Welding method and system

A welding method and control system technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of mutual influence and interference between welding wire and welding parts, so as to improve control effect, ensure stability and avoid interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

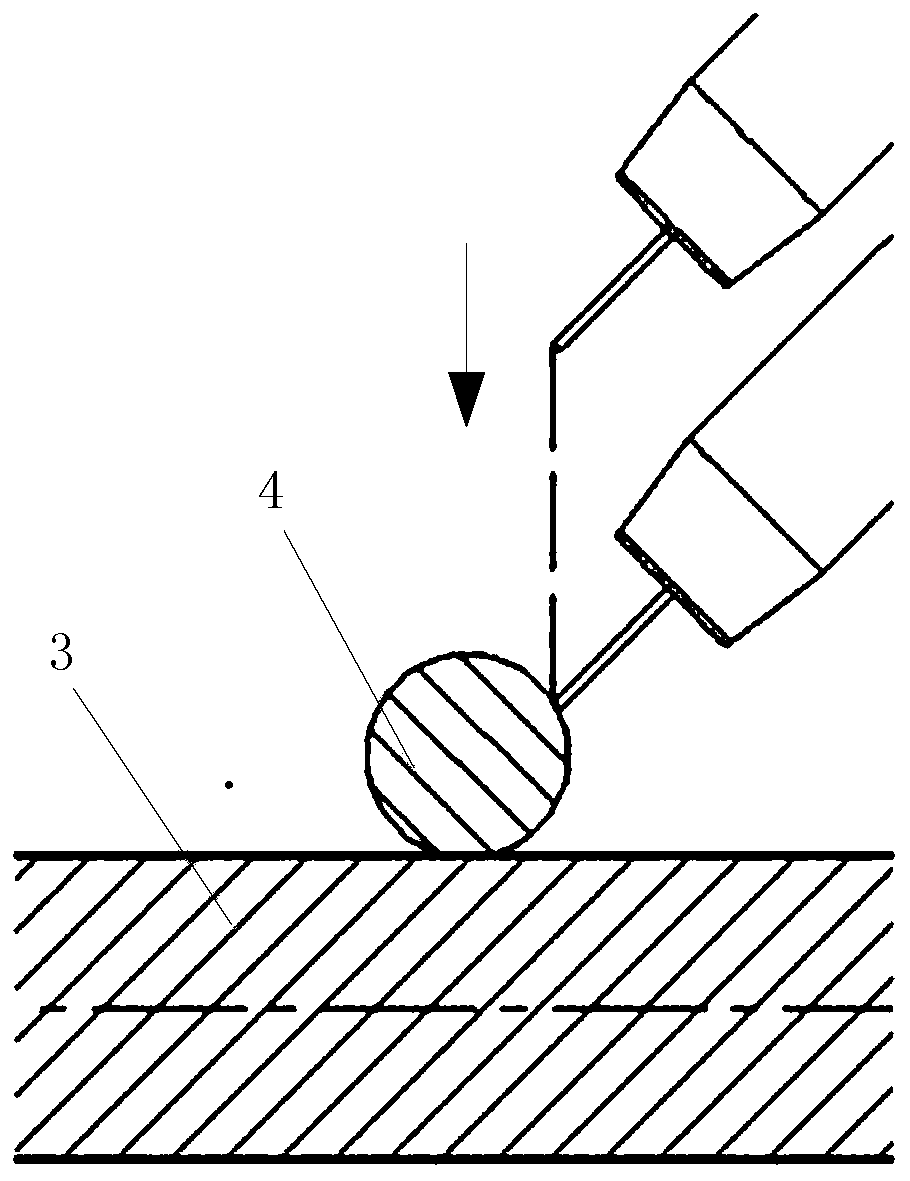

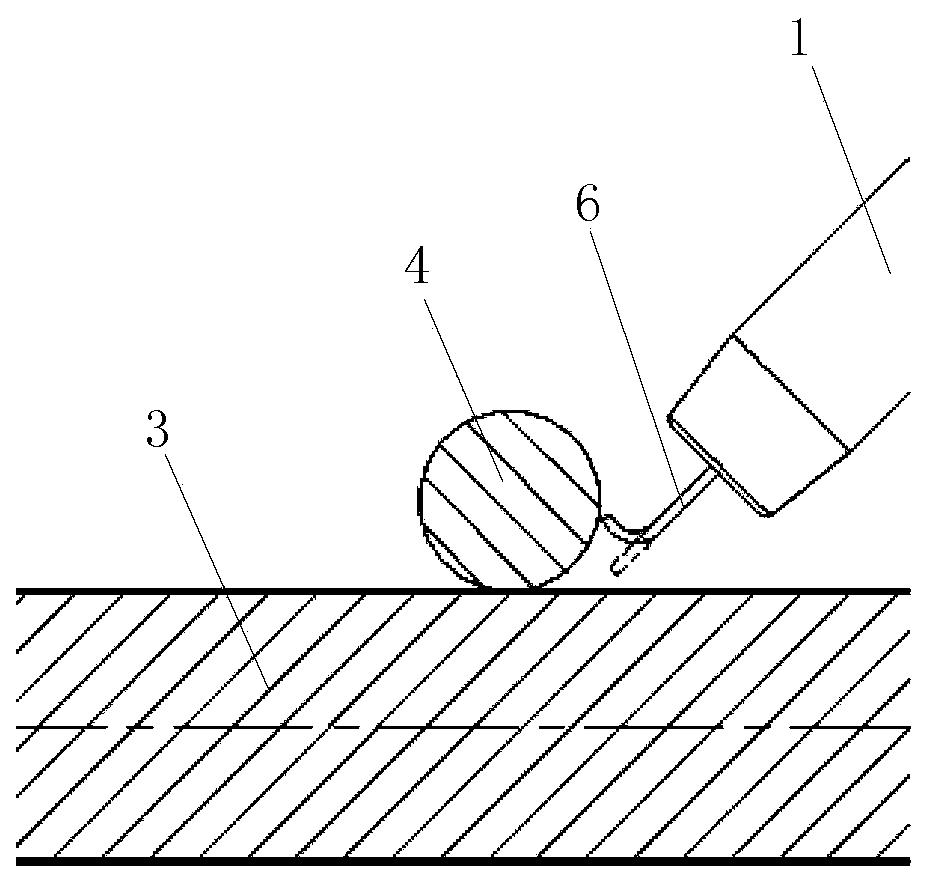

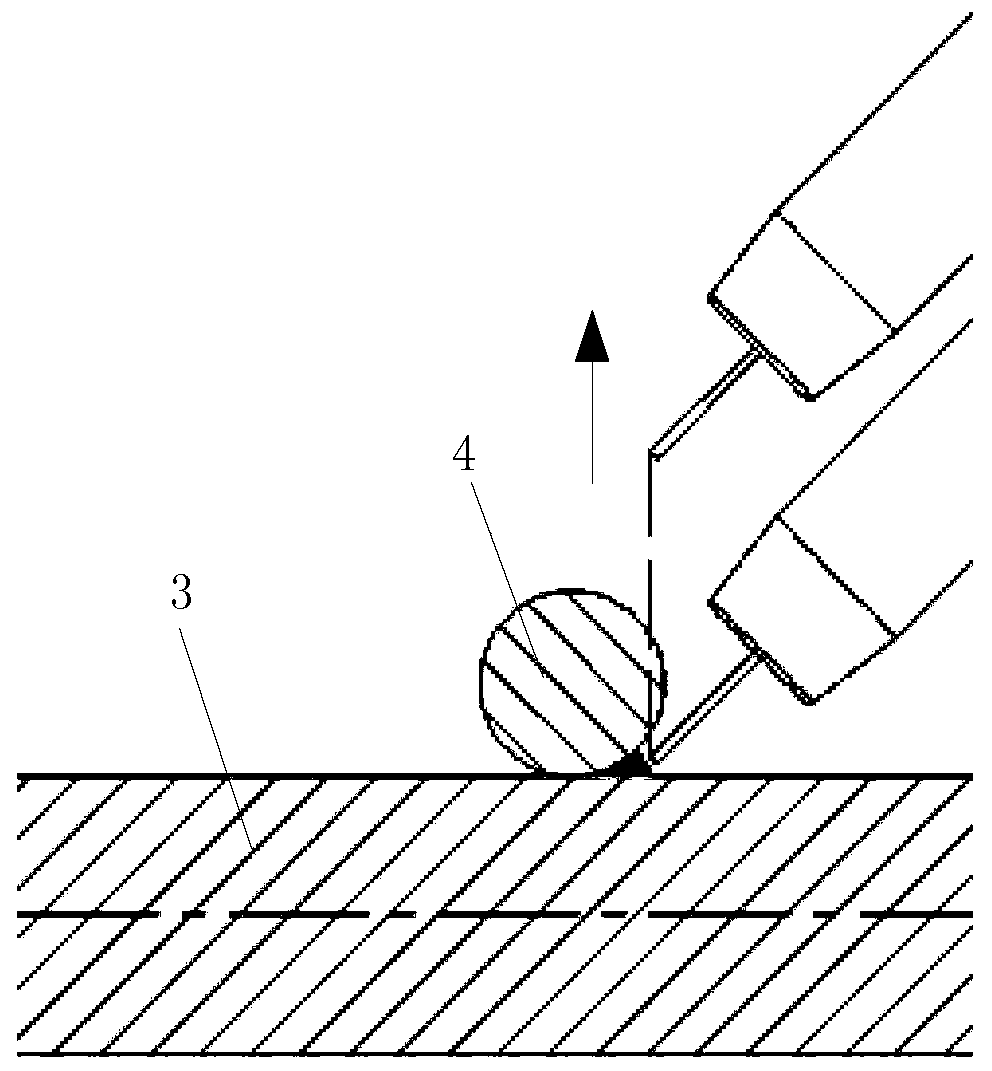

[0040] A welding method, using a welding torch to weld the first weldment and the second weldment, and at any time before starting welding, the welding wire is retracted in a direction away from the welding spot between the first weldment and the second weldment. The welding wire is retracted to a position where the welding wire does not contact the first weldment and the second weldment when the welding wire moves towards the welding spot.

[0041] This embodiment is applicable to the welding of the main reinforcement and the winding reinforcement during the automatic welding process of the reinforcement cage. The reinforcement cage is output and formed by the wire coiling machine. During the whole welding process, the reinforcement cage is in the process of continuous advancement and rotation, which can avoid the interference of the winding wire on the welding wire. Among them, weldment one 3 is the main rib, and weldment two 4 is the winding rib.

[0042] In addition to th...

Embodiment 2

[0045] A welding method, on the basis of Embodiment 1, further includes a wire feeding motor, the wire feeding motor is used to output the welding wire in the forward rotation during the welding process; the wire feeding motor is controlled to reverse by the wire withdrawal control system to realize the return of the welding wire retreat.

[0046] Including the external power supply VCC2, also including the wire feeder power supply VCC1 matched with the wire feeder motor;

[0047] Such as Figure 5 as shown, Figure 5 The dotted line in the middle represents the wire withdrawal control system:

[0048] When the wire withdrawal control system controls the power supply of the wire feeder to supply power for the wire feeder, that is, when K3 and K4 are closed and K1 and K2 are cut off, the wire feeder motor rotates forward;

[0049] When the wire withdrawal control system controls the external power supply to supply power to the wire feeding motor, that is, when K1 and K2 are ...

Embodiment 3

[0051] A welding method, on the basis of embodiment 1, comprising a wire feeder power supply VCC1 matched with the wire feeder motor;

[0052] Such as Figure 6 as shown, Figure 6 The dotted line in the middle represents the wire withdrawal control system. The wire withdrawal control system is used to control the power supply direction of the wire feeder power supply to the wire feed motor:

[0053] When the wire withdrawal control system controls the power supply of the wire feeder to supply power for the wire feeder, that is, when K3 and K4 are closed and K1 and K2 are cut off, the wire feeder motor rotates forward;

[0054] When the wire withdrawal control system controls the external power supply to supply power to the wire feeding motor, that is, when K1 and K2 are closed and K3 and K4 are cut off, the wire feeding motor reverses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com