Synchronizing circuit of hydraulic motors of two-column gantry lifter

A technology for hydraulic motors and lifts, applied in the directions of servo motors, servo motor components, mechanical equipment, etc., can solve the problems of difficulty in synchronizing the speed and displacement of ascending and descending, and achieve simple structure, reasonable design and high control precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

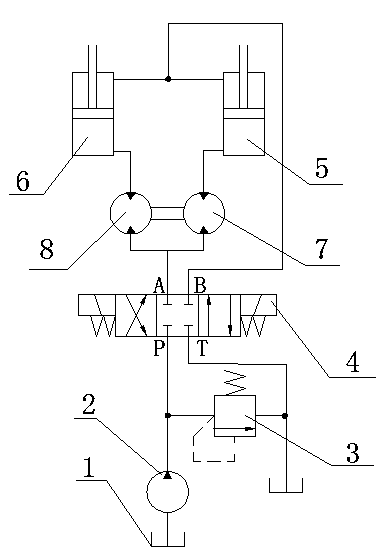

[0016] like figure 1 As shown, the hydraulic motor synchronous circuit of the two-column gantry lift includes oil tank 1, hydraulic pump 2, overflow valve 3, reversing valve 4, hydraulic cylinder A5, hydraulic cylinder B6, hydraulic motor A7, and hydraulic motor B8. The inlet oil pipe of the hydraulic pump 2 is connected to the oil tank 1, and the outlet oil pipe is connected to the overflow valve 3 and the reversing valve 4 respectively, and the oil return pipes of the overflow valve 3 and the reversing valve 4 are connected to the oil tank 1, and the reversing valve 4 is connected to the oil tank 1. The A oil port of valve 4 is divided into two branches, one branch is connected in series with hydraulic motor A7 and then connected with hydraulic cylinder A5, and the other branch is connected in series with hydraulic motor B8 and connected with hydraulic cylinder B6, said hydraulic motor A7 is connected with hydraulic cylinder A5 The rotating shaft of motor B8 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com