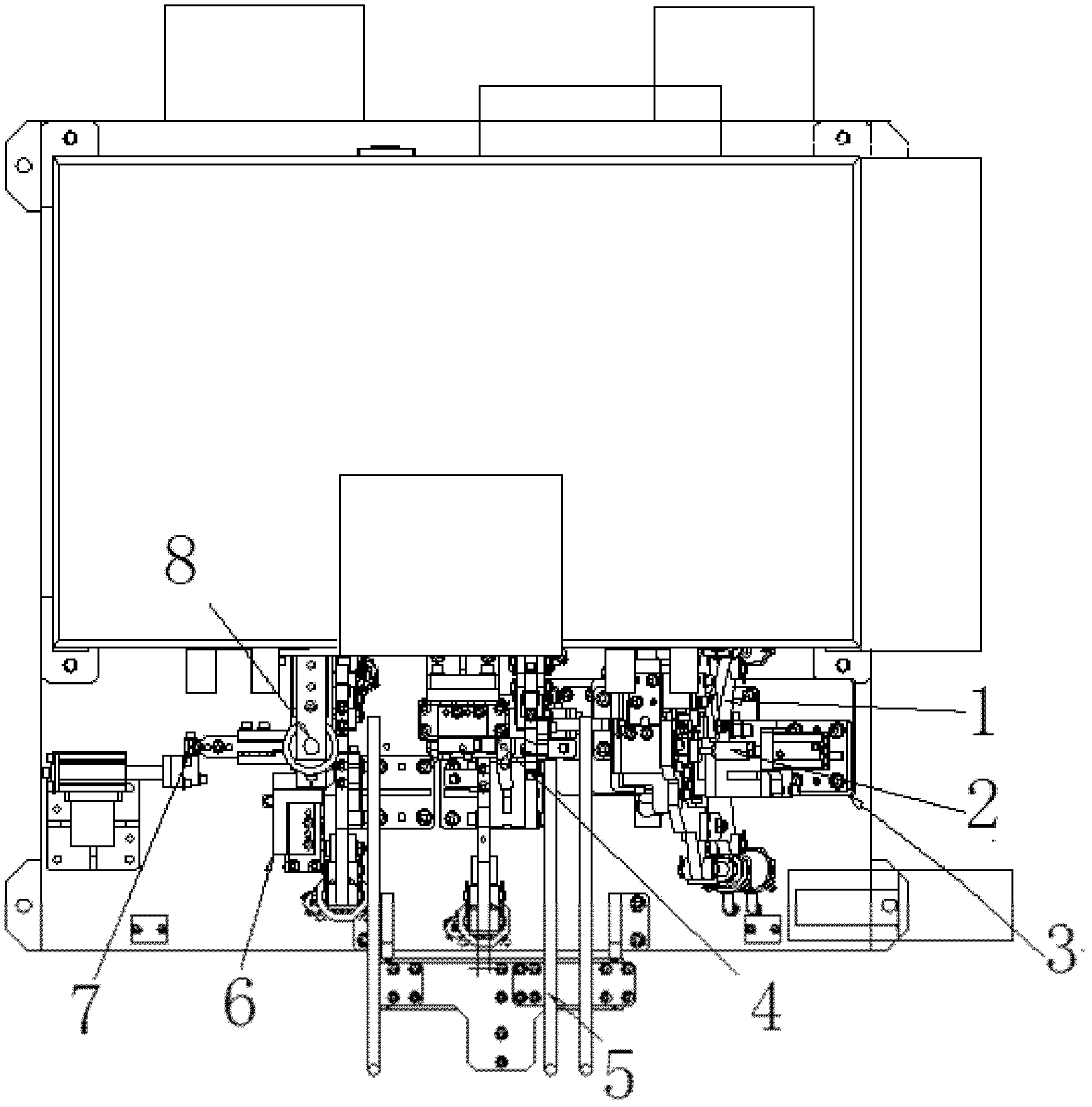

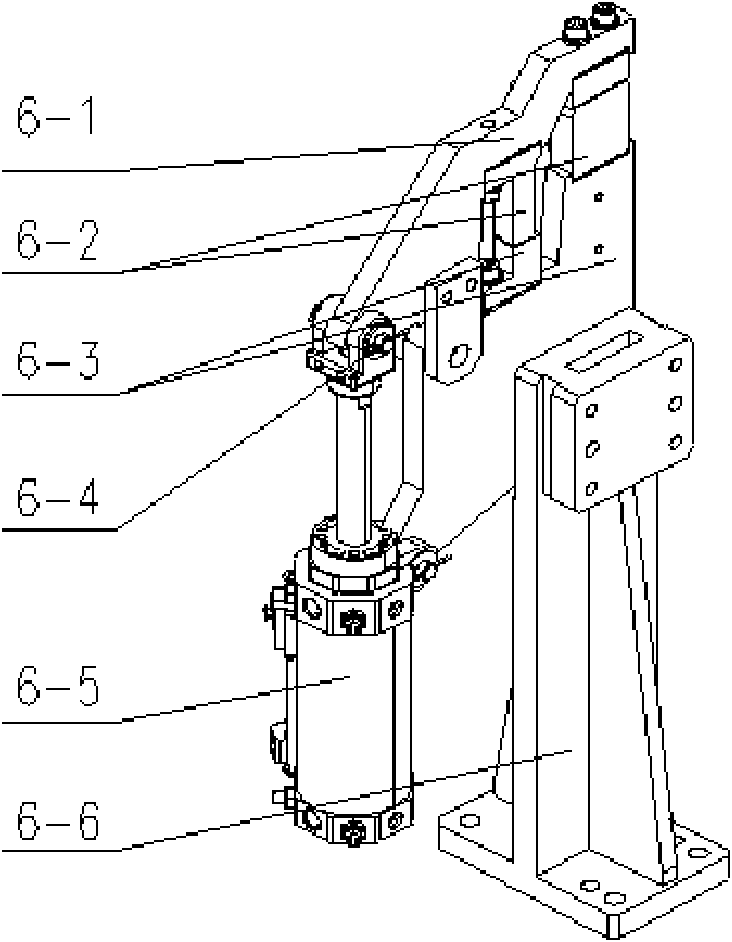

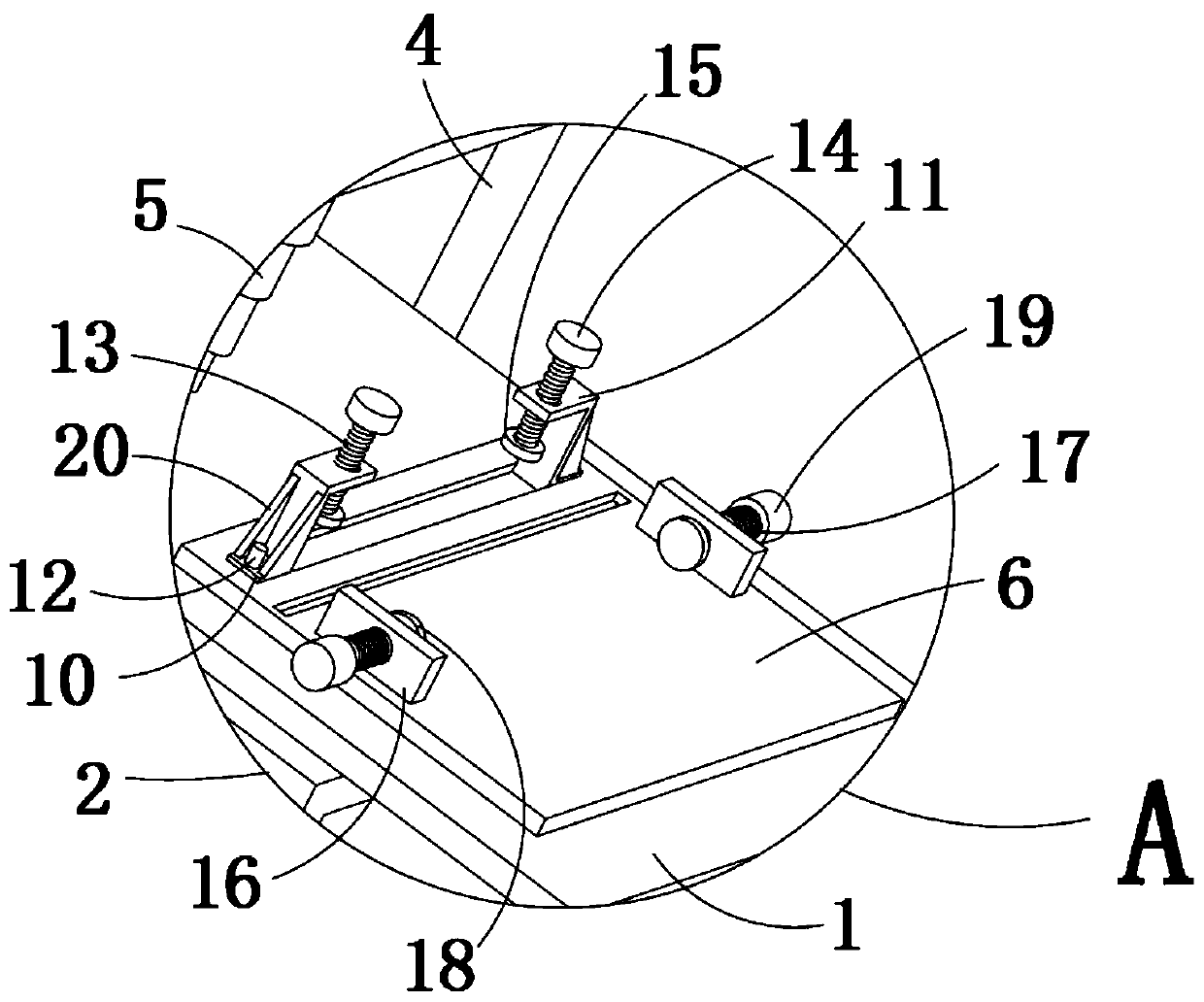

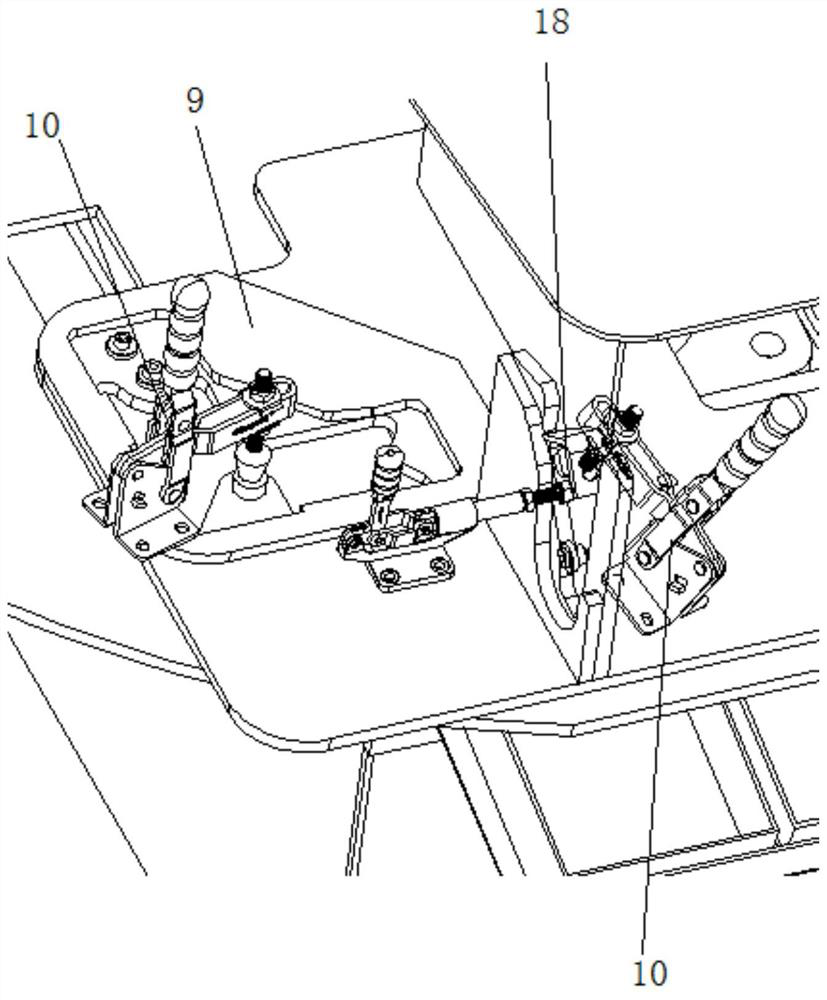

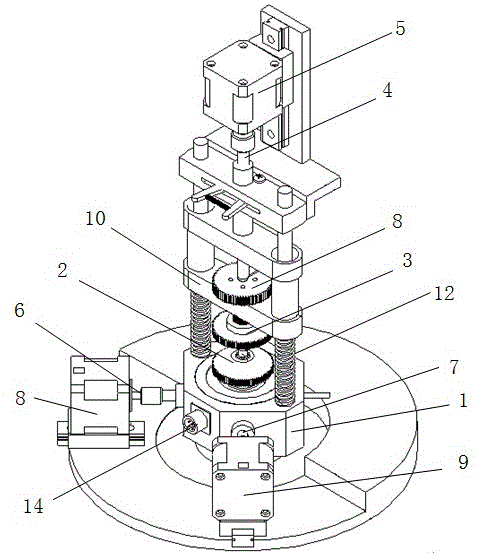

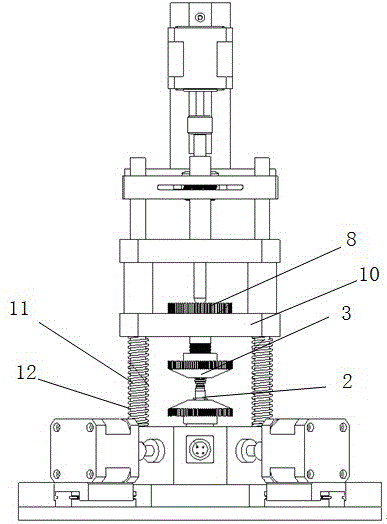

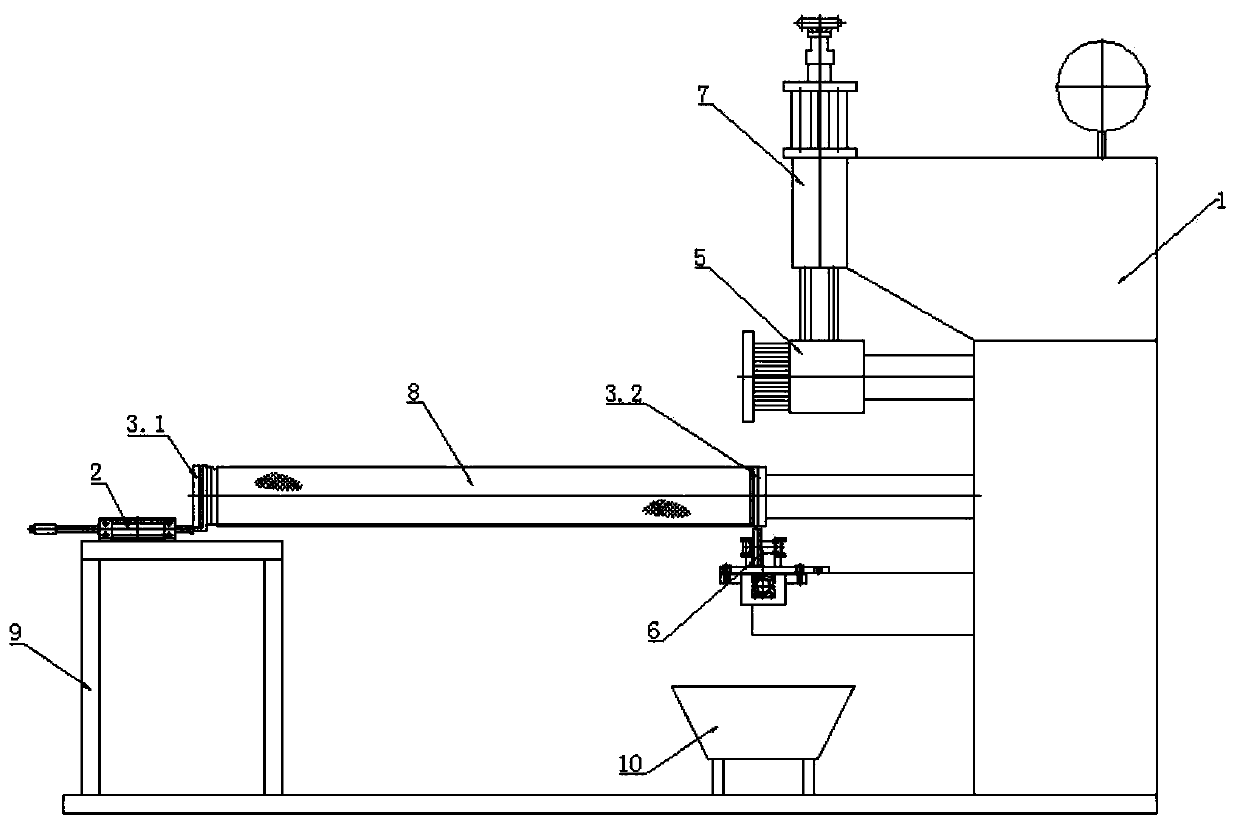

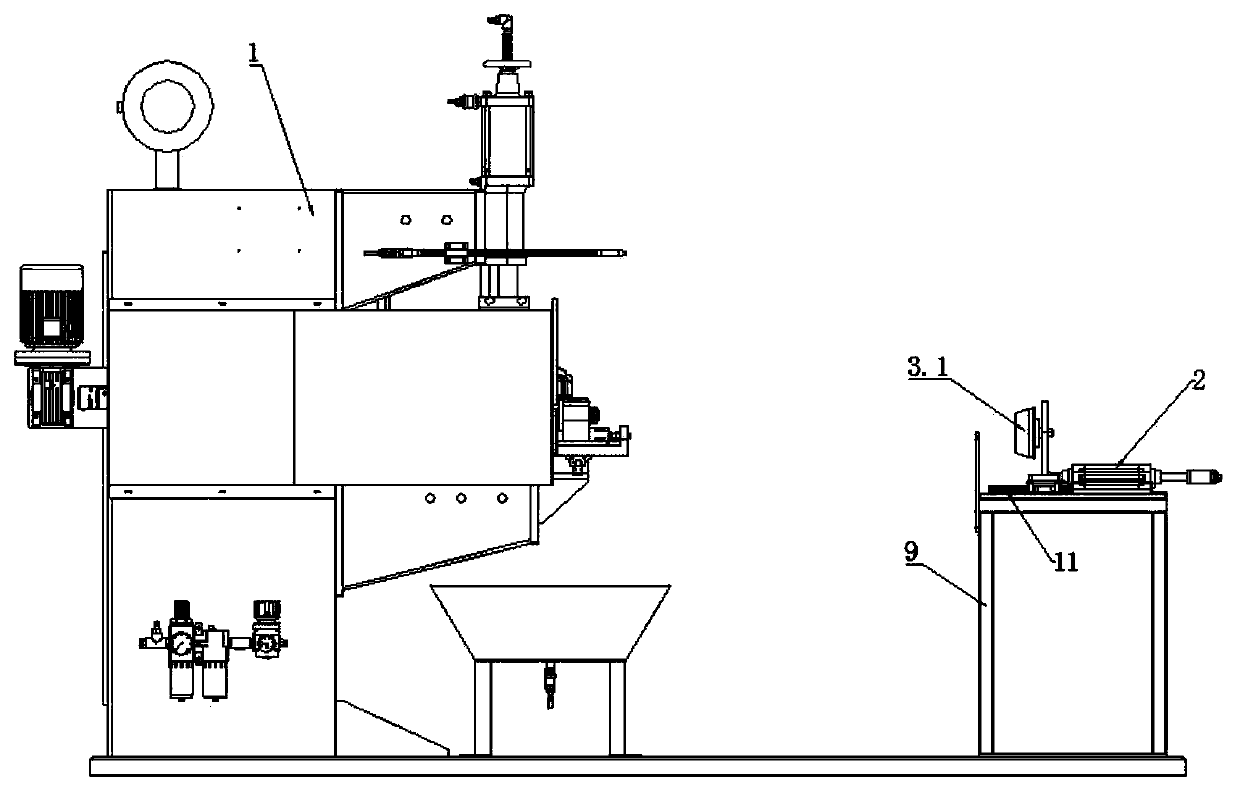

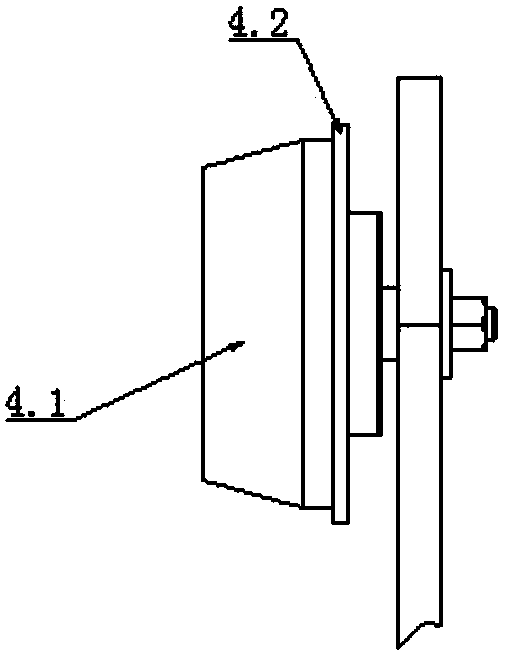

Tripod automatic spot welding method and device

ActiveCN102319975AImprove work efficiencyEnsure welding stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention relates to a tripod automatic spot welding method and a tripod automatic spot welding device. The tripod automatic spot welding method comprises the following steps that firstly, a chute and a triangular plate are placed in a cavity formed in a mode that clamping positioning mechanisms are combined, the clamping positioning mechanisms are respectively driven by a cylinder so as to fix the triangular plate and the chute, and both ends of the chute are positioned and clamped by the drive of the cylinder; a small bracket is placed in a cavity of a first clamping positioning mechanism, a control switch is pushed again, and clamping blocks of the first clamping positioning mechanism are closed to clamp the small bracket; after three parts are respectively fixed at the corresponding positions, the welding work is started, a first spot welding mechanism is used for carrying out fixed spot welding on the tripod and the chute, at the same time, a second spot welding mechanism is used for carrying out fixed spot welding on the small bracket and the chute, the first spot welding mechanism transversely and longitudinally slides to reach set positions by two groups of slide rails so as to complete spot welding of three welding spots, and the second spot welding mechanism also completes spot welding of two welding spots by a transverse moving guide rail; after the spot welding is completed, the clamping blocks are opened, an ejection mechanism is driven and lifted up by the cylinder so as to eject out a finished product. The tripod automatic spot welding method and the tripod automatic spot welding device are convenient for an operator to take out the finished product.

Owner:北京凌云东园科技有限公司

Power soft roll lithium ion battery of multi-roll core structure

InactiveCN106848385AIncrease productivityImprove stabilityFinal product manufactureSecondary cellsState of artEngineering

The invention discloses a power soft roll lithium ion battery of a multi-roll core structure. According to the power soft roll lithium ion battery, a positive plate, a diaphragm and a negative plate are coiled to form a single naked core, a plurality of naked cores are overlapped together in a parallel connection manner, an aluminum strip is welded with an aluminum lug, and a copper strip is welded with a nickel-plated lug or a nickel lug. Multiple naked cores are overlapped together in the parallel connection manner, and the aluminum strip and the copper strip of the naked core formed by the positive plate, the negative plate and the diaphragm in the coiled manner are arranged on one same side of the naked core. Compared with the prior art, the power soft roll lithium ion battery has the advantages that firstly, the large-current charge / discharge property of a polymer lithium battery of a coiled structure can be improved; secondly, the characteristics of simple process and high production efficiency of the coiled lithium battery are maintained; thirdly, precious nickel resources can be saved; fourthly, the service lives of a welding head and a cutter can be prolonged, the cost can be lowered, and the welding stability and consistency can be ensured.

Owner:GUANGDONG TEAMGIANT NEW ENERGY TECH CORP

Large-board fan-out double-sided antenna package structure and preparation method thereof

PendingCN110459510AReduce volumeEasy to integrateSemiconductor/solid-state device detailsAntenna supports/mountingsSolder maskSemiconductor chip

The invention discloses a large-board fan-out double-sided antenna package structure and a preparation method thereof. The large-board fan-out double-sided antenna package structure includes a carrierplate, a number of semiconductor chips, package layers, transmission layers, wiring layers, antenna layers, solder mask layers and metal bumps. The backs of the semiconductor chips are attached to the two sides of the carrier plate. The package layers are respectively located on the two sides of the carrier plate and cover the semiconductor chips, and the fronts of the semiconductor chips are exposed to the package layers. The transmission layers, the wiring layers and the antenna layers are all located on the package layers. One side of each transmission layer is electrically connected withthe corresponding package layer and the fronts of the corresponding semiconductor chips, and the other side is electrically connected with the corresponding wiring layer and the corresponding antennalayer. Each wiring layer has a pad area and a non-pad area. The solder mask layers are located on the package layers and cover the antenna layers and the non-pad areas. The metal bumps are welded to the pad areas of the wiring layers. The antenna layers occupy small volume, and the package structure is arranged reasonably. The integration performance of the antenna packaging structure and the efficiency of antennas can be improved. Surface warpage will not be caused due to the performance difference of materials. The accuracy, yield and welding stability during production can be guaranteed.

Owner:广东佛智芯微电子技术研究有限公司

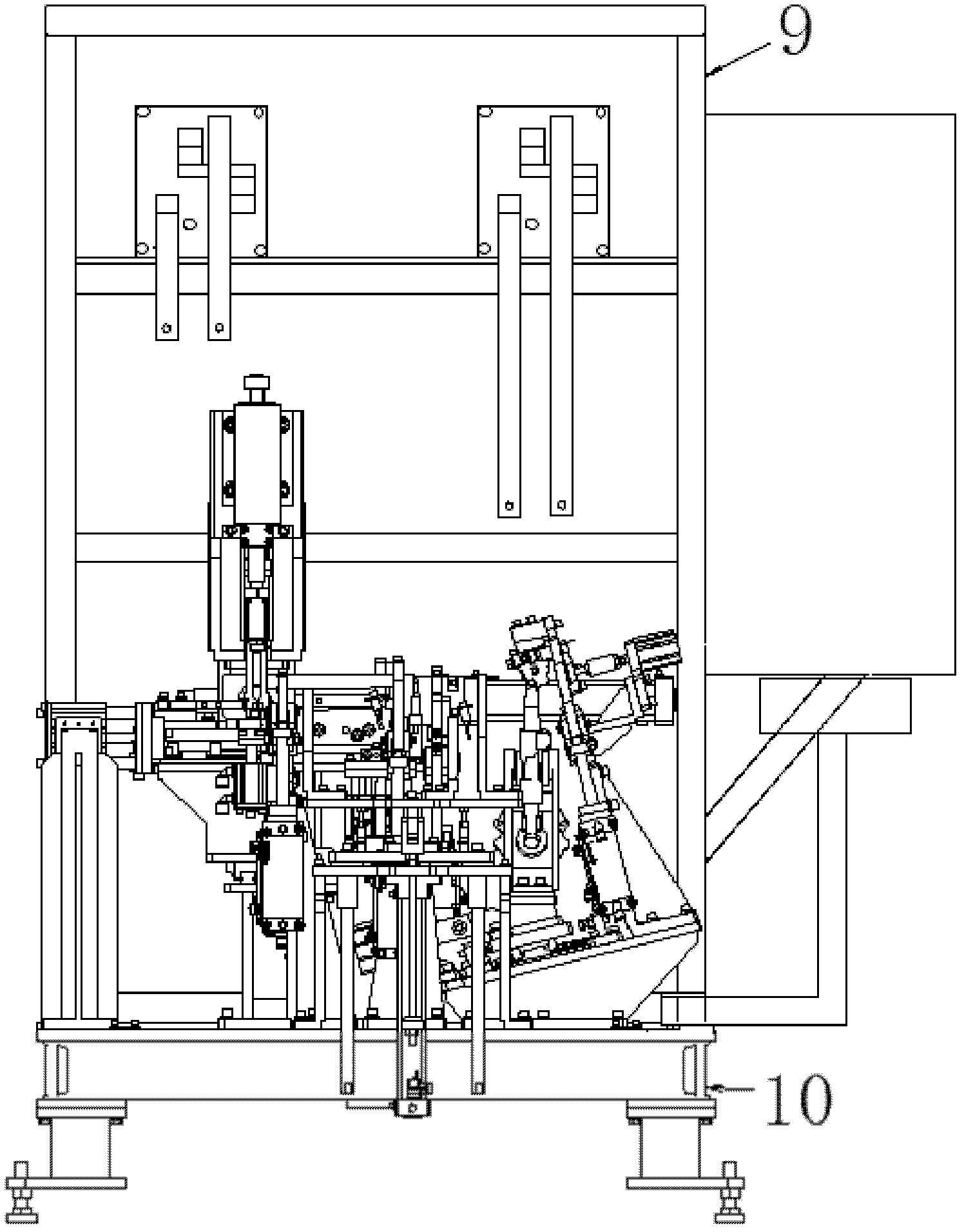

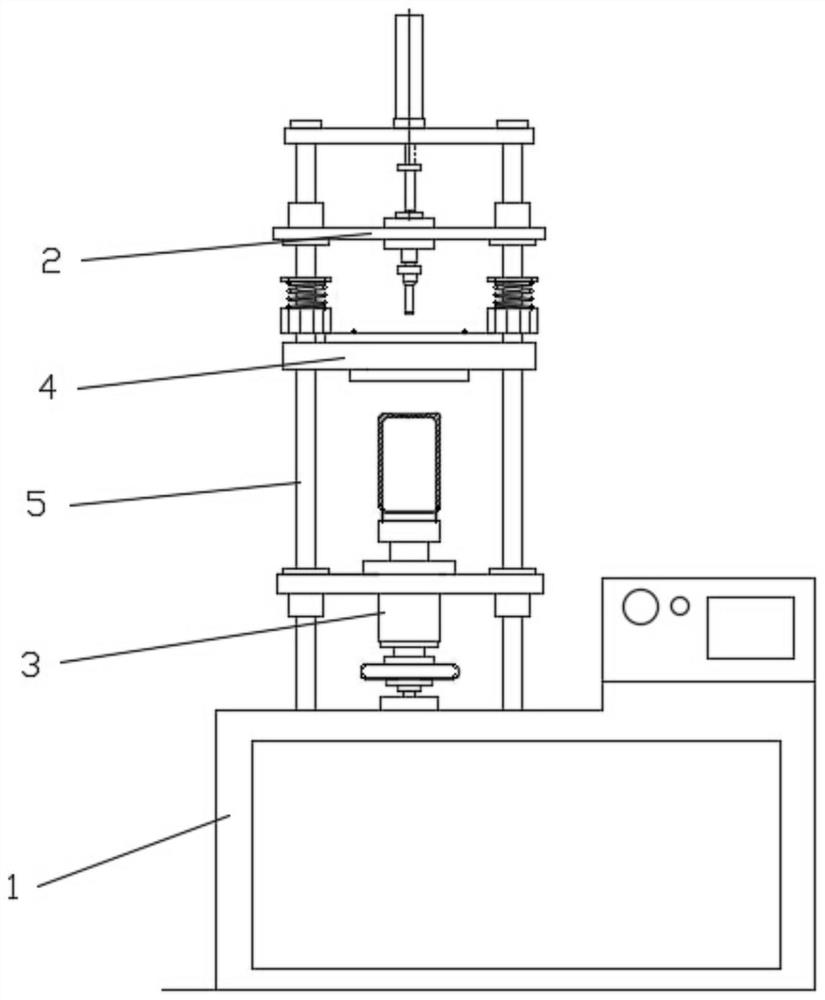

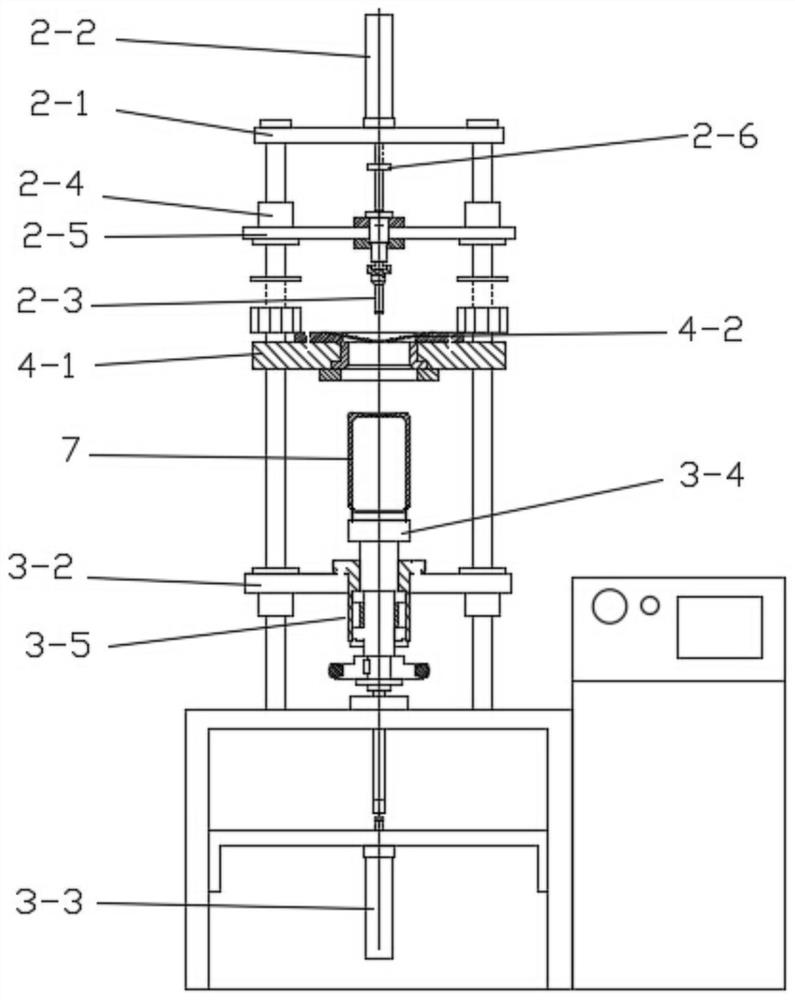

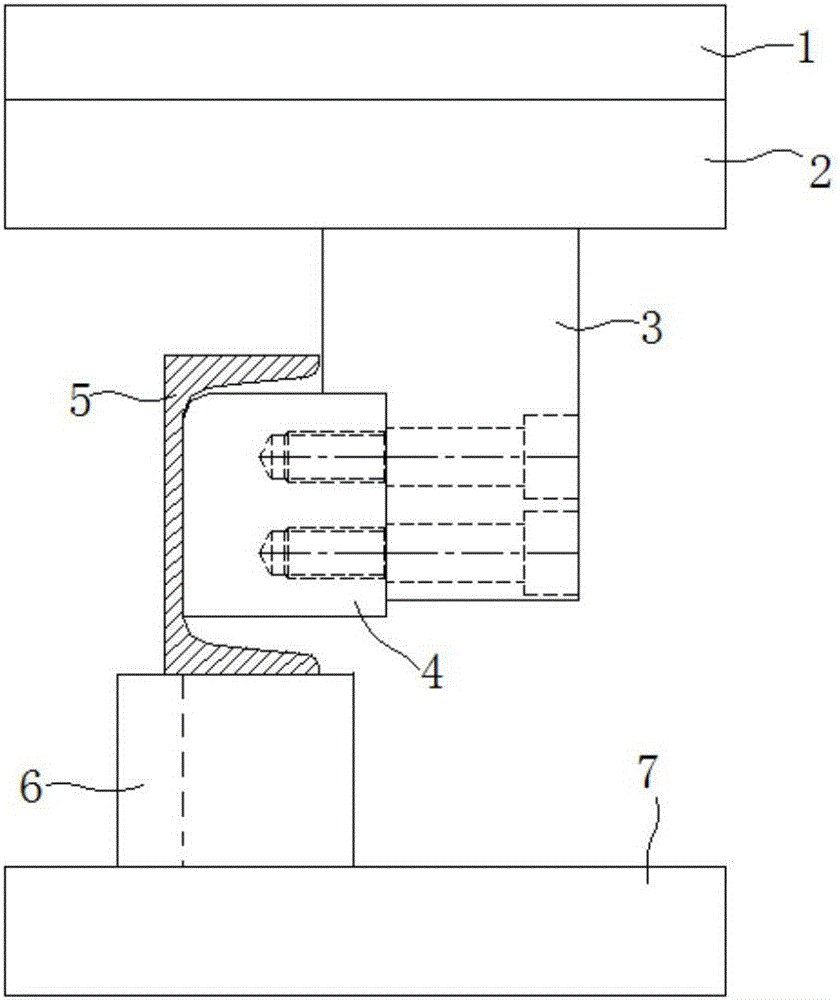

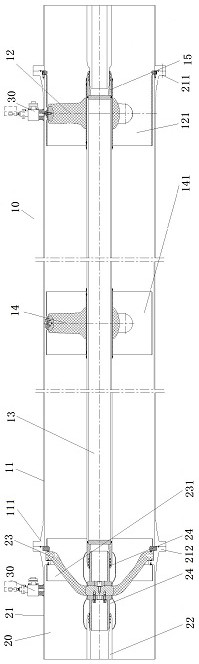

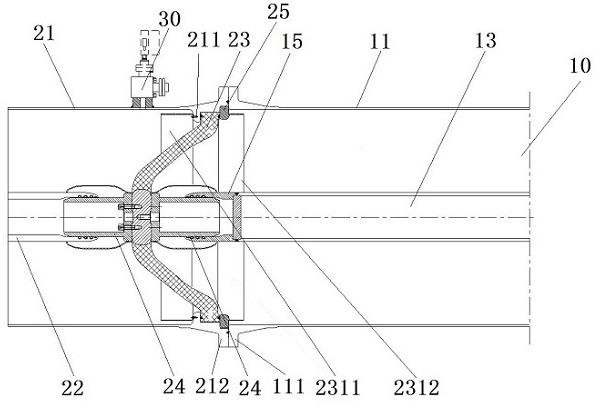

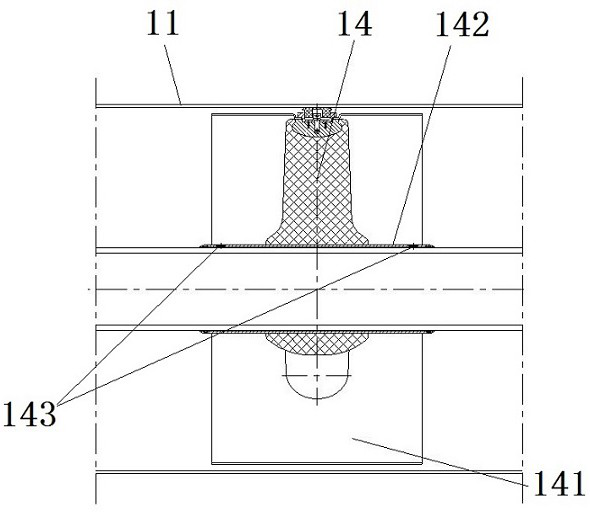

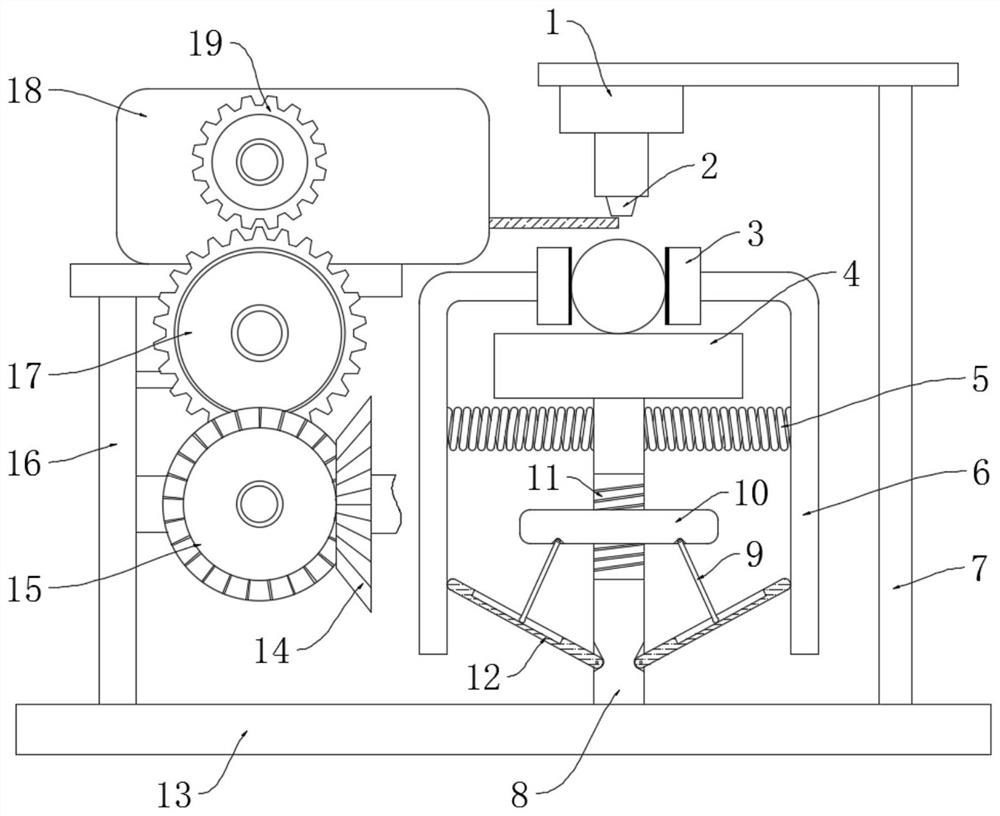

Welding equipment for air extraction hole in bottom of vacuum cup and machining process of welding equipment

PendingCN112589258AEnsure welding stabilityEnsure safetyLaser beam welding apparatusEngineeringMachining process

The invention relates to welding equipment for an air extraction hole in the bottom of a vacuum cup and a machining process of the welding equipment. The welding equipment comprises a machine frame base, wherein the machine frame base is provided with a top pressing device, a bottom lifting and rotating device and a guiding device which correspond to one another from top to bottom, and the top pressing device and the bottom lifting and rotating device are movably connected to the machine frame base; the top pressing device and the bottom lifting and rotating device move towards the guiding device; and the guiding device comprises a horizontally-arranged fixing plate, a conical surface arranged downwards is formed in the middle of the fixing plate, and a through hole is formed in the middleof the conical surface. Compared with the prior art, the welding equipment has the advantages that through the arrangement of the bottom lifting and rotating device and the guiding device, the to-be-welded position of the bottom of the vacuum cup is moved to the bottom of the conical surface of the guiding device, and the welding piece is moved to the to-be-welded position of the bottom of the vacuum cup under the action of gravity and the conical surface, so that the safety and the convenience of the welding process are ensured; and besides, the top pressing device is arranged to press the welding piece compactly, so that the welding stability of the welding piece and the vacuum cup is ensured.

Owner:浙江裕川工贸有限公司

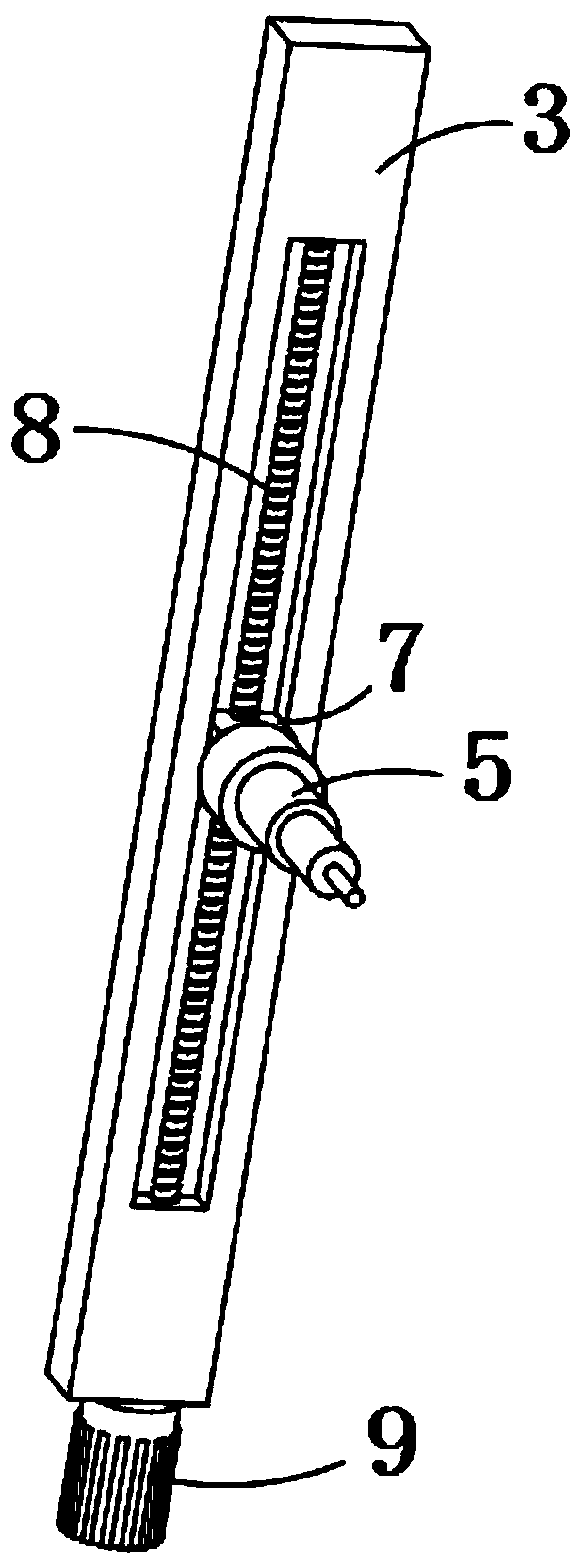

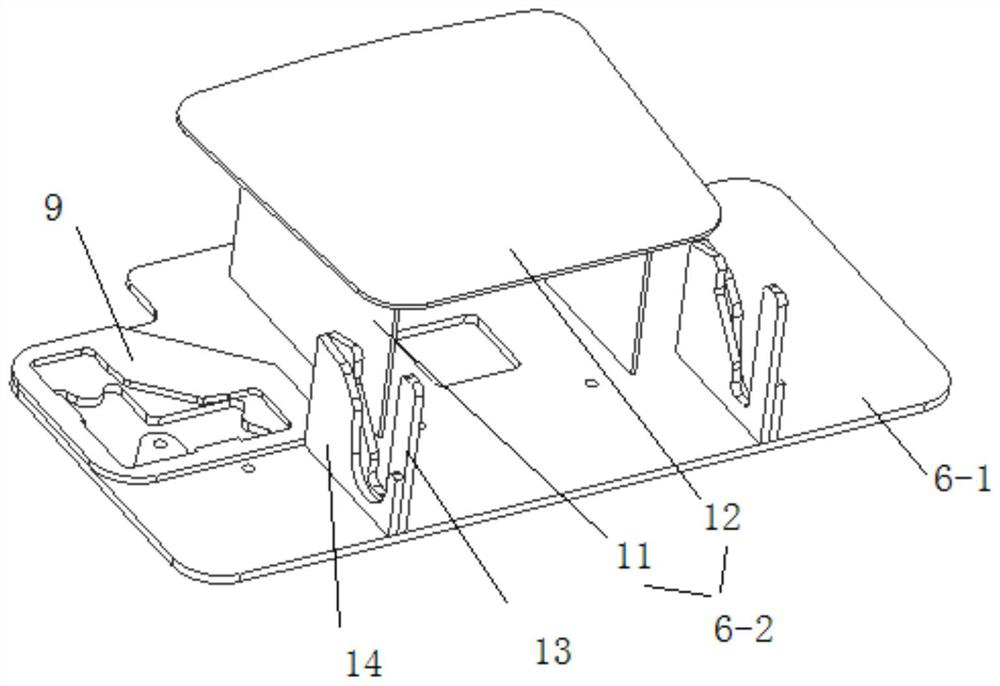

Portable operation platform for optical fiber fusion welding

ActiveCN105842789AReduce volumeIncrease the operating areaCoupling light guidesFusion weldingEngineering

The invention discloses a portable operation platform for optical fiber fusion welding. The portable operation platform includes an optical fiber fusion welding platform and an optical fiber cutting platform; the optical fiber fusion welding platform accommodates an optical fiber fusion welding machine; the optical fiber cutting platform is used for optical fiber treatment before optical fiber fusion welding; the optical fiber fusion welding platform is detachably connected with the optical fiber cutting platform through a connecting portion; a tripod fixing hole is formed in the bottom of the portable operation platform; the tripod fixing hole is in matched connection with a camera tripod; and waist sling fixing holes and neck sling fixing holes are formed at side portions of the portable operation platform and are used for fixing slings connected with an operator. The portable operation platform of the invention can be used under various conditions such as high-altitude space, ground and platforms, can facilitate the operation of the operator and can better adapt to various practical requirements.

Owner:INNO INSTR (CHINA) INC

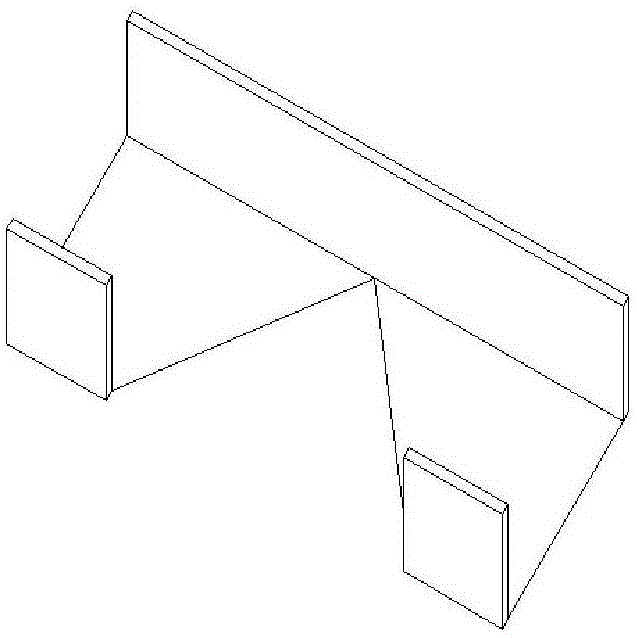

Machining device and method for steel channel grooving and bending combined assembly

ActiveCN106734518AAvoid bending deformationImprove processing efficiencyShaping toolsEngineeringMechanical engineering

The invention discloses a machining device and method for a steel channel grooving and bending combined assembly and belongs to the technical field of shearing and bending machining. The machining device comprises a rectangular groove cutting machining mold, a triangular groove cutting machining mold and a bending machining mold, wherein the rectangular groove cutting machining mold comprises a first movable cutter and a first fixed cutter; the first movable cutter is fixedly connected with a first movable cutter base, and the shearing edge face of the first movable cutter is a V-shaped face with the middle portion sunken downwards; the first fixed cutter is installed on a first fixed cutter base and forms a "rightward-right-angle-u-shaped" structure; the triangular groove cutting machining mold comprises a second fixed cutter and a second movable cutter; the second movable cutter is fixedly connected with a second movable cutter base; the shearing edge face of the second movable cutter is a plane inclined to the other side from the position of a sharp corner of the plane; and the second fixed cutter is installed on a second fixed cutter base and forms an "L-shaped" structure. By adopting the machining device to perform grooving and bending machining on steel channels, the machining efficiency and the machining quality can be remarkably improved, and the precision and the quality of the combined assembly are made to meet the using requirements.

Owner:马鞍山市欧姆科技发展有限公司

Welding equipment for processing rail damping backing plate

InactiveCN110465768AGuaranteed parallel stateFast Bar WeldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringInverted u

The invention discloses welding equipment for processing a rail damping backing plate. The welding equipment for processing the rail damping backing plate comprises a conveying belt, wherein an inverted U-shaped plate is fixedly arranged in the conveying belt; the width of the inverted U-shaped plate is larger than that of the conveying belt, and a transverse plate is horizontally arranged on theupper side of the conveying belt; two electric telescopic rods are symmetrically arranged on two sides of the conveying belt; one end of each electric telescopic rod is fixedly connected with the transverse plate, and the other end of each electric telescopic rod is fixedly connected with the inverted U-shaped plate; a welding gun is arranged on the lower side of the transverse plate, and is fixedly connected with the transverse plate through a horizontal moving mechanism; a carrying plate is fixedly arranged on the conveying belt; a first fixing mechanism and a second fixing mechanism are arranged on the carrying plate; and a welding groove is formed between the first fixing mechanism and the second fixing mechanism. The welding equipment can be used for processing the rail damping backing plate, strip-shaped pieces or parts can be stably welded to the edge of a plate-shaped main body, uniform welding is achieved, and the effect is good.

Owner:杭州凯傲轮业有限公司

Multi-station seat welding workstation

PendingCN112157378AEnsure welding stabilityGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesWorkbenchWelding

The invention discloses a multi-station seat welding workstation which comprises a station base, a first positioner and a second positioner are respectively erected at two ends of the station base, rotary workbenches are respectively arranged on the first positioner and the second positioner, two symmetrical stations are arranged on each rotary workbench, two stations of the first positioner are respectively provided with seat plate dies used for clamping a seat plate and a side supporting plate, each seat plate die comprises a first base plate, the middle of the first base plate is provided with a supporting plate, two symmetrically arranged clamping plate assemblies are arranged at the outside of the supporting plate, two stations of the second positioner are respectively provided with back plate dies used for clamping and fixing a back plate, each back plate die comprises a second base plate, a fixing lug frame corresponding to an adjusting support is arranged on the second base plate, and the middle of the station base is provided with a welding manipulator used for welding products on the stations. According to the multi-station seat welding workstation, the work continuity isensured, the work which is completed by six persons originally can be completed by one person, the work efficiency is improved, and the labor cost is lowered.

Owner:HEFEI HEAN MACHINERY MFG

Welding method and system

PendingCN109822253AAvoid interferenceImprove controlWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMutual influence

The invention discloses a welding method and system. A first welding piece and a second welding piece are welded by a welding torch, and at any time before welding is started, a welding wire retractsback in the direction away from a welding point between the first welding piece and the second welding piece. The aim is to provide the welding method and system for solving the problems that in the welding process of a crossed contact point of an existing mesh workpiece, a welding wire and welding pieces influence each other and interference happens, and the aims of avoiding mutual influences andpreventing interference are achieved. After wire retreating, the condition that the welding torch moves, consequently the welding wire at the tail end of an electric conduction nozzle interferes thewelding pieces is avoided, the welding wire at the tail end of the electric conduction nozzle is in the normal shape, the welding quality and the welding stability are ensured, stable arcing is ensured, and meanwhile, the problems of workpiece welding penetration or notch generation caused by the fact that the length of the welding wire cannot be accurately controlled are solved.

Owner:徐小华

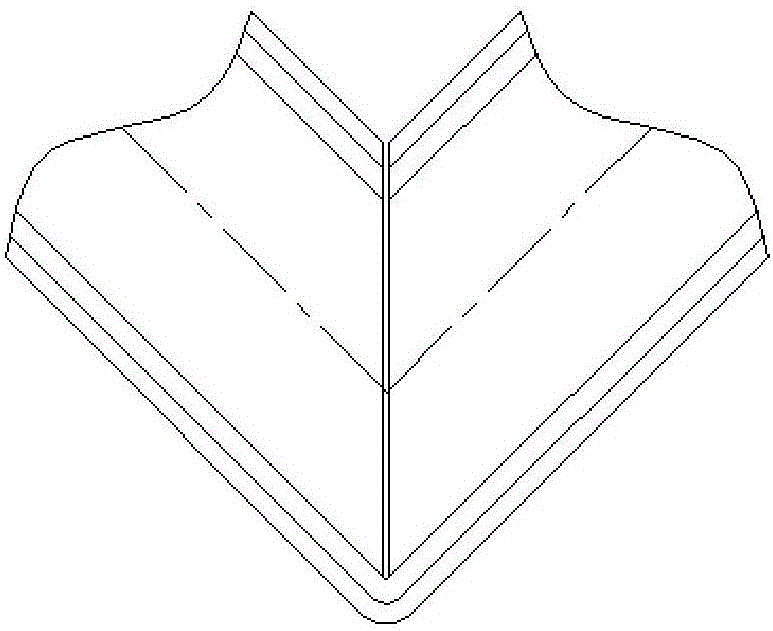

Symmetrical-hot-rolled composite plate blank and seal welding method thereof

ActiveCN111299974ALower manufacturing requirementsReduce manufacturing difficultyLayered productsArc welding apparatusIsosceles trapezoidStructural engineering

The invention relates to a symmetrical-hot-rolled composite plate blank and a seal welding method thereof. An enclosure frame comprises two parts, the first part forms the inner side of the enclosureframe, and the cross section of the first part is an isosceles trapezoid; the second part forms the outer side of the enclosure frame, the cross section of the second part is trapezoidal, and the length of the lower bottom edge of the second part is smaller than the length of the lower bottom edge of the first part; a groove is formed in the side, close to the enclosure frame, of the end of an upper base material; a special groove structure is formed through the innovative enclosure frame structure design, and the seal welding process is innovatively divided into two welding process flows; automatic welding equipment such as an arc welding robot or a special machine is adopted, and laser weld joint tracking and self-adaptive welding equipment is configured; a horizontal position welding mode is adopted, a high-penetration welding process is adopted for a root welding bead, and a high-deposition-rate welding process is adopted for a filling welding bead; and compared with the prior art,high-quality, high-efficiency and low-cost seal welding is realized through unique methods such as enclosure frame structure design, groove structure design, two-step welding process flow, welding process optimization and automatic welding equipment.

Owner:科斯焊接技术(无锡)有限公司

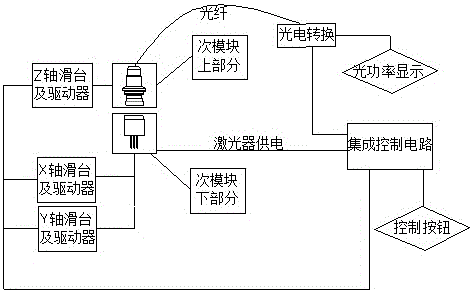

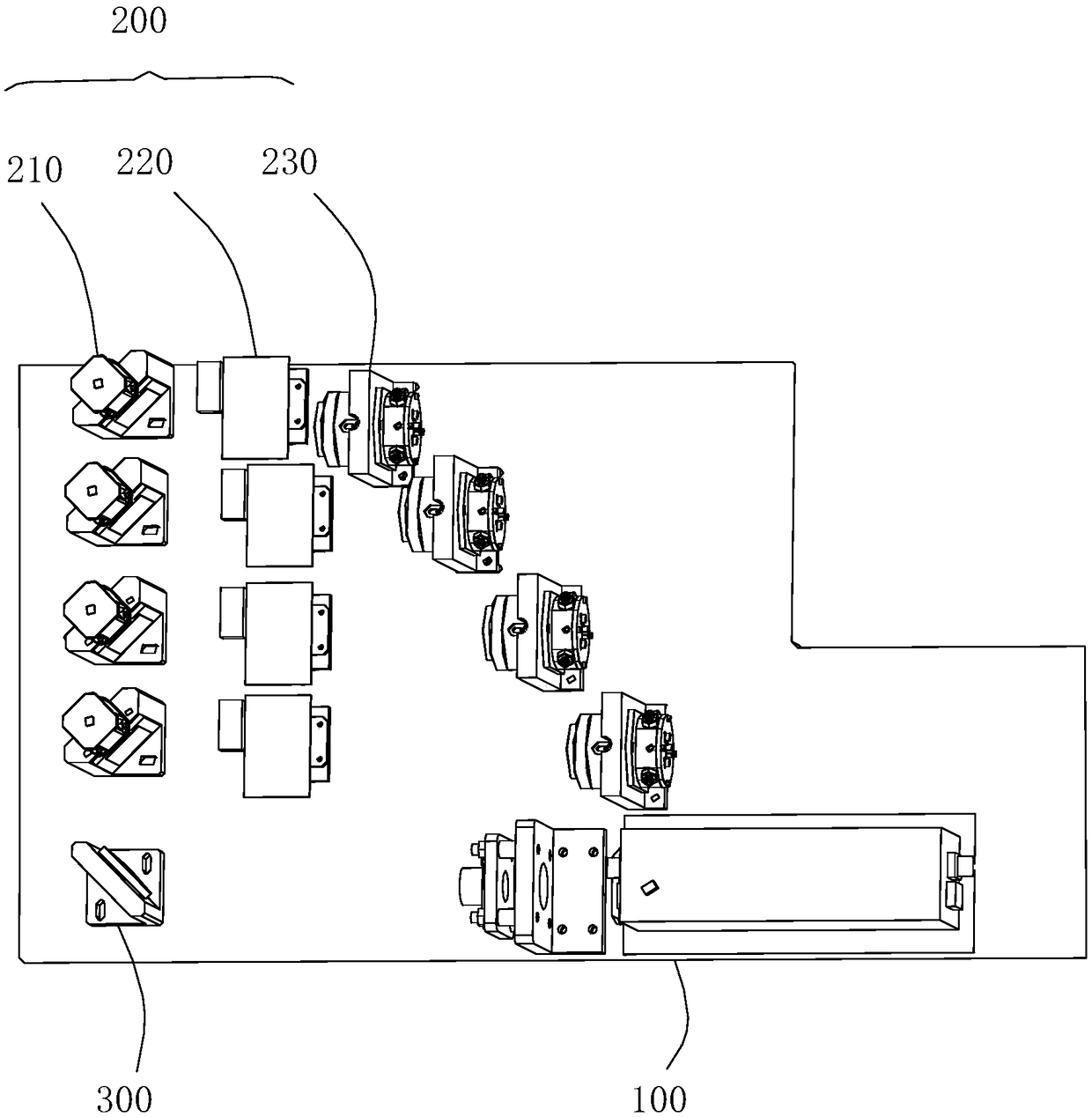

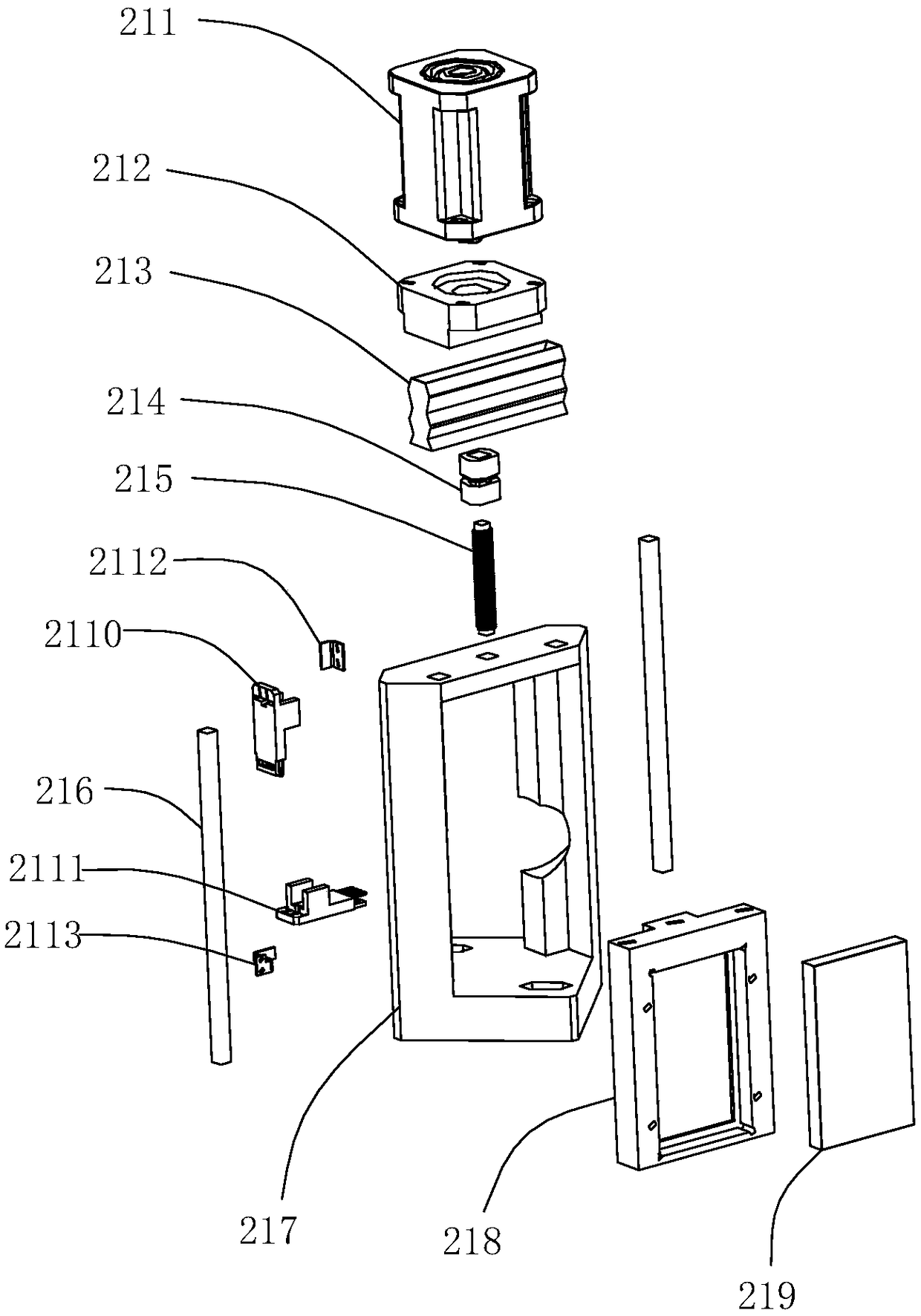

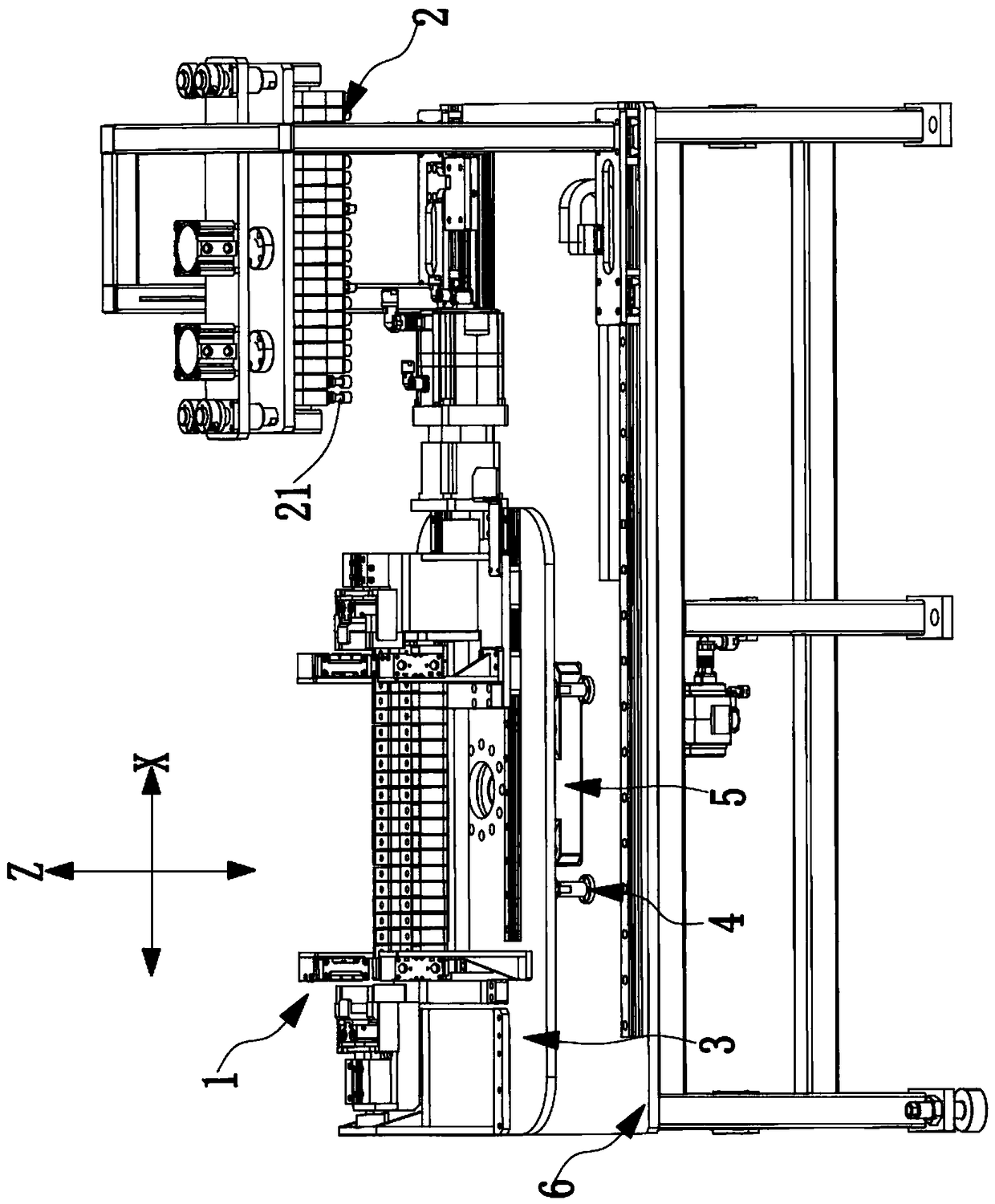

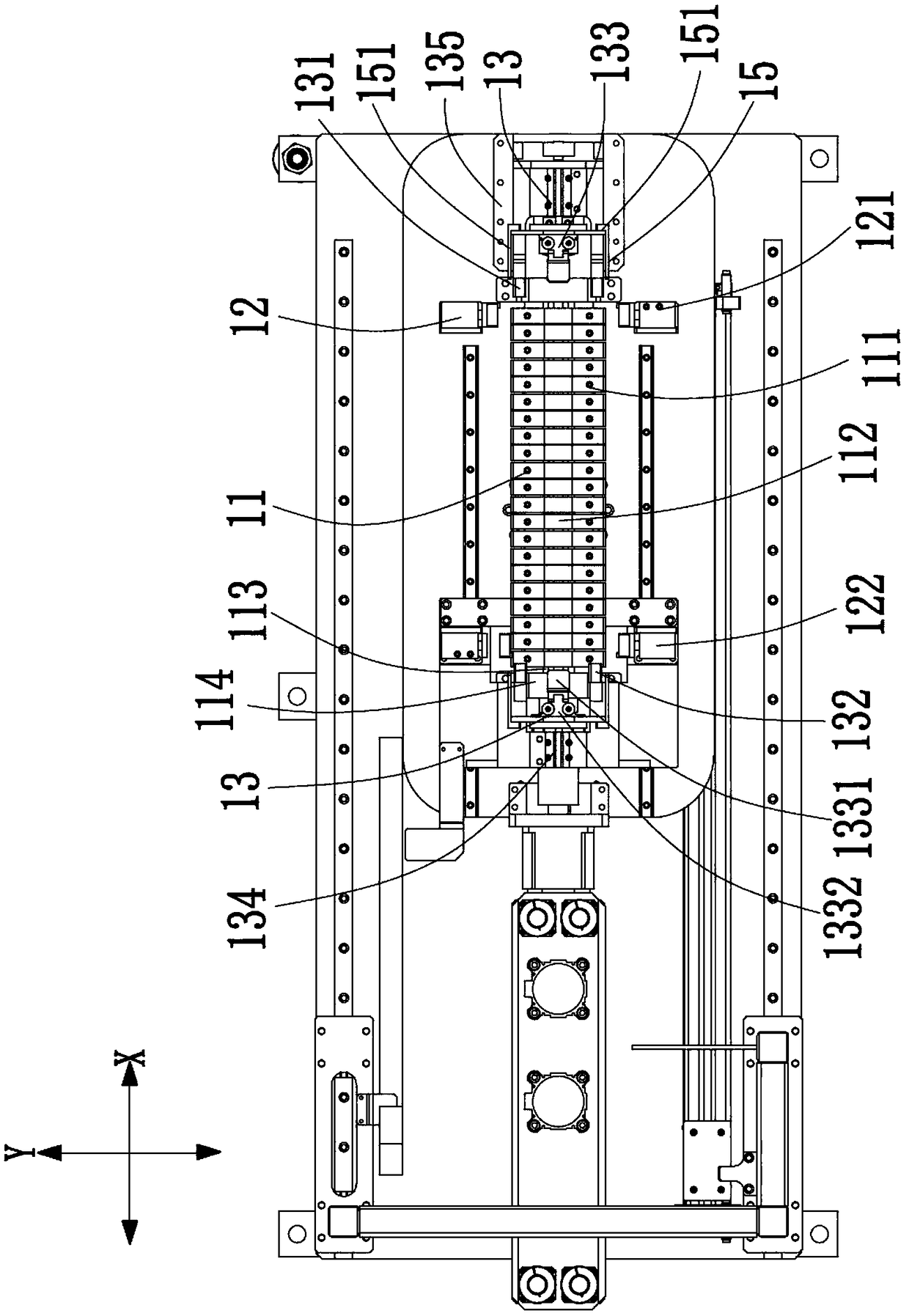

Device for automatically coupling optical communication sub-assemblies and method for eliminating delaying in coupling procedures

ActiveCN106772836AReduce human production costsReduce the influence of human factorsCoupling light guidesCouplingComputer module

The invention discloses a device for automatically coupling optical communication sub-assemblies and a method for eliminating delaying in coupling procedures. The device comprises a base, a lower fixture, an upper fixture, a Z shaft, a Z shaft driver, an X shaft, a Y shaft, an X shaft driver and a Y shaft driver. The lower fixture is carried on the base, the upper fixture corresponds to the lower fixture and is positioned above the lower fixture, the Z shaft is connected with the upper fixture, can move in the vertical direction and can be driven by the Z shaft driver to move, the X shaft is connected with the lower fixture and can transversely move, the Y shaft is connected with the lower fixture and can transversely move, the X shaft can be driven by the X shaft driver to move, and the Y shaft can be driven by the Y shaft driver to move; the lower portion of the lower fixture extends into the base, and the X shaft and the Y shaft are inserted into the base and are connected with the lower fixture; the movement directions of the X shaft are perpendicular to the movement directions of the Y shaft. The device and the method have the advantages that the traditional multi-operator manual coupling modes can be replaced owing to high-integration modes of equipment, and accordingly the production efficiency can be improved; optical power change can be automatically monitored in real time, accordingly, the product process monitoring capacity can be improved, products with great optical power change can be screened in real time, and the qualification rate of the products can be increased.

Owner:JIANGSU ALLRAY

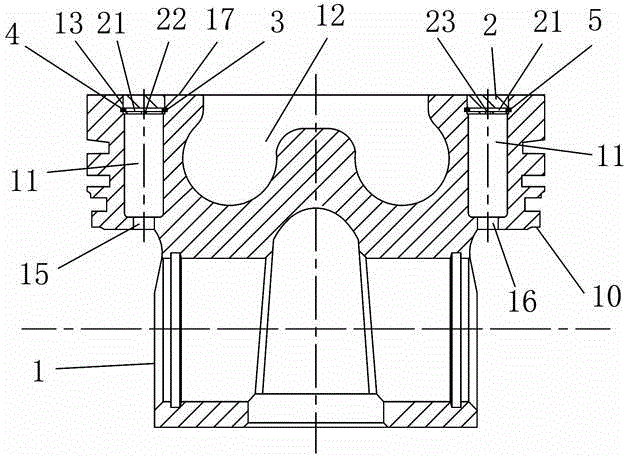

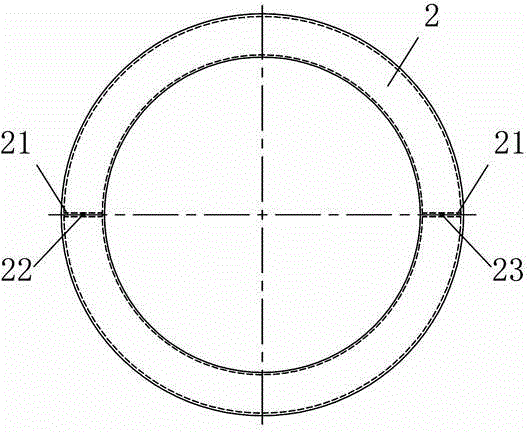

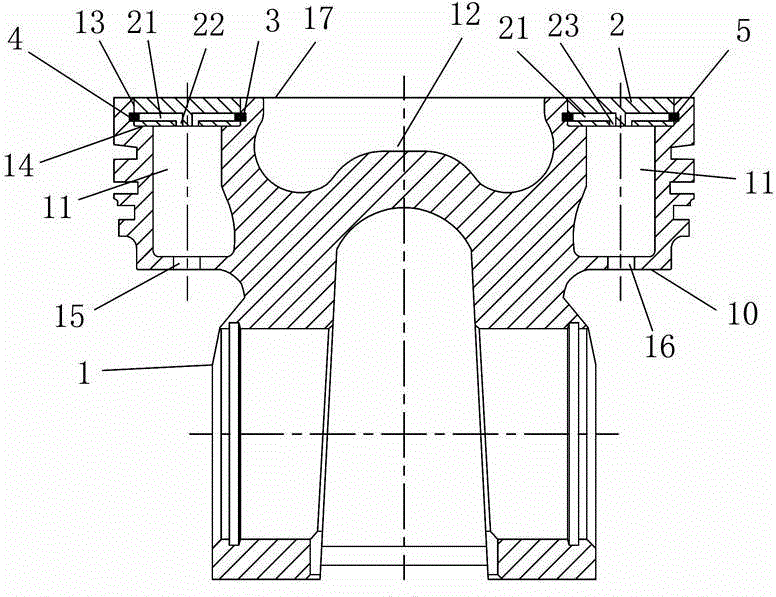

Steel piston forming inner cooling oil way based on laser welding and machining method of steel piston

ActiveCN106150749AExtended service lifeReduce weightMachines/enginesPistonsCombustion chamberEngineering

The invention discloses a steel piston forming an inner cooling oil way based on laser welding and a machining method of the steel piston. The steel piston comprise a piston body and an annular sealing plate; a piston head part of the piston body is provided with the inner cooling oil way and a combustion chamber; the inner cooling oil way surrounds the combustion chamber, and the piston head part is further provided with an oil inlet hole and an oil outlet hole which communicate with the inner cooling oil way; an annular opening is formed in the upper end of the inner cooling oil way and located in the top end of the piston head part; the annular sealing plate is embedded in the annular opening and connected and fixed through laser welding, the upper end of the inner cooling oil way is sealed, an inner annular channel is formed by the inner circle of the annular sealing plate and the side wall of the annular opening in a surrounding manner, an outer annular channel is formed by the outer circle of the annular sealing plate and the side wall of the annular opening in a surrounding manner, and the inner annular channel and the outer annular channel are filled with high-temperature-resisting heat isolation rings used for forming a laser welding pool. The method comprises the first step of component machining, the second step of laser welding and assembling, the third step of heat treatment and the fourth step of post machining. The steel piston and the machining method have the beneficial effects of being high in machining cost, good in quality stability and low in machining cost.

Owner:强哲菲

Fuzzy control method for cooperating type CO2 welding circuit-shorting transition and welding machine thereof

InactiveCN1113723CBest synergistic matching relationshipGuaranteed stabilityArc welding apparatusInterference resistanceClosed loop

The present invention relates to a fuzzy control method for CO2 short-circuiting transfer welding and its welding machine. It is characterized by that it adopts a closed-loop control method combining parameters-matched coordinate control and parameters-regulated fuzzy control, on the basis of the real-time detection on short circuiting transfer frequiency of reflecting stability of welding process, according to the coordinate relationship between all welding parameters and short circuiting transfer frequencies, it makes fuzzy treatment to detected data to define the regulating quantity of all parameters to make real-time regulation to make short circuiting transfer frequency keep stable in a certain range to ensure the optimum matching relationship between all parameters. Said invention possesses the advantages of good parameter matching property, strong anti-interference capacity and stable welding course.

Owner:BEIJING UNIV OF TECH +1

Bus bar unit and pipe bus bar

InactiveCN112152174AAvoid the problem that the length of the plug is too short or even falls offPrecise positioningTotally enclosed bus-bar installationsStructural engineeringMechanical engineering

The invention relates to the technical field of GIL and provides a bus unit and a pipeline bus. The bus unit comprises a bus cylinder and a conducting rod, wherein one end of the bus cylinder is provided with a fixed insulator which is fixedly arranged relative to the bus cylinder, two axial ends of the fixed insulator are provided with a fixed connecting seat and a plug-in connecting seat respectively, the fixed connecting seat is used for fixing and conductively connecting the corresponding conducting rod in the bus unit or in the adjacent bus unit, and the plug-in connecting seat is used for plug-in matching and conductively connecting the corresponding conducting rod in the bus unit or in the adjacent bus unit. The fixed connecting seat and the plug-in connecting seat arranged on the two sides of the insulator in the bus unit change a conductive rod in the prior art into a mode that one end is fixed and the other end is telescopic, the telescopic movement of only one end of the conductive rod is limited, and the whole conductive rod can still adapt to temperature change through self telescopic deformation; a problem that the insertion length of the conducting rod is too short and even falls off when the conducting rod expands with heat and contracts with cold can be effectively avoided.

Owner:PINGGAO GRP +1

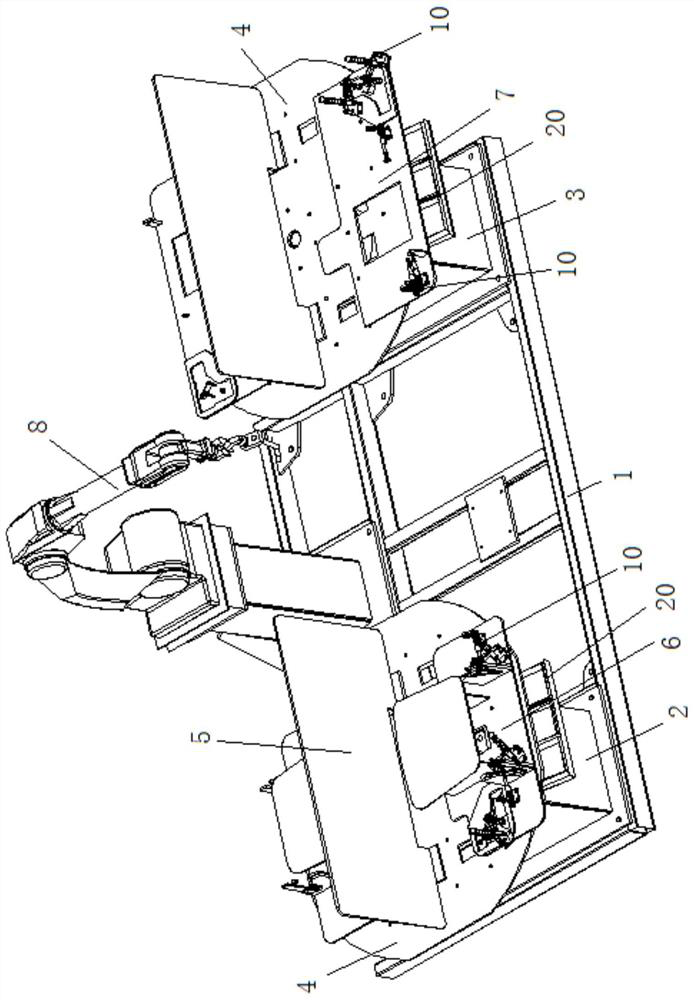

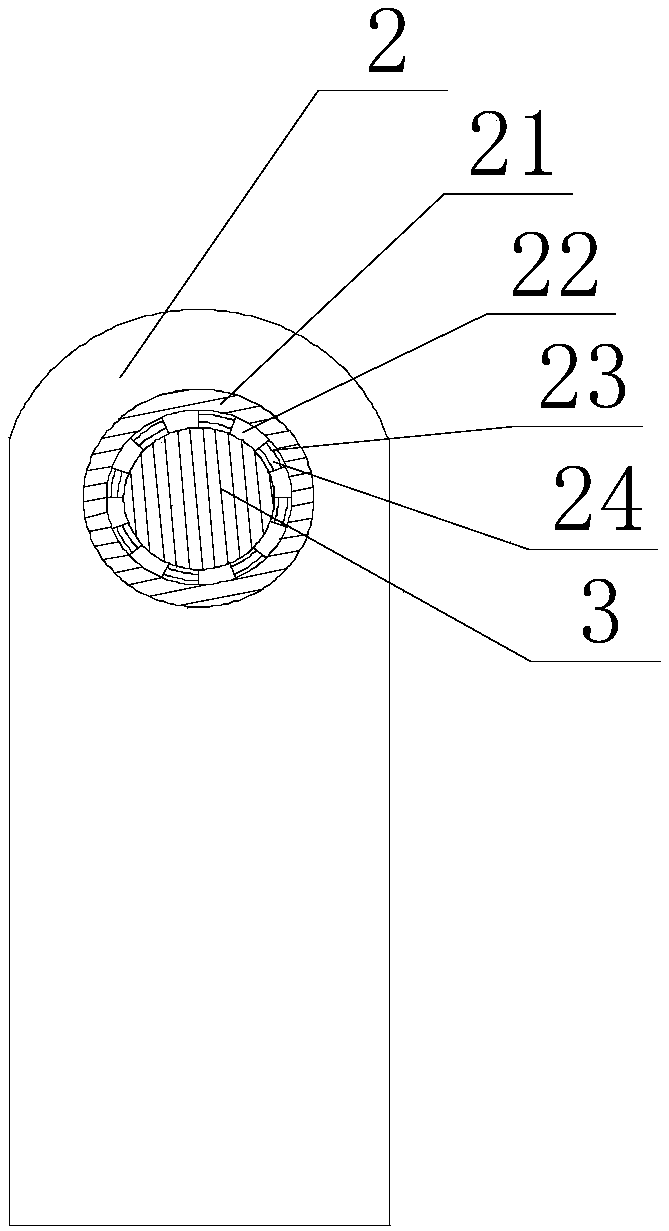

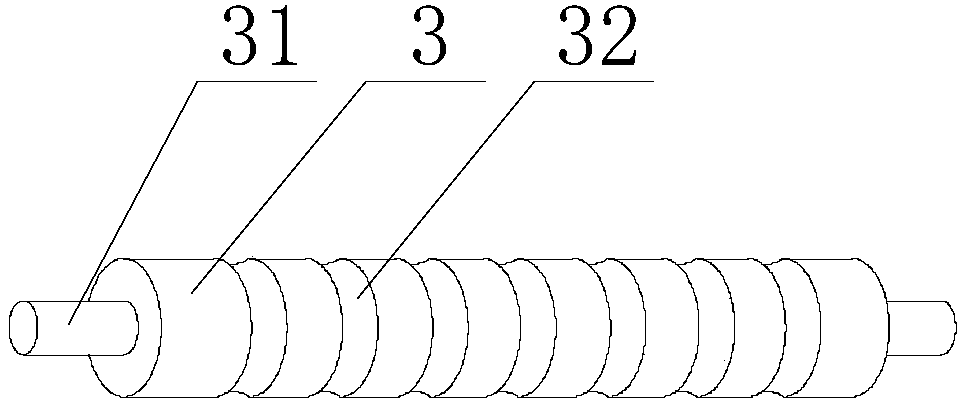

Adjusting device used for welding of landscape pillar steel reinforcement cage

InactiveCN107717303APrevent fallingEnsure welding stabilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

The invention discloses an adjustment device for welding the reinforcement skeleton of landscape columns, which includes a turntable and a mounting plate, and a support column is arranged on the turntable, and the support column is arranged obliquely and forms an included angle with a horizontal line, and the value of the included angle is 45°~60°, a column perpendicular to the horizontal plane is fixed on the upper end of the supporting column, the mounting plate is fixed on the column, and at least one mounting seat is arranged on the surface of the mounting plate, and a fixed The plate is provided with a mounting hole on the fixed plate, and the two ends of the conveying roller are arranged in the mounting hole through the rotation of the rotating shaft. In view of the defect in the prior art that the steel cage with large axial length tends to fall in the middle during the seam welding process, the applicant added a supporting component to the seam welding machine, which is used to support the steel cage during the seam welding process to ensure The axes of multiple main bars will not be deformed due to gravity factors, ensuring that the welding points of the reinforcing bars on the main bars are always at the preset points, and improving the strength of the formed reinforcement cage.

Owner:成都谭记胖哥农业服务有限公司

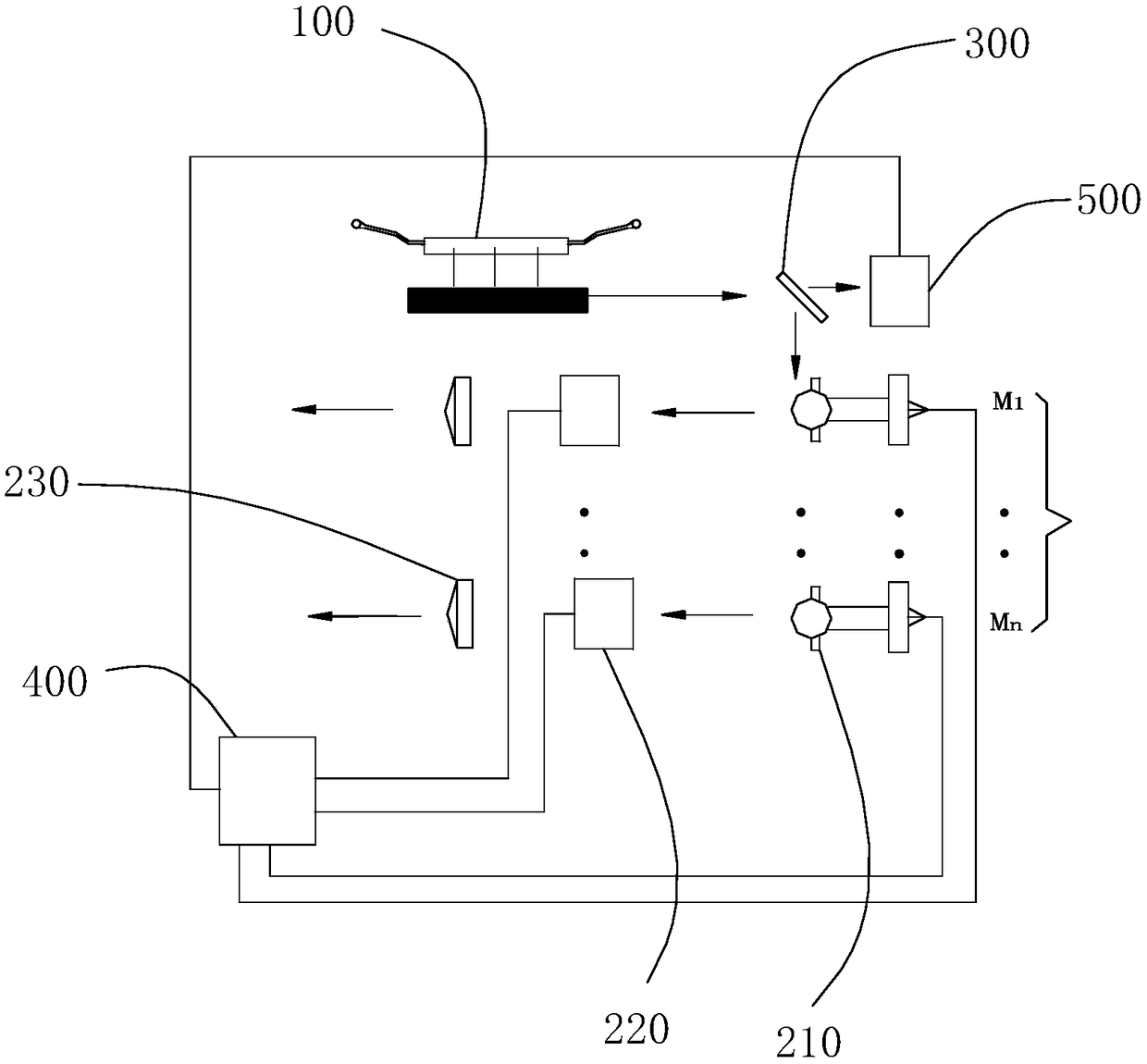

YAG multi-beam light splitting gradual-change type light path negative feedback control system

PendingCN109483051AEnsure welding stabilityMeet the requirements of laser welding processLaser beam welding apparatusNegative feedbackControl system

The invention discloses a YAG multi-beam light splitting gradual-change type light path negative feedback control system. The system comprises a laser device, at least one coupling light path assembly, a quartz reflecting mirror and a control device; each coupling light path assembly comprises a gradual-change type light splitting device, a first energy negative feedback device and a laser coupler; the quartz reflecting mirror is arranged at an angle of 45 degrees with light beams of the laser device, each gradual-change type light splitting device is arranged at an angle of 45 degrees with refraction light beams of the quartz reflecting mirror, the refraction light beams of the first energy negative feedback devices, the refraction light beams of the laser couplers and the refraction light beams of the gradual-change type light splitting devices are located on a straight line, and the first energy negative feedback devices are located between the laser couplers and the gradual-changetype light splitting devices; and the first energy negative feedback devices and the gradual-change type light splitting devices are connected to the control device. According to the technical scheme,the multi-path simultaneous welding stability of a precision device is guaranteed, and the requirements of diversified laser welding technologies in multiple occasions are met; and meanwhile, the manufacture and maintenance costs are low, the use is simple, and the debug is rapid and convenient.

Owner:深圳镭锳激光科技有限公司

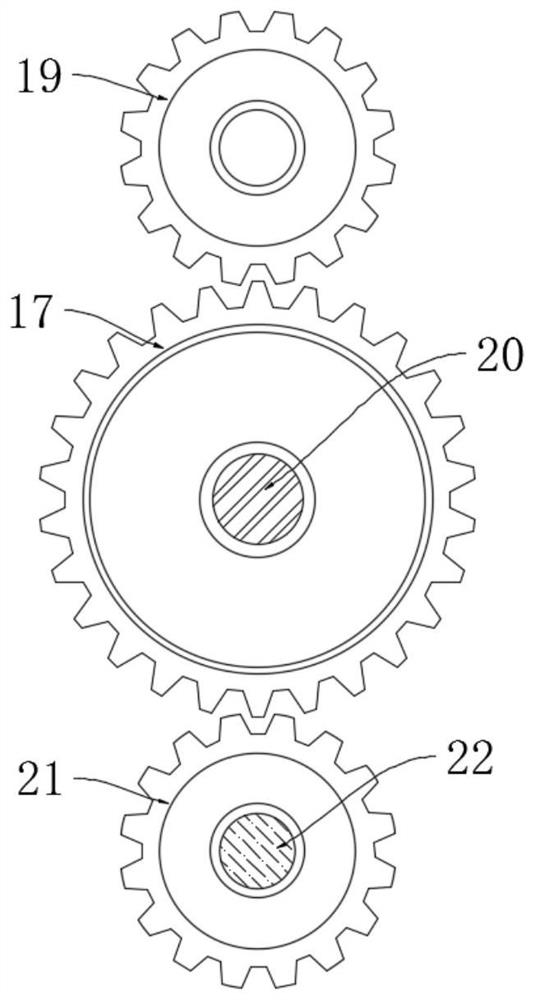

Coaxial cable shielding layer welding machine

ActiveCN111715963AAvoid shakingImprove stabilityMetal working apparatusSolder feeding devicesCoaxial cableRotation - action

The invention discloses a coaxial cable shielding layer welding machine. The coaxial cable shielding layer welding machine comprises a bottom plate, a mounting frame, a supporting rod and a fixing frame, wherein the mounting frame, the supporting rod and the fixing frame are fixed to the bottom plate. An air cylinder is fixedly mounted on the mounting frame, and the output end of the air cylinderis connected with a welding head; the upper end of the supporting rod is connected with a welding table, and the welding head is coaxial with the welding table, the supporting rod is provided with a fixing mechanism, the fixing frame sequentially fixedly supports a coil feeding box, a motor and a fixing rod from top to bottom, the output end of the motor is fixedly connected with a first gear, thefirst gear symmetrically meshes with a second gear and a third gear, a wire feeding mechanism is arranged in the coil feeding box, and the second gear is fixedly connected with the wire feeding mechanism through a straight rod. The coaxial cable shielding layer welding machine has a simple structure, can fix a cable to the center position of the welding table through simple rotation action, and ensure the stability of the welding. In addition, the coaxial cable shielding layer welding machine only needs one motor to drive, has a small transmission error, and can improve the welding quality ofthe shielding layer.

Owner:杭州临安万隆线缆有限公司

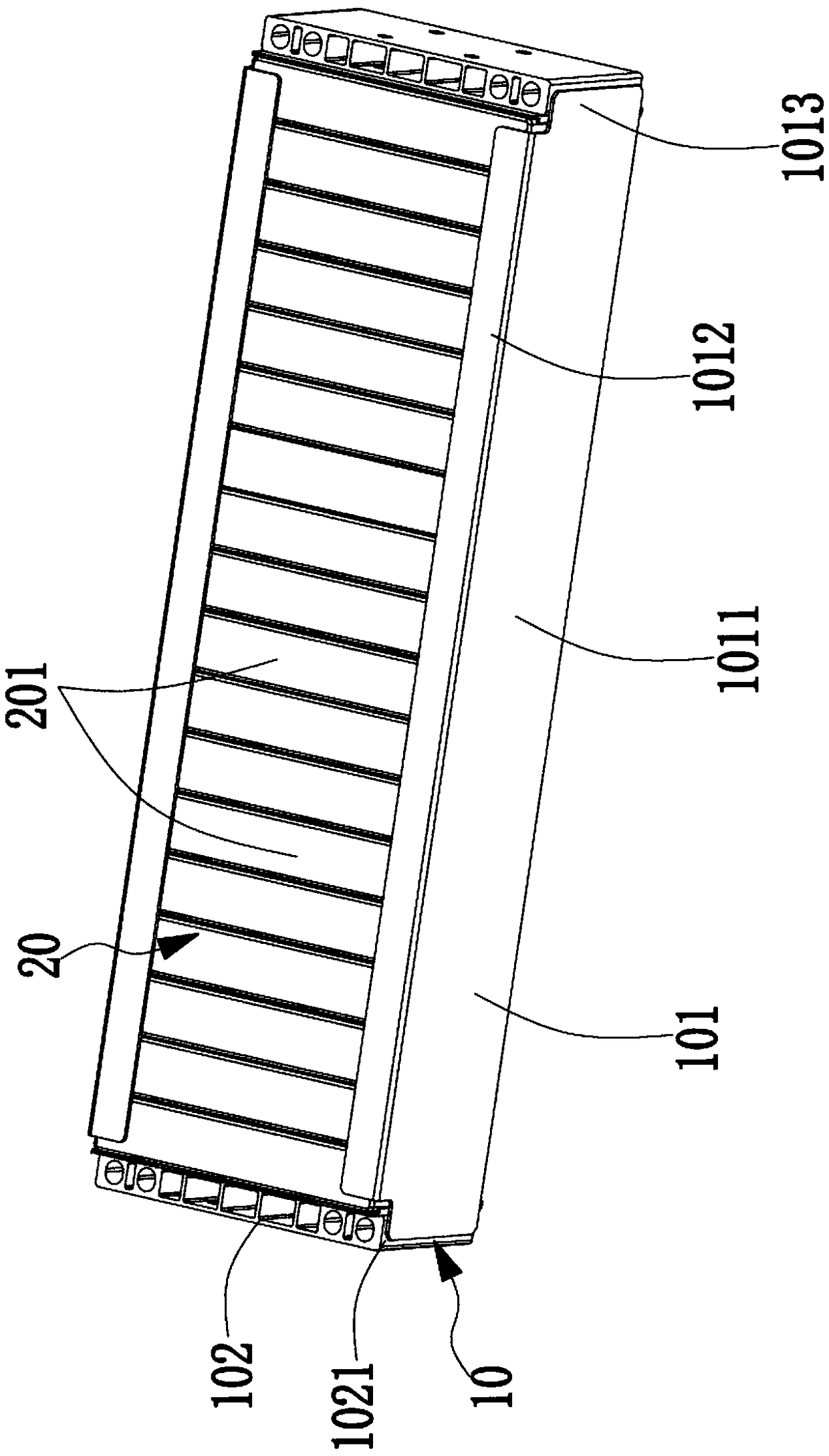

Cell module side panel welding precise positioning device, welding robot and welding method thereof

ActiveCN108772650AExquisite designSimple structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a cell module side panel welding precise positioning device, a welding robot and a welding method thereof. The cell module side panel welding precise positioning device comprises a fixed tool for bonding side panels in positions to be welded of cell modules, and a leveling tool for applying pressing force on the bottom surface of each cell of the cell modules through a setof extension columns and cooperating with the fixed tool to level the bottom surfaces thereof. The device is delicate in design and simple in structure, and can effectively bond the cell modules withthe side panels through the fixed tool to lay the foundation for subsequent welding; and in addition, through cooperation between the leveling tool and the fixed tool, when the height differences of the bottom surfaces of the cells exist, the bottom surfaces of the cells are leveled to guarantee full contact of each cell with the side panels, so that the false welding problem in subsequent weldingis prevented, and the welding stability and the welding quality are guaranteed.

Owner:HEFEI JUYI POWER SYST CO LTD

Welding process of rigid fireproof cable

InactiveCN114188098AFully contactedEnsure welding stabilityApparatus for heat treatmentSoldered/welded connectionsElectrical conductorMachining process

The invention belongs to the technical field of welding processes, and particularly relates to a rigid fireproof cable welding process which comprises the following steps: copper strip uncoiling, clamping, flattening, transverse cutting, lining paper and packaging. According to the step of clamping and conveying, a copper strip which is uncoiled and then runs is conveyed into a leveler in a clamping mode through a pair of rubber face rollers. The welding process of the rigid fireproof cable has the beneficial effects that copper strip uncoiling, copper strip decontamination, copper strip acid pickling, copper pipe forming, conductor emptying, tension stretching and welding are adopted, and the periphery of a copper strip is extruded by utilizing an arc-shaped ring during welding, so that the inner surface of the copper strip is in full contact with the inner surface of a copper core; the welding stability between the inner surface of the copper strip and the inner surface of the copper core is guaranteed, then the machining processes of rolling, annealing, rolling and annealing are conducted, the welding quality is improved, the number of procedures is small, and the welding quality is high.

Owner:南通好尔特智能装备制造有限公司

Full-automatic circular seam welder

PendingCN111037075AWork around length constraintsEnsure welding stabilityCurved planar seam weldingSeam weldingStructural engineering

The invention relates to the technical field of seam welders, in particular to a full-automatic girth seam welder, and aims to solve the problem that a traditional circular seam welder is complex in working procedures and low in efficiency. The full-automatic circular seam welder comprises a body and a roll welding device, the roll welding device comprises an upper roll welding wheel and a lower roll welding wheel, the upper roll welding wheel moves up and down through a first air cylinder; a support is arranged at the side, away from the roll welding device, of the machine body; a positioningdevice is arranged on the body and comprises a fixed shaft and a clamping shaft which are located at the same height, and the clamping shaft is located on the support and connected with the support in a sliding mode. The problem that the circumferential seam welding procedure is complex is solved, the length of a workpiece is prevented from being limited by means of the positioning device, and good development prospects are achieved in the technical field of seam welders.

Owner:XINXIANG XINLI PURIFICATION TECH

Manufacturing method for ceramic heating element

ActiveCN108882405AStable resistivityImprove conductivityOhmic-resistance electrodesHeating element materialsTunnel kilnNitrogen gas

The invention discloses a manufacturing method for a ceramic heating element. According to the manufacturing method, the ceramic heating element adds iron powder into tungsten paste, and the stabilityof the tungsten paste is neutralized and the solidity of later brazing is improved; and the addition of ruthenium oxide not only improves the conductivity of welding electrodes, but also ensures thestability of specific resistance in printed circuits. The manufacturing method uses the combination of high pressure and hot pressure when two layers of green layers are pressed, and the problem of poor binding force of a film layer after sintering is solved; and in the process of sintering, ammonia is filled in, nitrogen and hydrogen are obtained by pyrolysis of ammonia in a tunnel kiln by usinghigh temperature, sintering is performed after a reducing gas atmosphere is formed, oxidation is prevented, the cost of sintering is reduced, hydrogen gas gushing from both ends of the tunnel kiln isignited to form a protective gas film, and water obtained after hydrogen ignition can not only effectively cool sintered ceramic sheets, but also alleviate the problem of low strength of unsintered green sheet in the sintering process.

Owner:珠海华宇宏瑞科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com