Al-Mg-Zn-Mn aluminum alloy welding wire and preparation method thereof

An al-mg-zn-mn, aluminum alloy welding wire technology, applied in the field of aluminum alloys, can solve the problems of unfavorable thermal deformation and cold deformation processing, affecting the arc stability in the welding process, and the spheroidization of excess crystal phase, so as to improve the finished product The effect of solving the low joint strength and strengthening the weld metal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

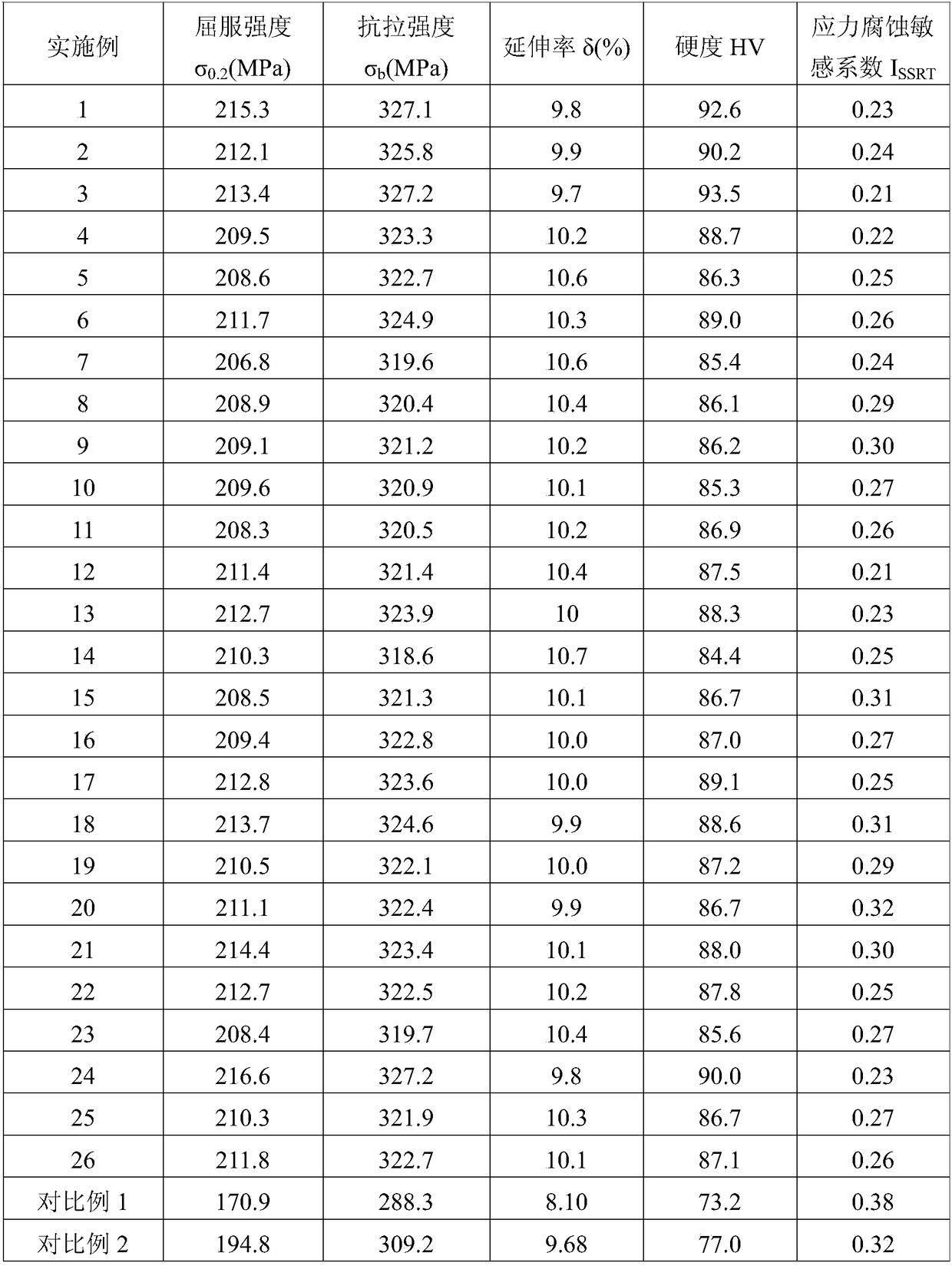

Examples

Embodiment 1

[0047] An Al-Mg-Zn-Mn aluminum alloy welding wire, which contains the following components and mass percentages: Zn: 2.99%, Mg: 5.45%, Mn: 0.98%, Ti≤0.15%, Cr≤0.15%, Fe≤ 0.25%, Si≤0.25%, the total amount of other impurity elements≤0.15%, the content of a single impurity element≤0.05%, and the balance is Al. The diameter of the Al-Mg-Zn-Mn aluminum alloy welding wire is 1.2mm.

[0048] A preparation method of Al-Mg-Zn-Mn aluminum alloy welding wire, comprising the following steps:

[0049] (1) Alloy smelting: use graphite clay crucible to smelt in a resistance furnace, first add industrial pure aluminum, and add industrial pure zinc when the aluminum is semi-melted; when Al+Zn is completely melted and the melt temperature reaches 750°C, add Al-Mn Master alloy, and add a small amount of covering agent, when the master alloy is completely melted, stir the melt, when the melt temperature reaches 730°C, add industrial pure magnesium, and fully stir; then slagging, degassing and ref...

Embodiment 2

[0075] An Al-Mg-Zn-Mn aluminum alloy welding wire, which contains the following components and mass percentages: Zn: 2.99%, Mg: 5.45%, Mn: 0.98%, Ti≤0.15%, Cr≤0.15%, Fe≤ 0.25%, Si≤0.25%, the total amount of other impurity elements≤0.15%, the content of a single impurity element≤0.05%, and the balance is Al. The diameter of the Al-Mg-Zn-Mn aluminum alloy welding wire is 1.2mm.

[0076] A preparation method of Al-Mg-Zn-Mn aluminum alloy welding wire, comprising the following steps:

[0077](1) Alloy smelting: smelting in a resistance furnace through a graphite clay crucible, first add industrial pure aluminum, and add industrial pure zinc when the aluminum is half-melted; when Al+Zn is completely melted, and the melt temperature reaches 755°C, add Al-Mn Master alloy, and add a small amount of covering agent, when the master alloy is completely melted, stir the melt, when the melt temperature reaches 725°C, add industrial pure magnesium, and fully stir; then slagging, degassing a...

Embodiment 3

[0087] An Al-Mg-Zn-Mn aluminum alloy welding wire, which contains the following components and mass percentages: Zn: 1.91%, Mg: 5.39%, Mn: 1.01%, Ti≤0.15%, Cr≤0.15%, Fe≤ 0.25%, Si≤0.25%, the total amount of other impurity elements≤0.15%, the content of a single impurity element≤0.05%, and the balance is Al. The diameter of the Al-Mg-Zn-Mn aluminum alloy welding wire is 1.2mm.

[0088] A preparation method of Al-Mg-Zn-Mn aluminum alloy welding wire, comprising the following steps:

[0089] (1) Alloy smelting: use graphite clay crucible to smelt in a resistance furnace, first add industrial pure aluminum, add industrial pure zinc when the aluminum is semi-melted, add Al-Mn when the melt temperature reaches 760°C when Al+Zn is completely melted Master alloy, and add a small amount of covering agent, when the master alloy is completely melted, stir the melt, when the melt temperature reaches 720°C, add industrial pure magnesium, and fully stir; then slagging, degassing and refinin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com