Screw tap with self-lubricating cooling structure

A cooling structure and tap technology, which is used in manufacturing tools, thread cutting tools, metal processing equipment, etc., can solve the problems that the cooling holes cannot meet the cooling requirements, the cooling effect needs to be improved, the number of cooling holes is not easy, and the cooling effect is remarkable. The effect of improving the cooling uniformity and improving the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

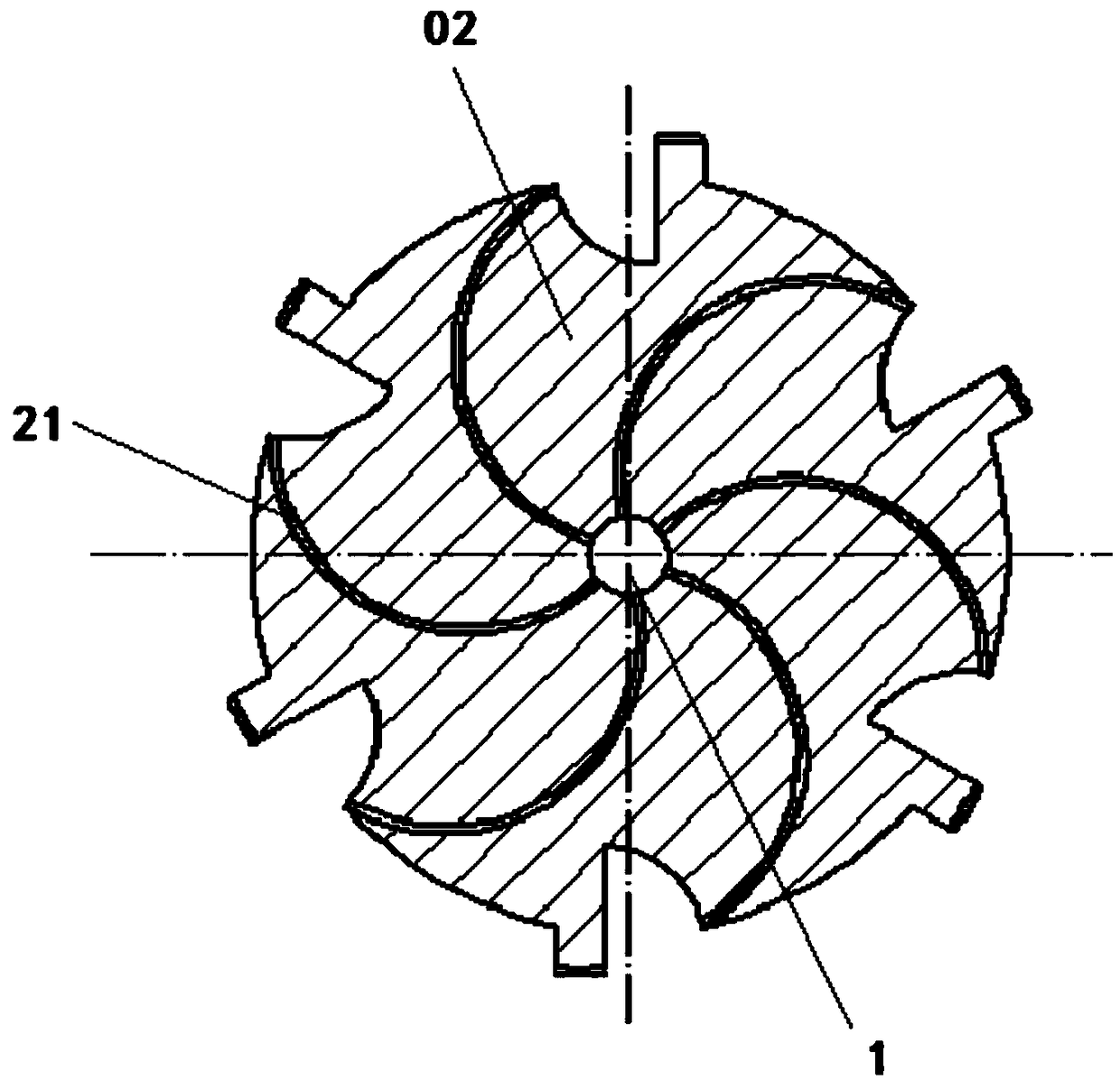

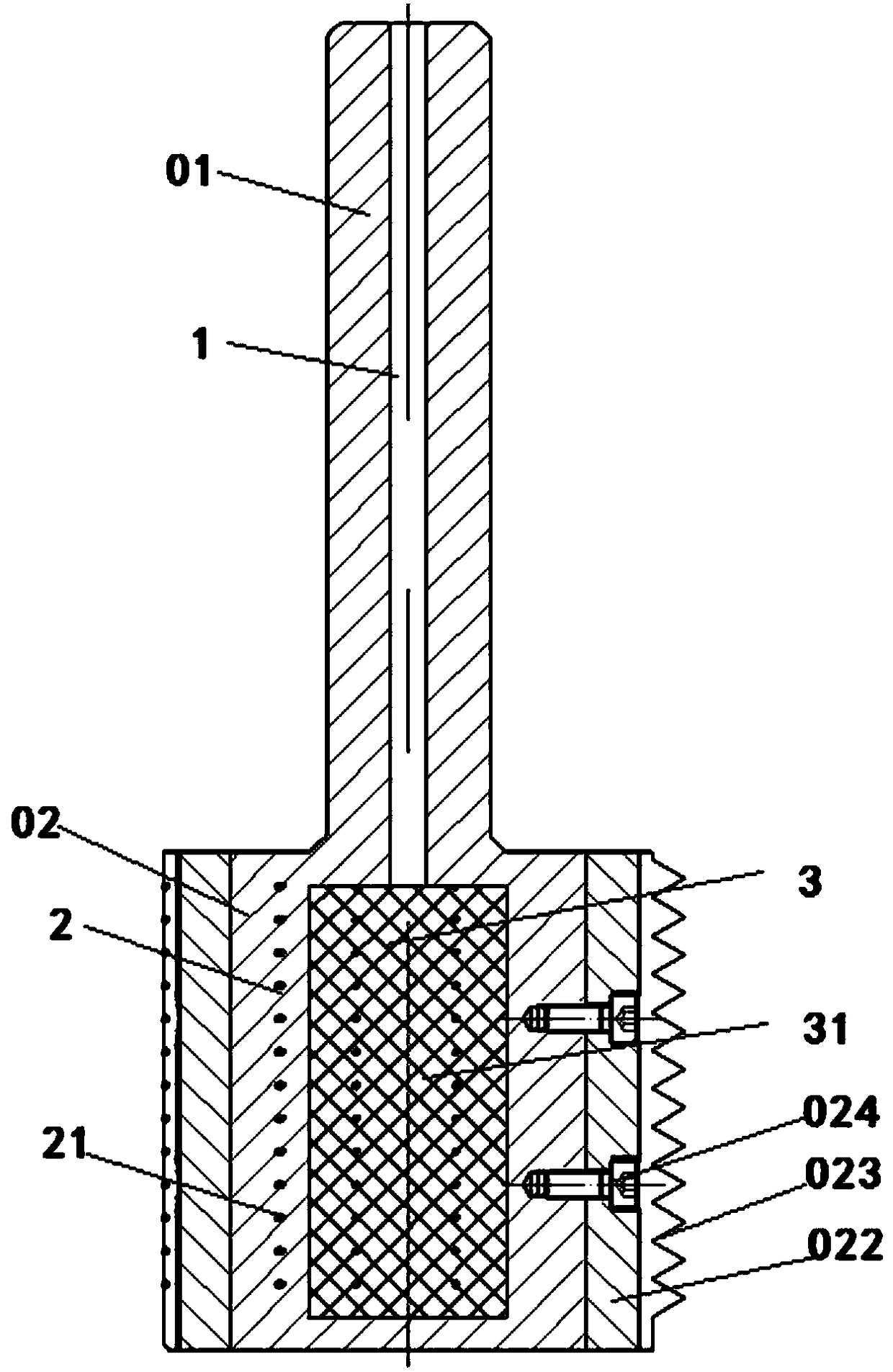

[0039] like figure 1 and figure 2 As shown, a tap with a self-cooling and lubricating structure includes a tap shank 01, a tap head 02, and a cooling lubricant main channel 1; the cooling lubricant main channel is arranged in the tap shank 01 and the tap head 02 along the axial direction 1. Cooling and lubricating liquid sub-flow channels 2 are set in the tap head 02, and multiple groups are arranged in sequence along the cooling and lubricating liquid flow direction in the cooling and lubricating liquid main channel 1; each group of cooling and lubricating liquid sub-flow channels 2 is evenly distributed in the circumferential direction Composed of a plurality of branched cooling and lubricating flow channels 21 (each branched cooling and lubricating flow channel 21 is opened radially), one end of each branched cooling and lubricating flow channel 21 communicates with the cooling and lubricating liquid main flow channel, and the other end faces the tapping area; The branche...

Embodiment 2

[0041] like image 3 and Figure 4 Shown, on the basis of embodiment 1, the present invention also has further optimized design:

[0042] 1. A temporary cooling and lubricating fluid storage area 3 is provided in the tap head 02. The cooling and lubricating fluid temporary storage area 3 includes a matrix 31 arranged between the cooling and lubricating fluid main flow channel 1 and multiple sets of cooling and lubricating fluid auxiliary flow channels 2. The base body 31 is provided with a plurality of pores connected from its center to the entire outer surface; the plurality of pores communicate the cooling lubricant main channel and the cooling lubricant secondary channel; the cooling lubricant flows through the cooling lubricant main channel 1 to the cooling lubricant temporary storage Zone 3, so that the cooling lubricant can be temporarily stored at this position before the tap is ready for tapping, and the cooling lubricant can pass through the branch cooling lubricant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com