Multipoint grid method flue gas mixed sampling device

A flue gas sampling and flue gas mixing technology, applied in sampling devices, temperature measurement of moving fluids, etc., can solve the problems of complicated operation, deviation of measurement results, long time consumption, etc., and achieve the effect of ensuring accuracy and convenient flue gas temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0019] Example.

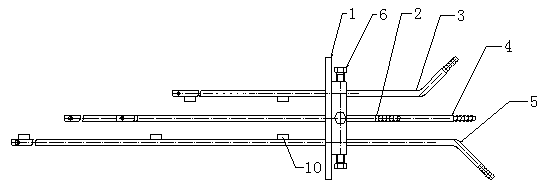

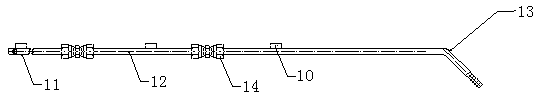

[0020] see Figure 1 to Figure 3 .

[0021] This embodiment is a multi-point grid method flue gas mixing sampling device, including a pipe base 1, multiple flue gas sampling pipes, fixing bolts 6, multiple connecting hoses 7 and a flue gas analyzer 9, all flue gas The sampling tubes are installed parallel to each other on the tube base 1, the flue gas sampling tube is fixed on the tube base 1 by the fixing bolt 6, one end of the flue gas sampling tube is connected with the connecting hose 7, and the connecting hose 7 is connected with the flue gas analyzer 9 The other end of the flue gas sampling pipe is provided with a sampling hole.

[0022] The tube base 1 is used to seal the flue gas samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com