Welding equipment for air extraction hole in bottom of vacuum cup and machining process of welding equipment

A technology of welding equipment and processing technology, which is applied in the field of welding equipment and processing technology of the vacuum hole at the bottom of the thermos cup, can solve the problems that affect the yield of the thermos cup, and it is difficult to ensure that the vacuum hole is completely blocked, so as to ensure safety and Convenience, stable vacuum sealing, and the effect of ensuring welding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

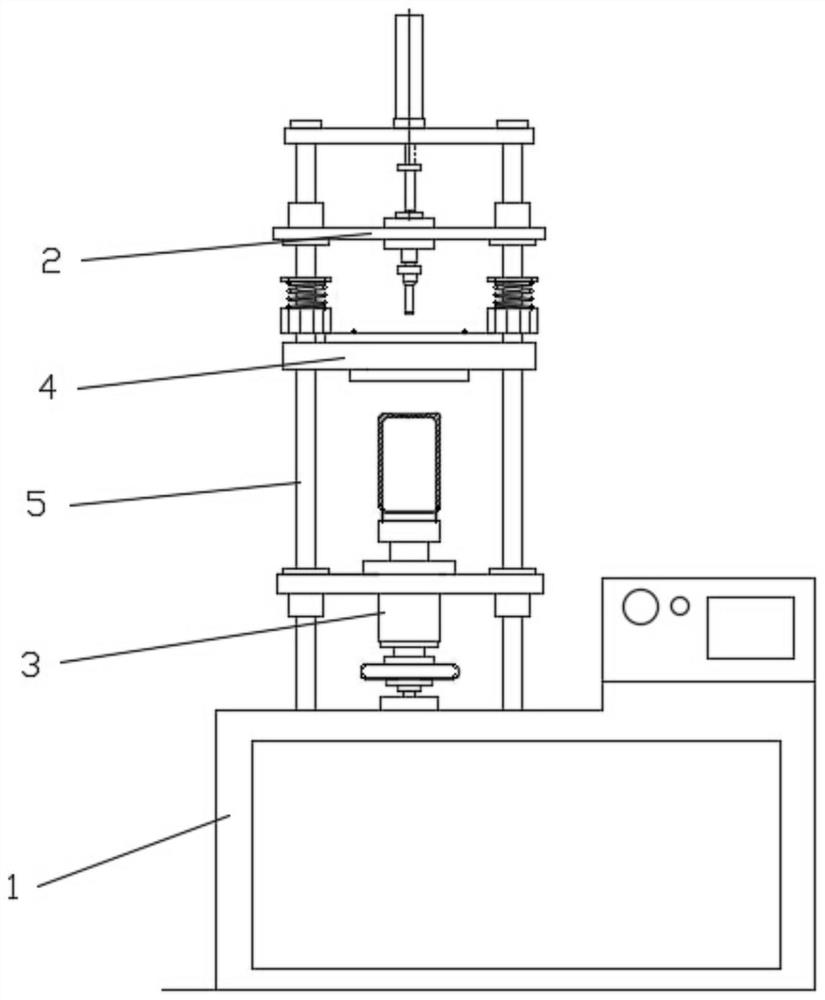

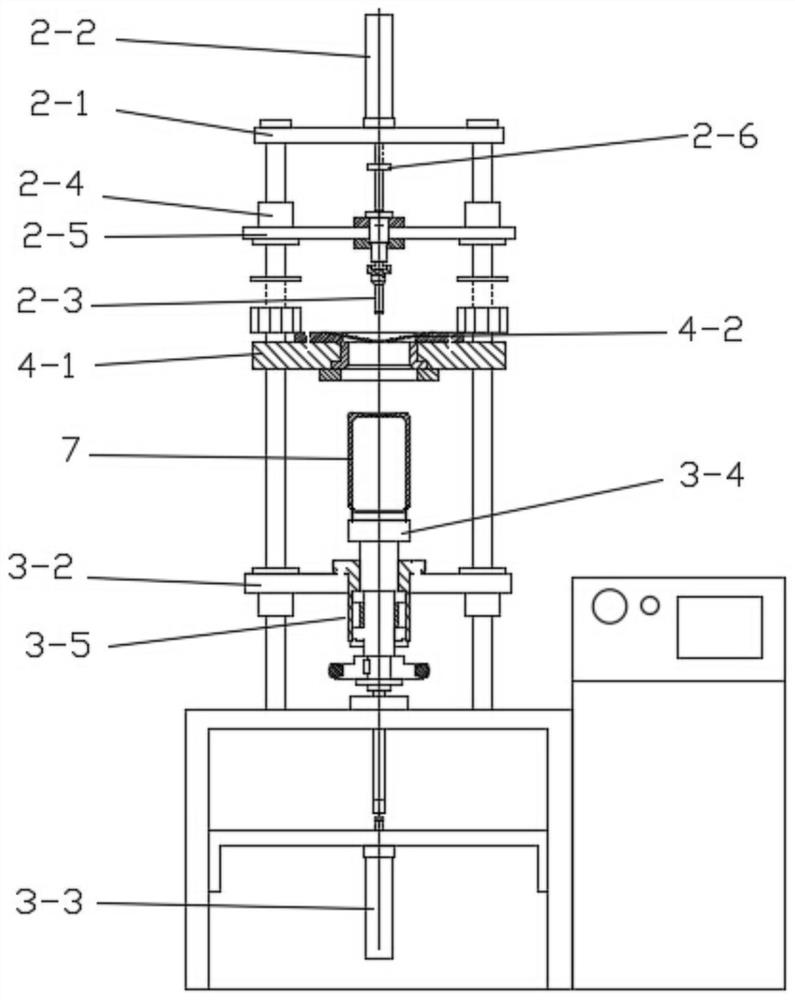

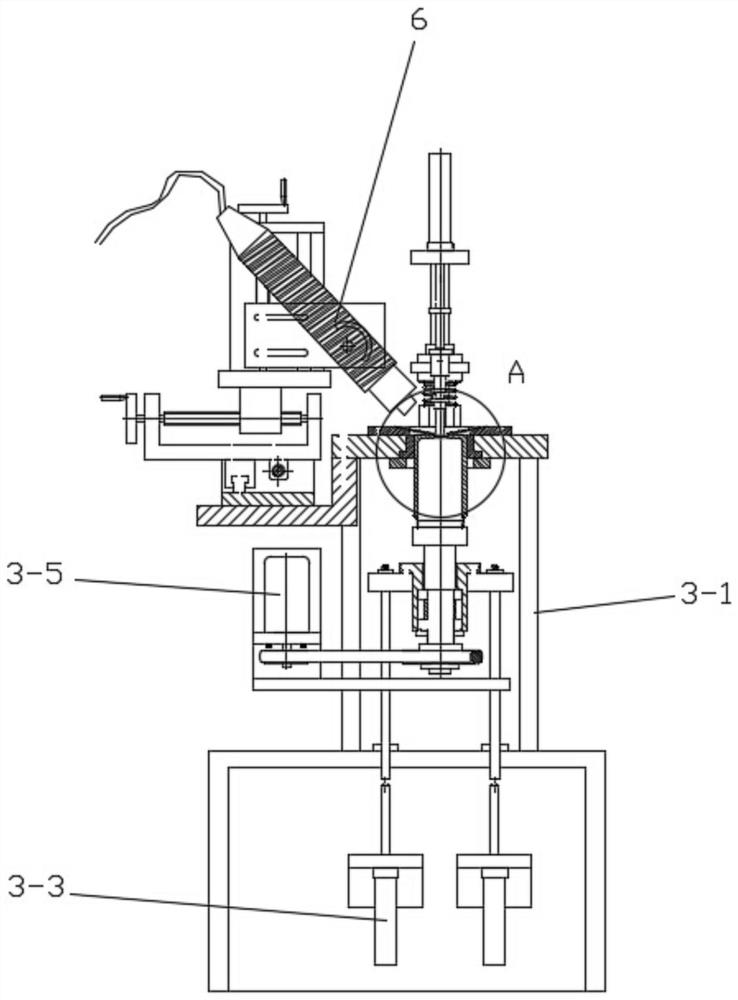

[0036] Such as Figure 1-7 As shown in the figure, a welding device for the air extraction hole at the bottom of a thermos cup includes a frame base 1, and a corresponding top pressing device 2, a bottom lifting and rotating device 3 and a guiding device are arranged on the frame base 1 from top to bottom. 4. The top pressing device 2 and the bottom lifting and rotating device 3 are movably connected to the frame base 1, and both the top pressing device 2 and the bottom lifting and rotating device 3 move toward the direction of the guide device 4; the guide device 4 includes a horizontally arranged fixed plate 4-1, the middle part of the fixed plate 4-1 is formed with a downwardly arranged conical surface 4-2, and the middle part of the conical surface 4-2 is formed with a through hole; the frame base 1 is also provided with a laser welding device 6, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com