Heat management pipe of electric-vehicle power battery and balance method and calibration system thereof

A technology for power batteries and electric vehicles, applied in circuits, secondary batteries, electrical components, etc., can solve problems such as inconsistent coolant flow, poor temperature balance, and inability to ensure that the pressure difference between the inlet and outlet is consistent with each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

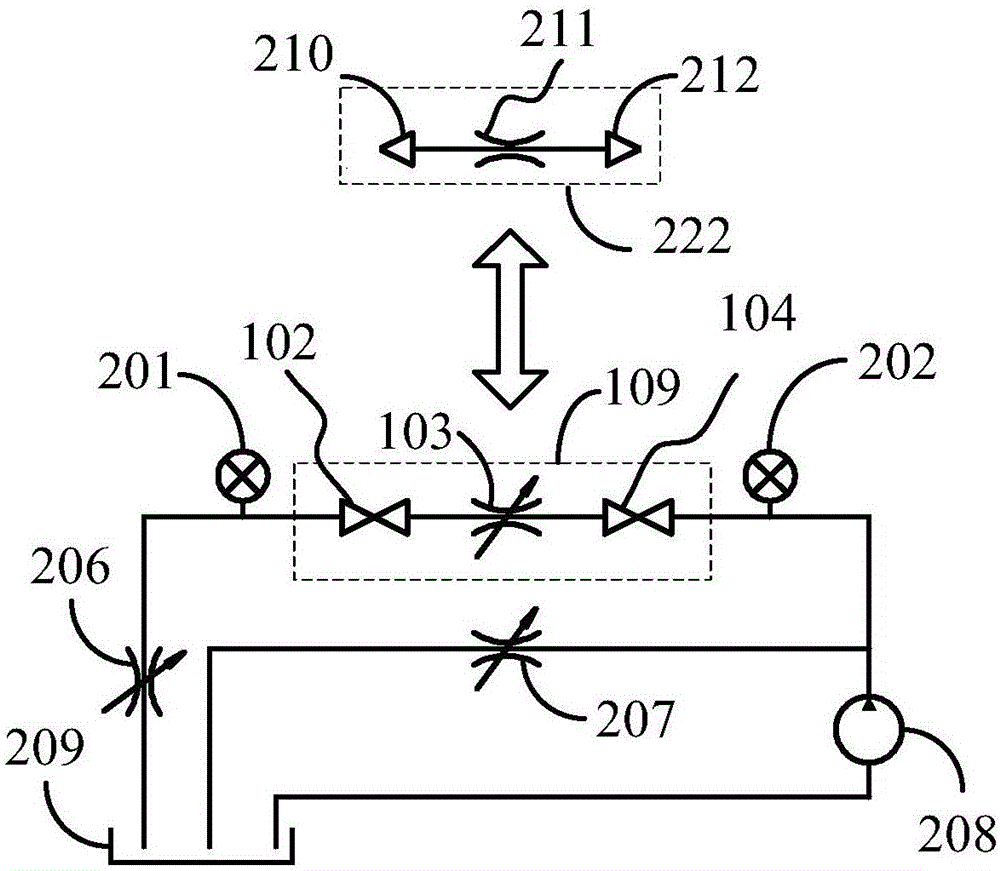

[0057] In order to have a clearer understanding of the technical features, purposes and effects of the invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, in which the same reference numerals represent the same parts.

[0058] For the sake of brevity and intuition in description, the solution of the present invention is described below by describing several representative implementation manners. Numerous details in the embodiments are only used to help the understanding of the solutions of the present invention. But obviously, the technical solutions of the present invention may not be limited to these details when implemented. In order to avoid unnecessarily obscuring the solution of the present invention, some embodiments are not described in detail, but only a framework is given. Hereinafter, "including" means "including but not limited to", and "according to..." means "at least accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com