Novel stuffing filling equipment

A technology for stuffing and equipment, applied in metal processing, grain processing, food forming, etc., can solve the problems of weakening competition level, large equipment volume, and unsimplified structure, so as to increase channel length, increase storage capacity, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

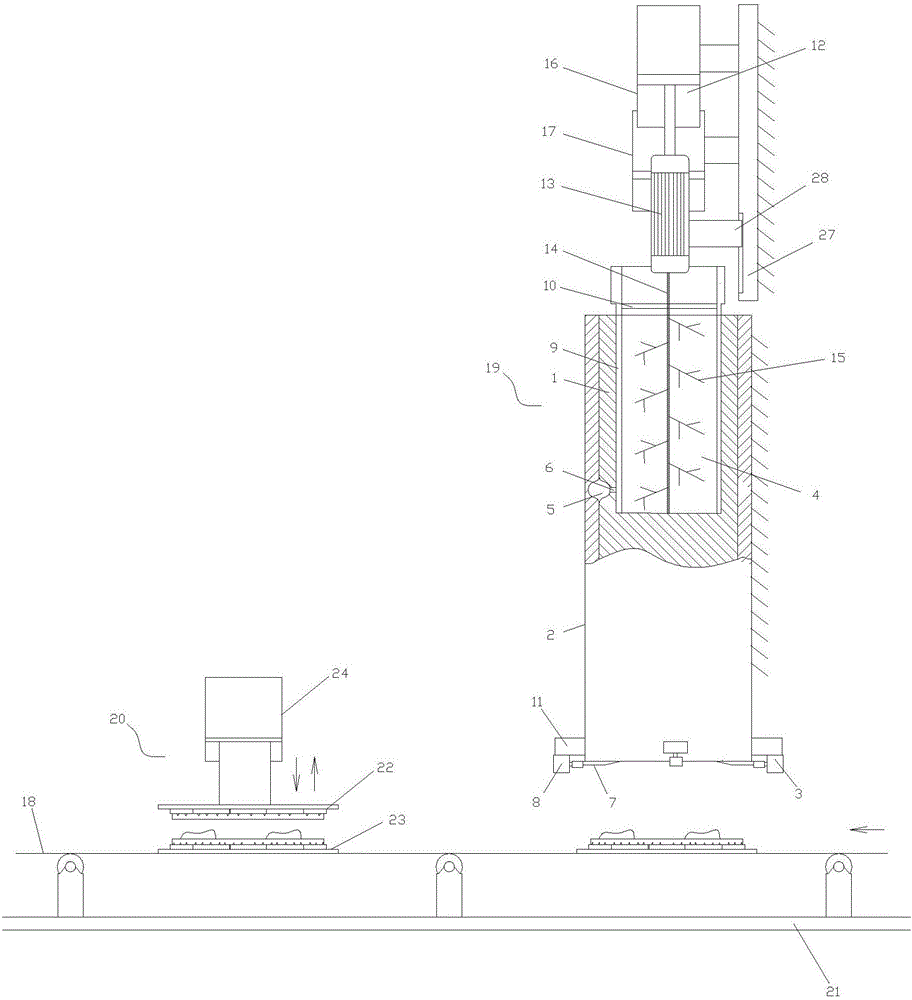

[0032] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] like Figure 1-7 As shown, a new type of stuffing equipment in this embodiment includes a frame 21 and a conveyor belt 18 arranged on the frame, as well as an integrated smashing and stuffing system 19 and a filling system 20 arranged successively along the conveyor belt,

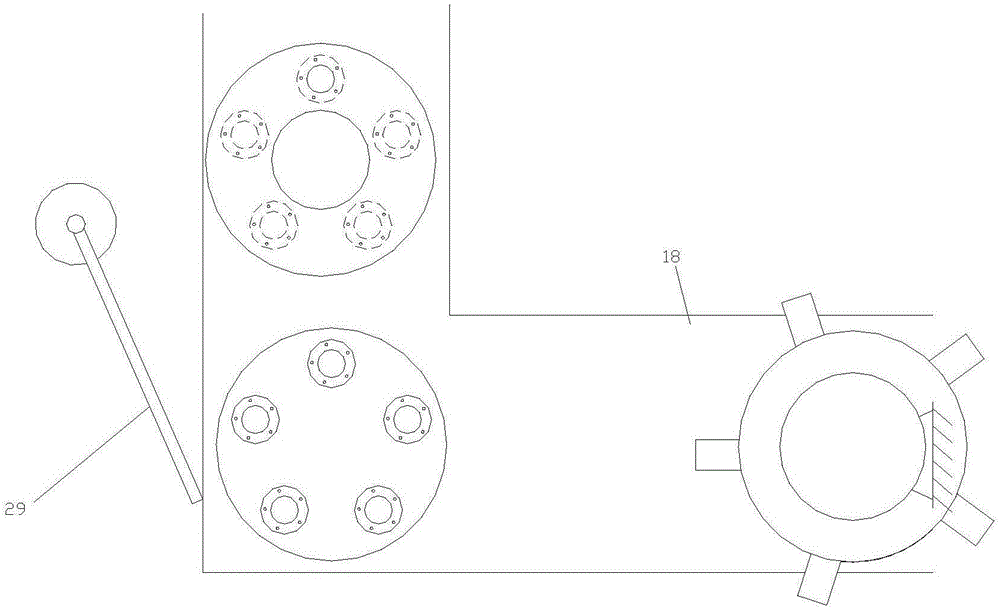

[0034] like figure 1 , 3 As shown in 4 and 4, the integrated system 19 for crushing and dividing stuffing includes a material storage inner cylinder 1, a sealed outer cylinder 2, a masher 12 and a cutting mechanism 3, the material storage inner cylinder has a material storage chamber 4, and the sealed outer cylinder is sleeved on the On the outer surface of the material storage inner cylinder, in particular, a plurality of spiral material storage channels 5 are arranged between the material storage inner cylinder and the sealed outer cylinder, such as image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com