Welding equipment for processing rail damping backing plate

A technology for welding equipment and shock-absorbing pads, which is applied to the field of rail shock-absorbing pads, can solve the problems that the reinforcement structure and installation structure of shock-absorbing pads are not identical, manual errors are prone to occur, and welding quality is reduced, etc. The effect of welding smooth, fast strip welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

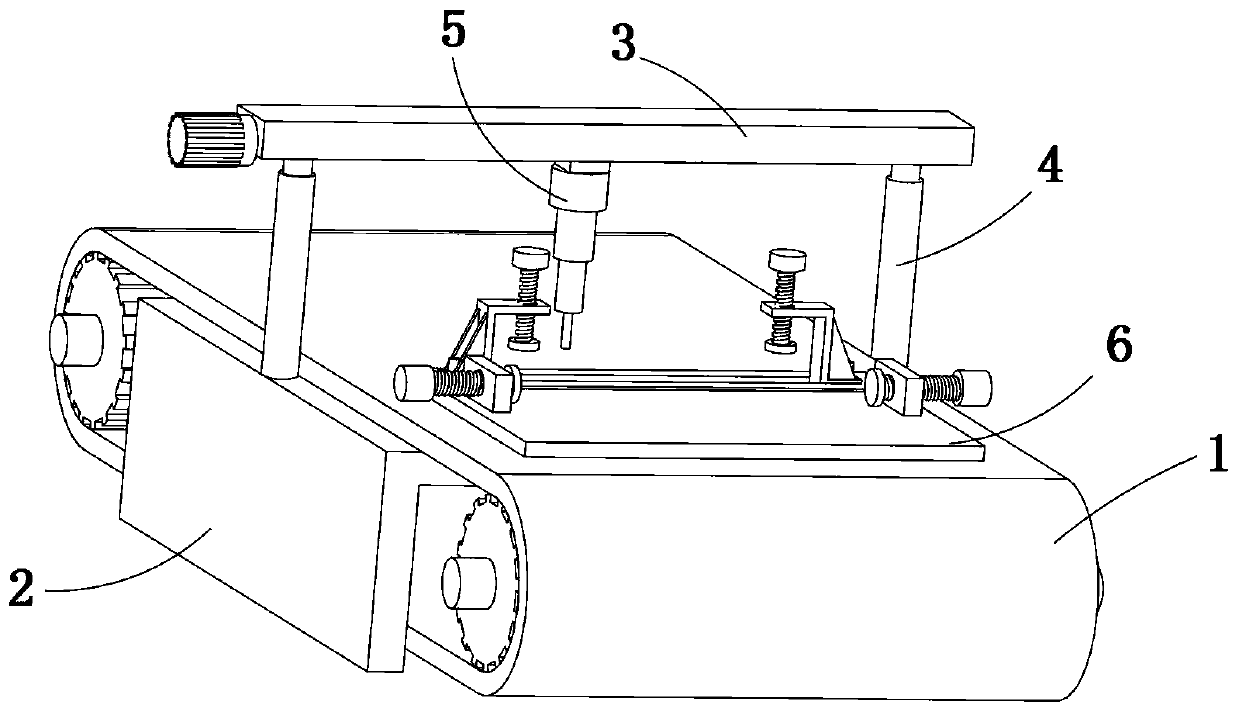

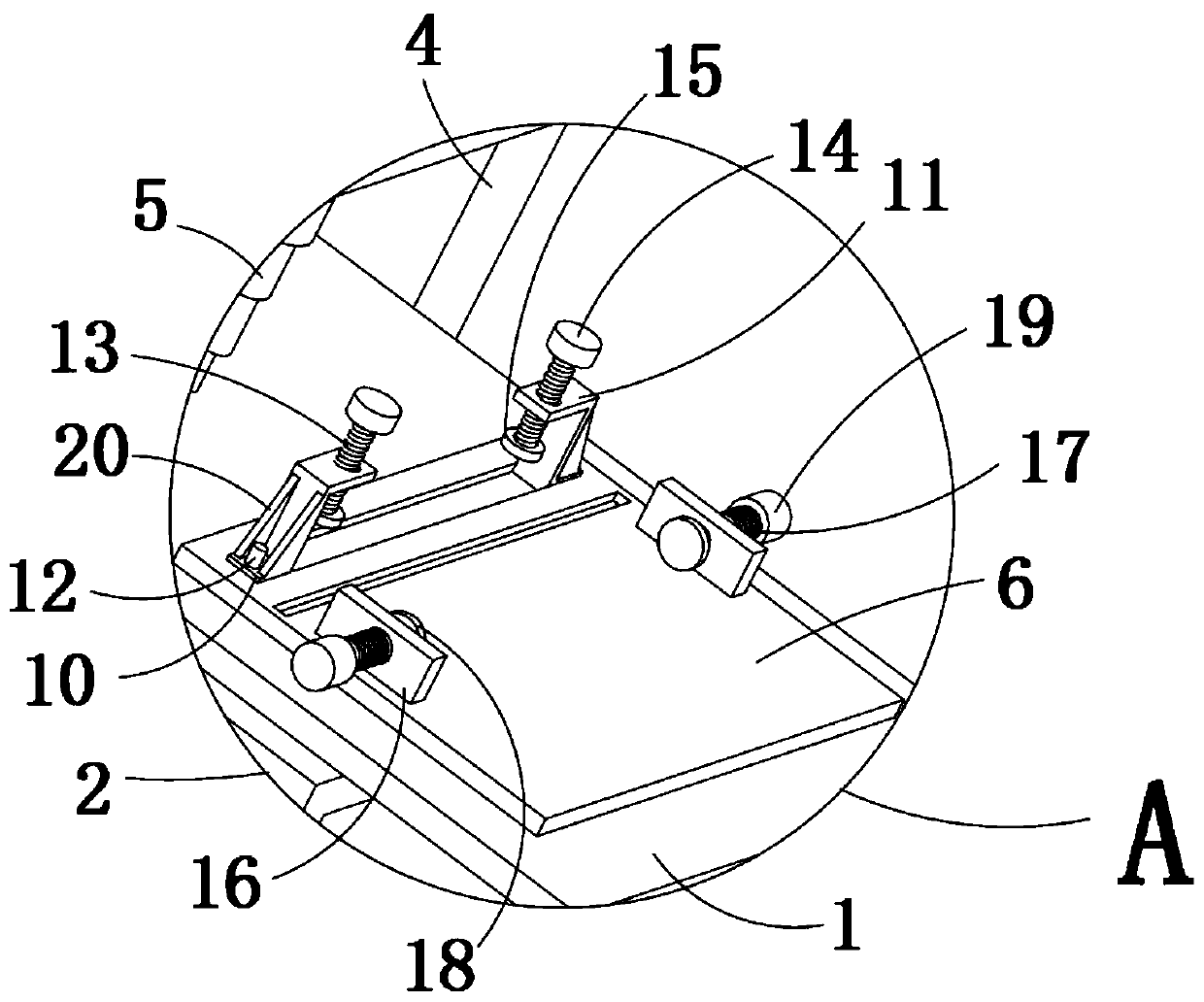

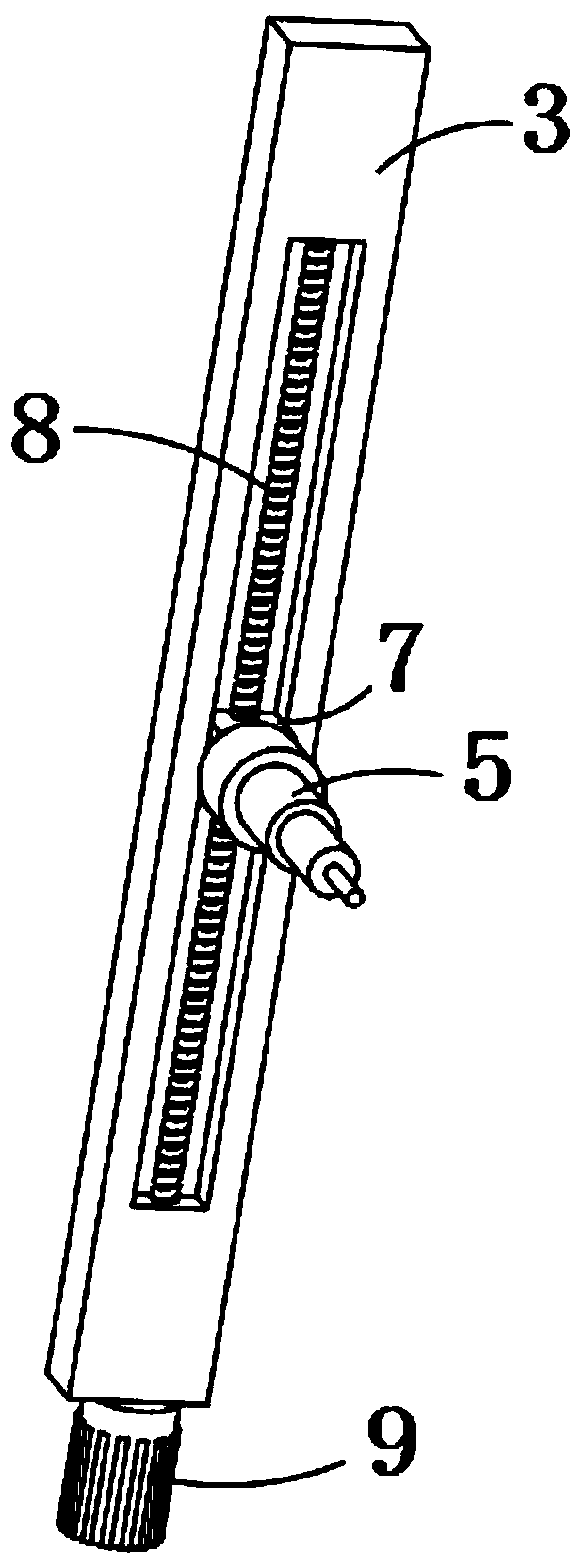

[0023] refer to Figure 1-4 , a kind of welding equipment used for the processing of track damping pads, comprising a conveyor belt 1, the conveyor belt 1 adopts the prior art, and can play a conveying role, and the conveyor belt 1 is fixed with an inverted U-shaped plate 2, and the inverted U-shaped The upper end surface of the plate 2 is provided with an opening, and a plurality of rollers 21 are evenly distributed in the opening, and the upper side of the plurality of rollers 21 extends to the outside of the opening. When the conveyor belt 1 is working, the conveyor belt 1 and the inverted U-shaped plate 2 have a large friction, which is safe. The width of the inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com