Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Consistent traffic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

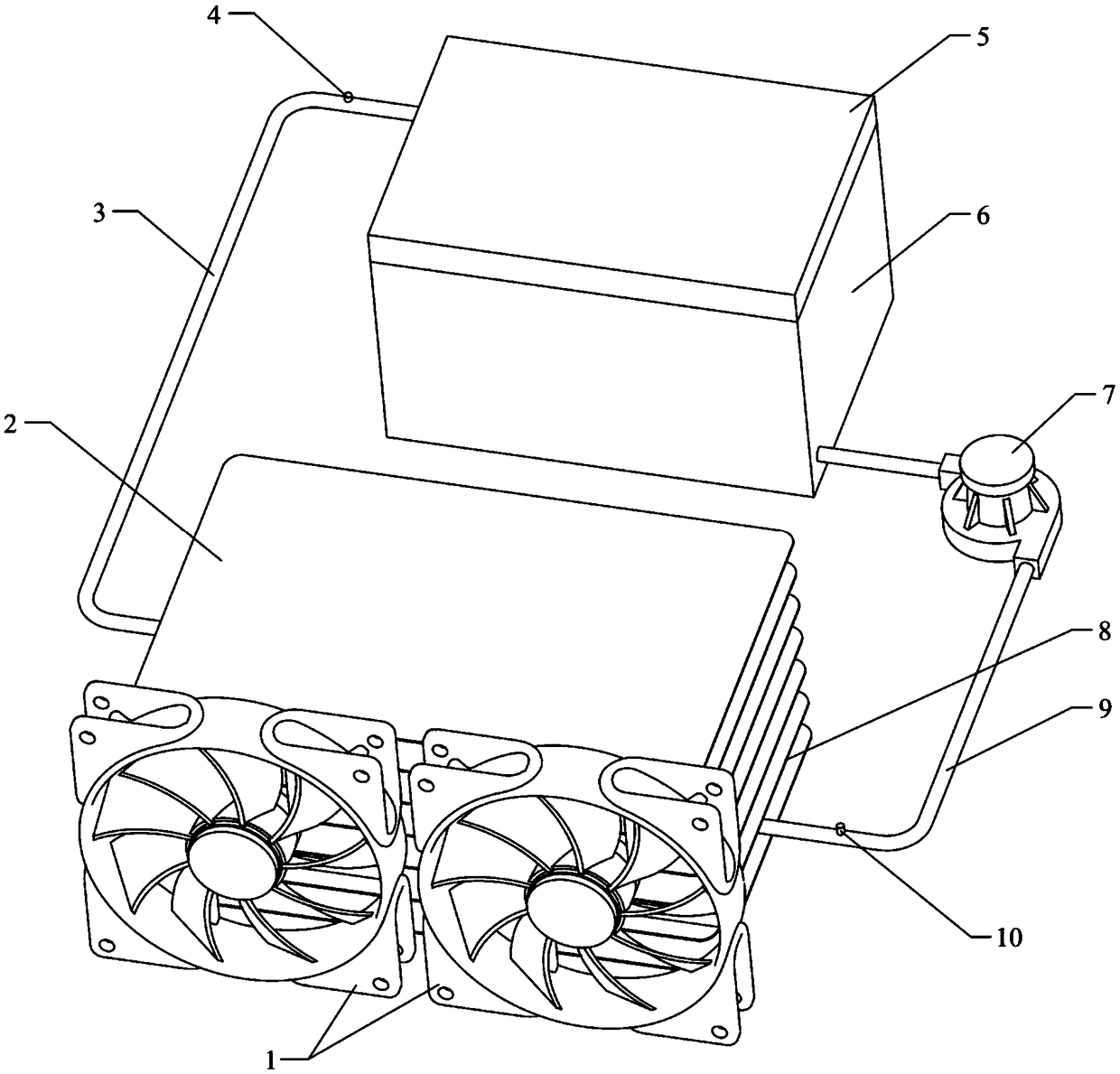

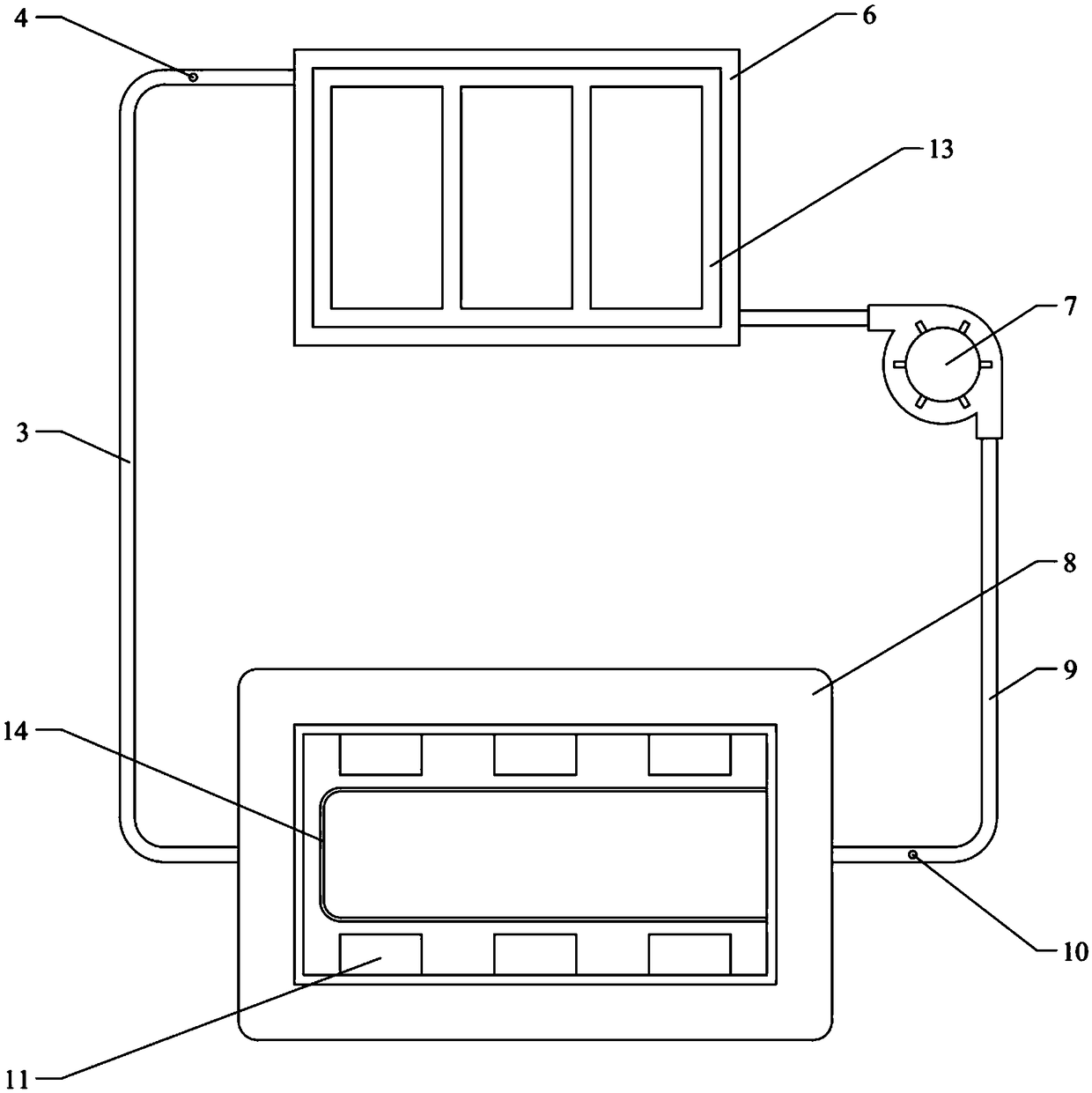

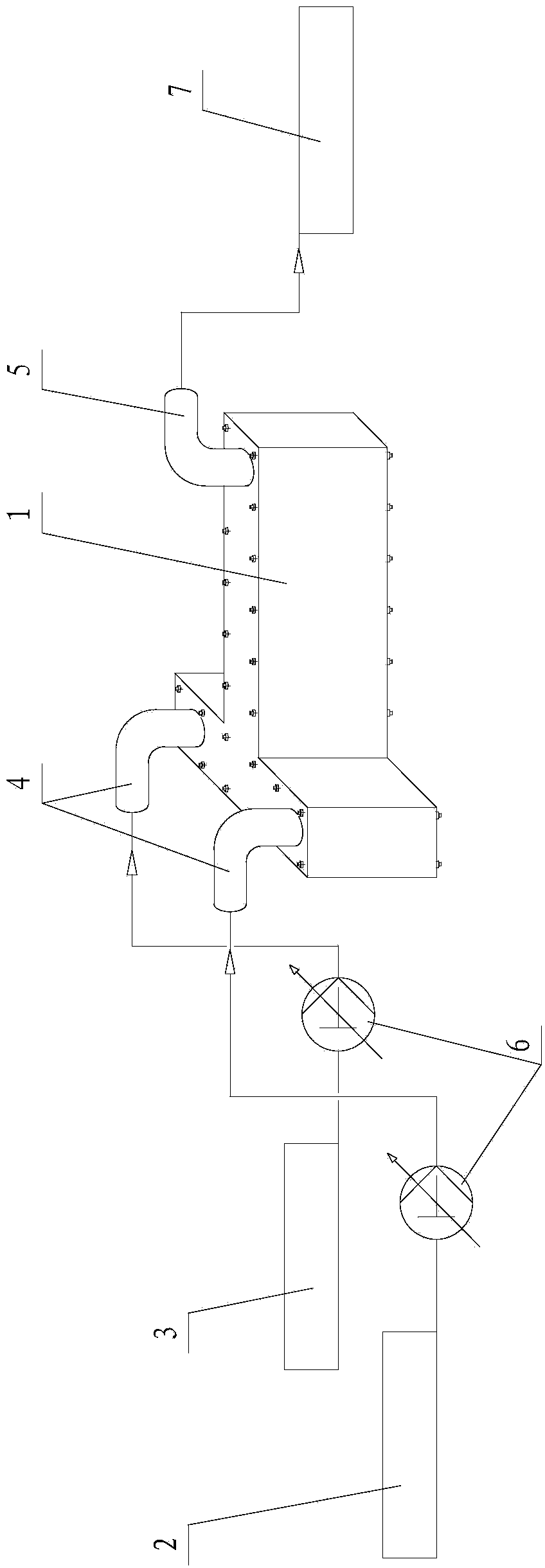

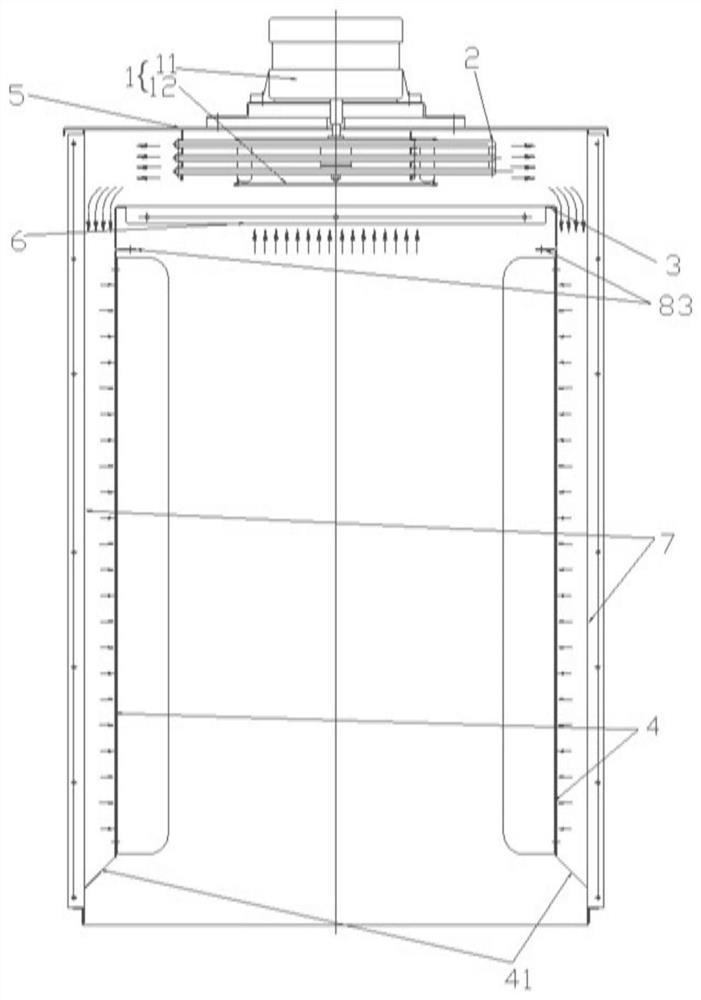

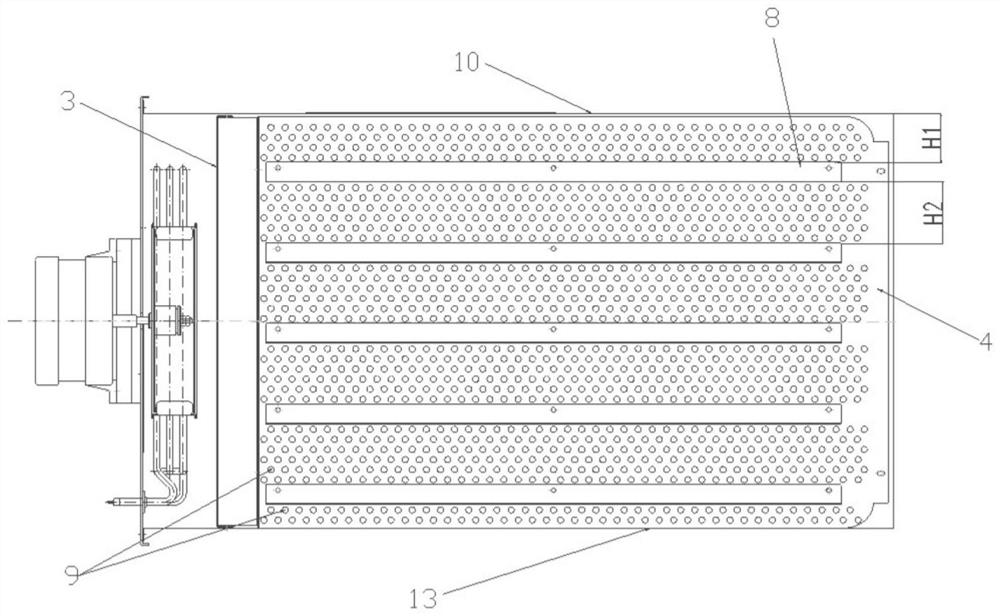

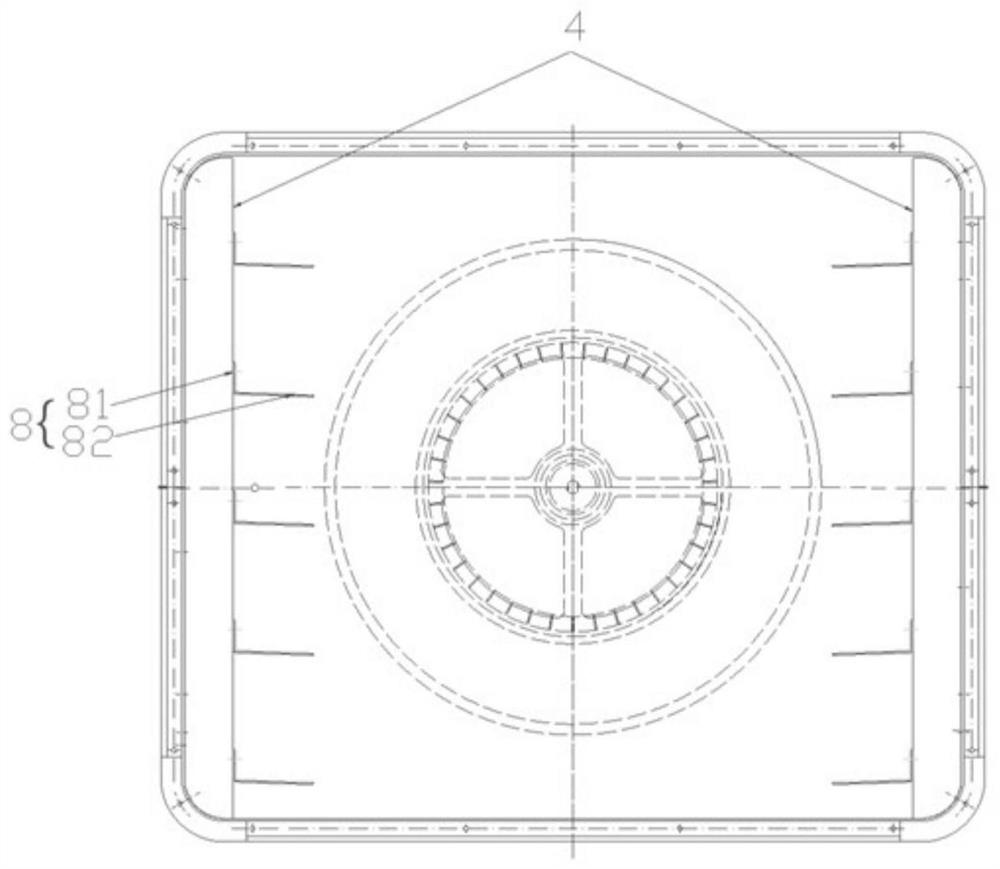

Temperature control system based on magnetic refrigeration technology, thermal management system and method for battery pack of electric vehicle

ActiveCN109149012AReduce the temperatureImprove cooling effectSecondary cellsVehicular energy storageElectrical batteryAutomotive battery

The present disclosure provides a temperature control system based on magnetic refrigeration technology, and thermal management system and method for battery pack of electric vehicle. A heat dissipation box is connected with one side of an accommodation box through a pipeline and the other side is connected to form a loop. The heat dissipation box comprises a heat dissipation box body, a pluralityof heat dissipation fins are sequentially sleeved on the outer edge, and an electromagnetic body and a heating pipe are arranged on the inner surface. The accommodation box comprises an outer heat insulating box body and an inner microchannel partition box, the microchannel partition box includes a plurality of accommodation chambers separated by microchannel partitions, At that front and rear wall surface of the box body, a plurality of transverse and longitudinal connected pipelines are arrange inside the box body, A plurality of connecting branch pipes are arranged inside the microchannelseparator, The connecting branch pipe is communicated with the connecting pipe, and the temperature drop of the magnetic fluid coolant flowing out of the radiator box is caused by the magnetocaloric effect of the magnetic refrigerating material, so that the temperature of the magnetic fluid coolant entering the container box from the cold flow pipe can be effectively reduced, and the consistency of the internal temperature of the acted object can be maintained.

Owner:SHANDONG UNIV

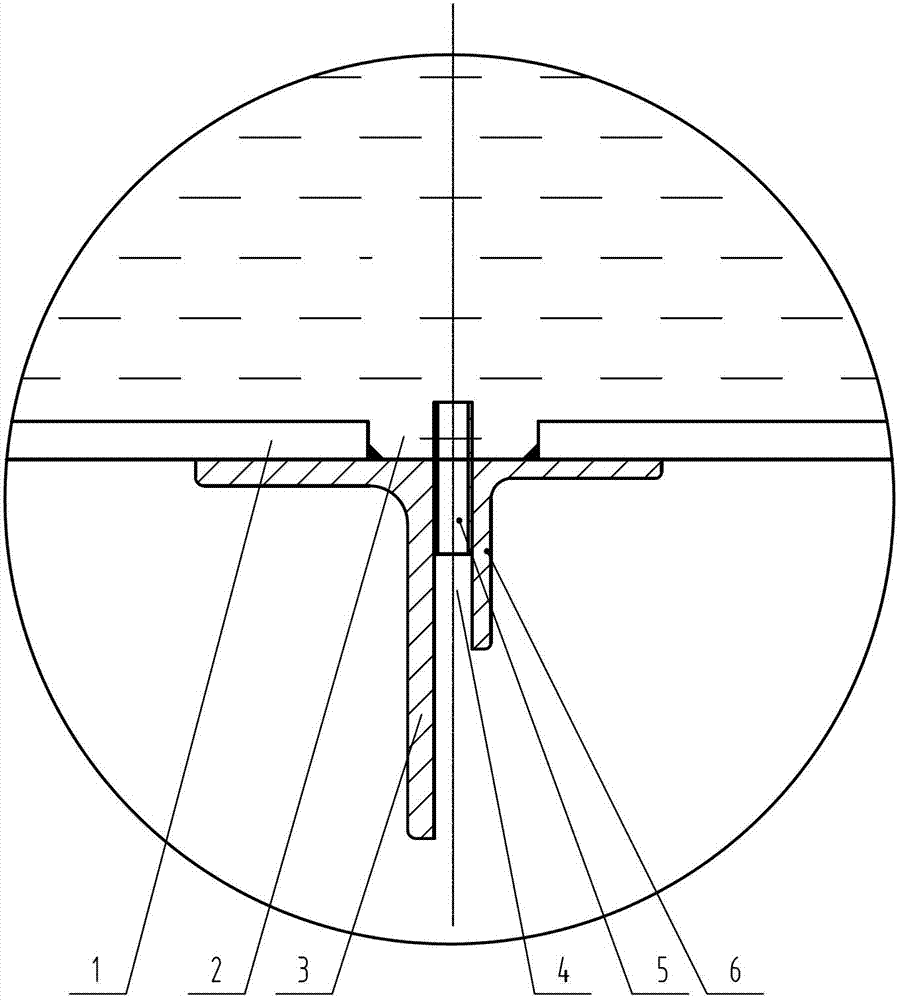

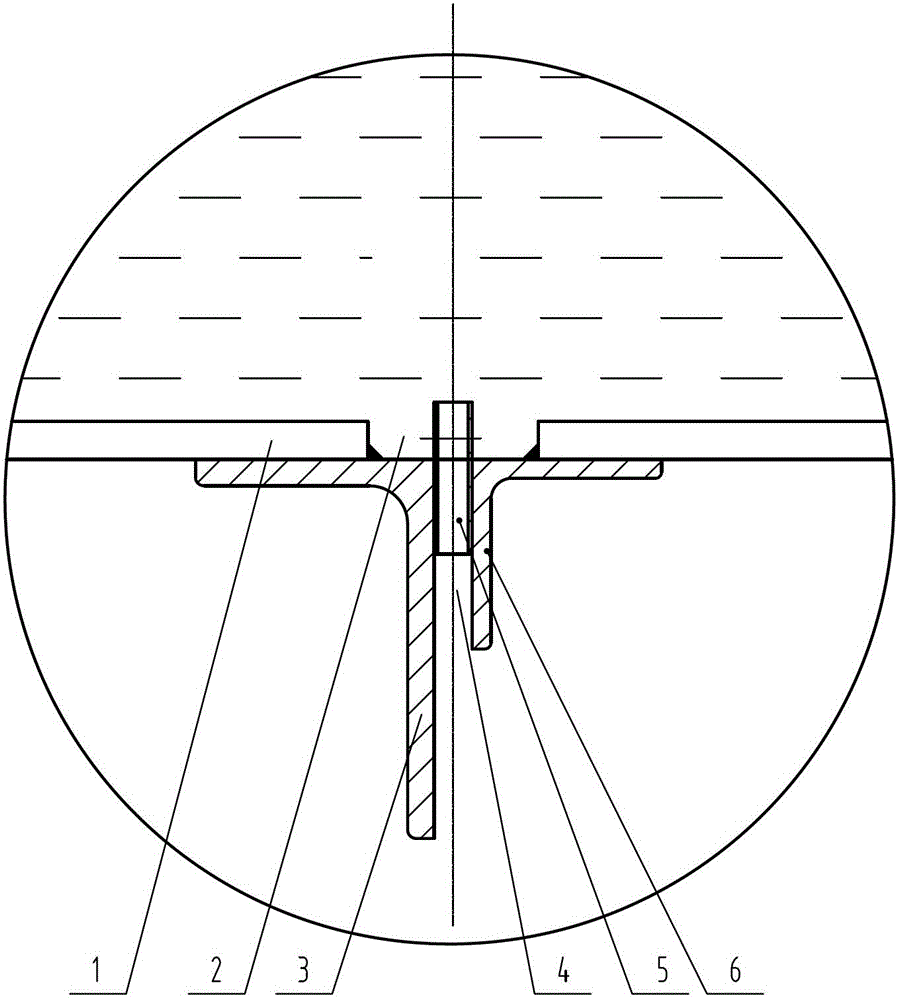

Refrigerant distributing device and parallel flow heat exchanger

ActiveCN102914100AConsistent trafficImprove heat transfer efficiencyEvaporators/condensersFluid circulation arrangementEngineeringRefrigerant

The invention discloses a refrigerant distributing device which comprises a collecting pipe, flat pipes and an input pipe, wherein the flat pipes are communicated with the collecting pipe, and the input pipe is used for inputting refrigerants. At least one partition is arranged in the collecting pipe, the collecting pipe is partitioned into a plurality of chambers by the partitions, and the chambers are communicated with the flat pipes and are communicated with the input pipe through connecting pipes respectively. The invention further provides a parallel flow heat exchanger with the refrigerant distributing device. By the aid of the refrigerant distributing device, heat exchange efficiency of the heat exchanger can be improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

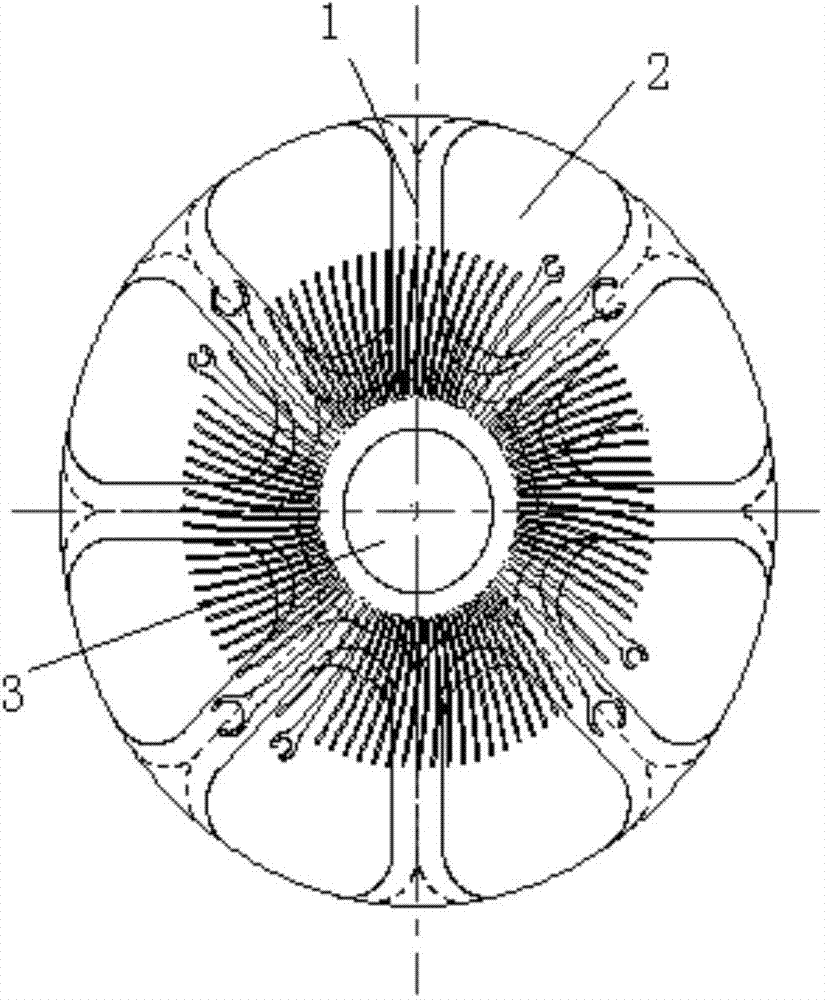

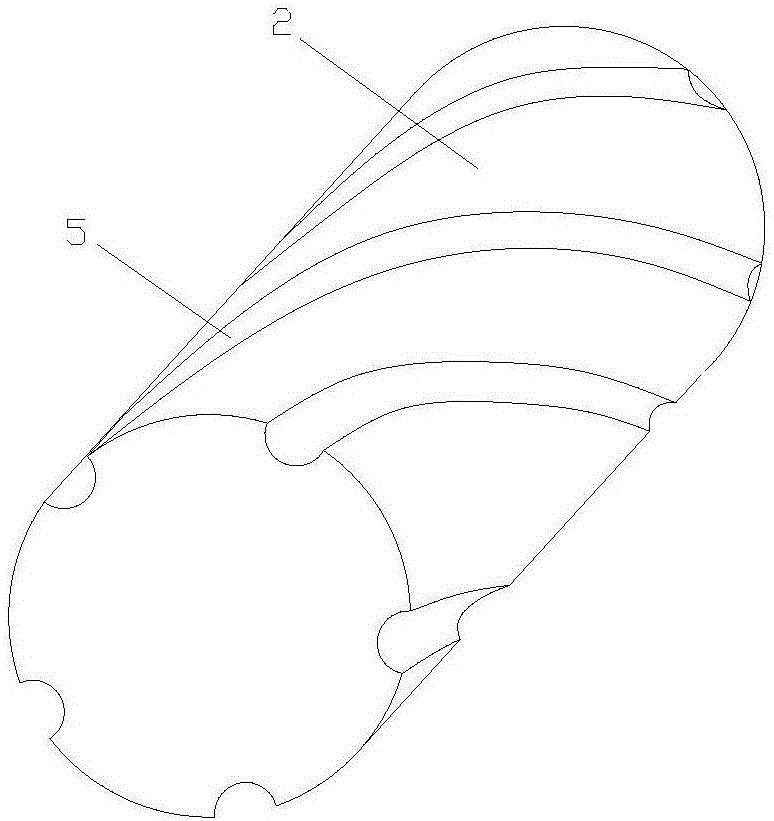

High-multiple aluminum profile extrusion die and extrusion technology

ActiveCN103586303AImprove cooling effectIngenious designExtrusion diesSurface roughnessTooth position

The invention discloses a high-multiple aluminum profile extrusion die which comprises an upper die and a lower die and is characterized in that a plurality of shunting bridges are uniformly distributed on the material feeding surface of the upper die along the circumference; a plurality of shunting holes are formed among the shunting bridges; a false shunt is arranged at the center of the material feeding surface of the upper die; a welding chamber is formed in the upper die; the material feeding end of the lower die is designed into a plane; the lower die is provided with a working tape communicated with a material guide opening; a plurality of tooth position die holes and a plurality of assembling position die holes are formed in the working tape. The invention also discloses an extrusion technology for producing an aluminum profile through the die. The high-multiple aluminum profile extrusion die disclosed by the invention guarantees the consistency of flowing speeds and flow rates of metals under a design form that the flow rates are uniformly distributed to all the shunting hole structures, so that stress on the die is alleviated. The working tape of the extrusion die is ingenious and compact in design and can achieve flatness, perpendicularity and low surface roughness after being treated, so that the yield of products is improved, and the profile extruded through the working tape has a good heat dissipation effect.

Owner:东莞市东联铝业有限公司

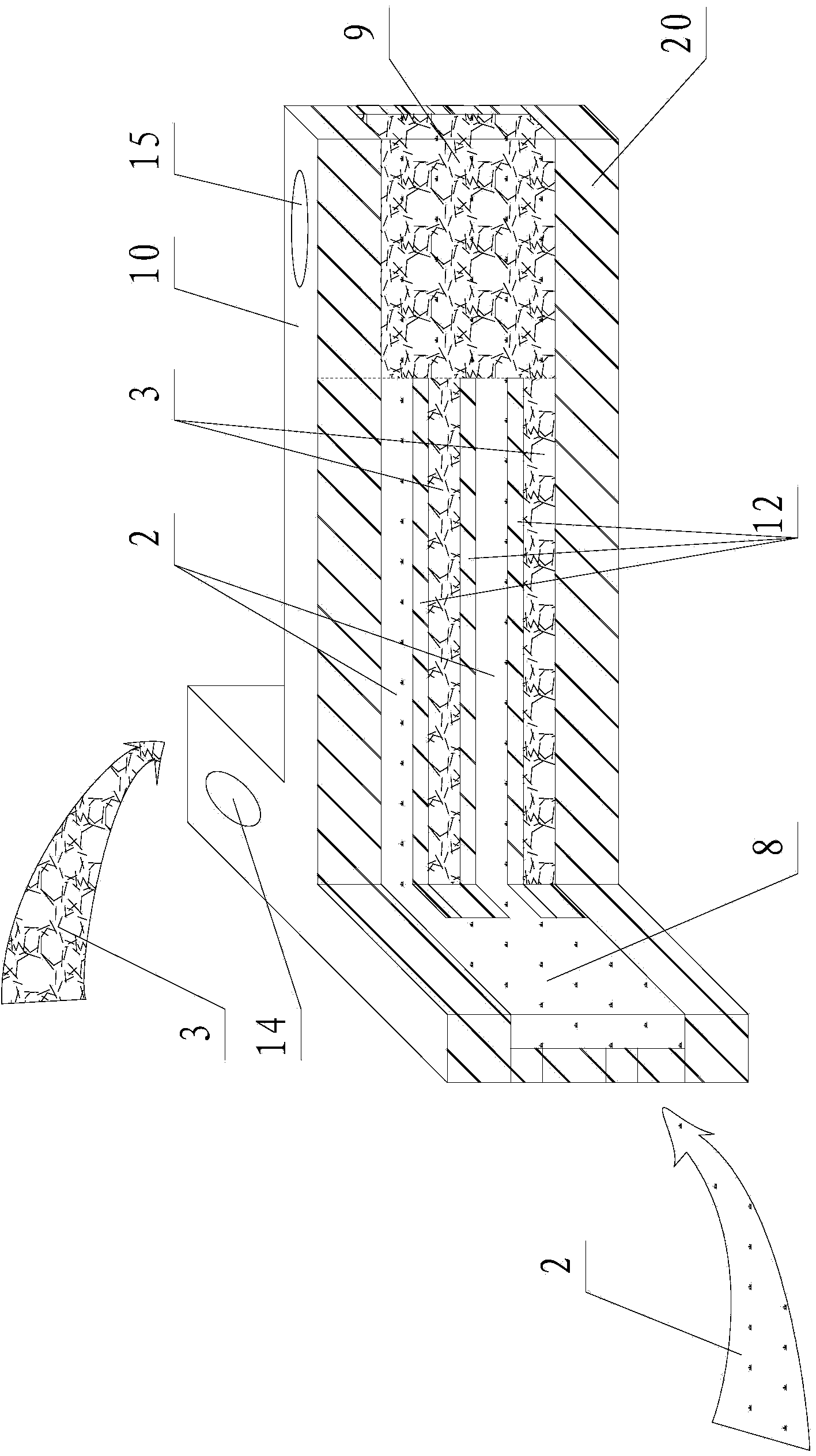

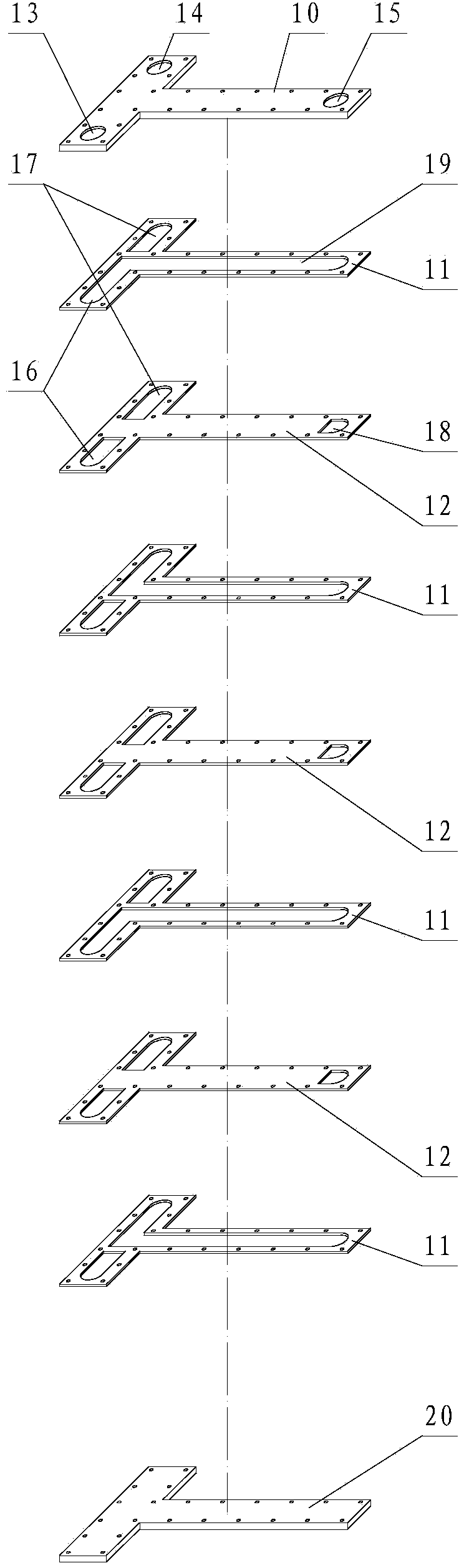

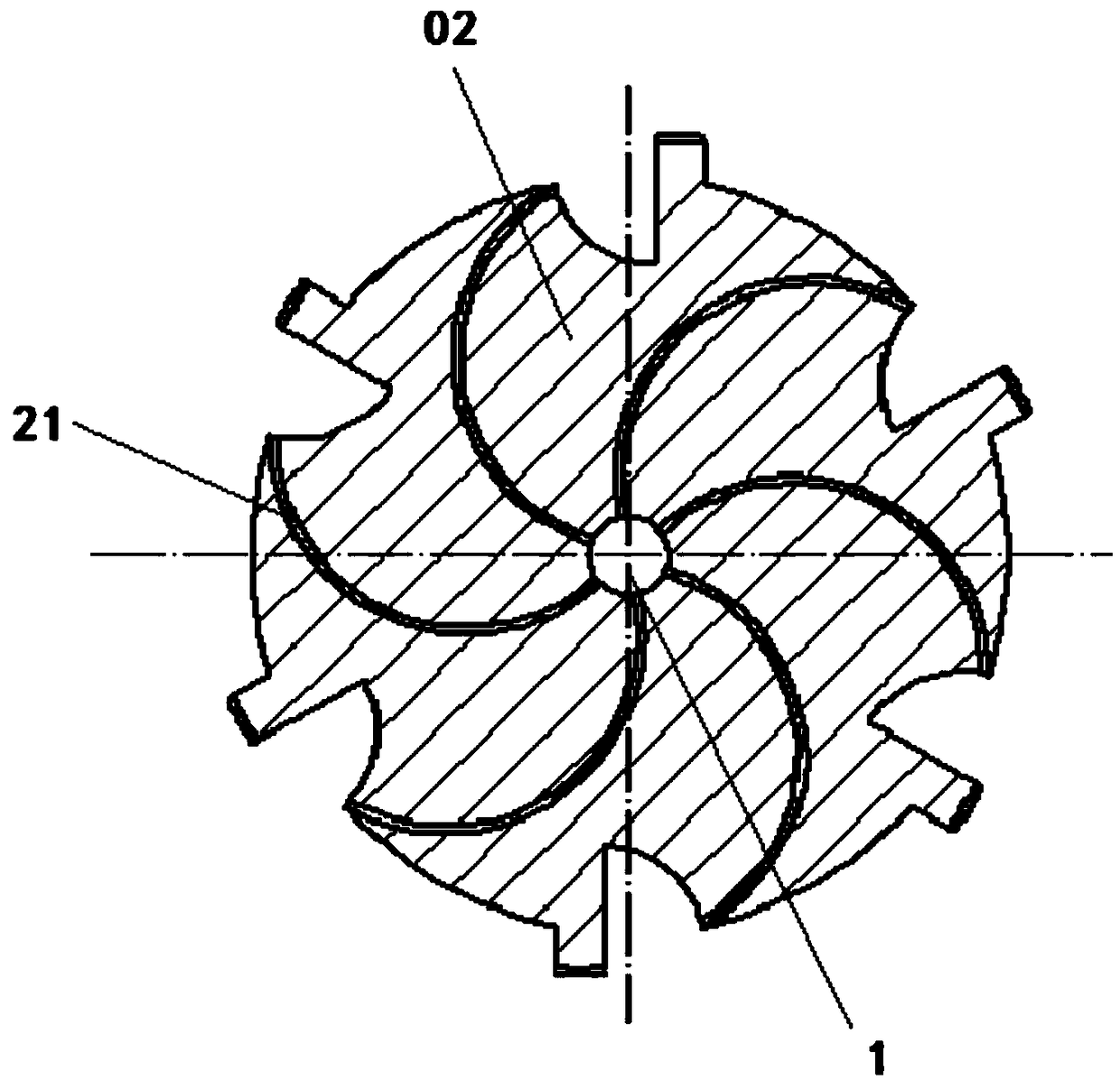

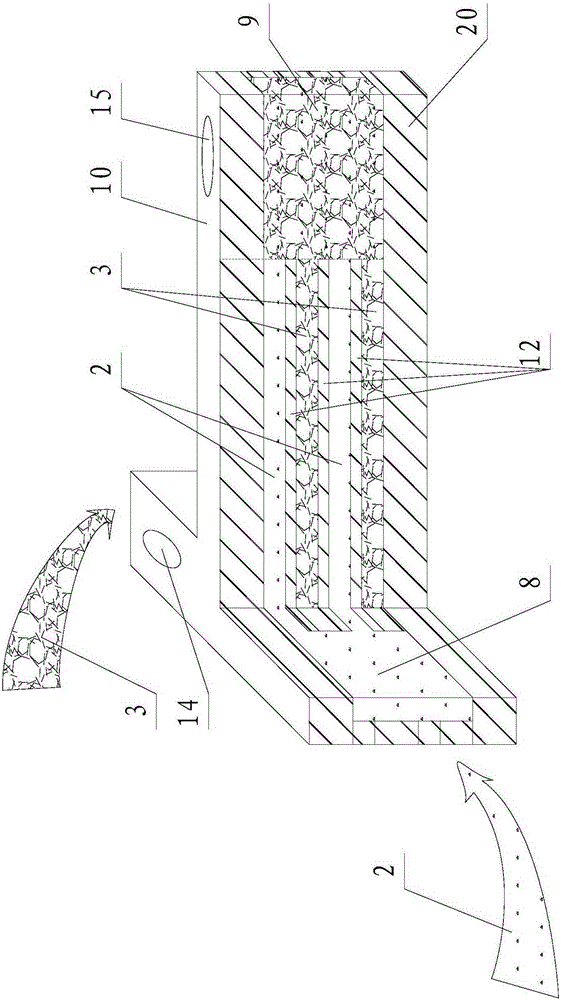

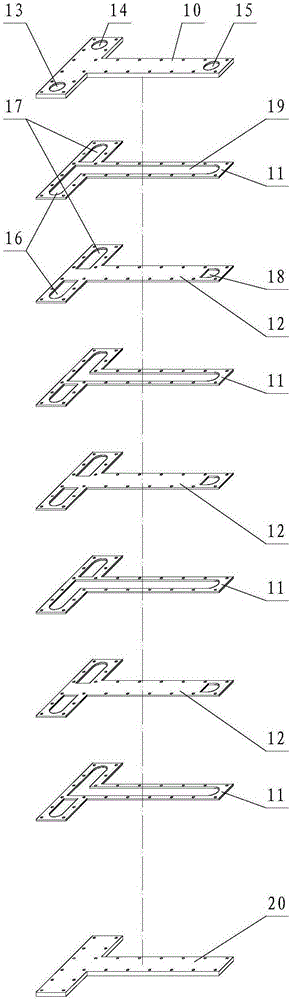

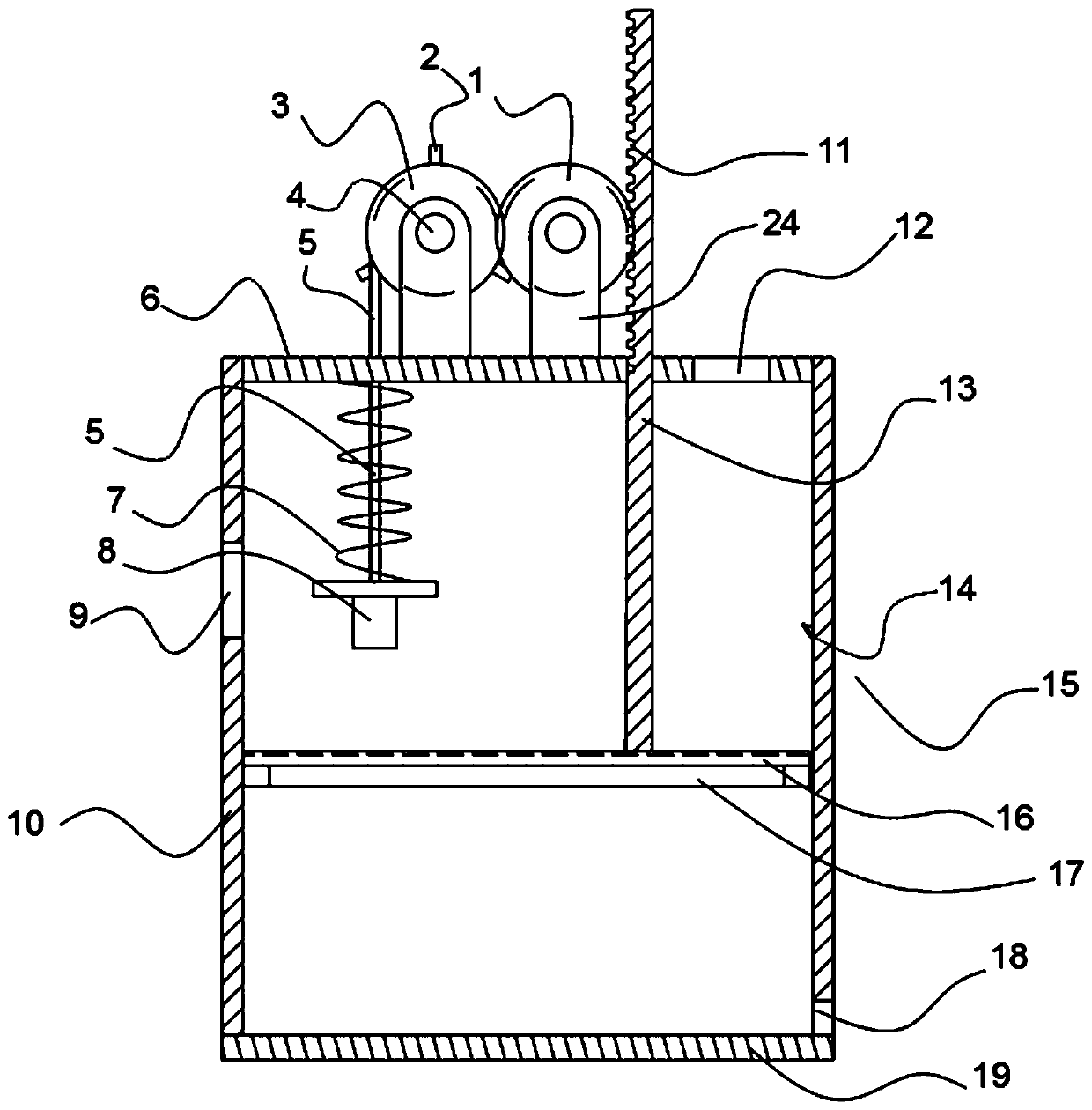

Combined type layered fluid partition mixing device and its application

ActiveCN103977720AFacilitates high-precision machiningExpand the wetted perimeterFlow mixersChemical/physical/physico-chemical processesChemical industryChemical reaction

The invention relates to a mixing device in the chemical industry, and in particular to a combined type layered fluid partition mixing device and its application. The fluid partition mixing device has a layered structure, is respectively provided inside with independent resident chambers for containing different fluids and a mixed chamber for containing the mixed fluid, each resident chamber is respectively communicated with the mixed chamber through a layered partition channel, and the layered partition channels with different fluids passing through are arranged independently and alternately from top to bottom, and different fluids in the resident chambers outflow respectively through the corresponding layered partition channels, and the outflow fluids are arranged alternately in layers, and mixed in the mixing chamber and outflow; and the fluid partition mixing device can be used for liquid-liquid mixing, liquid-gas mixing or gas-gas mixing. The mixing device of the invention is simple for processing and convenient for maintenance, and is mainly used for rapid mass transfer, heat transfer and polymerization, nitration, sulfonation, esterification, diazotization, coupling, acid-base neutralization and other various chemical reactions.

Owner:中国中化股份有限公司 +1

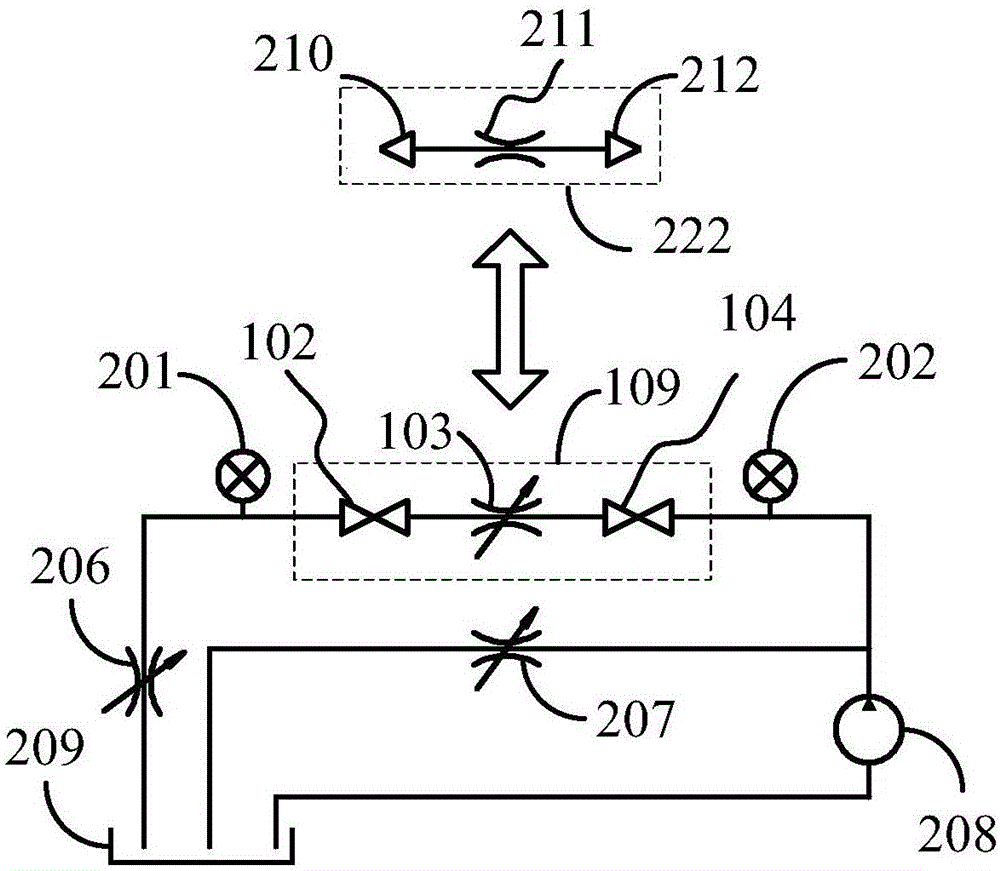

Heat management pipe of electric-vehicle power battery and balance method and calibration system thereof

The embodiment of the invention discloses a heat management pipe of an electric-vehicle power battery and a balance method and calibration system thereof. The heat management pipe comprises a cooling-liquid main loop and a plurality of branch pipes respectively connected to the cooling-liquid main loop. Each branch pipe comprises a water chamber for cooling a corresponding battery module, and a first pressure meter is arranged at an inlet of the water chamber of each branch pipe; a first flow meter is arranged at an outlet of the water chamber of each branch pipe; a first orifice valve installation position is arranged between an inlet of each branch pipe and the inlet of the water chamber of the branch pipe, and an adjustable orifice valve assembly or a fixed orifice valve assembly calibrated based on the adjustable orifice valve assembly is detachably installed at each first orifice valve installation position. By means of the heat management pipe and the balance method and calibration system, the temperature balance between cells can be improved.

Owner:CH AUTO TECH CORP CO LTD

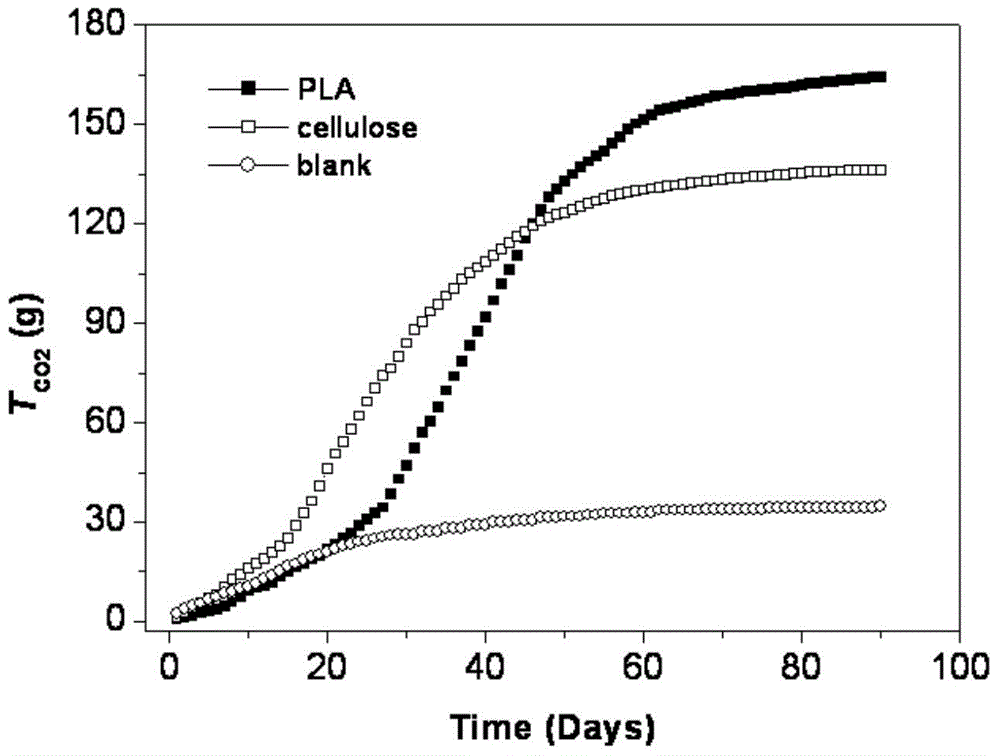

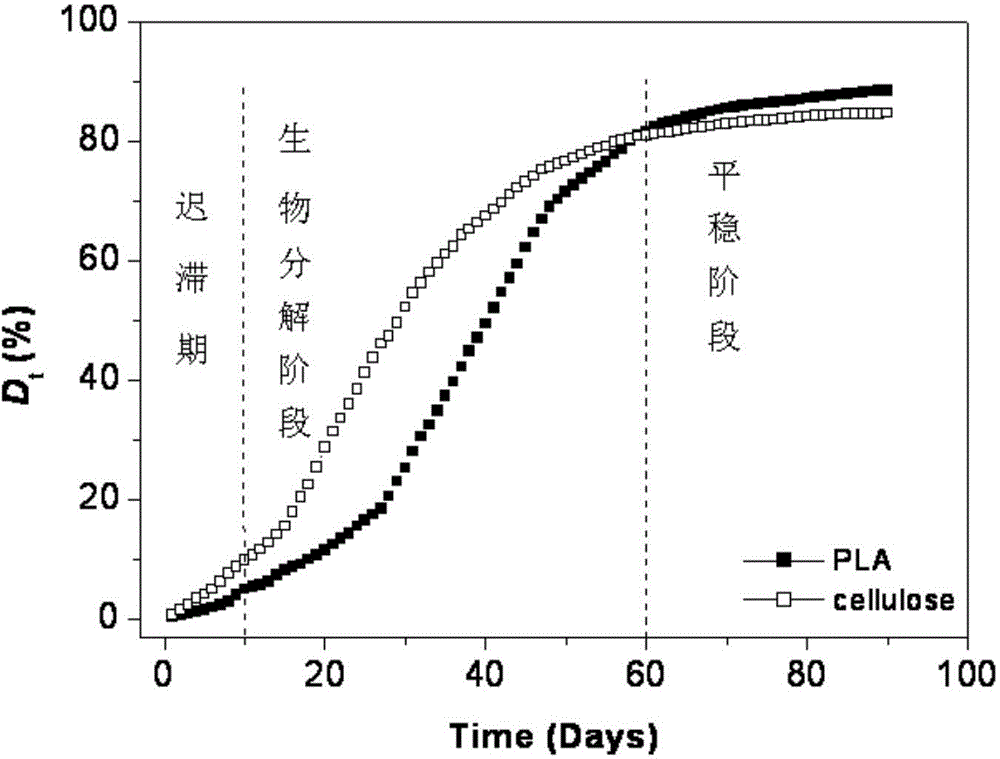

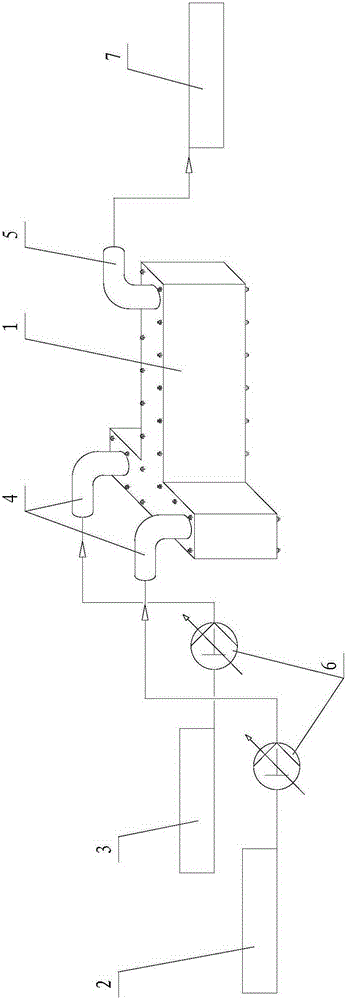

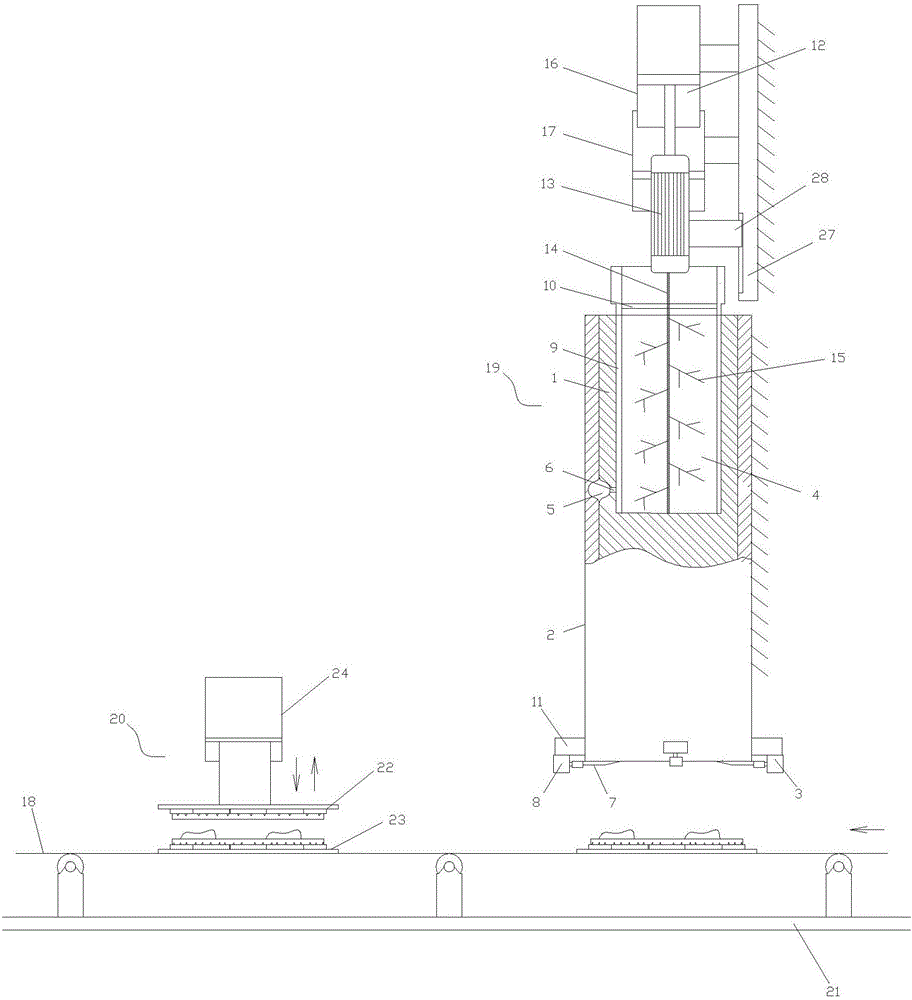

Material biological degradability detection evaluation equipment and method

InactiveCN104949911AAvoid enteringMaintain humidityWeather/light/corrosion resistanceCo2 absorptionProviding material

The invention provides material biological compost degradability detection evaluation equipment and a material biological compost degradability detection evaluation method. The equipment comprises an air supply and purification system, an air flow control system, a compost reaction system, a temperature control system and a CO2 absorption system which are arranged in sequence, wherein the air supply and purification system comprises an air compressor, a suck-back preventing bottle, an air purification bottle, a pressure maintaining valve, a pressure regulating valve and an electromagnetic valve, connected in sequence; the air flow control system comprises a flow control device; the compost reaction system comprises a humidification bottle and a compost reaction bottle; the CO2 absorption system comprises a condensation bottle and a CO2 absorption bottle. The equipment and the method have the benefits that inorganic carbon dissolved in the CO2 absorption bottle can be detected periodically through a potentiometric titration method to be taken as the accumulated CO2 emission capacity generated by the compost reaction bottle, and the method is simple and accurate.

Owner:SHENZHEN ACAD OF METROLOGY & QUALITY INSPECTION

Multipoint grid method flue gas mixed sampling device

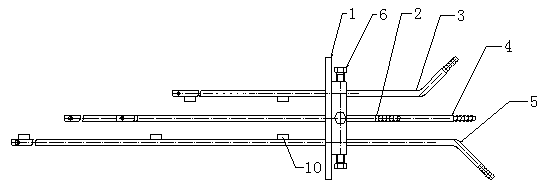

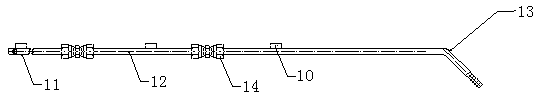

PendingCN107631915AGuaranteed accuracyConvenient flue gas temperatureWithdrawing sample devicesTemperature measurement of flowing materialsFlueFlue gas

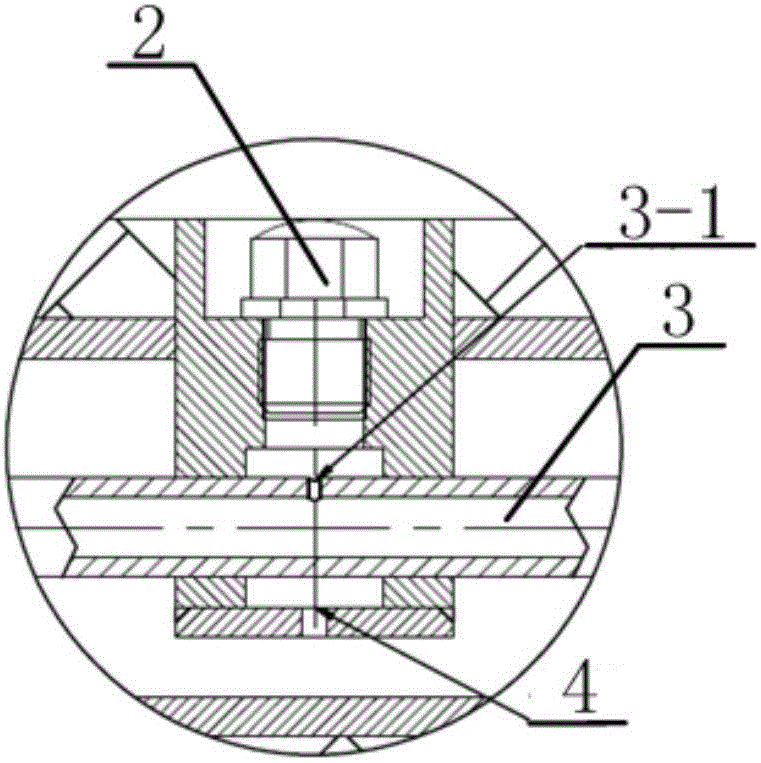

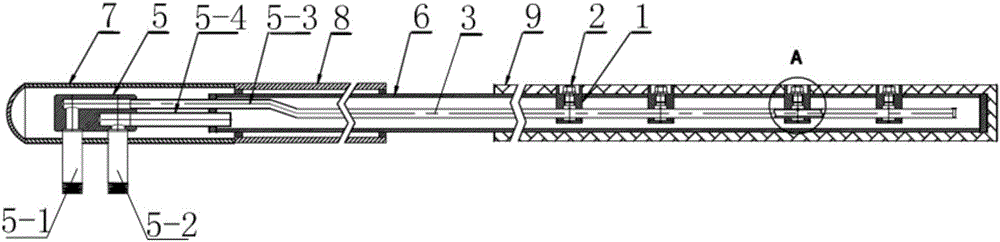

The invention relates to a multipoint grid method flue gas mixed sampling device. The device is characterized in that: it includes a pipe base, a plurality of flue gas sampling pipes, a fixation bolt,connecting hoses and a flue gas analyzer. All the flue gas sampling pipes are arranged on the pipe seat parallel to each other, and are fixed on the pipe seat through the fixation bolt, one ends of the flue gas sampling pipes are connected to the connecting hoses, the connecting hoses are connected to the flue gas analyzer, and the other ends of the flue gas sampling pipes are equipped with sampling holes. According to the invention, the distance by which the flue gas sampling pipes pass through the pipe base can be adjusted to adapt to the grid partition requirements of flues with differentdepths, and through matching of the sampling ports of the flue gas sampling pipes and the length of the sampling pipes, the flow of each flue gas sampling pipe can always maintain consistent, the accuracy of flue gas sampling measurement is guaranteed, also thermocouple fixed tubes are installed at the same time, thus facilitating measurement of flue gas components and flue gas temperature simultaneously.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

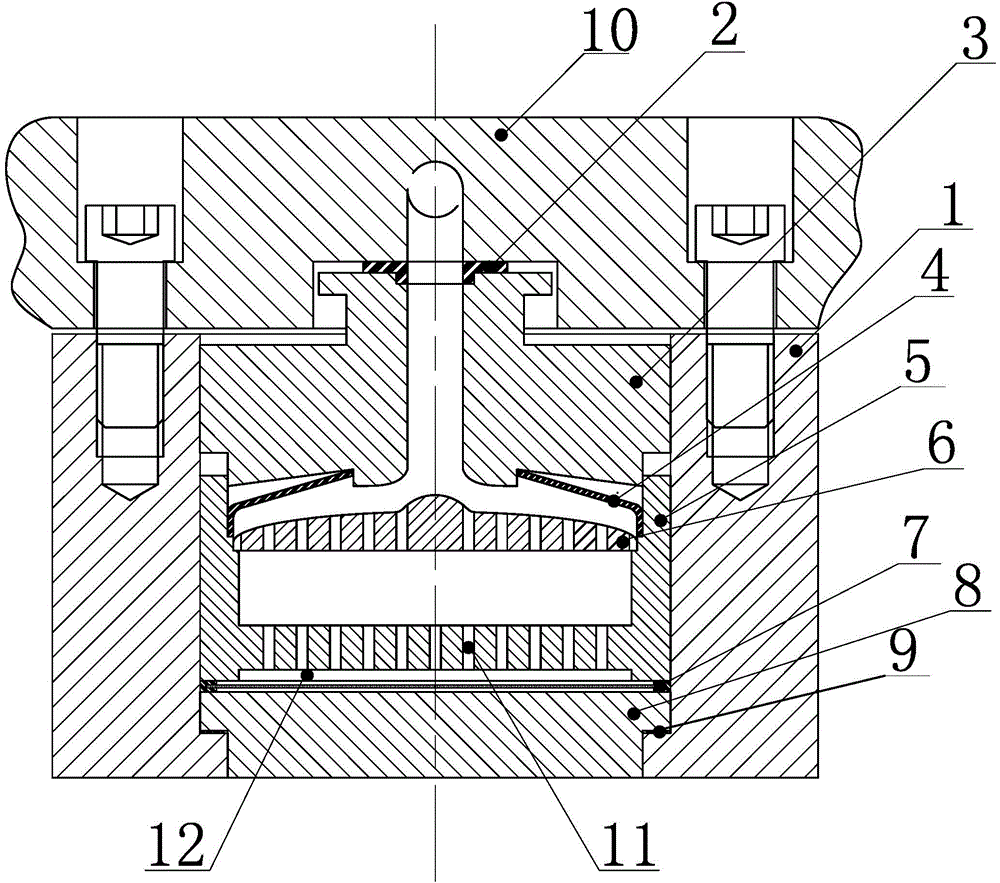

Spinning device for dry-jetting and wet-spinning method

InactiveCN104153008AReduce processing costsFit closelySpinnerette packsSpinning head liquid feederFiberSlurry

A spinning device for a dry-jetting and wet-spinning method comprises a base, wherein a sand cavity is formed in the base, a distributing plate, a partition plate, a multi-layer filter screen and a spinneret plate are sequentially arranged in the sand cavity from top to bottom. A gland moving in the axial direction is installed in the base, arranged above the sand cavity and provided with a size flow channel, an inlet of the size flow channel is communicated with a size outlet of a spinning box, and an outlet of the size flow channel is communicated with the sand cavity; the distributing plate is arranged at the downstream position of the outlet of the size flow channel, and a plurality of flow guide holes are evenly distributed in the distributing plate; flow guiding holes are evenly distributed in the partition plate, and the portion, between the partition plate and the distributing plate, of the sand cavity is filled with filter sand; a certain gap is formed between the multi-layer filter screen and the partition plate to form a pressure stabilizing chamber; the spinneret plate makes close contact with the lower surface of the multi-layer filter screen. The spinning device is good in sealing effect, not prone to leaking size, the size flows without dead angles, and therefore the performance of fibers is ensured.

Owner:SHANDONG YINGLI IND

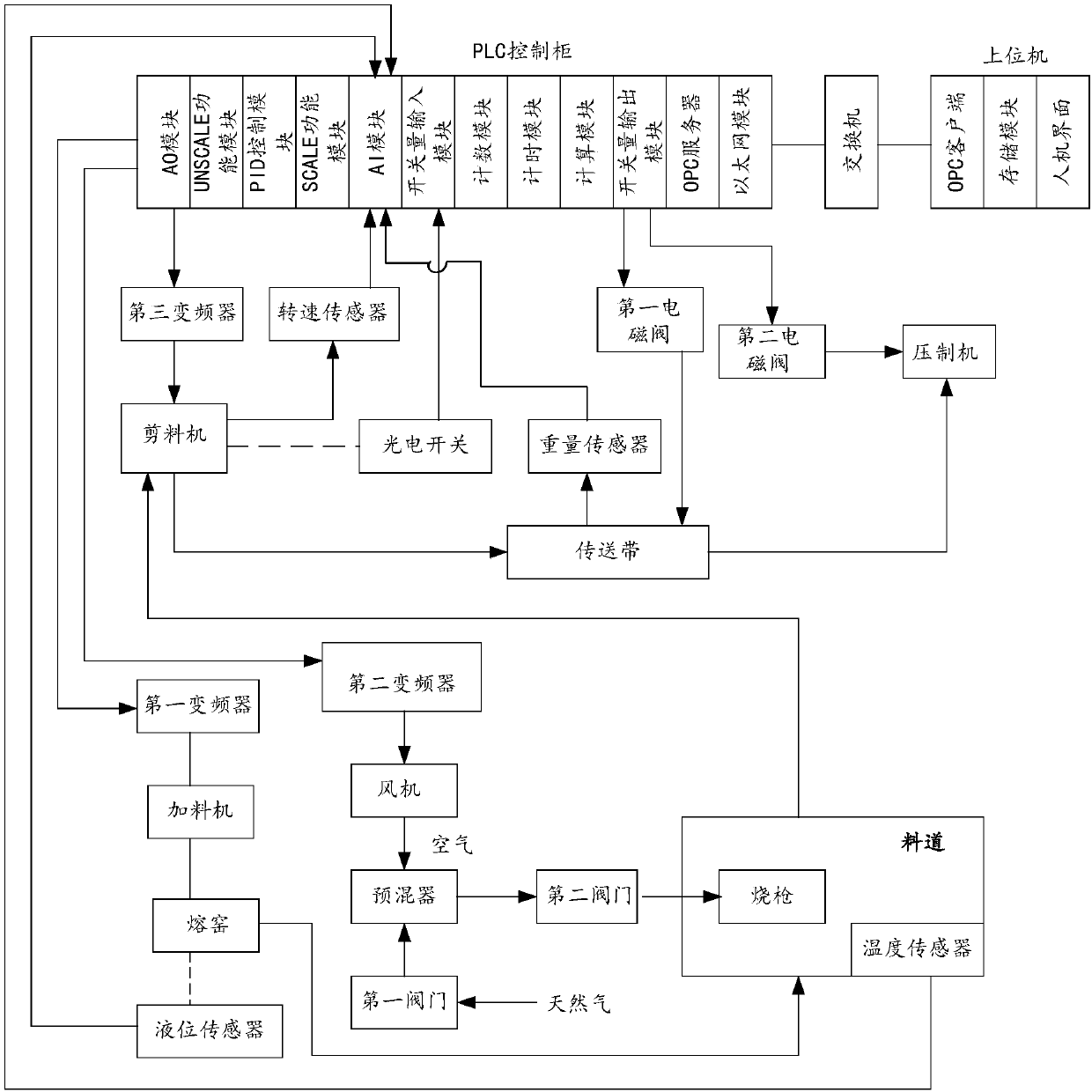

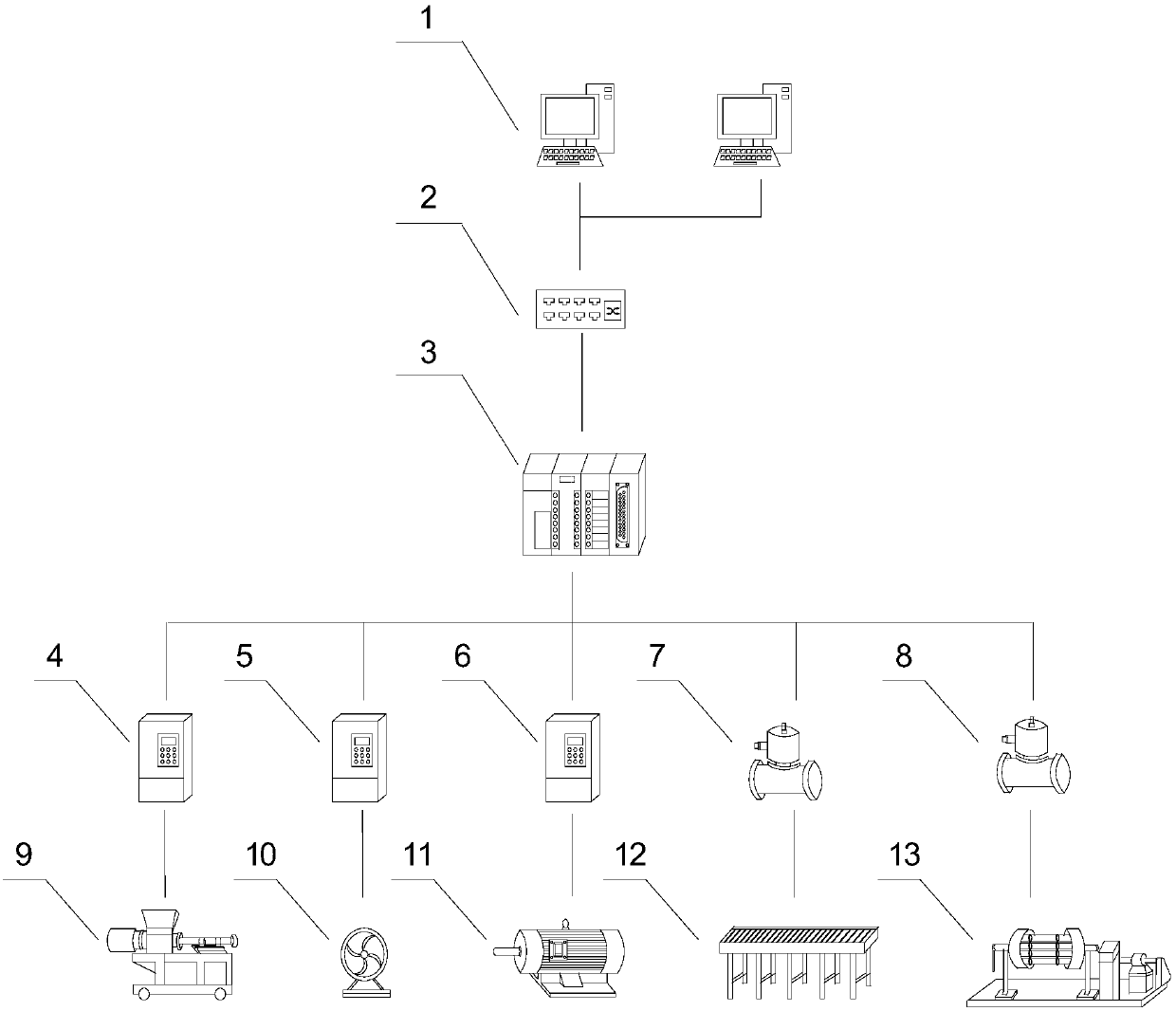

Automatic control system of glass production flow

ActiveCN107632583ASave combustion energyConsistent trafficProgramme total factory controlFrequency changerTemperature control

The present invention discloses an automatic control system of a glass production flow. The automatic control system comprises a PLC control cabinet, a first frequency converter, a feeding machine, amelting furnace and a liquid level sensor which are used to control the liquid level of the melting furnace, a second frequency converter, a draught fan, a premixer, a first valve, a second valve, a lance, a material channel and a temperature sensor which are used to control the temperature of the material channel, a third frequency converter, a material cutting machine, a rotating speed sensor, aconveyor belt, a photoelectric switch, a weight sensor, a first solenoid valve, a pressing machine and a second solenoid valve which are used to control the molding of the glass. An AO module of thePLC control cabinet is connected with the first, second and third frequency converters, an AI module is connected with the liquid level sensor, the temperature sensor, the rotating speed sensor and the weight sensor, a switching value input module is connected with the photoelectric switch, and a switching value output module is connected with the first and second solenoid valves, so that the problems that the conventional flow efficiency is low, and the quality of the glass is not high, are solved.

Owner:四川虹禾晶科技有限公司

Gating system with multistage split transverse runners

InactiveCN104325085ADrag loss is the sameConsistent trafficMelt-holding vesselsFoundry mouldsEngineering

The invention discloses a gating system with multistage split transverse runners, and belongs to the casting technology. The flow rates of the internal runners of the existing gating system are different, the transverse runners of the gating system disclosed by the invention comprises at least two stages; the central point of each transverse runner of each stage is set as a diverging point, and the central point of the first stage of transverse runners corresponds to a straight runner; each transverse runner of each stage is symmetrically connected with the next stage of two transverse runners relative to the central point of the transverse runner, and the next stage of transverse runners is vertical to the former stage of transverse runners at the communication sites; each transverse runner of the last stage is symmetrically connected with two internal runners relative to the central point of the transverse runner, and the internal runners are vertical to the last stage of transverse runners at the communication sites. According to the invention, multistage transverse runners are formed by the method of splitting the transverse runners, the two ends of the last stage of transverse runners are respectively communicated with one internal runner to finally form a gating system with the straight runner as a centre of symmetry, and the flow rate in each runner can be kept uniformly during casting.

Owner:ZHEJIANG JIALI WIND POWER TECH

Multi-party statistical query method based on differential privacy protection technology

ActiveCN110222092AEnsure safetyConsistent query speedDigital data information retrievalDigital data protectionDifferential privacyData exchange

The invention discloses a multi-party statistical query method based on a differential privacy protection technology. The method comprises the step of performing summation calculation in a multi-partyenvironment, includingdetermining n parties participating in the multi-party environment, determining a first numerical value in each party, and selecting a first numerical value and a second numerical value from the parties, generating n-1 different numerical values meeting the Laplace distribution of the first numerical value and the second numerical value in each party, selecting any participant in each party, performing data exchange calculation according to the different numerical values to obtain a third numerical value, and calculating the sum of the third numerical values of any participant; performing the maximum value calculation in the multi-party environment, comprising the following steps: determining n parties participating in the multi-party environment, respectively determining a plurality of fourth numerical values in the parties, converting the fourth numerical values into binary numerical values, and obtaining the maximum values of the output values in sequence according to the summation calculation process.

Owner:DONGGUAN UNIV OF TECH

Thermal cycle air duct structure system and hot air oven

The embodiment of the invention discloses a thermal cycle air duct structure system and a hot air oven. The system comprises a hot air assembly and an air duct assembly, the hot air assembly comprises a fan and a heating pipe, the air duct assembly comprises a fan cover and two air duct baffles, the fan cover is vertically arranged on the front side of the heating pipe, and one ends of the two air duct baffles are connected to the fan cover so that an air cavity is formed among an inner container of the oven, the fan cover and the two air duct baffles; the fan sucks air in the middle of the inner container of the oven into the space between the fan cover and the rear wall through the air inlet to form an airflow, and the heating pipe can heat the airflow so that the heated airflow, namely hot air, fills the air cavity and is exhausted to the baking tray through the air outlets in the air duct baffles, and hot air can also exist in the part not close to the fan; and furthermore, each baking tray is heated uniformly, the surface of the food is colored consistently, the taste and the appearance are ensured, and the user experience is improved.

Owner:青岛海氏烘焙电器有限公司

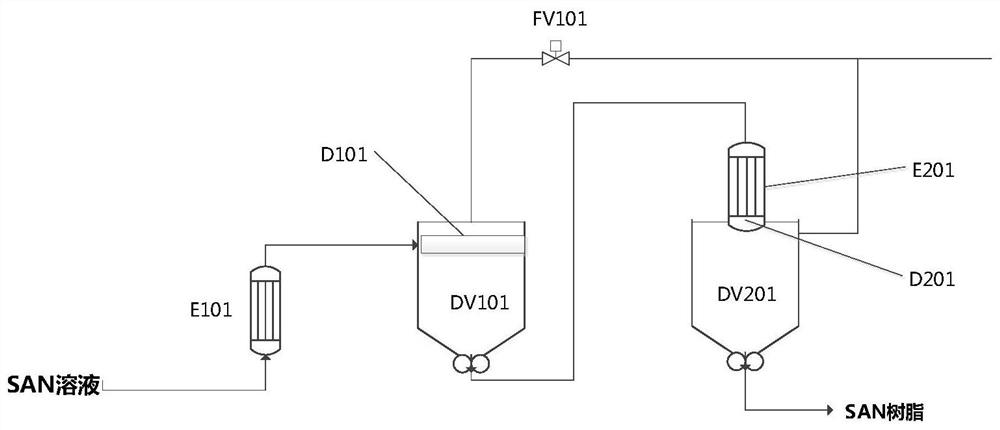

Water-fertilizer all-in-one machine

PendingCN107258193AAvoid strandedReduce cloggingHollow article cleaningPressurised distribution of liquid fertiliserAgricultural engineeringEnvironmental engineering

The invention discloses a water-fertilizer all-in-one machine. The machine comprises a tank body, wherein an upper bin opening, a lower bin opening and a water fertilizer inlet are formed in the tank body; the water fertilizer inlet is respectively communicated with a fertilizer inlet pipe and a water inlet pipe; the upper bin opening is used for placement of filter screens and filter elements, and the lower bin opening is used for placement of drainage pipes; the water-fertilizer inlet is formed in the upper end of the side face of the tank body, so that an air pressure bin is formed in the upper part in the tank body. The water-fertilizer all-in-one machine has the advantages that, when water and fertilizer are mixed for irrigation, pressure is smooth, flow is kept to be uniform, and the tank body can be backwashed, so that massive water-fertilizer and impurities are prevented from staying inside the tank body, blockage for filter elements, filter screens and other parts inside the tank body can be reduced, and the irrigation effect is improved.

Owner:山东神针农业科技有限公司

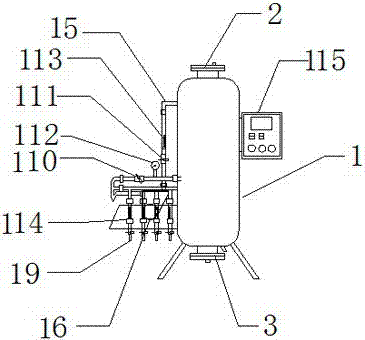

Output water pressurizing device of overflowing settling tank

ActiveCN103801112AConsistent trafficAvoid cavitationLiquid separation auxillary apparatusDewatering/demulsification with mechanical meansExhaust valveCavitation

The invention discloses an output water pressurizing device of an overflowing settling tank, which is designed to pressurize output water from an overflowing settling tank. The output water pressurizing device of the overflowing settling tank is characterized in that the overflowing settling tank is connected with the upper part of a closed water tank through a high-level water tank; the top of the closed water tank is connected with a combined air vent valve and a water pressure sensor; the lower part of the closed water tank is connected with a water pump water suction pipe; the bottom of the closed water tank is connected with an emptying valve; a water output end of the water pump water suction pipe is connected and communicated with a water pump of a control cabinet, a check valve, an electric flow adjustment valve and a de-oiling tank. The pressurizing device is capable of automatically turning on and off the water pump according to pressure variation of the close water tank, and continuously adjusting the opening degree of the electric flow adjustment valve, so that the flow of output water of the overflowing settling tank and the flow of the water pump can be consistent, and the system can run continuously and safely; a water inlet pipe of the water tank and the water pump water suction pipe are arranged inside the closed water tank in an upper input and lower output manner, so that air in output water of the high-level water tank can be sufficiently separated out inside the tank and removed. Therefore, the cavitation phenomenon can be avoided. The pressurizing device uses an airtight method to pressurize the overflowing settling tank to output water, and has the advantages of good water supply continuity and high security property.

Owner:PETROCHINA CO LTD

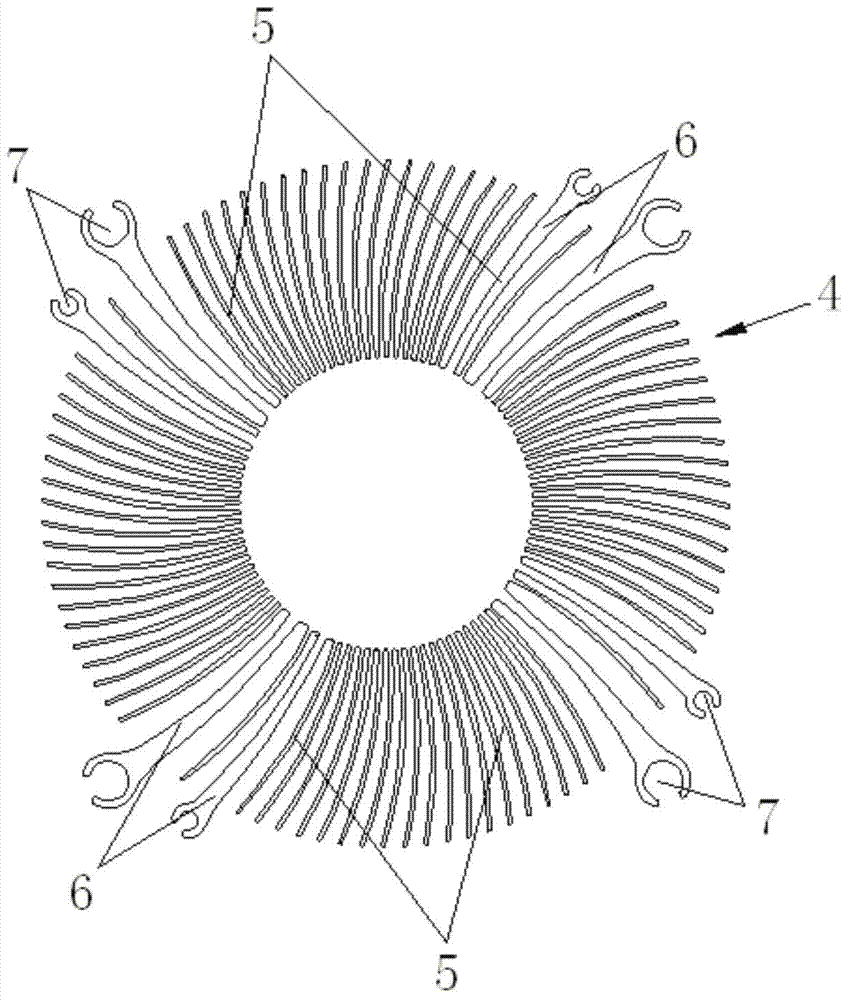

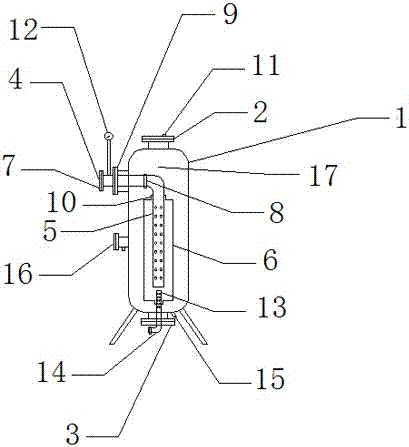

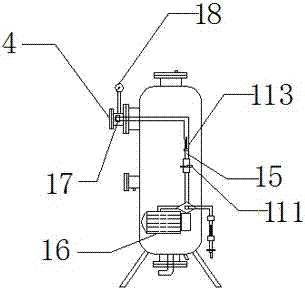

Devolatilization device and SAN (Styrene Acrylonitrile) resin devolatilization process

ActiveCN113304709AAvoid interferenceLarge film forming areaChemical/physical/physico-chemical processesFeed devicesPolymer scienceAcrylonitrile

The invention discloses a devolatilization device and an SAN resin devolatilization process. A material distributor is arranged at a material inlet of the devolatilization device, a plurality of holes are formed in the material distributor, flow guide wires are arranged at the holes, and barbs are arranged on the flow guide wires. According to the devolatilization process, the two-stage series devolatilization device is adopted for removing volatile components, the devolatilization device is adopted for devolatilization, the film forming property of the material is good, the volatile component content of the obtained material is small, and the devolatilization efficiency is high.

Owner:WANHUA CHEM (SICHUAN) CO LTD +1

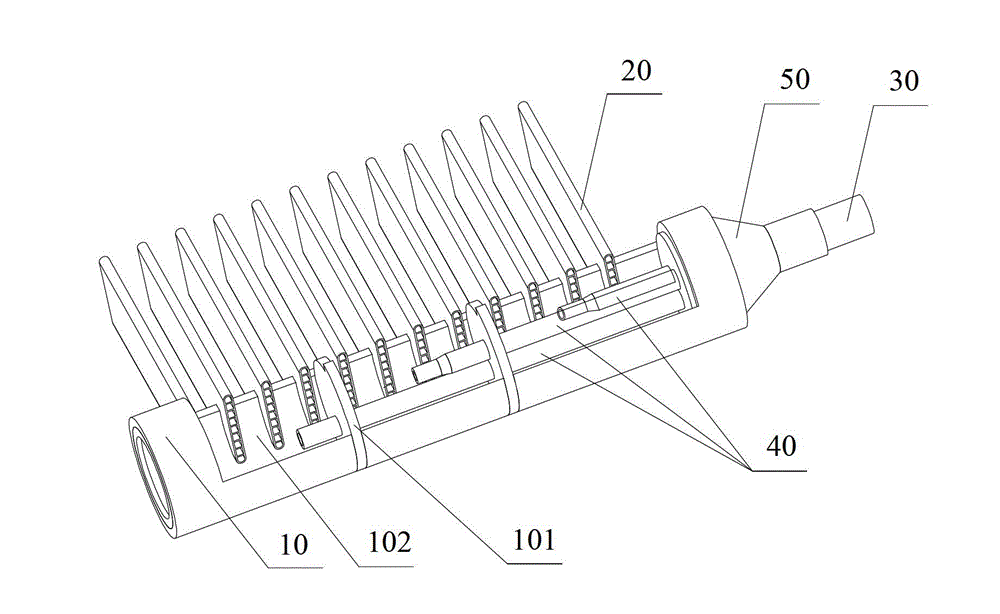

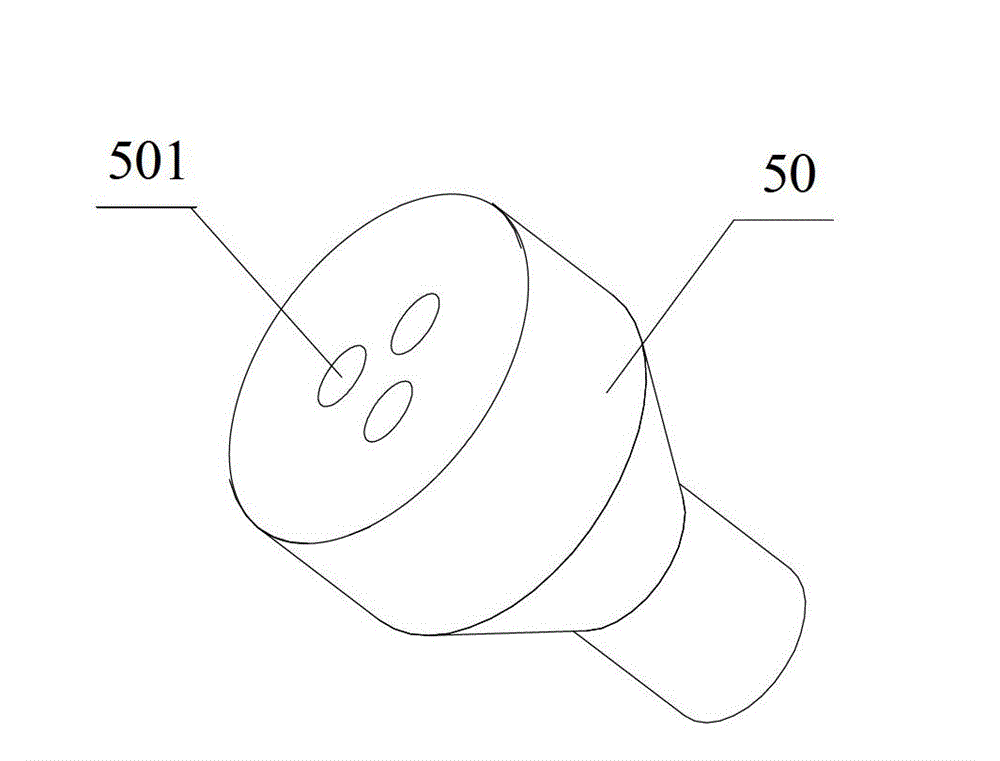

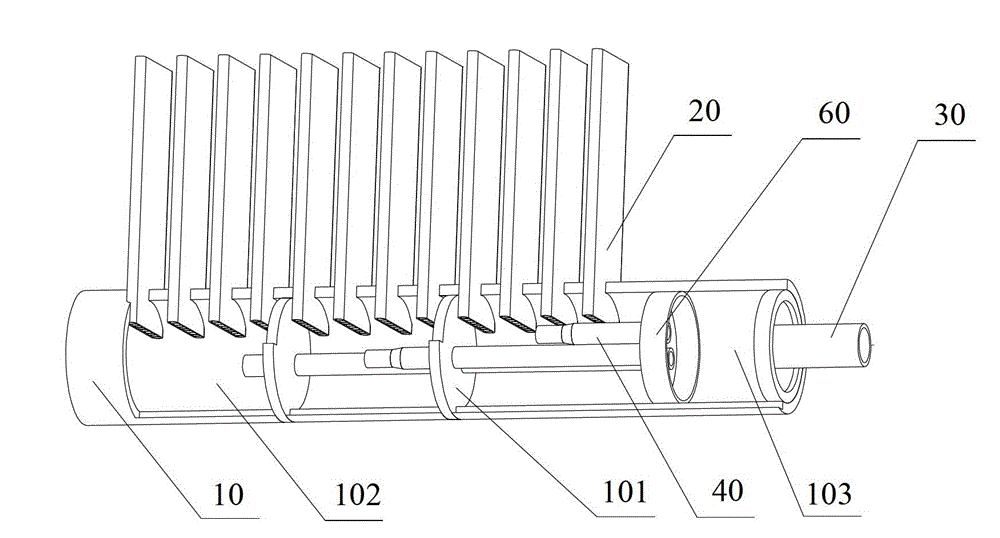

Screw tap with self-lubricating cooling structure

ActiveCN109352099AImprove cooling effectEnsure direct actionThread cutting toolsEngineering3D printing

The invention particularly relates to a screw tap with a self-lubricating cooling structure. The screw tap comprises a screw tap handle, a screw tap head and a cooling lubricating fluid main runner, the cooling lubricating fluid main runner is axially arranged in the screw tap handle and the screw tap head, and further comprises a cooling lubricating liquid auxiliary flow channel, the cooling lubricating liquid auxiliary flow channel is arranged in the screw tap head, a plurality of groups of cooling lubricating liquid are sequentially arranged along the flow direction of the cooling lubricating liquid in the cooling lubricating fluid main flow channel, each group of cooling lubricating fluid sub-flow channels is composed of a plurality of branch cooling and lubricating flow channels whichare uniformly distributed in the circumferential direction, one end of each branch cooling lubricating flow channel is communicated with the cooling lubricating liquid main flow channel, the other end of each branch cooling lubricating flow channel faces the tapping area, the branch cooling and lubricating flow channel is arc-shaped, the screw tap handle, the screw tap head and the cooling lubricating fluid main flow channel, and the cooling and lubricating fluid sub-runners are processed and formed in a 3D printing mode. According to the screw tap, the tapping area can be directly and uniformly cooled, and the cooling cost is low.

Owner:XI AN JIAOTONG UNIV +1

A combined laminar fluid distribution and mixing device and its application

ActiveCN103977720BFacilitates high-precision machiningExpand the wetted perimeterFlow mixersChemical/physical/physico-chemical processesChemical industryChemical reaction

The invention relates to a mixing device in the chemical industry, and in particular to a combined type layered fluid partition mixing device and its application. The fluid partition mixing device has a layered structure, is respectively provided inside with independent resident chambers for containing different fluids and a mixed chamber for containing the mixed fluid, each resident chamber is respectively communicated with the mixed chamber through a layered partition channel, and the layered partition channels with different fluids passing through are arranged independently and alternately from top to bottom, and different fluids in the resident chambers outflow respectively through the corresponding layered partition channels, and the outflow fluids are arranged alternately in layers, and mixed in the mixing chamber and outflow; and the fluid partition mixing device can be used for liquid-liquid mixing, liquid-gas mixing or gas-gas mixing. The mixing device of the invention is simple for processing and convenient for maintenance, and is mainly used for rapid mass transfer, heat transfer and polymerization, nitration, sulfonation, esterification, diazotization, coupling, acid-base neutralization and other various chemical reactions.

Owner:中国中化股份有限公司 +1

Multifunctional stuffing division system

ActiveCN106720002AIncrease the lengthSame trafficFood shapingDough processingEngineeringMaterial storage

The invention discloses a multifunctional stuffing division system and belongs to the technical field of food processing. The multifunctional stuffing division system comprises a material storage inner barrel provided with a material storage cavity, a masher capable of working in a whole-length range of the material storage cavity, a sealing outer barrel which sleeves the outer surface of the material storage inner barrel, and a spiral material storage channel arranged between the material storage inner barrel and the sealing outer barrel; a barrel wall of the material storage inner barrel is provided with a plurality of stuffing discharging holes for communicating the spiral material storage channel with the material storage cavity; and the multifunctional stuffing division system further comprises a splitting mechanism. According to the multifunctional stuffing division system, a stuffing body is divided into stuffing flows with fixed section areas through the spiral material storage channel, and flow speeds of the stuffing flows are the same when extruding force effects in the material storage cavity are the same, so that the flows are the same; on the basis, the splitting mechanism is used for splitting accurately, so that the weight of each part of the stuffing body is the same; and finally, accurate stuffing division is realized. Meanwhile, the spiral material storage channel is set into a spiral structure and the length of the channel can be increased, so that a material storage capacity is enlarged, the equipment volume is easily reduced and the manufacturing cost is reduced.

Owner:CHONGQING NIANJI FOOD

Novel stuffing filling equipment

ActiveCN106622518ASame weightThe same extrusion force makes the flow rate of stuffing flow consistentFood coatingFood shapingEngineeringMechanical engineering

The invention discloses novel stuffing filling equipment and belongs to the technical field of food processing. The novel stuffing filling equipment comprises a machine frame, a conveying belt, a mashing and stuffing dividing integrated system and a stuffing filling system. The mashing and stuffing dividing integrated system comprises a storage inner cylinder, a masher, a sealing outer cylinder and a spiral storage channel, wherein the storage inner cylinder is provided with a storage cavity, the masher can work within the full-length range of the storage cavity, the outer surface of the storage inner cylinder is sleeved with the sealing outer cylinder, and the spiral storage channel is arranged between the storage inner cylinder and the sealing outer cylinder. The cylinder wall of the storage inner cylinder is provided with a plurality of stuffing outlets which communicate with the spiral storage channel and the storage cavity. Through the spiral storage channel, stuffing is divided into stuffing flows with a fixed sectional area, the flow speeds of the stuffing flows are made to be consistent under the same extrusion force in the storage cavity, and accordingly the effect that the flows are identical is ensured; and on that basis, the weights of all stuffing bodies are completely consistent through precise splitting of a splitting mechanism, and finally precise stuffing dividing is achieved.

Owner:CHONGQING NIANJI FOOD

Medical sewage treatment device

ActiveCN111359287AConsistent trafficHigh trafficStationary filtering element filtersGear wheelSewage treatment

The invention relates to a medical sewage treatment device. The medical sewage treatment device comprises a filtering water box, wherein a filter screen is movably assembled in the filtering water boxalong an up-down direction in a guiding manner; a floating part is fixedly arranged on the filter screen; a vertically-arranged transmission rod is arranged at the upper side of the filter screen; atransmission rack is arranged on the transmission rod; a filter screen travel switch and a sundry outlet are arranged on the side wall of the filtering water box; an impact block is connected with andarranged at the inner side of the top part of the filtering water box through a vertically-arranged pressure spring; a rotating shaft is rotatably assembled at the outer side of the top part of the filtering water box; a winding drum is connected with and arranged on the rotating shaft in a sleeving manner; a pull rope connected with the impact block is wound on the winding drum; a winding drum clutch is arranged at one side of the winding drum on the rotating shaft; a gear mechanism in transmission connection with the transmission rack is connected with and arranged on the rotating shaft; the medical sewage treatment device further comprises a controller in control connection with the winding drum clutch; and the controller is in signal connection with the filter screen travel switch. The medical sewage treatment device provided by the invention can conveniently clean sundries at one side of the filter screen.

Owner:HENAN CANCER HOSPITAL

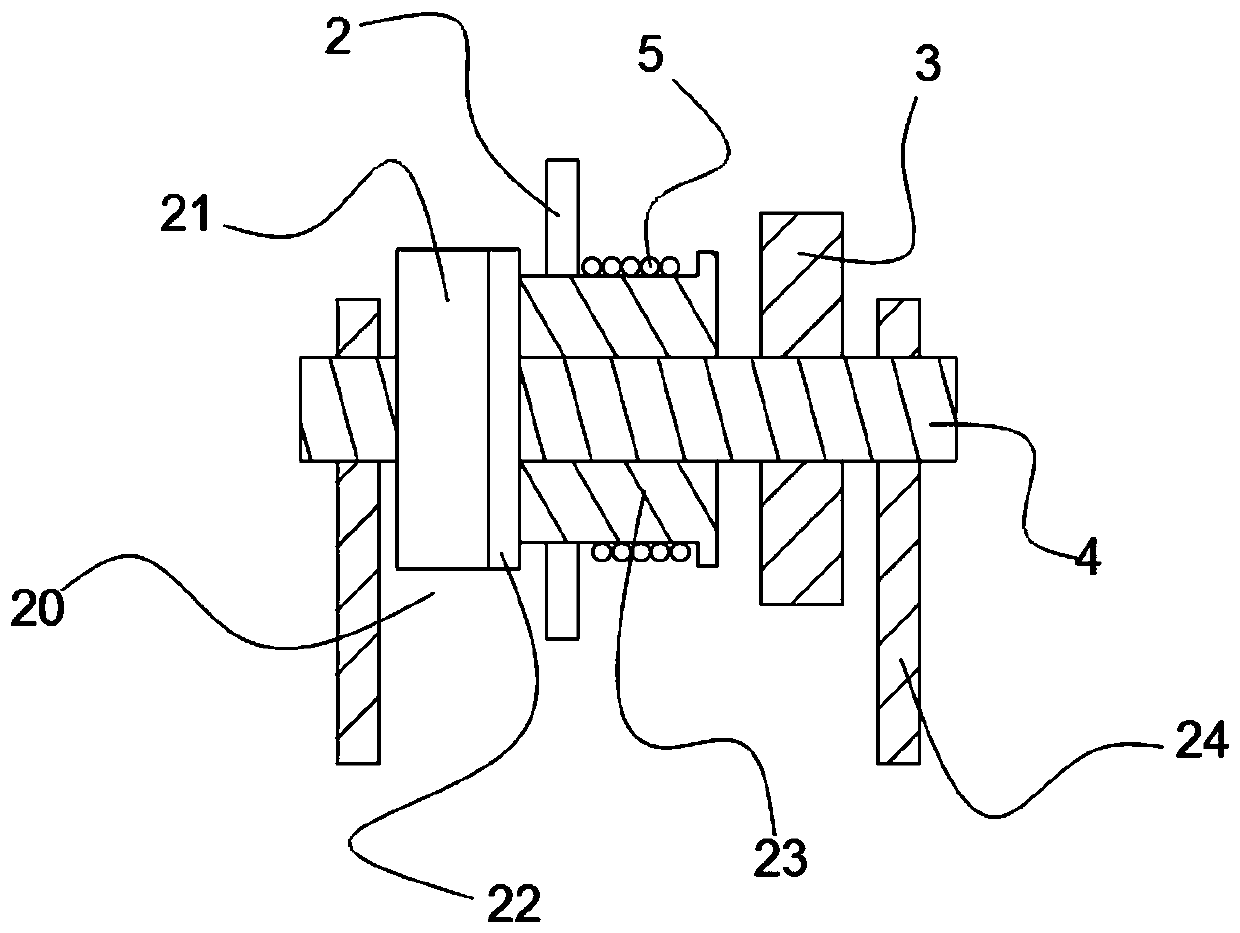

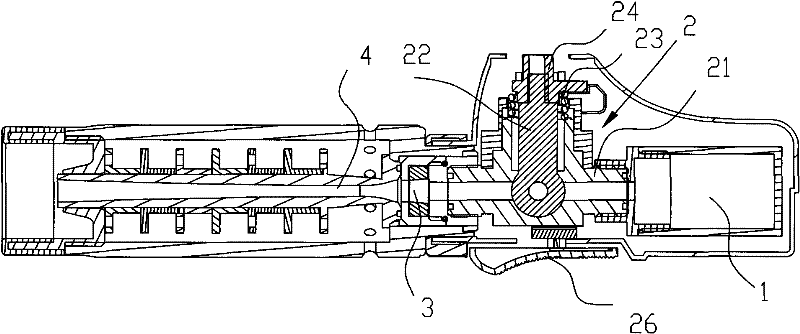

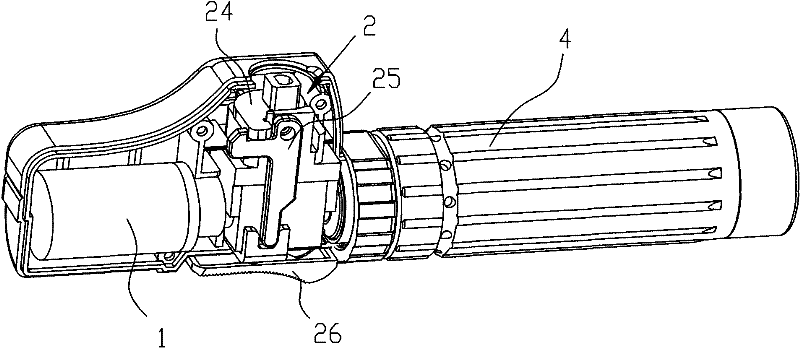

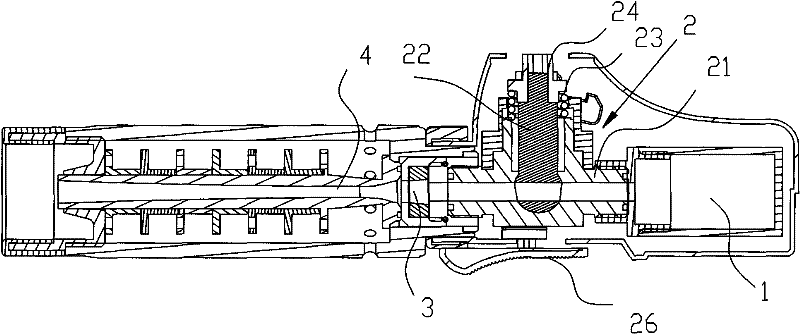

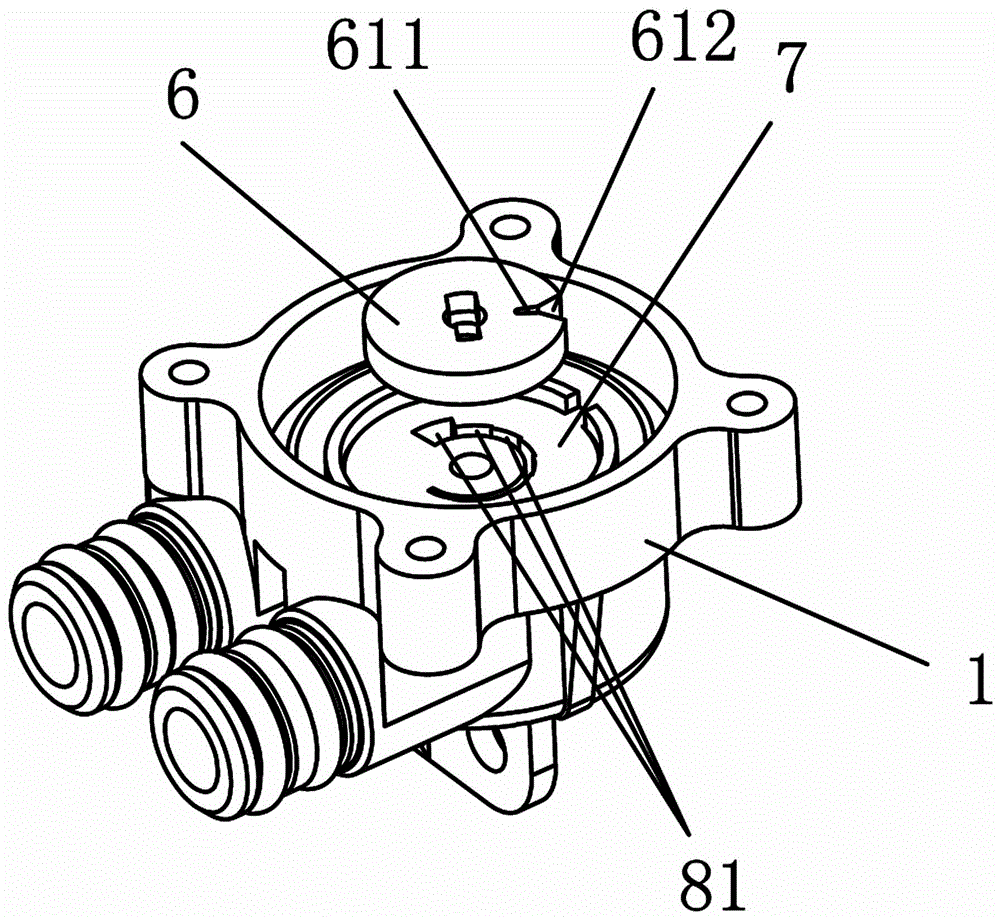

Needleless powder injection medicament administration device

The invention discloses a needleless powder injection medicament administration device. The device comprises an air bottle, a controlled release mechanism, a medicament-carrying box and an airflow spraying tube, which are connected in sequence, wherein the controlled release mechanism is a ball valve mechanism; and the ball valve mechanism further comprises a valve body connected with the air bottle and the medicament-carrying box, the valve body is provided with a valve core used for connecting or disconnecting the air bottle and the medicament-carrying box, and the valve body is also provided with an elastic mechanism driving the valve core to rotate. Compared with the conventional piston column-shaped valve, the device has the advantages that: the ball valve mechanism has higher air tightness, so that the air tightness of the whole system is greatly improved, the injection failure caused by air leakage can be avoided to the maximum extent, and the service life of an injector is prolonged; and because the valve core of the ball valve mechanism is big in diameter and air-discharging quantity, the air-discharging process can be completed in the shortest time, and the air-discharging effect of the ball valve mechanism is far better than that of the piston column-shaped valve.

Owner:THE FIFTH MEDICAL CENT OF CHINESE PLA GENERAL HOSPITAL

Linear water curtain device

The invention relates to a linear water curtain device, comprising a water tank, wherein the bottom of the water tank is provided with a straight slit; a linear water outlet and a high mixed edge are respectively fixed at the two sides below the straight slit; the high mixed edge and the linear water outlet are respectively made of angle iron and arranged back to back; the bottom margin of the high mixed edge is higher than the bottom margin of the linear water outlet; a plurality of quantitative tubes are arranged between the linear water outlet and the high mixed edge; the tops of the quantitative tubes are communicated with the interior of the water tank; and the bottoms of the quantitative tubes are higher than the bottom margin of the high mixed edge. According to the invention, the linear water outlet and the high mixed edge have effect of reinforcing the straight slit of the water tank bottom, and the quantitative tubes can guarantee the uniform distance between the linear water outlet and the high mixed edge and guarantee the consistent thickness of the quenching medium water curtain; and a quantification mixing zone formed by the quantitative tubes and the linear water outlet, the linear water outlet and the high mixed edge can allow the quenching medium to be mixed uniformly and make the flow consistent.

Owner:无锡信德隆工业炉有限公司

Linear water curtain device

The invention relates to a linear water curtain device, comprising a water tank, wherein the bottom of the water tank is provided with a straight slit; a linear water outlet and a high mixed edge are respectively fixed at the two sides below the straight slit; the high mixed edge and the linear water outlet are respectively made of angle iron and arranged back to back; the bottom margin of the high mixed edge is higher than the bottom margin of the linear water outlet; a plurality of quantitative tubes are arranged between the linear water outlet and the high mixed edge; the tops of the quantitative tubes are communicated with the interior of the water tank; and the bottoms of the quantitative tubes are higher than the bottom margin of the high mixed edge. According to the invention, the linear water outlet and the high mixed edge have effect of reinforcing the straight slit of the water tank bottom, and the quantitative tubes can guarantee the uniform distance between the linear water outlet and the high mixed edge and guarantee the consistent thickness of the quenching medium water curtain; and a quantification mixing zone formed by the quantitative tubes and the linear water outlet, the linear water outlet and the high mixed edge can allow the quenching medium to be mixed uniformly and make the flow consistent.

Owner:无锡信德隆工业炉有限公司

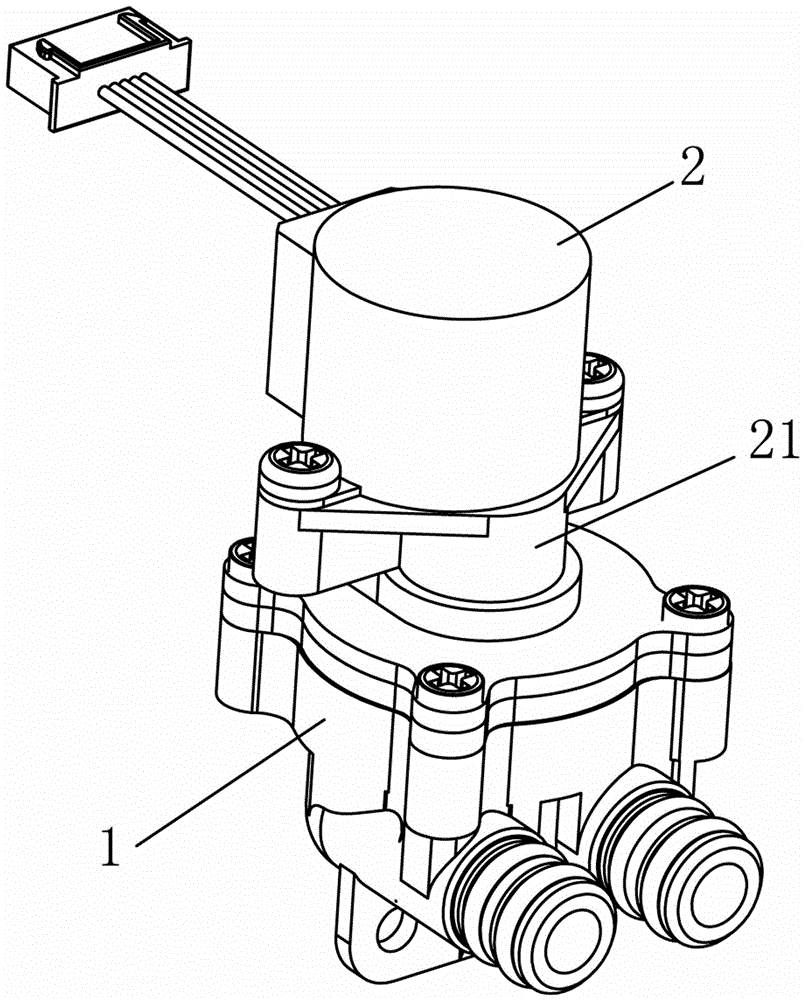

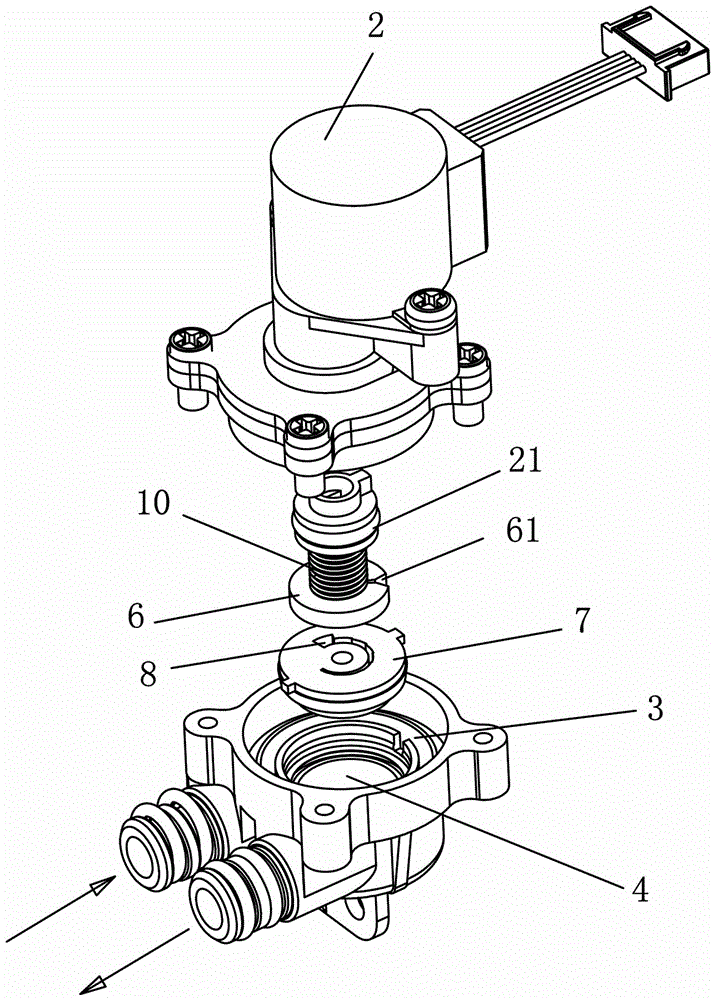

Flow regulating valve

ActiveCN105972239AOvercoming the deficiency of imprecise controlSimple structureSlide valveWater flowControl channel

The invention discloses a flow regulating valve which comprises a valve body and a valve element driving mechanism. A water inlet pipeline, a water outlet pipeline and a valve element assembly connected with the water inlet pipeline and the water outlet pipeline are arranged on the valve body. The flow regulating valve is characterized in that the valve element assembly comprises a first valve element and a second valve element. An opening is formed in the first valve element, and a water through hole is formed in the second valve element. The water through hole comprises at least two water through hole sections communicating with one another. Every two adjacent water through hole sections are different in size. The opening of the first valve element and the water through hole of the second valve element communicate with the water inlet pipe and the water outlet pipe correspondingly. The face, with the opening, of the first valve element is attached to the face, with the water through hole, of the second valve element. The valve element driving mechanism drives the first valve element or the second valve element to rotate so that an overlapped interval between the opening of the first valve element and the water through hole of the second valve element forms a water flow control channel communicating with the water inlet pipe and the water outlet pipe. The flow regulating valve has the advantages that flow control is accurate, and the overall structure is simple and reasonable.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

High polymer adjuvant adding device of disposal sanitary product production line

The invention discloses a macromolecule additive feeder used in product line of one-time sanitary product, with uniform feeding amount and easy operation. It is characterized in that: the outer surfaces of feeding axle and the outlet of storage hopper are distributed with herring groove; the gas inlet of blow tube is through to the gas tube of air compressor. Since said feeding axle has symmetry herring groove, the axial pushing force can be eliminated and the feeding axle can rotate stably, therefore, the fed amount is uniform; and it uses compressed air to blow material and feed material in passive pressure, to automatically add macromolecule additive in the production.

Owner:ANQING HENG CHANG MACHINERY

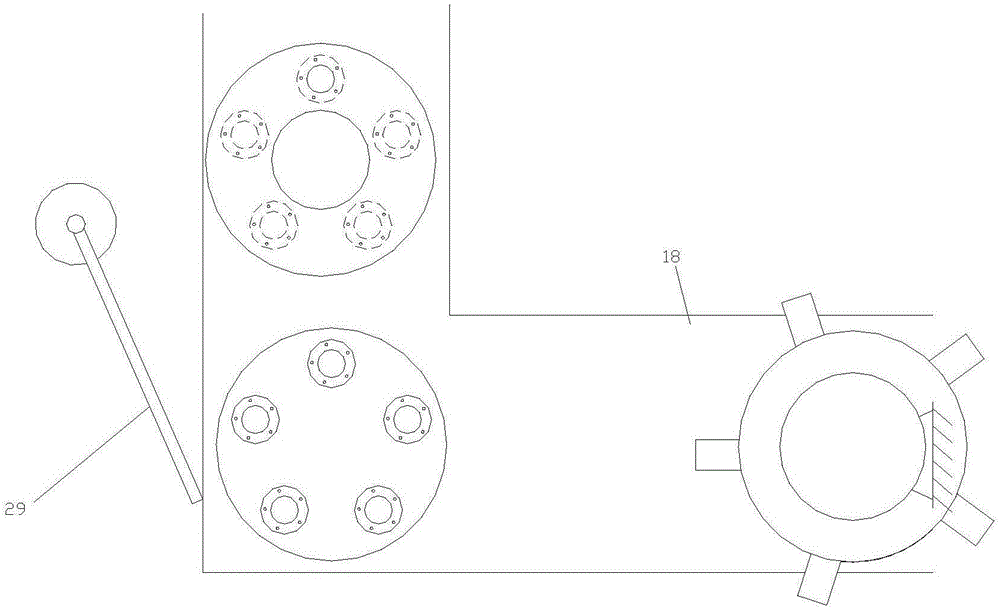

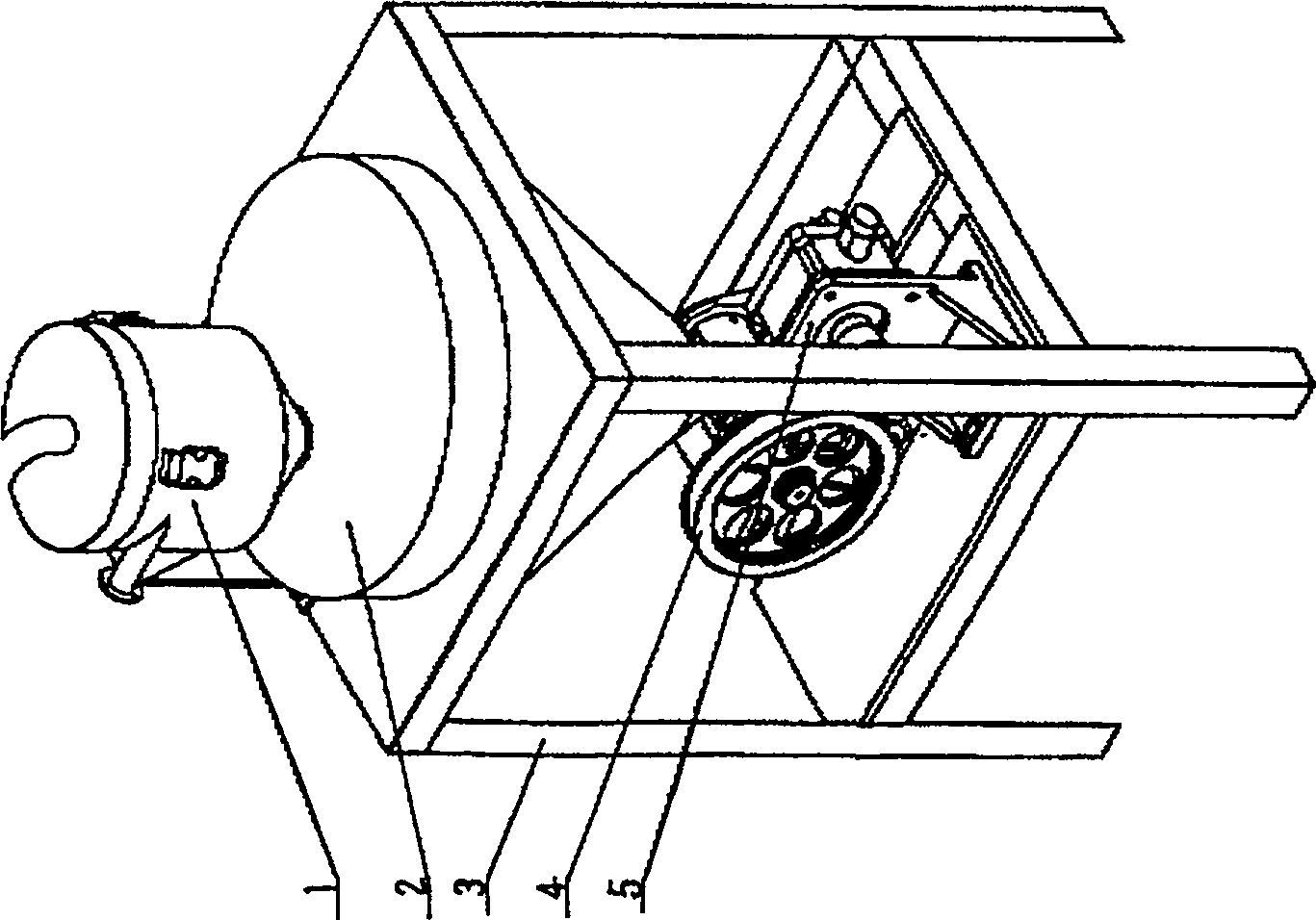

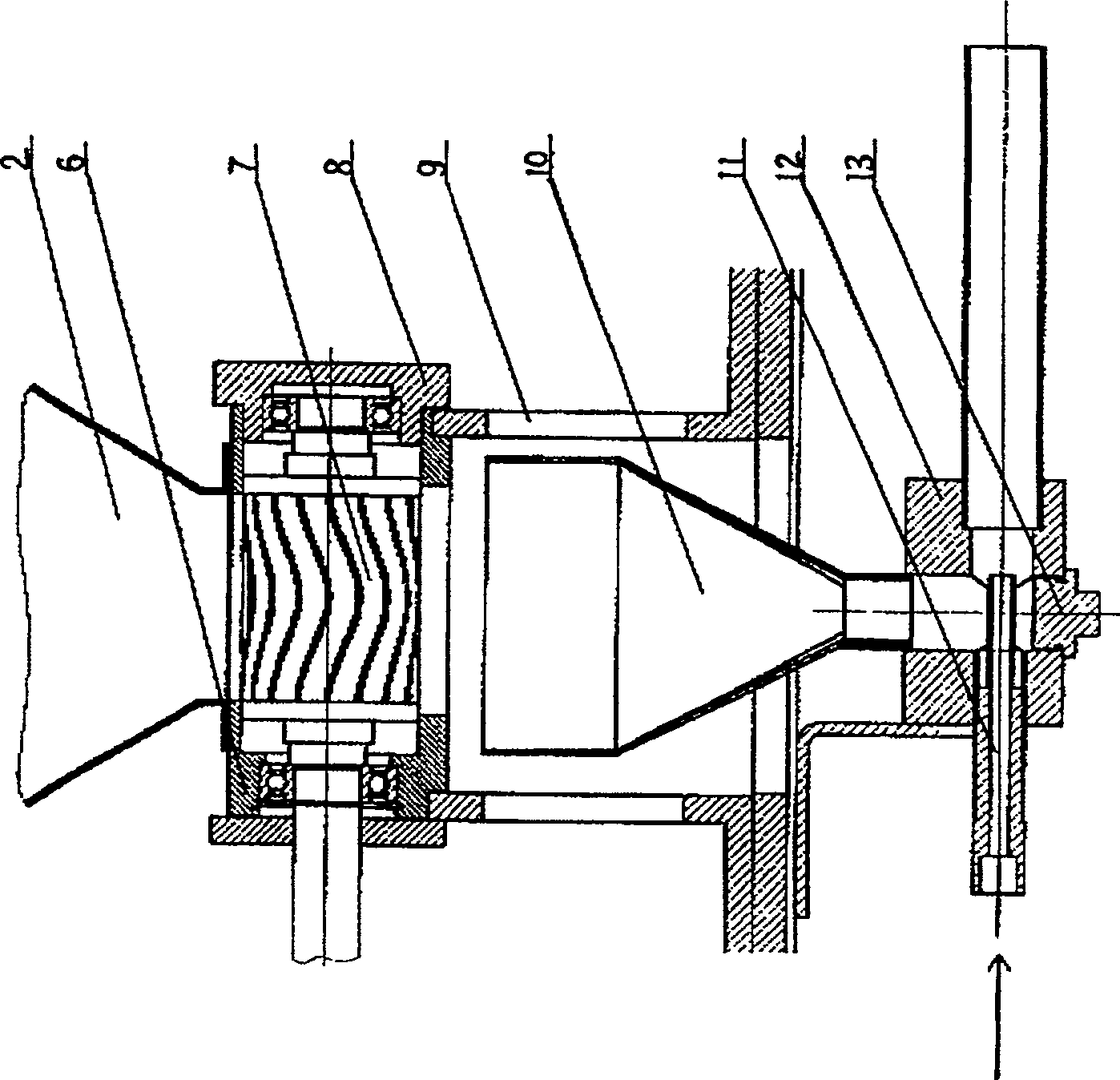

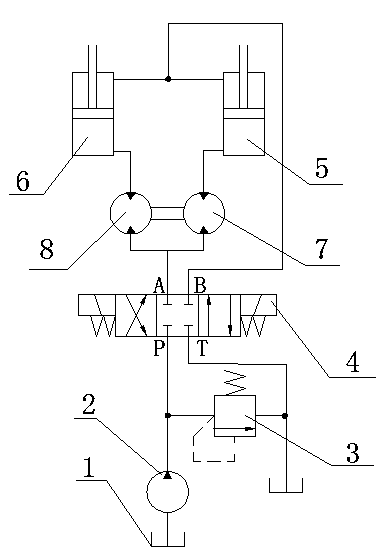

Synchronizing circuit of hydraulic motors of two-column gantry lifter

InactiveCN104196807AConsistent trafficHigh control precisionServomotor componentsServomotorsHydraulic motorHydraulic cylinder

The invention discloses a synchronizing circuit of hydraulic motors of a two-column gantry lifter and belongs to the field of hydraulic transmission. The synchronous circuit comprises an oil tank, a hydraulic pump, an overflow valve, a reversing valve, a hydraulic cylinder A, a hydraulic cylinder B, a hydraulic motor A and a hydraulic motor B. An inlet oil pipe of the hydraulic pump is connected with the oil tank, an outlet oil pipe is respectively connected with the overflow valve and the reversing valve, an oil return pipe of the overflow valve and the reversing valve is connected with the oil tank, an oil port A of the reversing valve is divided into two branches, one branch is serially connected with the hydraulic motor A and then connected with the hydraulic cylinder A, and the other branch is serially connected with the hydraulic motor B and then connected with the hydraulic cylinder B. The hydraulic motor A is fixedly connected with a rotary shaft of the hydraulic motor B. The synchronizing circuit solves the problem that during operating of the two-column gantry lifter, ascending and descending speed and displacement are less synchronous of the hydraulic cylinders, and has the advantages of simple structure, reasonableness in design and manufacturability.

Owner:芜湖高昌液压机电技术有限公司

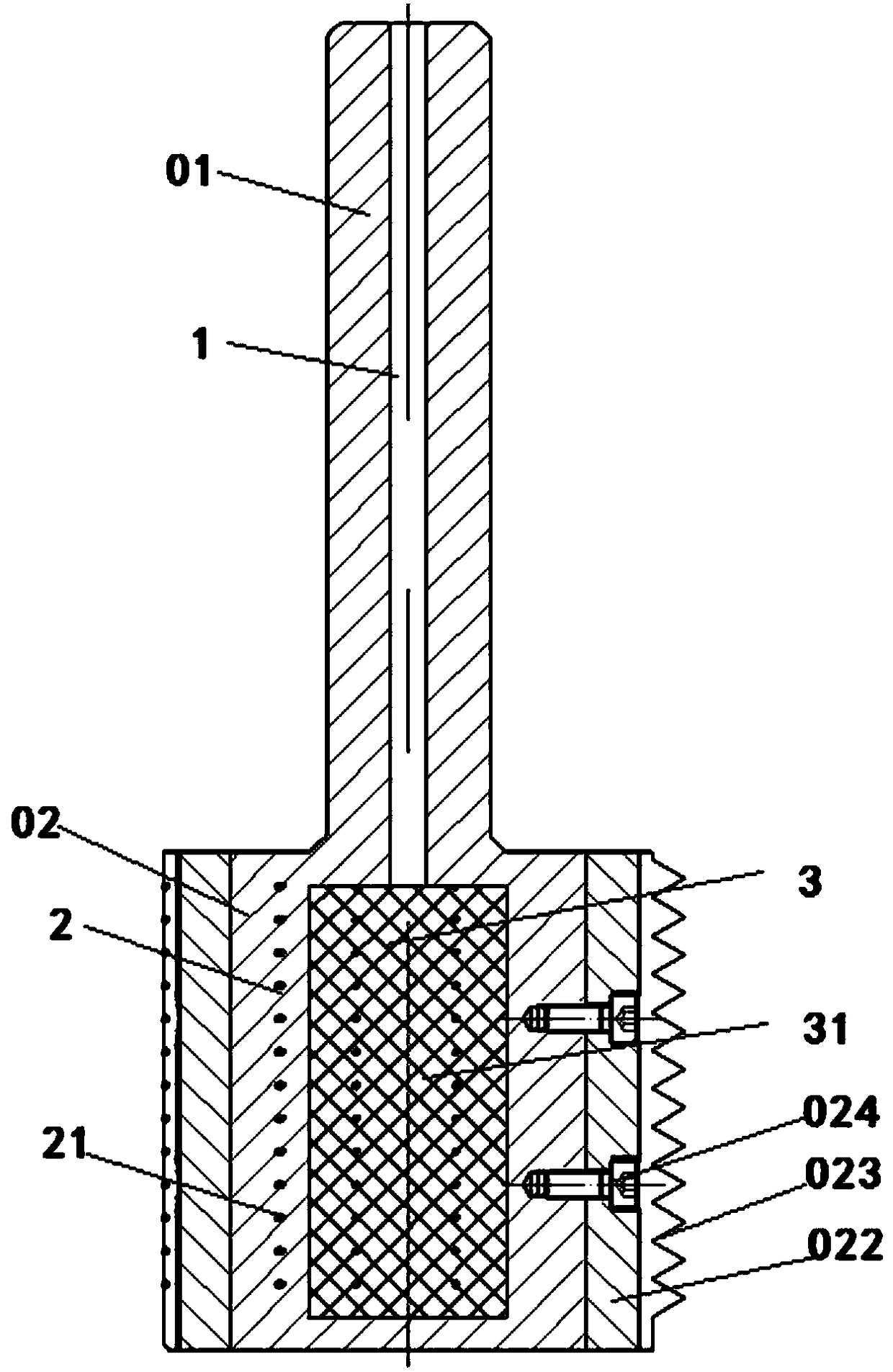

Novel denitration nozzle base, multinozzle denitration spray gun barrel and denitration spray gun

ActiveCN106345297AStable pressureConsistent trafficDispersed particle separationPulp and paper industryGun barrel

The invention relates to the technical field of waste gas treatment and particluarly relates to a novel denitration nozzle base, a multinozzle denitration spray gun barrel and a denitration spray gun. According to the denitration spray gun, a reduction agent liquid enters into the denitration spray gun through a reduction agent inlet, flows along the inner wall of a liquid pipe and is sprayed out through a through hole in the liquid pipe; compressed air enters into a first sleeve through a compressed air inlet, is sprayed out through air inlets formed in the bottom ends of the nozzle bases, is mixed and atomized into 40-80mu m fine fogdrops in cavities of the nozzle bases, and then enters into the nozzles so as to be sprayed out. Since the inner diameter of the through hole in the liquid pipe and the inner diameter of the air inlet are quite small; under a condition that 3-5 nozzle bases are arranged, the liquid is sprayed out through the through hole in the liquid pipe, gas is sprayed through the air inlets formed in the bottom ends of the nozzle bases and then is mixed in the cavities of the nozzle bases, so that the pressure in a whole gun body is basically kept stable, the flow of each nozzle of the spray gun is consistent, flow atomization is quite uniform, and the denitration efficiency is obviously improved.

Owner:SHANGHAI RYE SPRAYING INTELLIGENT SYST +1

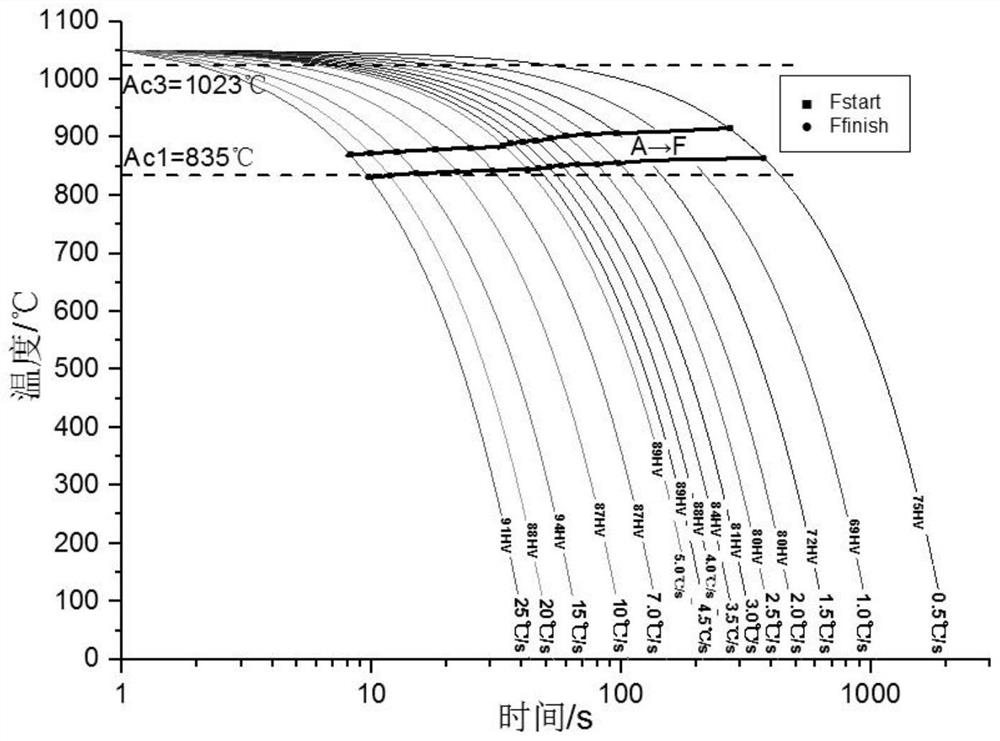

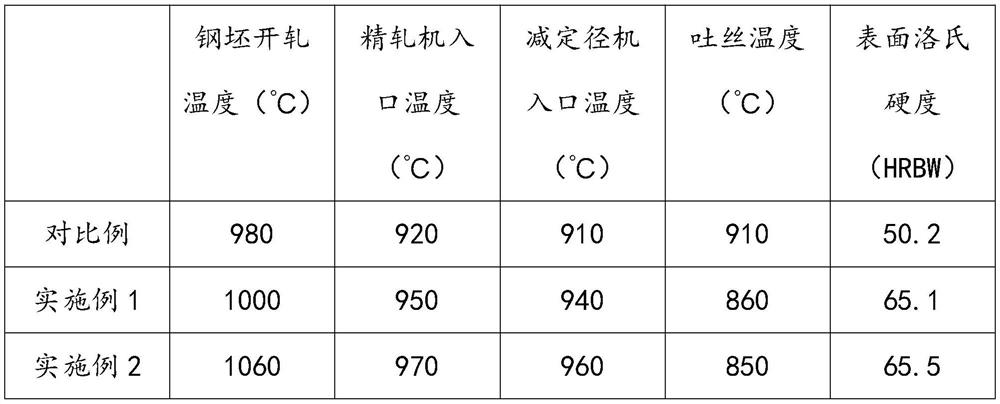

Control method for ultra-low carbon steel CH1T edge fine grains

The invention relates to a control method of ultra-low carbon steel CH1T edge fine grains. The control method of the ultra-low carbon steel CH1T edge fine grains comprises the following steps of controlling the heating temperature of a steel billet at 950 to 1120 DEG C to ensure that the steel billet is fully austenitized; and controlling the initial rolling temperature of the steel billet to be 1000 to 1060 DEG C, controlling the inlet temperature of a finishing mill to be 930 to 970 DEG C, controlling the inlet temperature of a reducing and sizing mill of a rolled piece to be 920 to 960 DEG C, and controlling the spinning temperature to be 840 to 860 DEG C. By adjusting the rolling process, rolling of a finishing mill group and a reducing and sizing mill group between two phase areas is effectively avoided, and the mixed crystal phenomenon of steel wire rods is avoided from the source, so that an ultra-low carbon steel CH1T edge fine grain structure can be stably controlled, the edge grain size reaches the 10.5 to 11.5 level, a core structure reaches the 7.5 to 8.5 level, the fine grain layer thickness reaches 700 to 1000 micrometers, the surface hardness after steel wire drawing is ensured, and customer personalization requirements are met.

Owner:SGIS SONGSHAN CO LTD

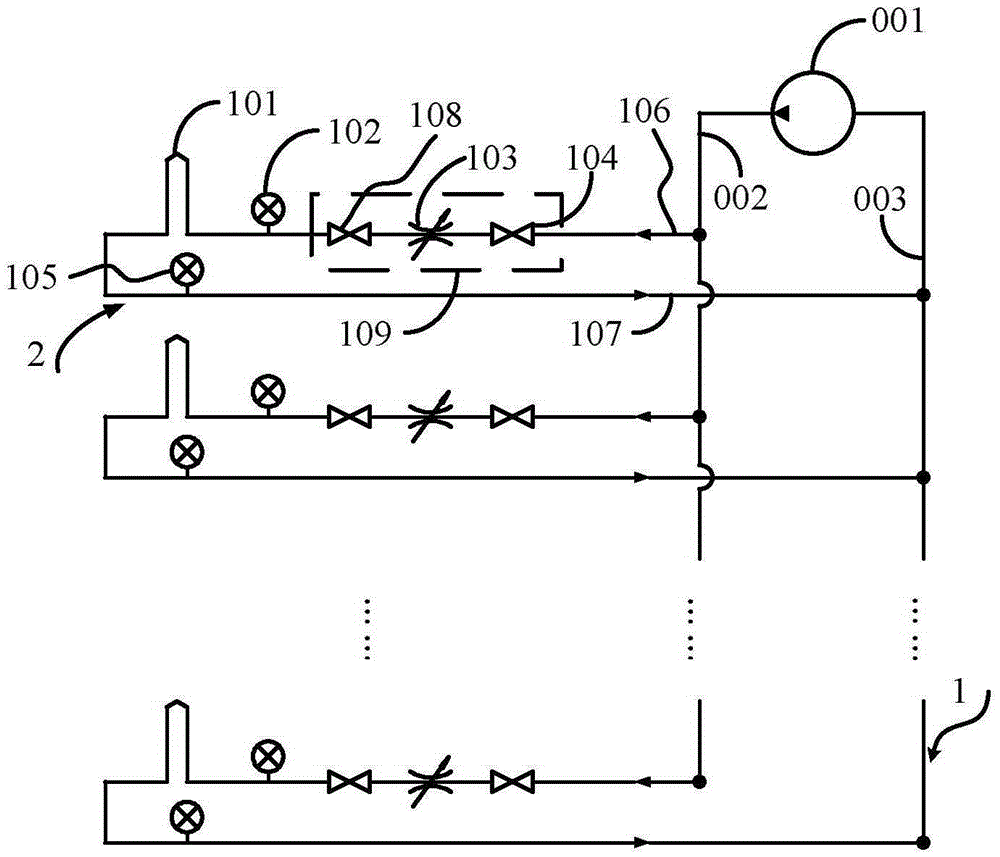

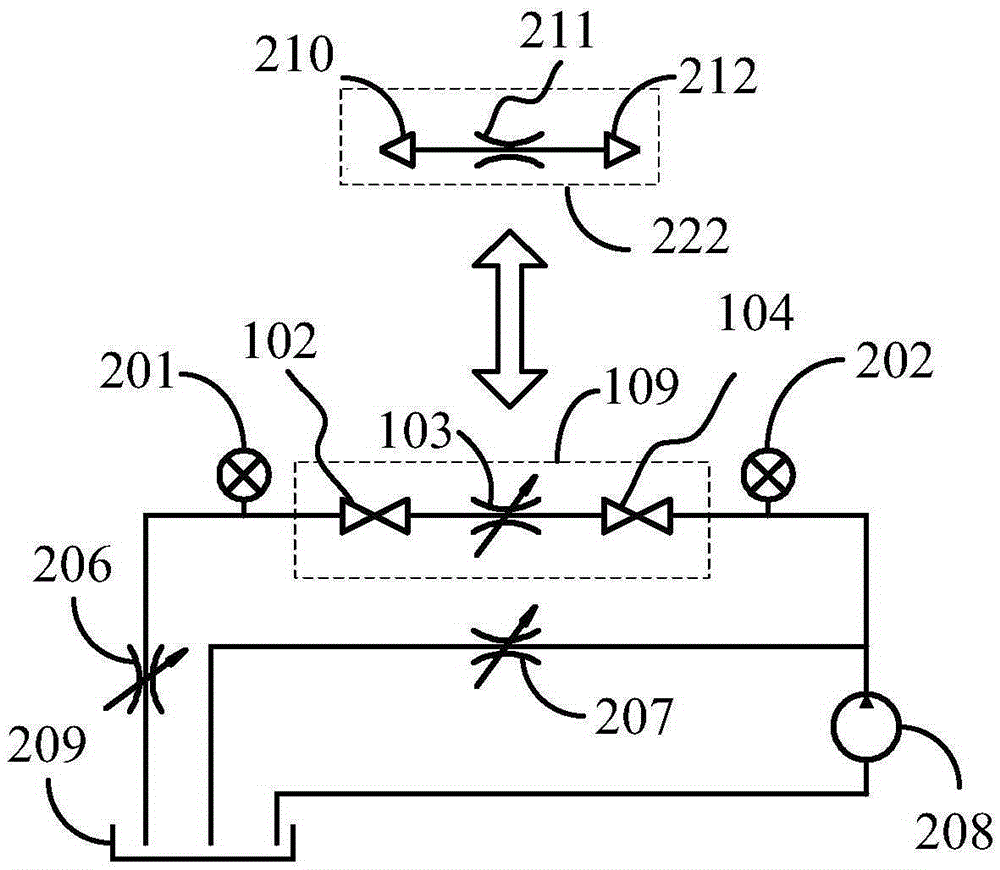

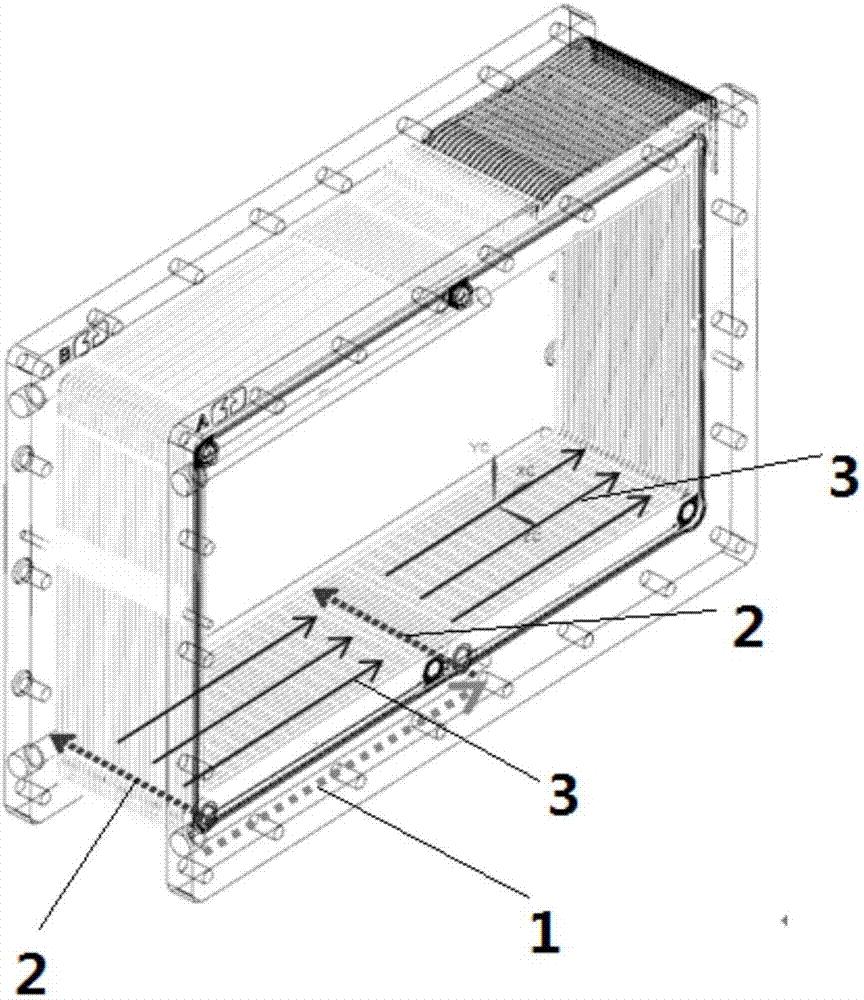

Thermal management pipeline of electric vehicle power battery, and balance method and calibration system of thermal management pipeline

The embodiment of the invention discloses a thermal management pipeline of an electric vehicle power battery and a balance method of thermal management pipeline. The thermal management pipeline comprises a cooling liquid main loop and a plurality of branch pipelines (2), wherein the plurality of branch pipelines (2) are separately connected to the cooling liquid main loop (1), each branch pipeline (2) comprises a water chamber (101), the water chamber (101) is used for cooling a corresponding battery module, a first pressure meter (102) is arranged at the entrance of the water chamber (101) of each branch pipeline (2), a second pressure meter (105) is arranged at the exit of the water chamber (101) of each branch pipeline (2), a first damping valve installation position is arranged between the entrance of each branch pipeline (2) and the entrance of each branch pipeline (2), and an adjustable damping valve assembly (109) or a fixed damping valve assembly (222) based on the adjustable damping valve assembly (109) is detachably arranged at the first damping valve installation position.

Owner:CH AUTO TECH CORP CO LTD

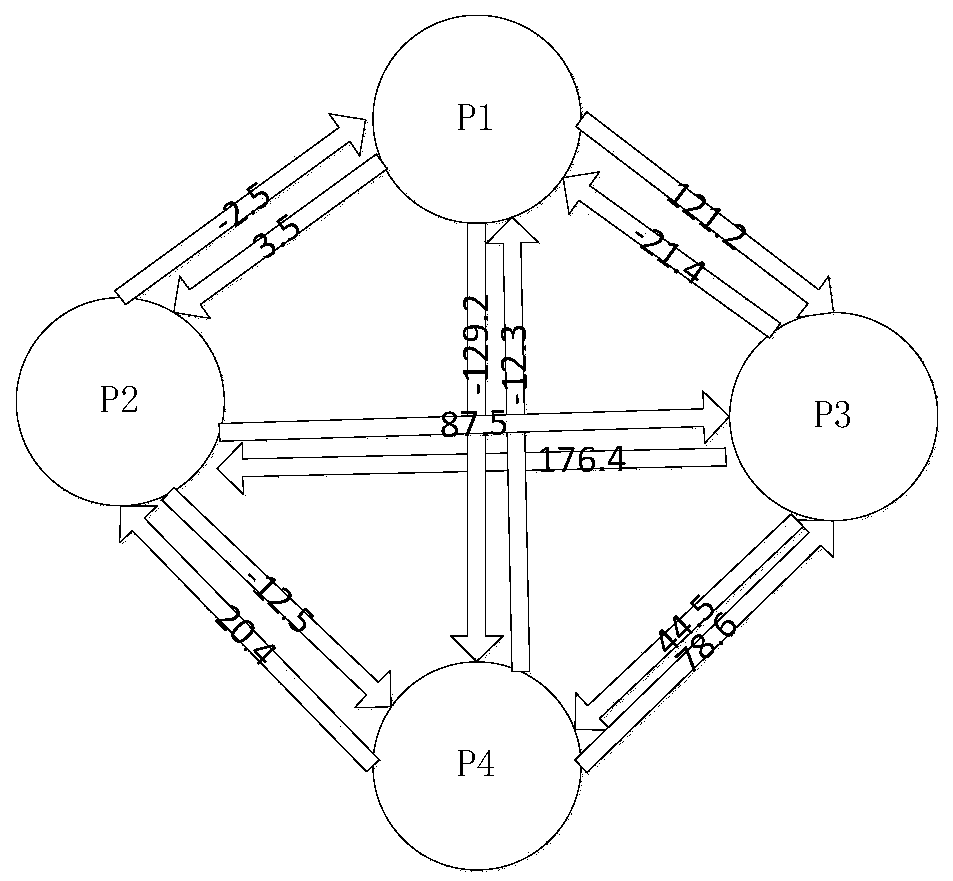

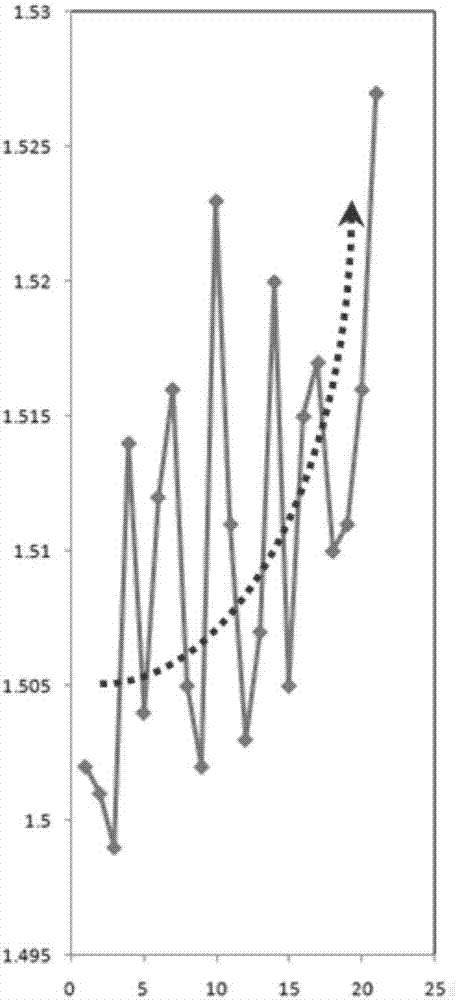

Redox flow battery electric stack and method for uniformly distributing electrolyte in each section of battery to improve battery performance

The invention discloses a redox flow battery electric stack and a method for uniformly distributing an electrolyte in each section of battery to improve battery performance. In the redox flow battery electric stack, the depth of an allocation runner of each section of battery is gradually increased from a public runner inlet, and / or the diameter of the public runner is gradually increased in an arithmetic progression manner from the public runner inlet. With the adoption of the redox flow battery electric stack, the electrolyte flow quantity flowing into each single battery is consistent, the linear speed of the electrolyte is 0.05-0.08m / s, the concentration of the electrolyte is 1.5-2mol / l, the inlet pressure of the electric stack is 0.5-1.5bar, and the running temperature of the electric stack is 30-40 DEG C. By the two methods, the electrolyte flow quantity flowing into each section of battery can be effectively maintained consistent, so that the range is reduced, the concentration range is reduced, the utilization ratio of the electrolyte is improved, and the battery efficiency is improved. By the scheme, the electrolyte is uniformly distributed on an electrode surface and flows rapidly, so that the energy efficiency of an all-vanadium redox flow battery is effectively improved, and the service lifetime of the battery is prolonged.

Owner:DALIAN RONGKE POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com