Bus bar unit and pipe bus bar

A technology of busbar and busbar barrel, which is applied in the field of GIL, can solve the problems affecting the stability of GIL connection, and achieve the effect of avoiding too short plug length or even falling off, ensuring stability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

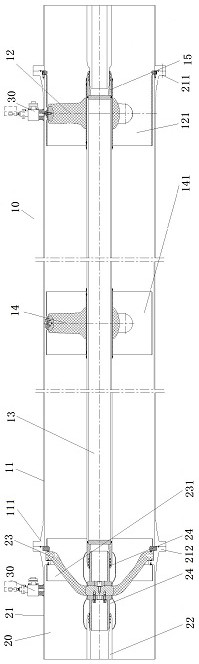

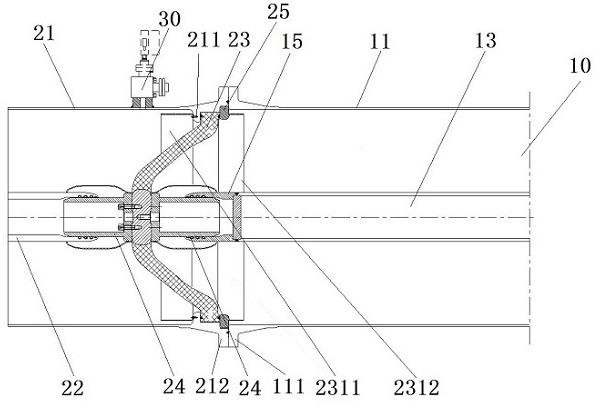

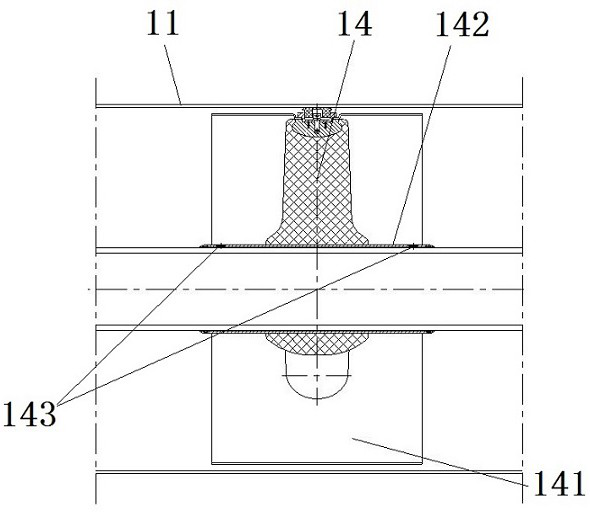

[0050] The specific implementation of the pipeline busbar and its busbar unit in the present invention will now be described in conjunction with the accompanying drawings.

[0051] Such as figure 1 As shown, it is an embodiment of the pipeline busbar in the present invention: the pipeline busbar is connected by a busbar unit. Rod insulators. There are two adjacent first busbar units 20 and second busbar units 10 in the pipeline busbar, and its structure includes a first cylinder body 21 and a second cylinder body 11 connected by flanges. Such as figure 2 As shown, the junction of the first cylinder 21 and the second cylinder 11, that is, between the first cylinder flange 212 and the second cylinder flange 111, is provided with a basin-type insulator 23 belonging to the first busbar unit 20, the basin One side of the type insulator 23 stops and cooperates with the flange 211 provided in the first cylinder 21, and the other side stops and cooperates with the stopper 25 sandw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com