High-multiple aluminum profile extrusion die and extrusion technology

A technology for extrusion dies and aluminum profiles, applied in the field of aluminum extrusion product manufacturing, can solve the problems of high scrap rate of extrusion dies, slow temperature emission, affecting product quality, etc., and achieves ingenious design, balanced aluminum feed, Consistent effect of metal flow velocity and flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

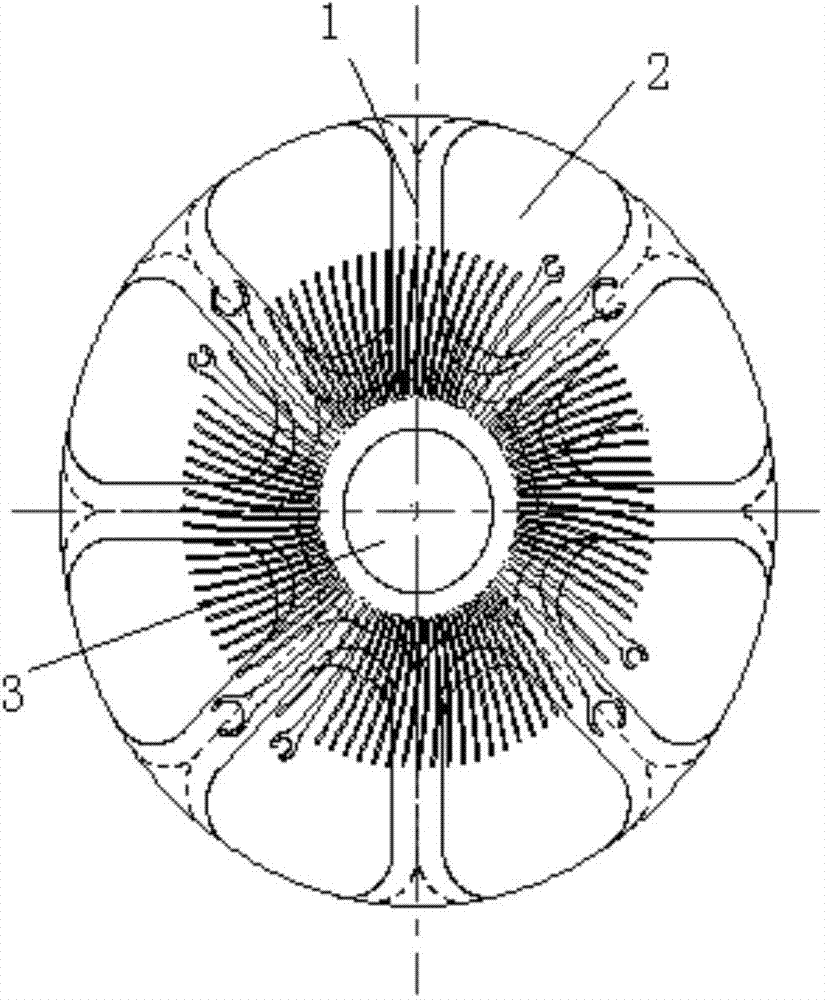

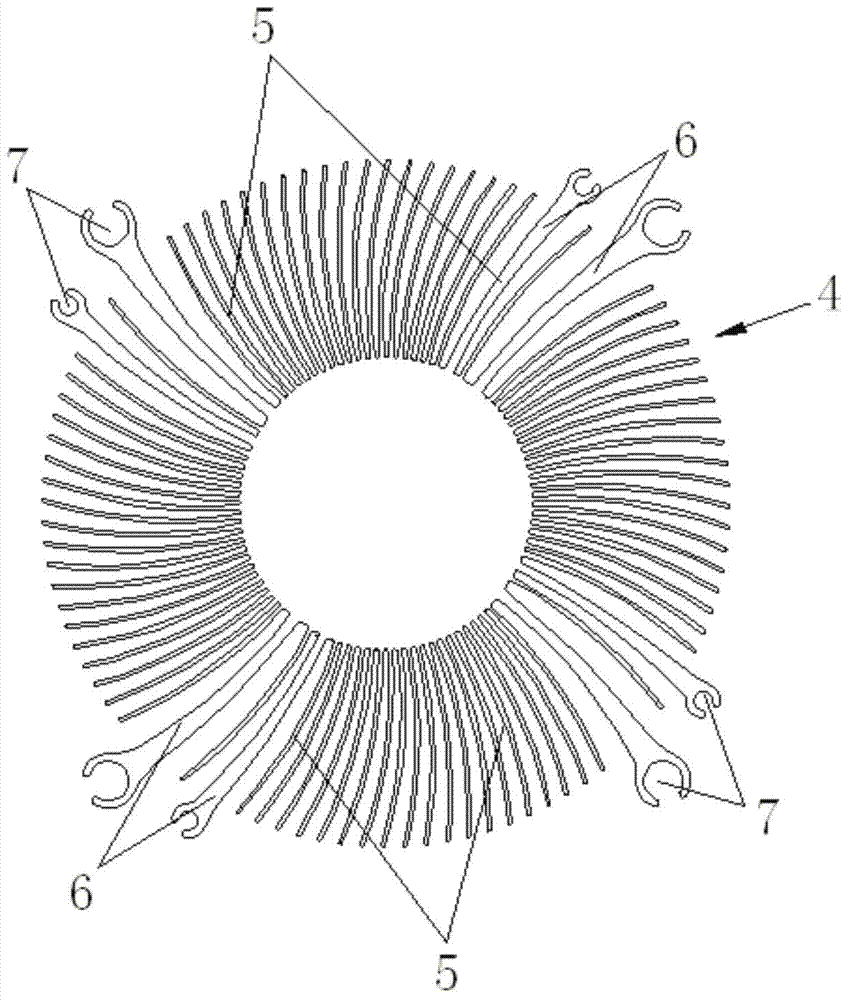

[0032] Embodiment 1: see Figure 1~2 , the high-magnification aluminum profile extrusion die provided in this embodiment includes an upper die and a lower die, and eight shunt bridges 1 are evenly distributed on the feed surface of the upper die, and the eight shunt bridges 1 are formed between 8 split holes 2, the center of the feed surface of the upper die is provided with a false split 3, the upper die is provided with a welding chamber; the feed end of the lower die is designed as a plane, and the lower die is provided with a guide A working belt 4 connected to the mouth, said working belt 4 is provided with a plurality of tooth position die holes 5 and a plurality of assembly position die holes 6 .

[0033] The plurality of tooth position die holes 5 and the plurality of assembly position die holes 6 are arranged in a spiral radial distribution at the center of the circle.

[0034] A plurality of tooth position die holes 5 on the working belt 4 are evenly distributed int...

Embodiment 2

[0053] Embodiment 2: This extrusion die can also have a plurality of shunt bridges evenly distributed on the circumference of the feeding surface of the upper die, and a plurality of shunt holes are formed between the plurality of shunt bridges, and the intersection of the shunt bridges is lower than The surrounding feed surface forms a concave surface, the diversion bridge on the feed surface and the concave surface are transitioned by a slope to form the first decompression angle, the feed port of the diversion hole on the concave surface forms the second decompression angle, and the two sides of the diversion bridge form the second decompression angle. Three decompression angles; the first, second and third decompression angles are all 90 degrees. Three decompression angles are set on the diversion surface, which effectively improves the fluidity of the metal, reduces the dead zone of metal flow, and improves the force of the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com