Power soft roll lithium ion battery of multi-roll core structure

An ion battery and power technology, applied in secondary batteries, structural parts, battery pack components, etc., can solve the problems of limiting the production capacity of polymer lithium batteries, complex lamination process, and low battery internal resistance, and achieve great improvement. The effect of current charge and discharge performance, cost reduction, and battery internal resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

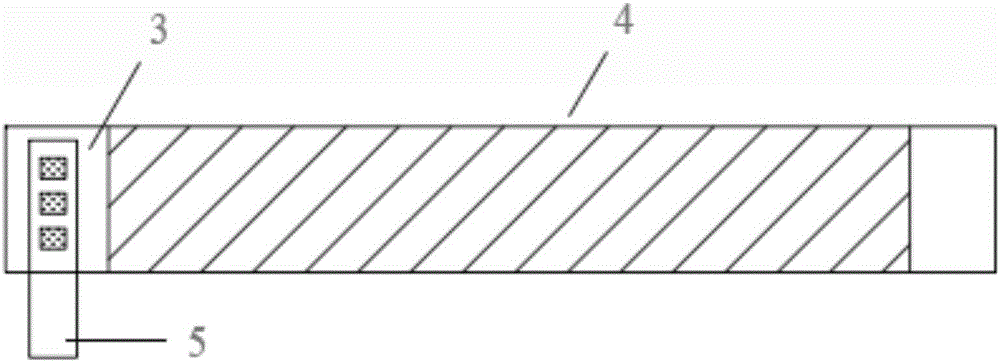

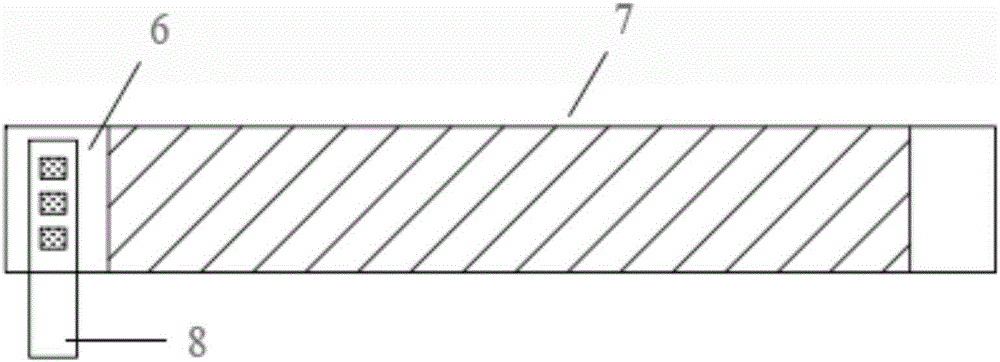

[0022] refer to figure 1 and figure 2 , the positive electrode sheet 4 is made of the first aluminum strip 5 by ultrasonic welding on the uncoated aluminum foil blank part 3 of the current collector; the negative electrode sheet 7 is made of the first copper strip 8 by ultrasonic welding on the uncoated copper foil blank part of the current collector 6 made.

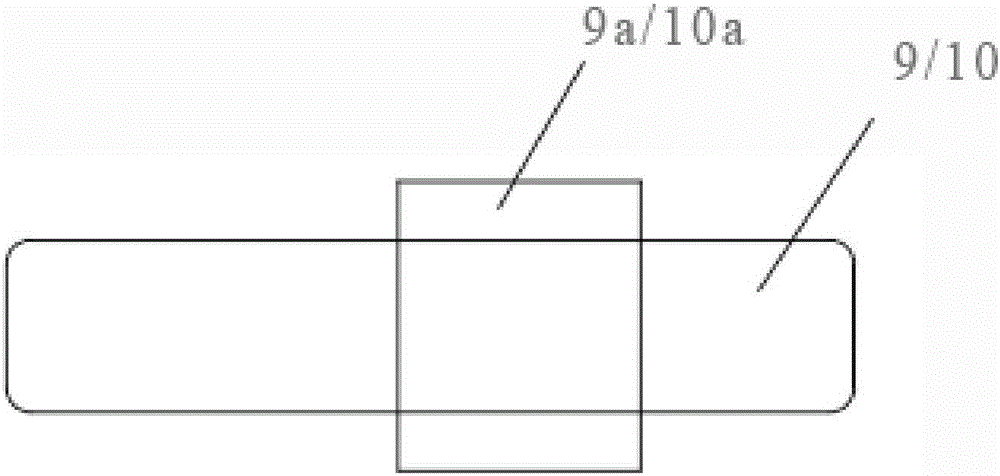

[0023] Such as image 3 and Figure 4 As shown, the single bare cell 1 is made by winding the positive electrode sheet 4, the negative electrode sheet 7, and the diaphragm 11, and the first aluminum strip 5 and the first copper strip 8 are distributed on the same side of the bare cell 1; The battery cells 1 are stacked and fixed in parallel to form a battery pack 2 , and a plurality of parallel first aluminum strips 5 form a second aluminum strip 12 , similarly, a number of parallel first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com