Flow regulating valve

A technology of flow regulating valve and valve core, which is applied in the direction of sliding valve, valve device, engine components, etc., to achieve the effect of simple structure and precise flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

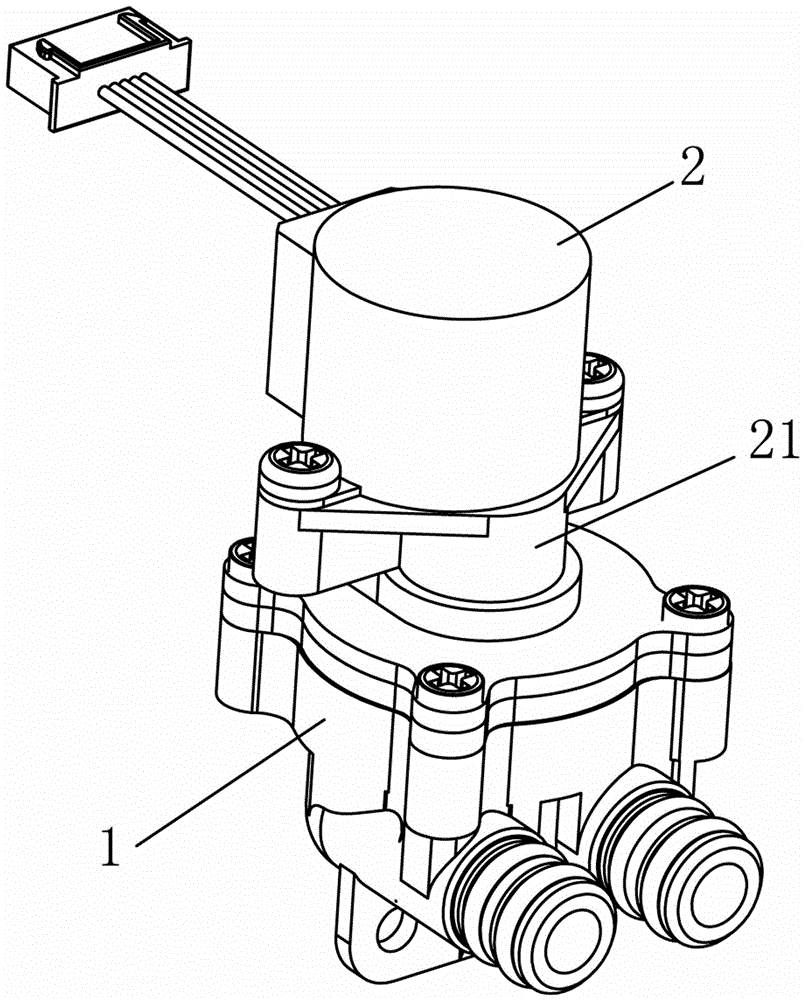

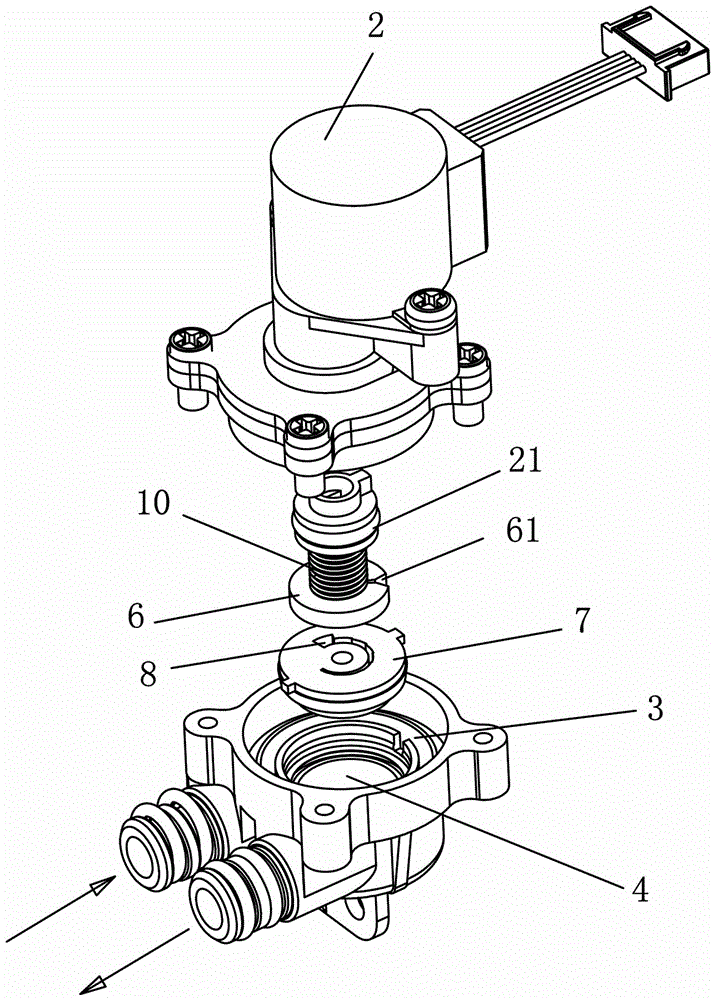

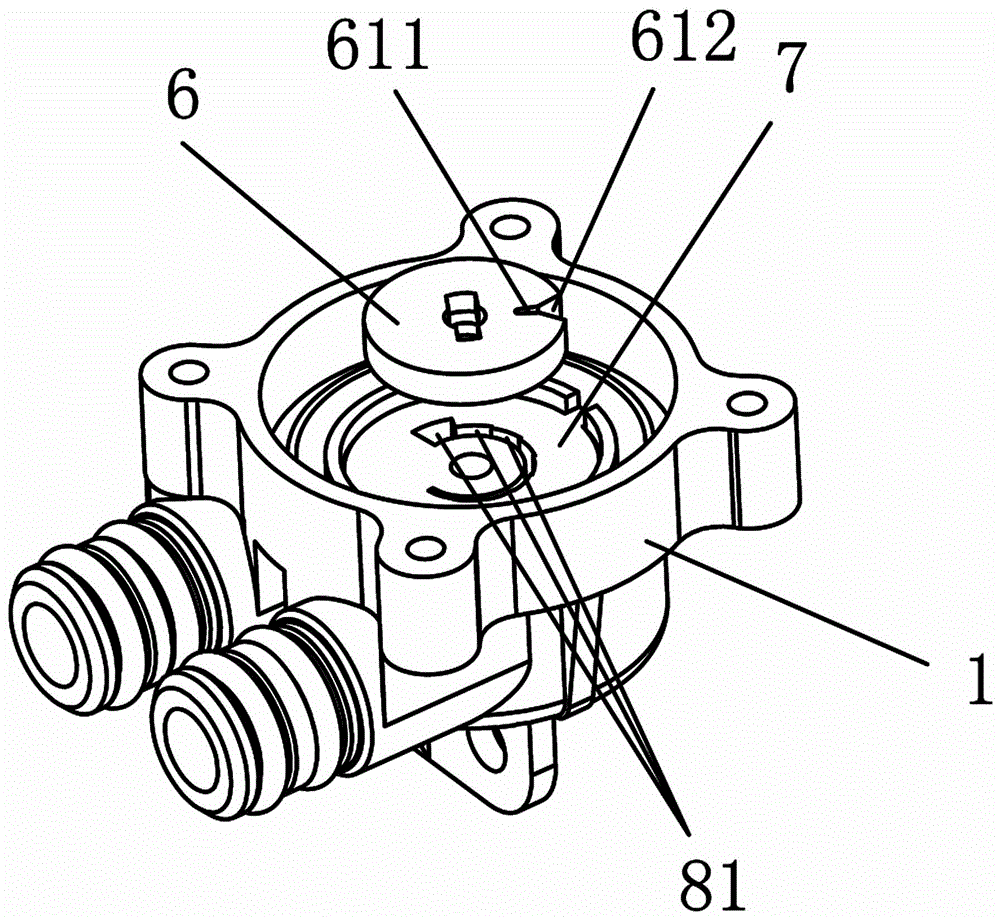

[0027] See Figure 1 to Figure 7 As shown, a flow regulating valve includes a valve body 1 and a valve core driving mechanism 2, the valve core driving mechanism 2 is a stepping motor, and the valve body 1 is provided with a water inlet pipeline 3, a water outlet pipeline 4 and a water inlet pipeline 3 and the spool assembly 5 of the water outlet pipeline 4, characterized in that the spool assembly 5 includes a first spool 6 and a second spool 7, the first spool 6 is provided with an opening 61, and the second spool 7 is provided with a water passage hole 8, the water passage hole 8 includes at least two sections of water passage hole sections 81 that communicate with each other, the sizes of the two adjacent water passage hole sections 81 are different, and the opening 61 of the first valve core It communicates with the corresponding water inlet pipeline 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com