Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Clean production environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ageing-resistant heat-insulation tarpaulin and production method thereof

InactiveCN101792975AImprove waterproof performanceGood insulation performanceHeating/cooling textile fabricsTextile treatment by pouringFiberPre treatment

The invention discloses an ageing-resistant heat-insulation tarpaulin. The tarpaulin is composed of a polymer cloth base and an ageing-resistant heat-insulation coating which is coated on the polymer cloth base in a casting mode. After aging is quickened for 236 hours by simulating natural manual work, the tensile strength of the tarpaulin is improved by at least 10%, the elongation at break thereof is improved by at least 5% than the elongation at break before aging, the ultraviolet reflectivity thereof is more than or equal to 80%, and the infrared obstruction rate thereof is more than or equal to 85%. The invention also discloses a preparation method thereof, comprising the following step: pretreating a heat-insulation material by utilizing a surface treating agent; and premixing the heat-insulation material with accessory ingredients such as vinyl type polymer, antioxidant and the like, then putting the heat-insulation material and the accessory ingredients into a double-screw extrusion casting coating machine to be fused, plasticized and extruded out to be casted and coated on the polymer fiber cloth base, and carrying out cooling shaping and reeling by utilizing a cooling roll to obtain the ageing-resistant heat-insulation tarpaulin. The tarpaulin product obtained by the invention has favourable water proofness, heat-insulating property and ageing-resistant property, wide application range, no pollution in the production process, small energy consumption, low cost and easy popularization and application.

Owner:SICHUAN UNIV

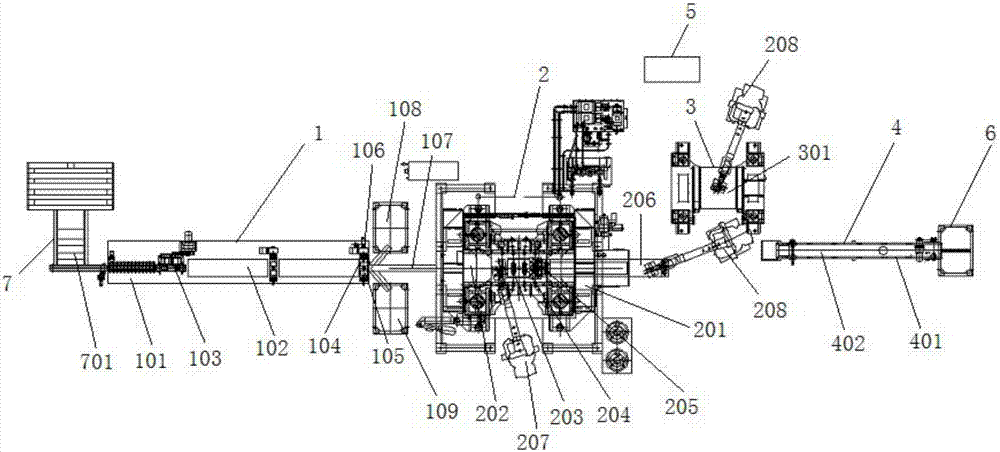

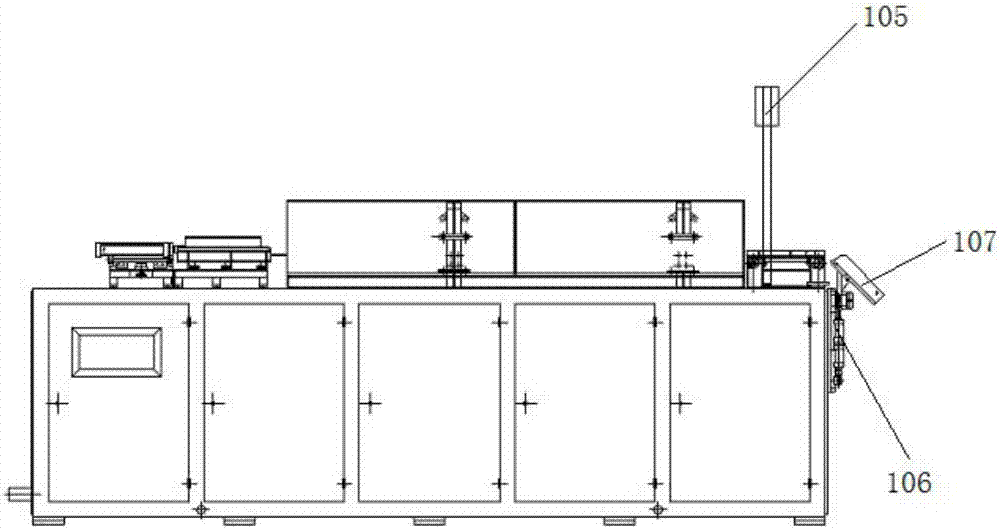

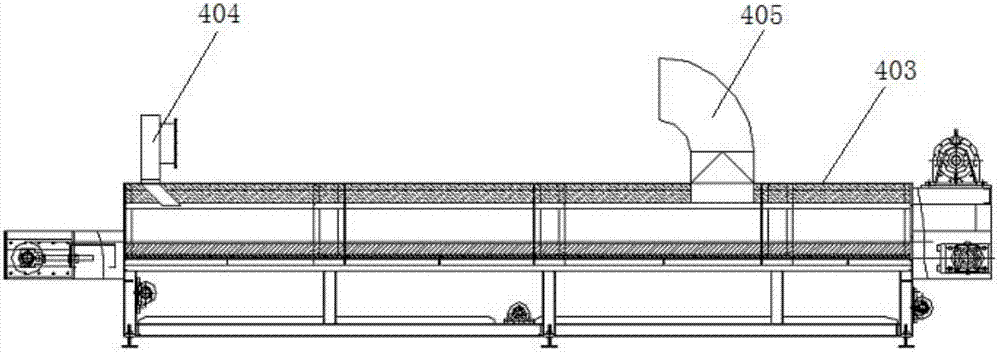

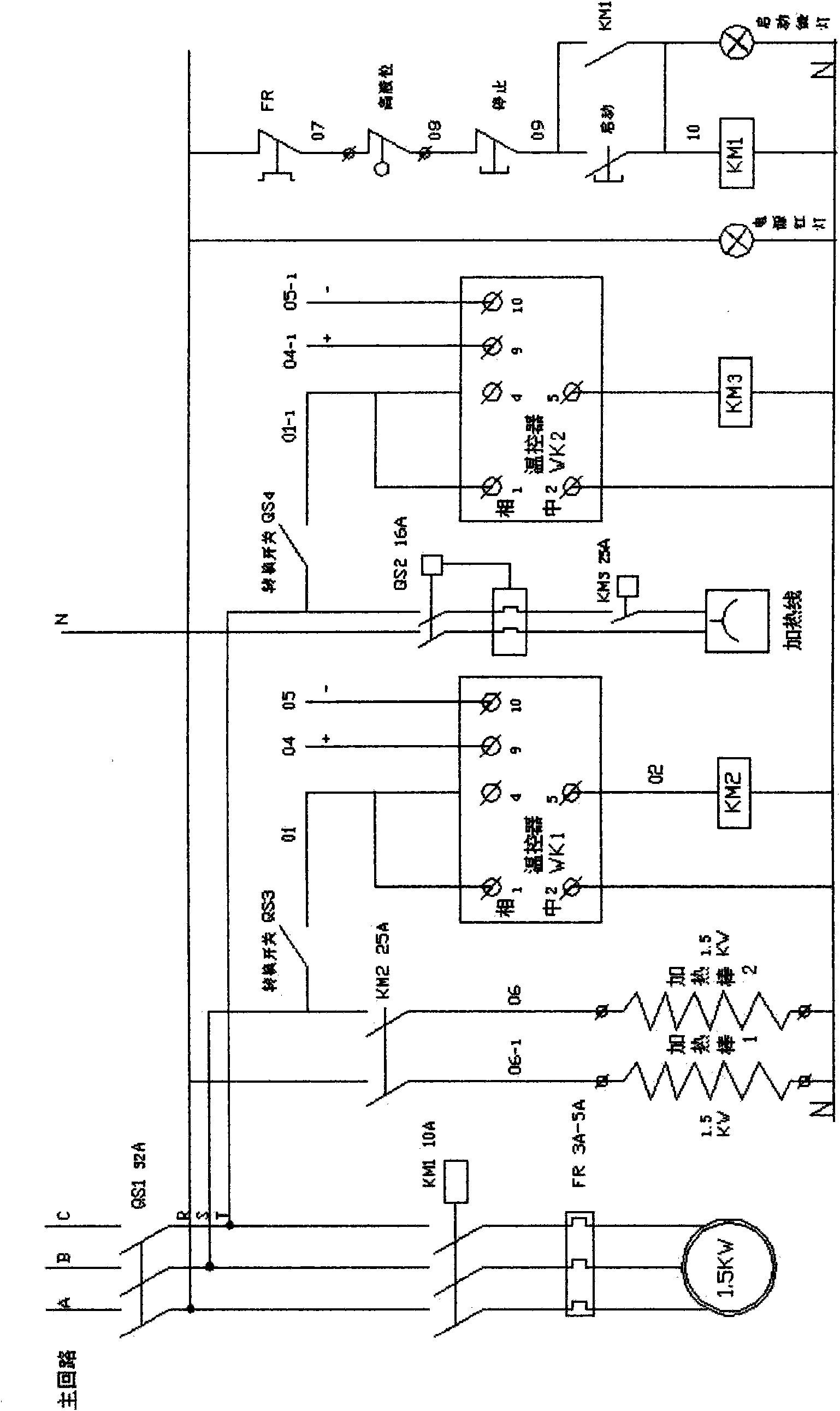

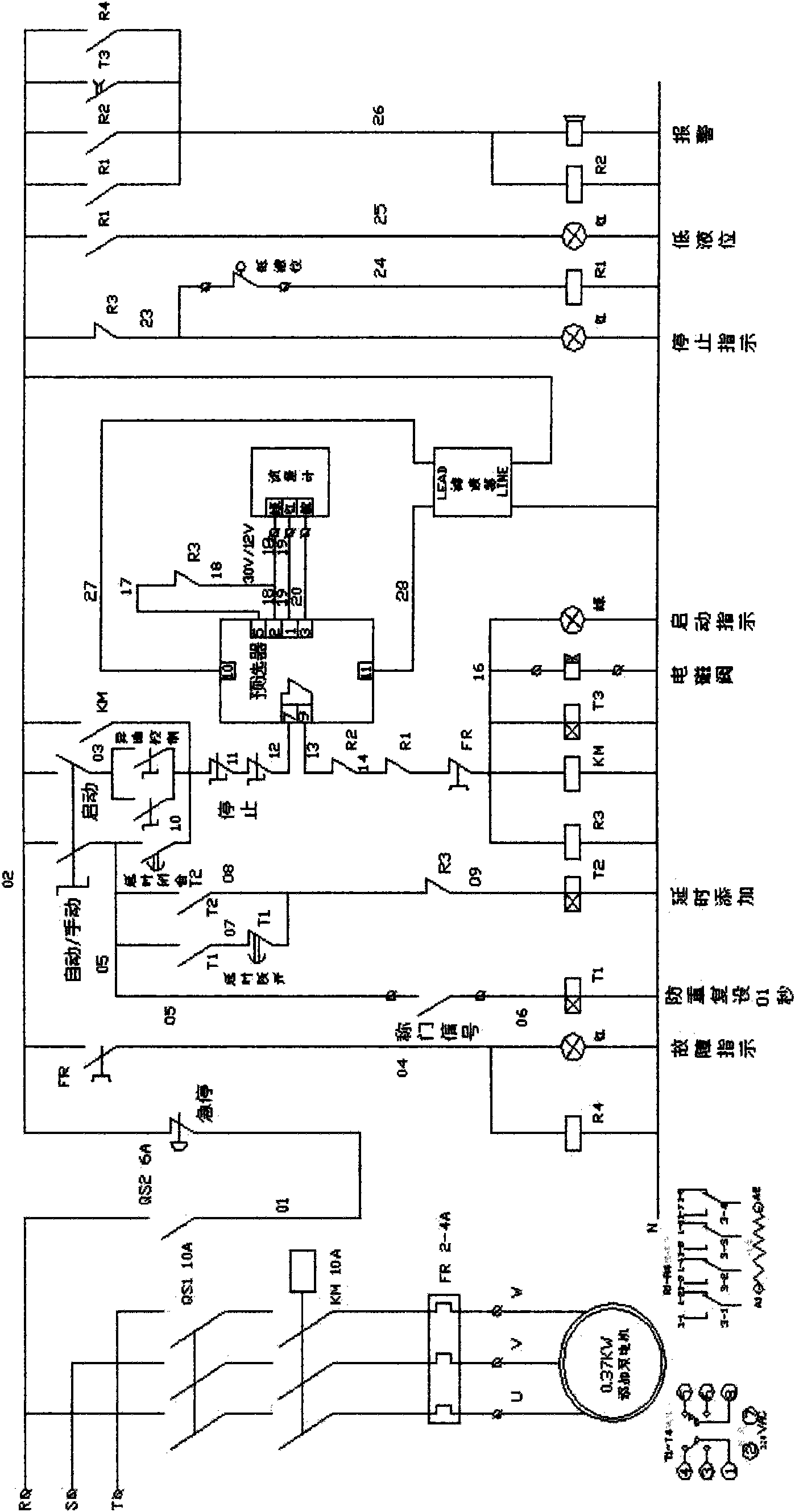

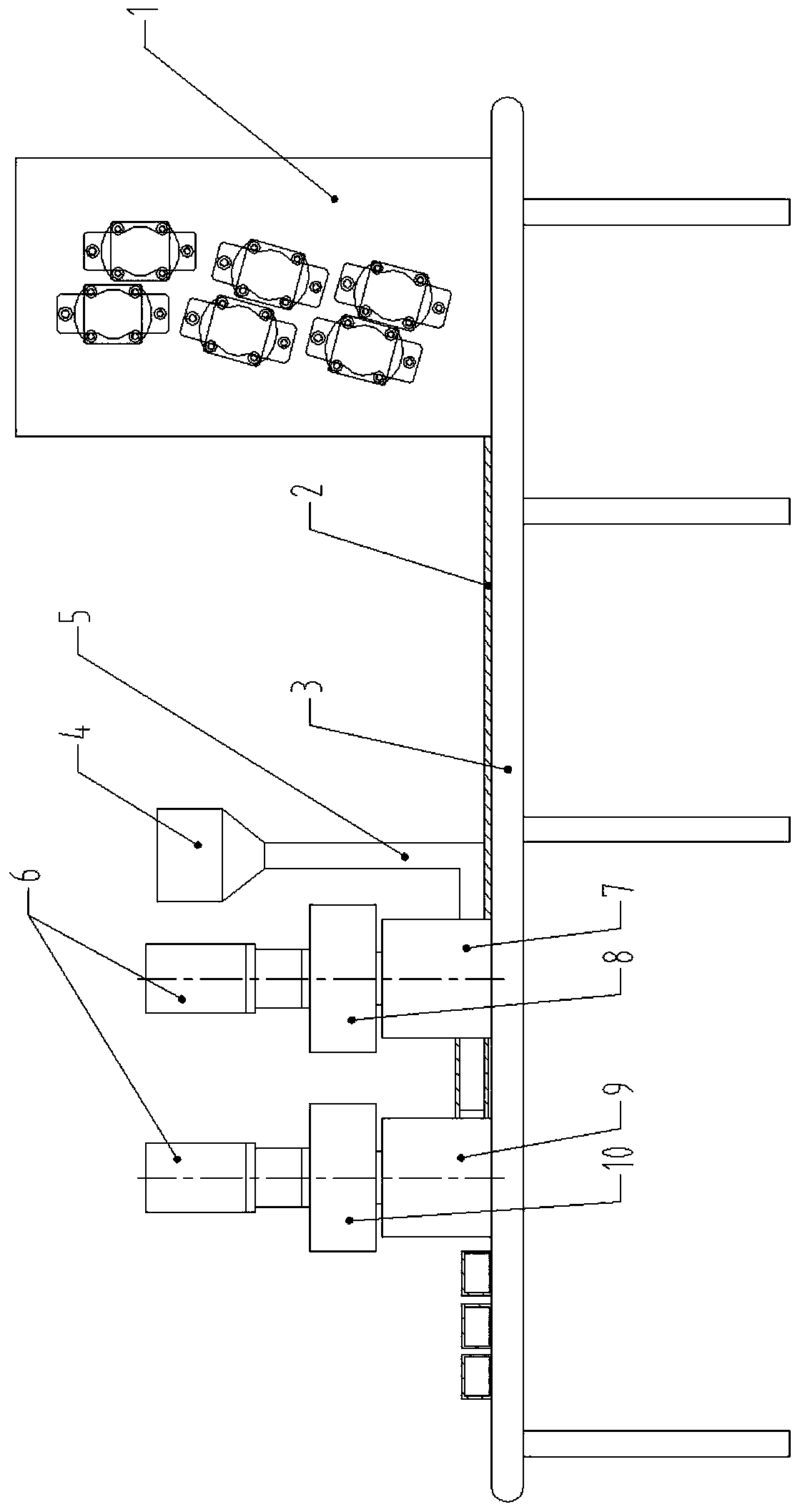

Full-automatic non-quenched-and-tempered steel forge piece production line

ActiveCN107442726AEmission reductionImprove electricity efficiencyForging/hammering/pressing machinesForging press drivesProduction linePunching

The invention discloses a full-automatic non-quenched-and-tempered steel forge piece production line. The production line comprises heating equipment, forging equipment, edge cutting and punching equipment, a cooling temperature control conveying chain, a finished product box and a programmable control system which are sequentially connected. According to the production line, a forge piece is heated at a time, continuous and automatic machining of multiple processes including upsetting, pre-forging molding, final forging molding, edge cutting, punching, heat treatment and the like is achieved, all machining processes need to be operated by one person, and the beneficial effects of being high in production efficiency and good in product quality are achieved.

Owner:CHONGQING VOCATIONAL INST OF ENG +1

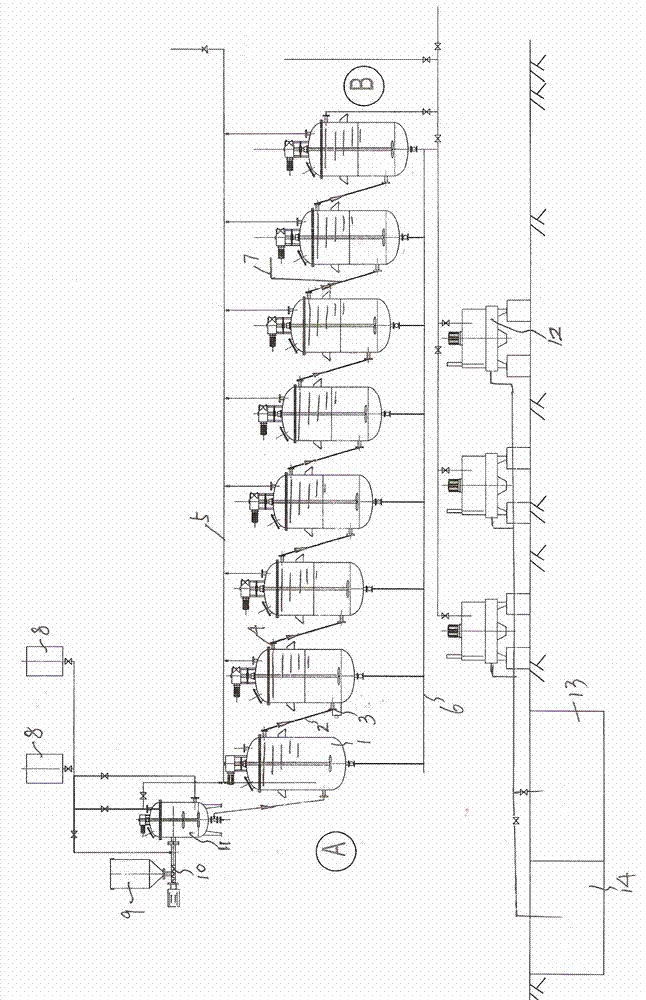

Continuous reaction production line consisting of multiple serially connected reaction kettles

InactiveCN103933923AReasonable structureImprove work performanceChemical/physical/physico-chemical stationary reactorsFeed devicesProduction lineWork performance

The invention discloses a continuous reaction production line consisting of multiple serially connected reaction kettles. The production line is formed by connecting multiple reaction kettles in series through material conveying pipes connected between the kettles; raw materials continuously enter the production line from the start end and then forcedly pass through all the reaction kettles in sequence; after being reacted, the raw materials are discharged from a material outlet in the tail end; height differences exist between all the reaction kettles; the materials enter the kettle from a material inlet in the lower side of the former kettle, then overflow from an overflow opening in the upper side of the kettle and flows into the material inlet in the lower side of the next kettle due to the fall action. The fall size is set according to the property of the materials in the kettles. The continuous reaction production line is reasonable in structure and high in working performance.

Owner:潘兆金

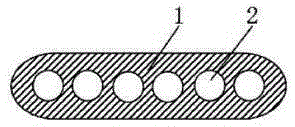

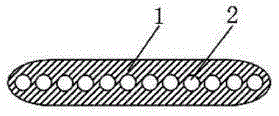

Thixotropic optical fiber filling paste for ribbon optical cable and preparation method thereof

ActiveCN102207594AStrong paste skeletonHigh thixotropic indexFibre mechanical structuresWeather resistanceOil separation

The invention relates to thixotropic optical fiber filling paste for a ribbon optical cable, which mainly comprises base oil, an oil separation inhibitor, a pour point depressant, an antioxidant, an organic gelling agent, an inorganic gelling agent and a thixotropic agent. The invention also provides a preparation method for the thixotropic optical fiber filling paste for the ribbon optical cable. The thixotropic optical fiber filling paste for the ribbon optical cable is mainly characterized in that: the thixotropic optical fiber filling paste has excellent colloid stability and oxidation stability, heat resistance, weather resistance, non separation of oil in a system, low acid value, high thixotropic index, high water resistance, no emulsification, good high-temperature trickle-down property, high temperature resistance and low temperature resistance, is mainly used to be filled in a loose tube of the ribbon optical cable so as to prevent water or other fluid from flowing into or moving into the optical cable, and provides excellent effects of resisting water, buffering and the like for the optical cable.

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

Hot-melting type filling paste for electric cable and preparation method thereof

ActiveCN102408637AImprove insulation performanceImprove waterproof performanceInsulated cablesInsulated conductorsElectrical conductorAntioxidant

The invention relates to hot-melting type filling paste for an electric cable, which mainly comprises base oil, insulation paste, an oil separation inhibitor, a thickening agent and an antioxidant. The invention further provides a preparation method of the hot-melting type filling paste. The hot-melting type filling paste for the electric cable provided by the invention has the main characteristics of excellent colloidal stability and oxidation stability, heat resistance, weather resistance, no oil separation in systems, small acid value, strong water resistance, no emulsification, excellent high / low temperature performance, and extremely-excellent electrical properties and dielectric properties; the hot-melting type filling paste is mainly applicable to filling air gaps in a cable core of a multi-conductor wire cable, or gaps among electric cable members of an any structure by heating, so as to prevent water or other fluid from flowing or migrating into the electric cable and provideexcellent functions in insulation, waterproofing, dampproofing, buffering and the like for the electric cable.

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

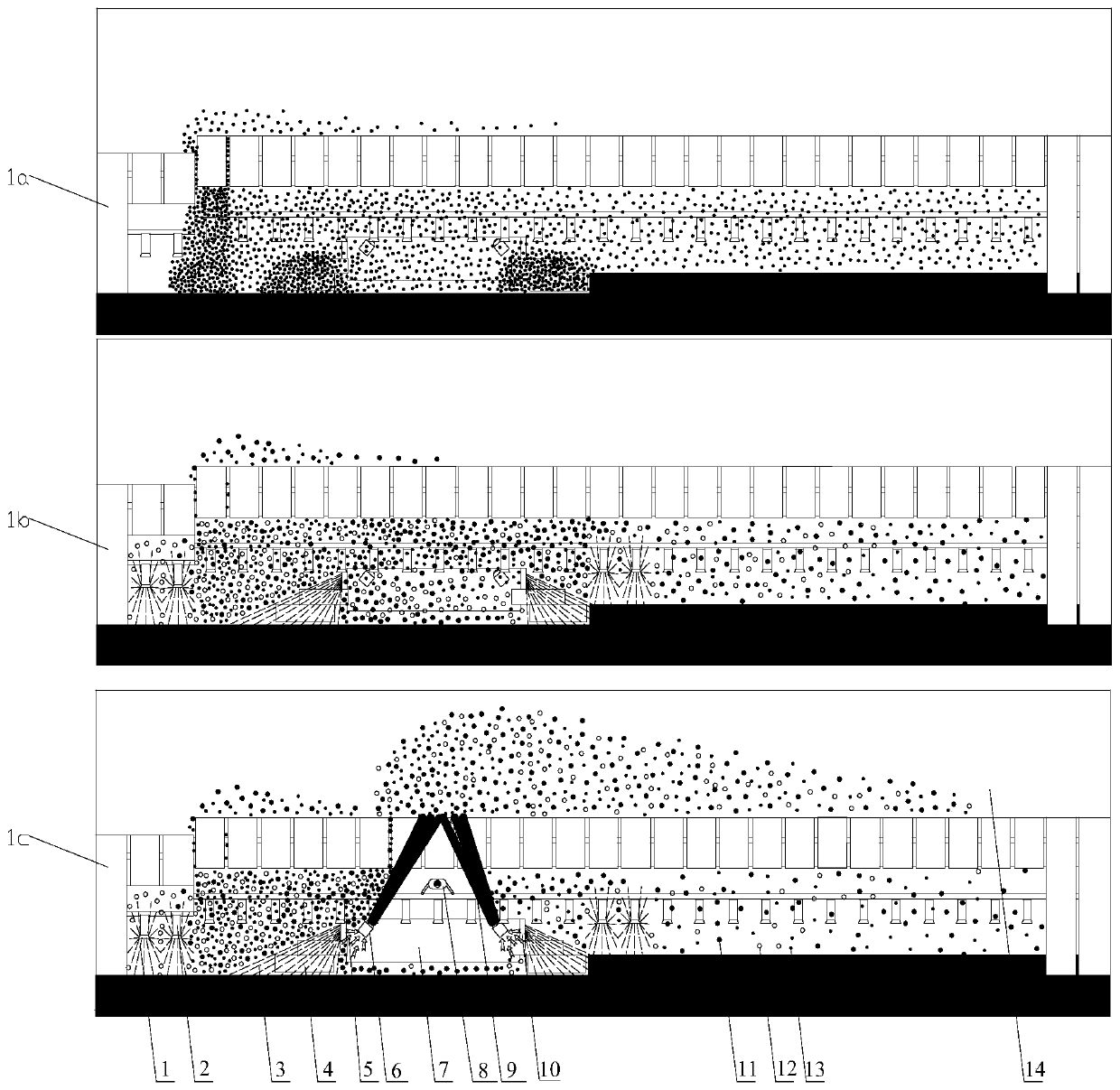

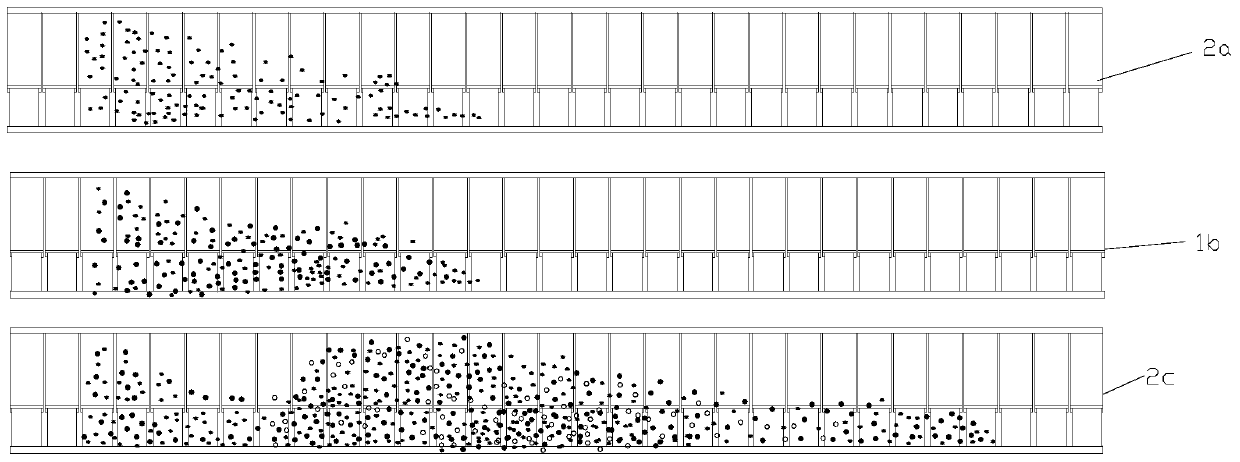

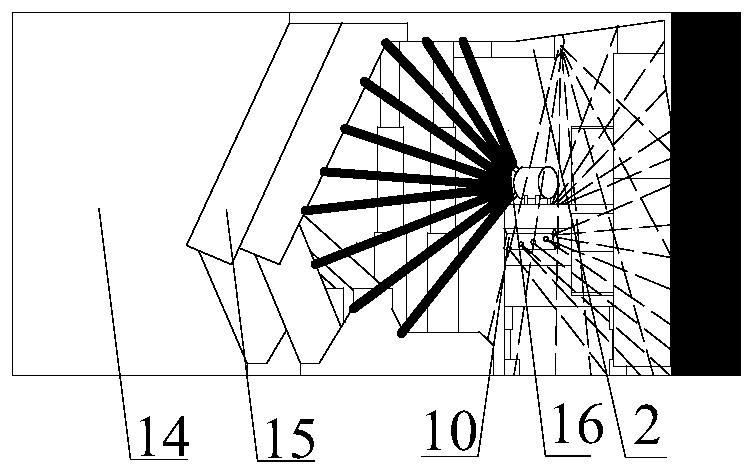

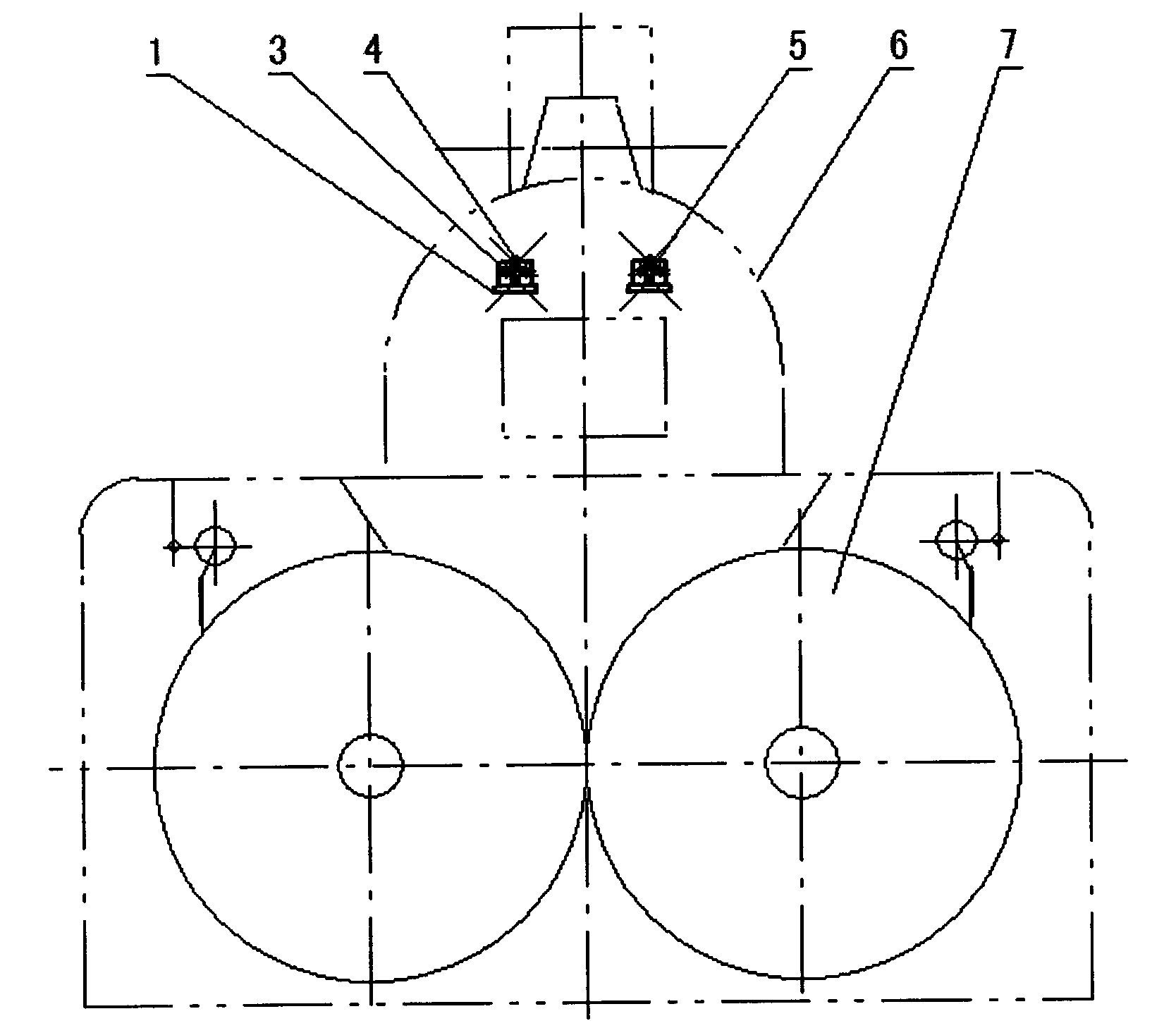

Fully mechanized mining face gettering-induction convection type dust control and removal wind fog screen device and method

ActiveCN110056350AEffective controlProduction environment safetyDust removalFire preventionDust controlEngineering

The invention discloses a fully mechanized mining face gettering-induction convection type dust control and removal wind fog screen device and method, and belongs to the technical field of coal mine dust removal. The fully mechanized mining face gettering-induction convection type dust control and removal wind fog screen device comprises draw-out dust clearing fans, fan-shaped flow guide hoods, coal cutter exterior spraying devices and spraying devices between hydraulic supports; the coal cutter exterior spraying devices and the spraying devices between the hydraulic supports are mounted on the two sides, close to rocker arms of a coal cutter, of a cutter body, the two hydraulic supports in front of a moving frame, and the two hydraulic supports on the downwind side of a front roller of the coal cutter correspondingly, and conduct spraying at a certain angle to form corresponding fog screens; a large amount of dust generated by the moving frame and coal cutting is subjected to atomization dust removal; and meanwhile, the two draw-out dust clearing fans which are symmetrically mounted on the positions, close to the cutter body of the coal cutter, of the rocker arms are started, exhaust inlets of the two draw-out dust clearing fans directly face the front roller and a rear roller of the coal cutter correspondingly, and wind outlets are connected with the fan-shaped flow guide hoods. The fully mechanized mining face gettering-induction convection type dust control and removal wind fog screen device and method have important practical significance for improving the operating environment of fully mechanized mining face workers and guaranteeing safety production of coal mines.

Owner:SHANDONG UNIV OF SCI & TECH

Device and method for adding liquid additive

ActiveCN102090701AReduce wasteAccurate and Stable Adding PrecisionFeeding-stuffTemperature controlGear wheel

The invention provides a device and a method for adding a liquid additive. The device comprises a storage tank, a material barrel, a connecting pipe, filters, an input pump, a central controller, a temperature controller, liquid level meters, nozzles, an adding pump, a flow meter and a control valve, wherein, the flow meter is a gear volumetric flow meter; a shell of the flow meter is internally equipped with two rotors which are directly meshed with each other and rotate under the action of pressure difference between an inlet and an outlet of the flow meter; the flow meter continuously discharges fluid which is filled in a metering space between a gear and the shell by means of rotation of the gear; and the flow meter obtains the fluid passing through the same by measuring rotating times of the gear. The device has the advantages of high and stable adding precision and accurate electrical control, thus effectively reducing labor consumption and raw material waste during the production process, and reaching an optimal service condition during the production process.

Owner:青岛宝佳智能装备股份有限公司

A kind of heat-melt flame retardant filling paste for cables and preparation method thereof

ActiveCN102280186AImprove flame retardant performanceImprove waterproof performanceInsulated cablesInsulated conductorsElectrical conductorHeat resistance

The invention relates to a hot melt type flame retardation filling paste for a cable, and the filling paste mainly is composed of base oil, an oil product fire retardant, polyisobutylene, a separating oil inhibitor, polyethylene wax, a fire retardant and an anti-oxidant. The invention provides a preparation method of the hot melt type flame retardation filling paste for a cable. The hot melt typeflame retardation filling paste for a cable mainly has the characteristics of good flame resistance, colloid stability, oxidation stability, heat resistance, weatherability, no oil separation of a system, small acid value, strong water-resistance, free of emulsification, excellent high and low temperature performance, excellent electrical performance and excellent dielectric property. The fillingpaste mainly is suitable for being heated and filled into air gap of a multi-conductor wire cable core or gap between cable components of any structure. Water or other fluid is prevented from flowingor migrating into the cable. Effects of flame retardation, insulation, waterproof, moistureproof, buffering and the like are provided for the cable.

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

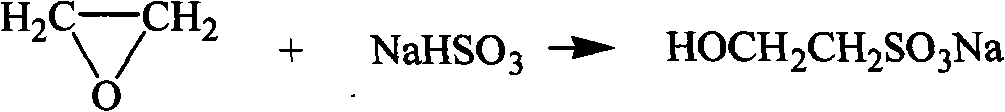

Method for preparing taurine

The invention discloses a preparation method for taurine which comprises the following steps that: 1. ethylene thioglycol is oxidized by oxidizer in the solvent to prepare hydroxyethylsulfonate; 2. the hydroxyethylsulfonate is reacted with ammonia to prepare taurine. The preparation method for taurine of the invention has short process route and low cost. The first-step oxidation reaction has mild conditions, can be made at normal temperature and has low energy consumption. The total reaction process has no waste liquid and waste residue, and no escape of sulfur dioxide gas, so the production environment is good. Compared with the prior commonly used method, the preparation method is more clean, can reduce large power consumption and manpower consumption, and the reaction yield can be improved by 20 percent compared with the general process.

Owner:常熟市虞东化工有限公司 +1

Alloying technique for semiconductor chip Au-Si solder

ActiveCN101503791AEvenly heatedImprove yieldVacuum evaporation coatingSputtering coatingTemperature controlSemiconductor chip

The invention discloses an alloying process for a semiconductor chip alloyed silicon solder. The alloying process comprises the following steps: S1, carrying out the surface treatment of a silicon slice to be alloyed; S2, coating one or a plurality of metallic layers on the back of the silicon slice subjected to the surface treatment by vaporization on the vacuum condition; and S3, sending the silicon slice coated with the metallic layers into a quick anneal oven for alloy treatment with the temperature of 490 to 550 DEG C and the time of 10 to 50 seconds. The alloying process replaces a conventional tubular type alloying furnace by the quick anneal oven which has the characteristics of accurate temperature control, quick temperature increase and decrease and short processing time in the process. In addition, the application of the quick anneal oven realizes the input and output of a single silicon slice so as to replace the tubular type alloying furnace which has the batch charge and discharge of hundreds of slices each time, make the silicon slice heated evenly, and consequently greatly improve the yield.

Owner:深圳深爱半导体股份有限公司

Step-by-step separation system and method for extracting salts from coking HPF desulfurizing solution by aqueous phase method

InactiveCN103818883AA decrease in the concentration of secondary saltsReduce secondary salt contentThiosulfates/dithionites/polythionitesThiocyanic acidSeparation technologyPhase method

The invention relates to a step-by-step separation system and method for extracting salts from coking HPF desulfurizing solution by an aqueous phase method. The step-by-step separation system comprises a primary filtering and decolorizing system, a first-level evaporating concentrating and crystallizing system, a second-level concentrating and crystallizing system, a repulping concentrating and crystallizing system, and a vacuum heating and condensing system, wherein the primary filtering and decolorizing system is communicated with the first-level evaporating concentrating and crystallizing system through a mother liquor tank, and is also communicated with the vacuum heating and condensing system; the first-level evaporating concentrating and crystallizing system is communicated with the second-level concentrating and crystallizing system, and is also communicated with the repulping concentrating and crystallizing system and the vacuum heating and condensing system. The step-by-step separation system adopts a step-by-step concentrating and separating technology of the aqueous phase method to separate and extract thiocyanate and thiosulfate from the desulfurizing solution through high separation and cold crystallization; meanwhile, separated secondary salt is recycled, so that the content of the secondary salt in the desulfurizing solution is decreased, the coking desulfurization is carried on in the positive direction, and the desulfurizing efficiency is improved; in addition, the recycled secondary salt has a high economic value, and the pollution problem due to the coking desulfurizing solution is solved.

Owner:光阳工程技术有限公司

Preparation method of compound Lonicera japonica granules

InactiveCN106074397ARemove completelyReduce degradation lossSenses disorderAntipyreticAlcoholAdditive ingredient

The invention belongs to the preparation of Chinese patent medicine and particularly relates to a preparation method of compound Lonicera japonica granules. The preparation method includes: preparing raw materials, performing water extraction, alcohol precipitation and vacuum drying, pelleting, and the like. The preparation method has the advantages that the problems that the prior art is long in production cycle, high in energy consumption, low in efficiency, poor in environment protection performance, complex in pelleting, and the like are solved, and the preparation method is low in effective component loss, short in process flow, low in production cost, low in energy consumption, and the like.

Owner:HEBEI GOGIN PHARMA

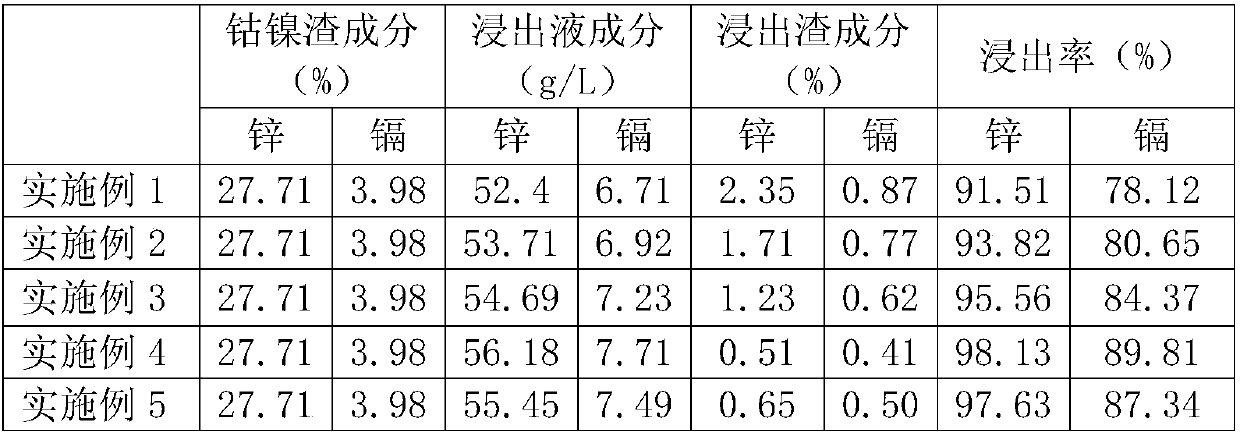

Improved method for treatment technology for secondary cobalt-nickel leaching residues

InactiveCN107699693AFull recoveryEfficient entryPhotography auxillary processesProcess efficiency improvementElectrolysisFiltration

The invention discloses an improved method for a treatment technology for secondary cobalt-nickel leaching residues. The method comprises the following steps of (1) carrying out filter pressing, specifically, pumping the secondary cobalt-nickel leaching residues into a filter press to be subjected to filter pressing, and taking the filter residues for later use; (2) carrying out slurrying; (3) carrying out leaching, specifically, pumping slurry to zinc oxide high-acid leaching tanks, adding 10m3 of the slurry into each tank, then adding spent zinc electrolytes and sulfuric acid, carrying out leaching for 6-8 hours under the conditions that the liquid-solid ratio is 5-6:1 and the temperature is 80-90 DEG C, controlling the initial acid concentration in the leaching process to be 150-180g / Land the final acid concentration to be 80g / L, and finally, carrying out filtration treatment on all materials so as to obtain leaching liquor and leaching residues; and (4) carrying out recycling, specifically, returning the leaching liquor to a zinc system to recycle zinc and cadmium and returning the leaching residues to a lead system to recycle lead and silver. The method has the advantages that the leaching rate of the zinc and the cadmium can be increased, the recovery rate of the zinc and the cadmium can be increased, the production cost can be lowered, and the labor intensity can be reduced.

Owner:南丹县南方有色金属有限责任公司

Special deodorant for chemical plant and preparation method thereof

InactiveCN107519516AHas bactericidal and deodorizing effectsEasy to prepareBiocideFungicidesNon toxicityAdditive ingredient

The invention discloses a special deodorant for a chemical plant and a preparation method thereof. The deodorant is prepared from the following ingredients in parts by weight: 5 to 20 parts of pseudolarice tincture, 3 to 8 parts of carboxymethylcellulose, 10 to 20 parts of purebred cinnamomum camphora ethanol extracts, 5 to 15 parts of citric acids, 4 to 10 parts of maleic acid, 4 to 10 parts of trimeric sodium phosphate, 5 to 12 parts of jasmine flower essence, 5 to 10 parts of sodium bisulfite, 3 to 8 parts of magnesium aluminum silicate and 2 to 8 parts of geranyl formate. The preparation method is simple; the prepared deodorant can be used for effectively eliminating foreign odor generated in the chemical plant; the production environment of chemical production is cleaned; in addition, non-toxicity and harmlessness are realized on the human body.

Owner:马鞍山中粮生物化学有限公司

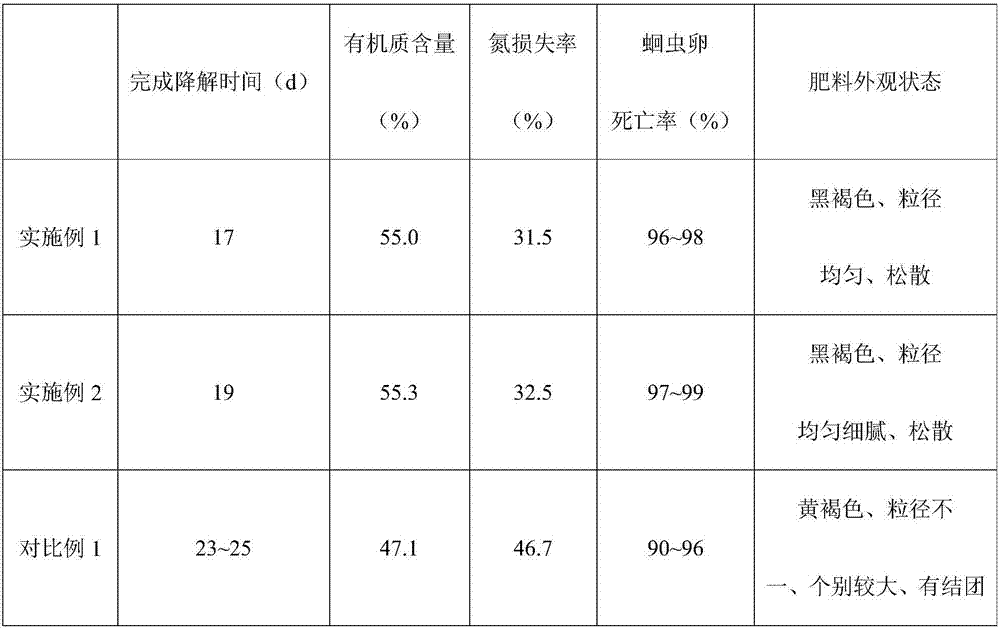

Garden waste lignin component fermentative degradation method

InactiveCN107188626AReduce volumeImprove decomposition rateBio-organic fraction processingBioloigcal waste fertilisersPre treatmentMushroom

The invention discloses a garden waste lignin component fermentative degradation method. The method includes the steps of: (1) crushing materials into materials with a particle size of 0.4-0.7cm; (2) placing the crushed materials into a first-stage fermentation area, adding a mushroom residue fermentation broth into the materials to keep the water content of the materials at 55%-65%, and conducting primary fermentation; (3) adding the mushroom residue fermentation broth into the materials subjected to primary fermentation, keeping the water content of the materials at 45%-55%, and then placing the materials in a second-stage fermentation area for secondary fermentation; and (4) putting the fermented materials subjected to secondary fermentation into a third-stage fermentation area for fermentation, thus finishing the whole fermentative degradation process. Directed at the characteristics of lignin in the materials, the method provided by the invention adopts physicochemical treatment method and biochemical treatment method for material pretreatment and material conditioning, and directed at the activity characteristics of bacteria, fungi, actinomycetes and other different dominant degrading floras at different temperature stages in the fermentative degradation process, realizes accurate condition control and efficient degradation of lignin.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

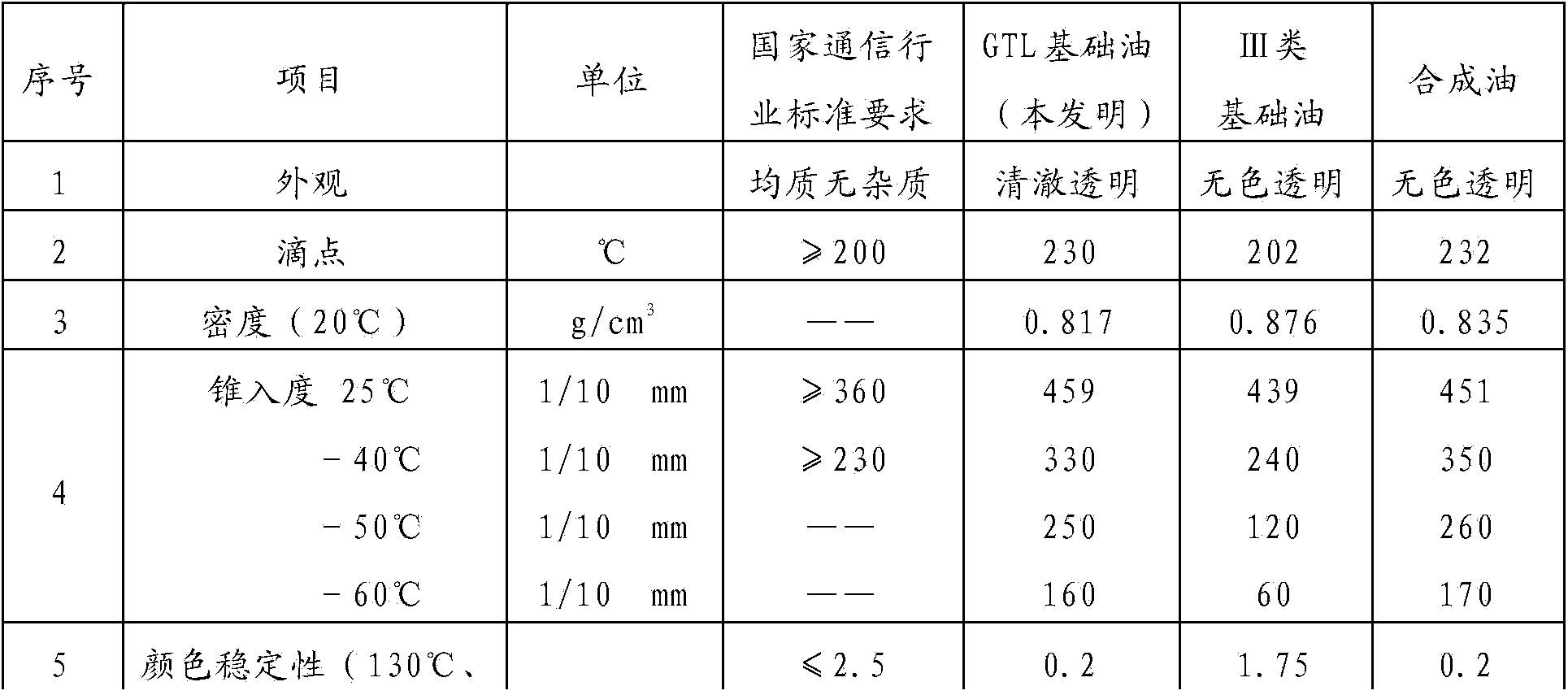

Optical cable GTL (Gas To Liquid) base oil filling paste and preparing method thereof

ActiveCN103809257AHigh transparencyTransparent appearanceFibre mechanical structuresWeather resistanceDecomposition

The invention discloses an optical cable GTL base oil filling paste. The optical cable GTL base oil filling paste is mainly composed of GTL base oil, oil decomposition inhibitor, thermoplastic synthetic rubber, antioxidant and thickener. The invention further discloses a preparing method of the optical fiber GTL base oil filling paste. The optical fiber GTL base oil filling paste has the advantages of being low in density, good in low-temperature performance and capable of being safely used as factice products for replacing synthetic oil in an environment of minus 50 DEG C, having good colloid stability, oxidation stability, heat resistance and weather resistance and being system-oil-decomposition-free in system and low in acid value; being high in thixotropic index, low in viscosity, strong in water-resistance, emulsification-free, good in high temperature drip, wide in environment temperature application range, and enabling an optical fiber to be always in a stress-free state inside a buffer tuber and a cable core to be always in a stress-free state inside a cable.

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

Hot-melting type filling paste for electric cable and preparation method thereof

ActiveCN102408637BImprove insulation performanceImprove waterproof performanceInsulated cablesInsulated conductorsElectrical conductorAntioxidant

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

Sterilization deodorant and preparation method

InactiveCN107019813ASimple preparation processRaw materials are easy to getBiocideDisinfectantsChlorhexidine AcetateFood flavor

The invention relates to a sterilization deodorant and a preparation method. The sterilization deodorant is prepared from the following raw materials in parts by weight: 15 to 20 parts of amino alcohol, 10 to 15 parts of menthol, 20 to 25 parts of sodium carbonate, 10 to 20 parts of essence, 5 to 10 parts of trisodium phosphate, 5 to 10 parts of citric acid, 20 to 45 parts of water, 5 to 10 parts of coconut oil and 5 to 10 parts of chlorhexidine acetate. According to the sterilization deodorant and the preparation method, provided by the invention, odor and bacteria in a chemical plant can be effectively removed and toxic and dangerous gas is not generated, so that a production environment of the chemical plant is cleaned; the deodorant has the advantages of simple preparation process, easiness of obtaining raw materials and relatively low cost.

Owner:余小琴

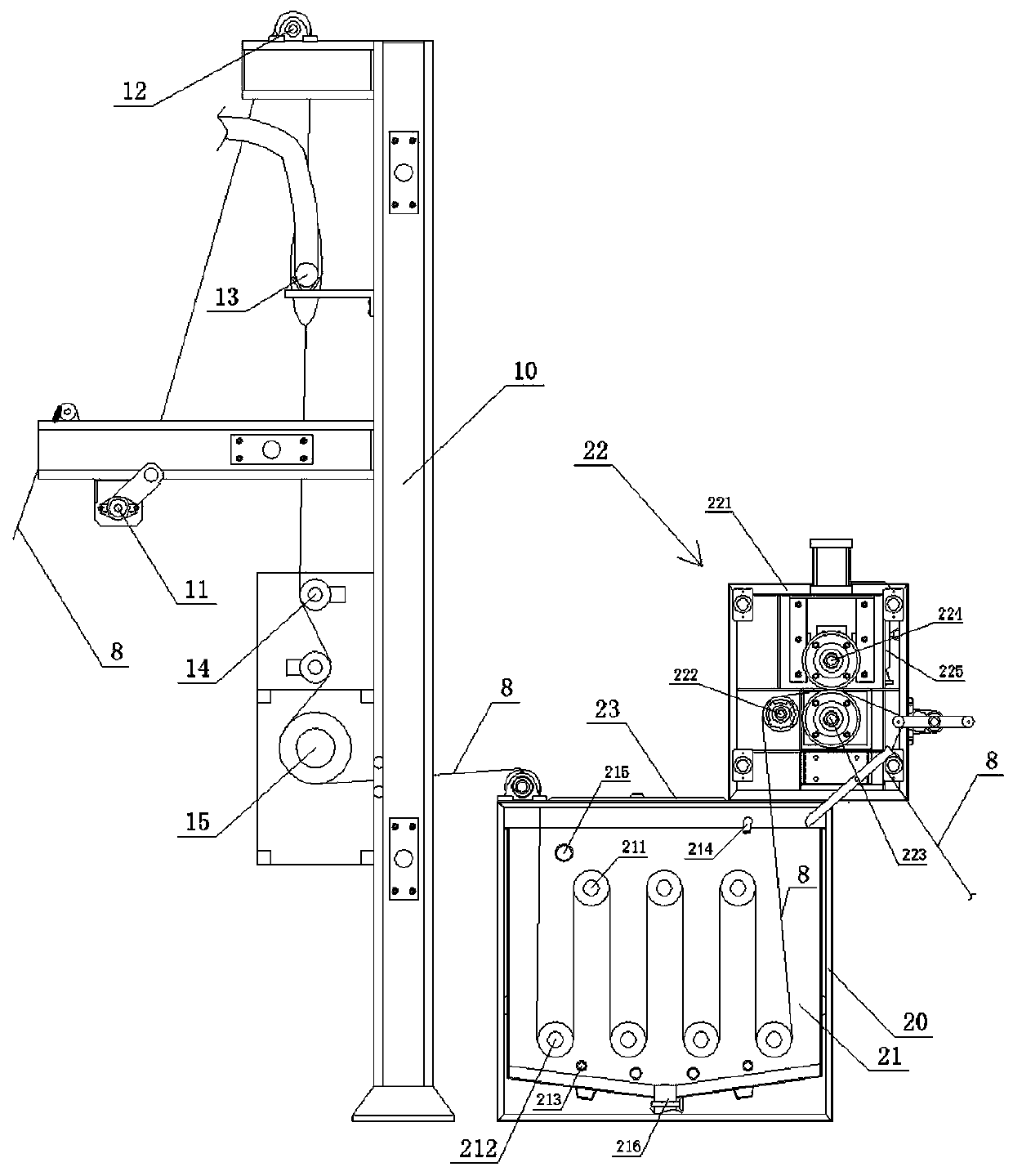

Digital dumpling production apparatus driven by micro motor

PendingCN111011417AReasonable distribution of powerFully automatedDough processingElectric machineryProcess engineering

The invention discloses a digital dumpling production apparatus driven by a micro motor, belongs to the technical field of food processing apparatuses. The technical problems of large occupied space and complex mechanism of a traditional dumpling production apparatus are solved. A forming die set comprises an edge pressing feeding die set and an edge pressing and cutting die set, kneaded dough ispressed into wrappers by a wrapper pressing device, the wrappers are conveyed to the forming die set through the conveying device, the feeding device is arranged at the wrapper input end of the forming die set, the wrappers wrap the feeding pipe, the wrappers are pressed into a barrel shape through the edge pressing feeding die set, the wrapper barrels are filled with the stuffing in the feeding pipe, and the dough barrels with the stuffing are made into independent dumplings through the edge pressing and cutting die set. In the production process of dumplings, automatic, digital, intelligentand informationized control can be realized, so that energy is saved, and a clean and environment-friendly production environment is provided.

Owner:山西长华机械设备有限公司

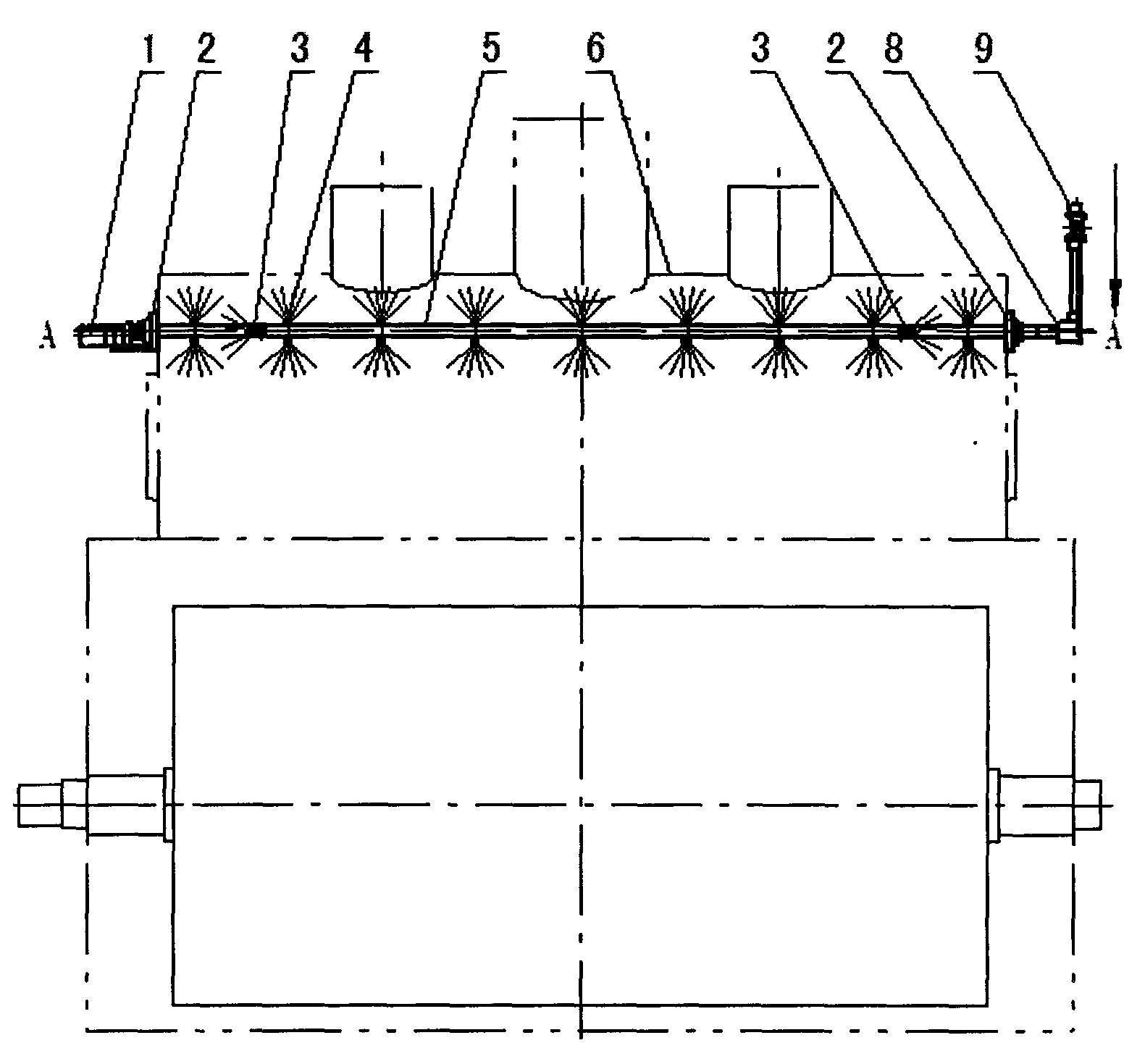

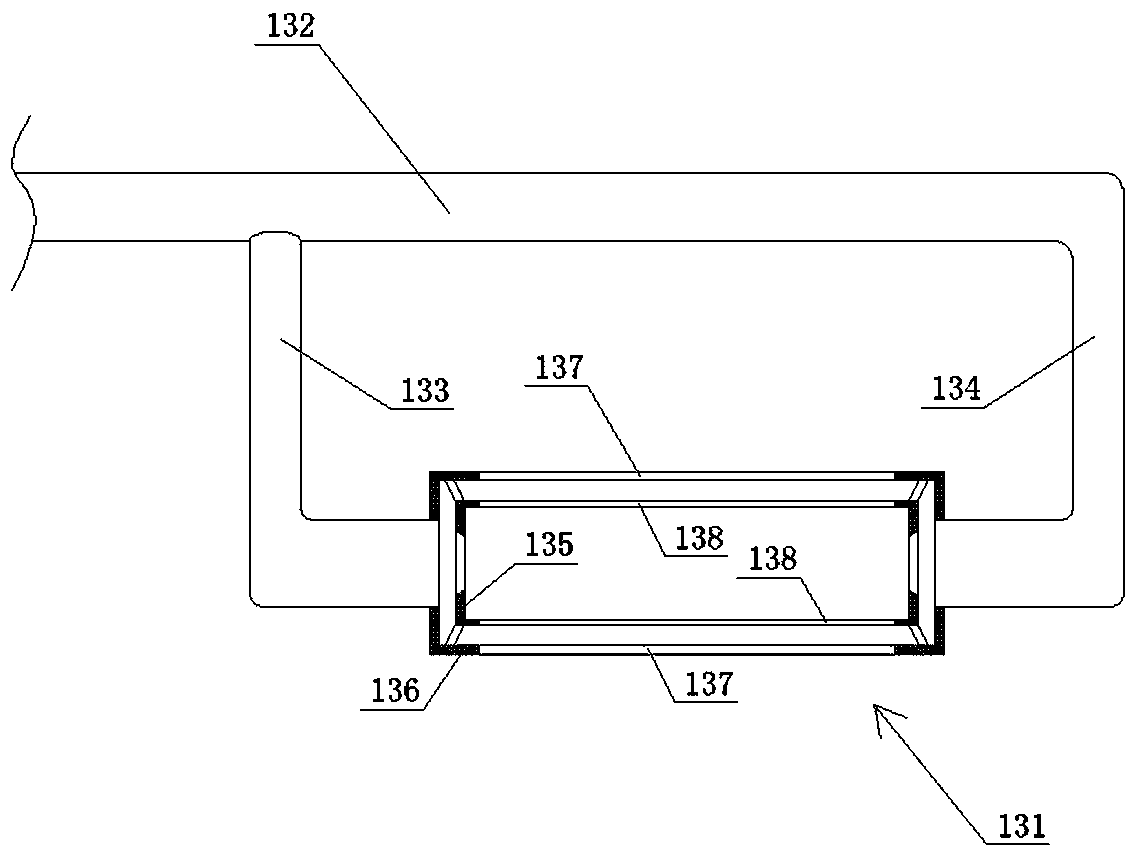

Non-detaching cleaning device for enclosed cover of rotary drum drier

InactiveCN103017506AClean production environmentSimple structureDrying solid materialsCleaning using liquidsWall plateEngineering

The invention discloses a non-detaching cleaning device for an enclosed cover of a rotary drum drier. The non-detaching cleaning device consists of a motor gearing down device, bearing bases, a tubular shaft and a rotary joint, wherein two or more sets of motor gearing down devices, bearing bases, tubular shafts and rotary joints can be arranged in the enclosed cover of the rotary drum drier for using; the tubular shaft is horizontally arranged on the inner upper part of the enclosed cover, and is supported by the bearing bases at the two ends; one end of the tubular shaft is connected with and driven by the motor gearing down device; the other end of the tubular shaft is connected with the rotary joint; and n pair of straight liquid spray pipes and two pairs of bent liquid spray pipes are fixedly arranged on the outer circle of the tubular shaft. Due to the adoption of the non-detaching cleaning device, scale deposits which tend to corrode easily and are accumulated on the inner wall of a wall plate of the enclosed cover, components of a feeding device and the outer walls of pipe fittings can be removed completely in time, and a long-time stable and clean production environment is provided for the production of high-quality foods or food raw materials.

Owner:东台市食品机械厂有限公司

Production method of organic liquid fertilizer

InactiveCN110590450AHigh in nutrientsEasy to measureAmmonium salt fertilisersFertilizer mixturesEnvironmental resistanceMicrobial agent

The invention provides a production method of an organic liquid fertilizer. The production method comprises the following steps: uniformly stirring 100-150 parts of excrement, 50-80 parts of straw, 30-50 parts of aquatic plants, 100-200 parts of biogas slurry and 0.5-2 parts of a microbial agent, performing composting fermentation for 20-30 days at room temperature so as to obtain a fermentation material, performing stirring extraction by using a sodium carbonate aqueous solution at 80-90 DEG C, performing filtering, performing evaporation concentration on the obtained filtrate till the density is 1.1-1.3 so as to obtain an extract, adding 0.1-0.2 part of a trace element, 5-10 parts of natural active organic matter, 1-5 parts of a natural surfactant and 0.5-2 parts of a soil improver, anduniformly mixing the components at the temperature of 45-60 DEG C, so as to obtain the organic liquid fertilizer. The fertilizer prepared by using the method has a good use effect and is an efficientenvironment-friendly organic liquid fertilizer.

Owner:GUIZHOU STANLEY FERTILIZER

Method for producing seaweed liquid fertilizer specifically for rhizoma gastrodiae

InactiveCN106854112ADoes not affect listing and salesNo pollutionAmmonium salt fertilisersOrganic fertilisersFiltrationEvaporation

The invention provides a method for producing seaweed liquid fertilizer specifically for rhizoma gastrodiae. The method comprises uniformly mixing 100-150 parts of seaweed extract, 0.1 to 0.5 parts of trace elements, 1 to 5 parts of botanical pesticide extract, 5 to 10 parts of a natural active organic matter, 1 to 5 parts of a natural surfactant and 1 to 5 parts of a soil improver. A preparation method of the seaweed extract comprises uniformly stirring 100 to 150 parts of natural seaweed powder, 100 to 200 parts of washing water of rice, 0.1 to 2.0 parts of an EM bacterial fermentation solution and 0.1 to 2.0 parts of sugar, carrying out composting fermentation at the room temperature to obtain a fermented seaweed material, stirring the fermented seaweed material and a sodium carbonate aqueous solution, carrying out extraction, carrying out filtration to obtain a filtrate, and carrying out evaporation concentration until density of 1.2-1.3 to obtain seaweed extract. The seaweed liquid fertilizer has good use effects and is highly effective and eco-friendly seaweed liquid fertilizer.

Owner:GUIZHOU UNIV

Ageing-resistant heat-insulation tarpaulin and production method thereof

InactiveCN101792975BImprove waterproof performanceGood insulation performanceHeating/cooling textile fabricsTextile treatment by pouringFiberPre treatment

The invention discloses an ageing-resistant heat-insulation tarpaulin. The tarpaulin is composed of a polymer cloth base and an ageing-resistant heat-insulation coating which is coated on the polymer cloth base in a casting mode. After aging is quickened for 236 hours by simulating natural manual work, the tensile strength of the tarpaulin is improved by at least 10%, the elongation at break thereof is improved by at least 5% than the elongation at break before aging, the ultraviolet reflectivity thereof is more than or equal to 80%, and the infrared obstruction rate thereof is more than or equal to 85%. The invention also discloses a preparation method thereof, comprising the following step: pretreating a heat-insulation material by utilizing a surface treating agent; and premixing the heat-insulation material with accessory ingredients such as vinyl type polymer, antioxidant and the like, then putting the heat-insulation material and the accessory ingredients into a double-screw extrusion casting coating machine to be fused, plasticized and extruded out to be casted and coated on the polymer fiber cloth base, and carrying out cooling shaping and reeling by utilizing a cooling roll to obtain the ageing-resistant heat-insulation tarpaulin. The tarpaulin product obtained by the invention has favourable water proofness, heat-insulating property and ageing-resistant property, wide application range, no pollution in the production process, small energy consumption, low cost and easy popularization and application.

Owner:SICHUAN UNIV

Chemical deodorant and preparation method

InactiveCN106975093AClean production environmentSimple preparation processDeodrantsTurpentineRaw material

The present invention relates to providing a chemical deodorant and its preparation method, comprising the following raw materials in parts by weight: 20-35 parts of amino alcohol, 10-25 parts of menthol, 15-20 parts of phenylacetic acid, and 5 parts of essence ~15 parts, 2~8 parts of eucalyptus oil, 5~10 parts of citric acid, 20~40 parts of water, 5~10 parts of turpentine, 5~10 parts of carboxymethyl cellulose. The chemical deodorant and its preparation method described in the present invention can effectively remove the stench in the chemical plant without producing toxic and dangerous gases, and clean the production environment of the chemical plant. The preparation process of the deodorant is simple, and the used The raw materials are easy to get and the cost is low.

Owner:余小琴

Production method of seaweed liquid fertilizer special for pseudostellaria heterophylla

InactiveCN106748157ADoes not affect listing and salesNo pollution in the processAmmonium salt fertilisersOrganic fertilisersPseudostellariaEffective microorganism

The invention provides a production method of a seaweed liquid fertilizer special for pseudostellaria heterophylla. According to the method, the seaweed liquid fertilizer is prepared by uniformly mixing 100 to 150 parts of seaweed extracting liquid, 0.1 to 0.5 part of microelements, 1 to 10 parts of botanical pesticide extracting liquid, 1 to 5 parts of natural active organic matters, 1 to 2 parts of natural surfactants and 1 to 2 parts of soil improvement agents, wherein a preparation method of the seaweed extracting liquid comprises the steps that 100 to 150 parts of natural seaweed powder, 100 to 200 parts of rice washing water, 0.1 to 2.0 parts of EM (effective microorganism) flora fermentation liquid and 0.1 to 2.0 parts of sugar are uniformly stirred and are then subjected to composting fermentation at room temperature to obtain a fermented seaweed material; a sodium carbonate water solution is used for stirring and extraction; filtering is performed; the obtained filter liquor is evaporated and concentrated to reach the density being 1.2 to 1.3; the seaweed extracting liquid is obtained. The use effect is good; the seaweed liquid fertilizer belongs to an efficient and environment-friendly seaweed liquid fertilizer.

Owner:GUIZHOU UNIV

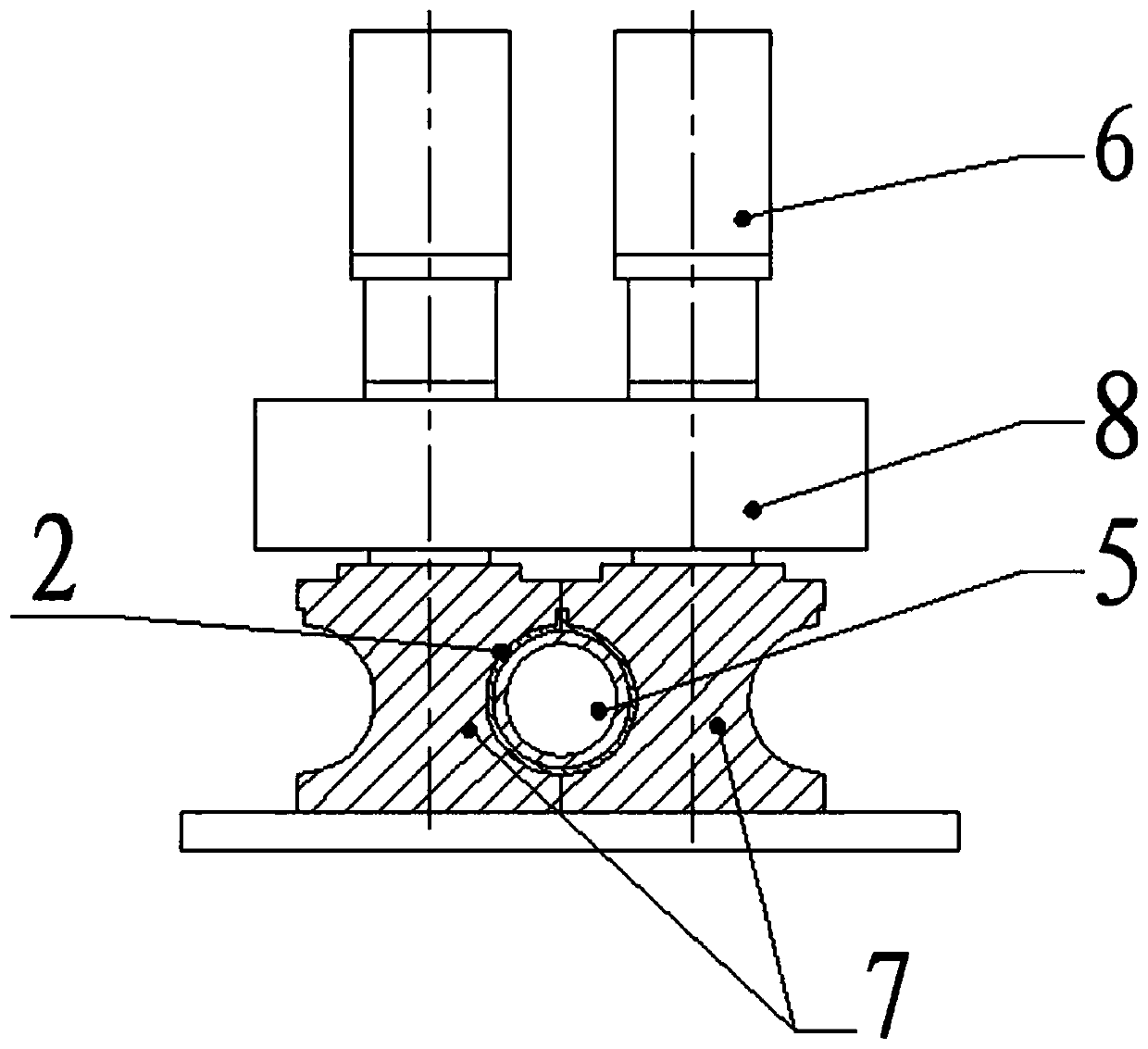

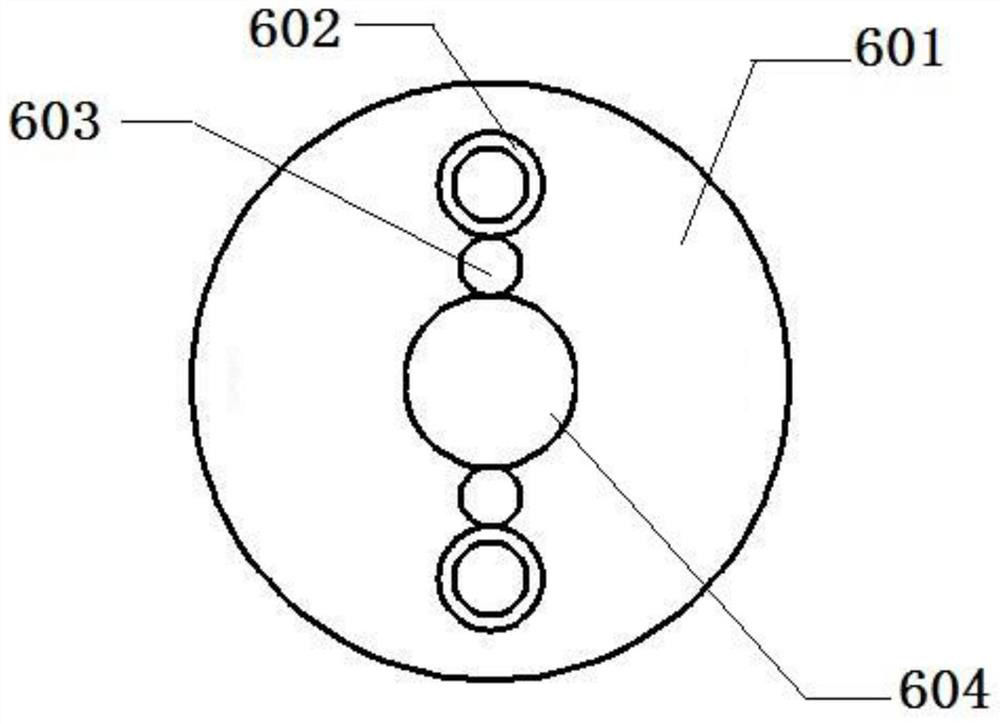

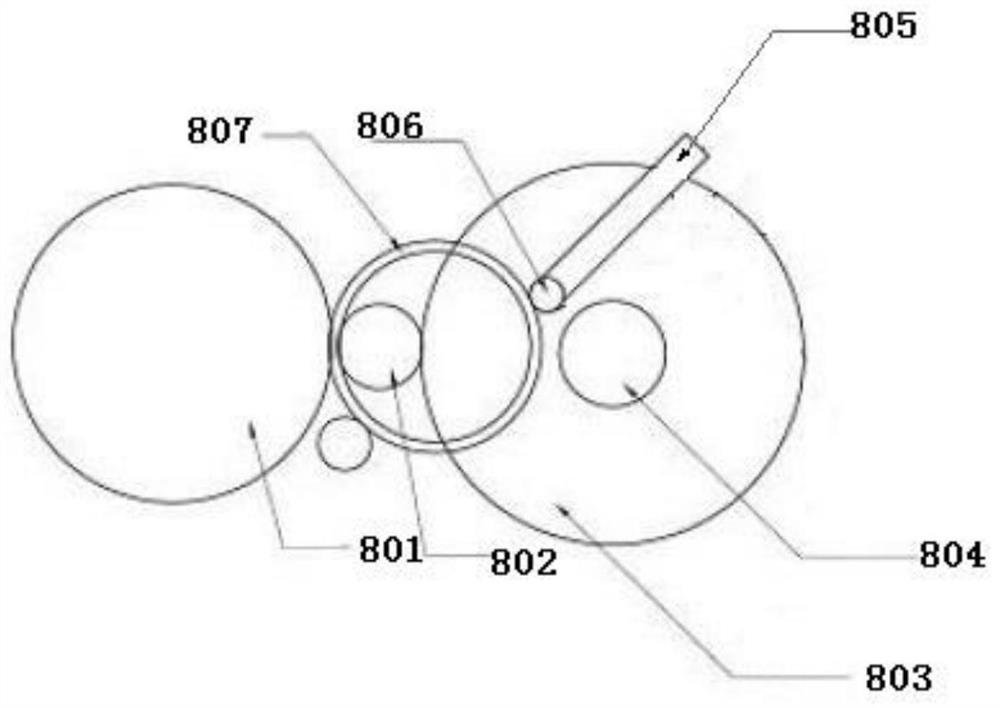

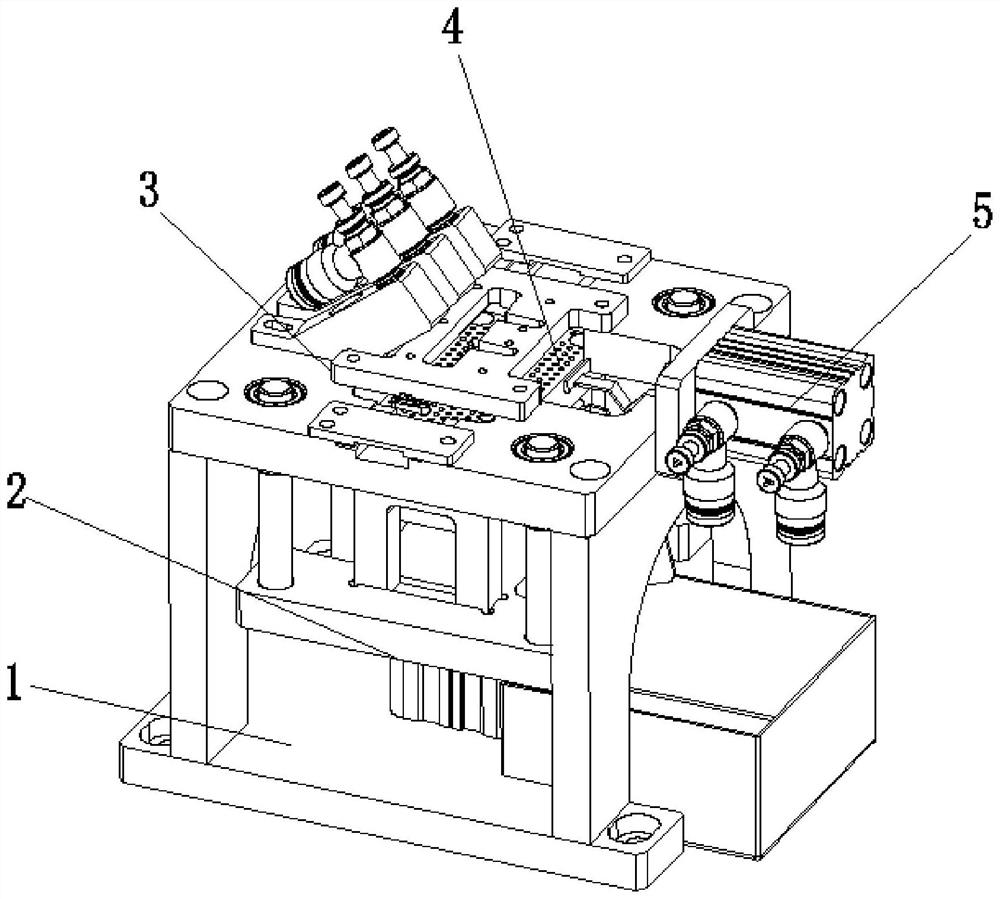

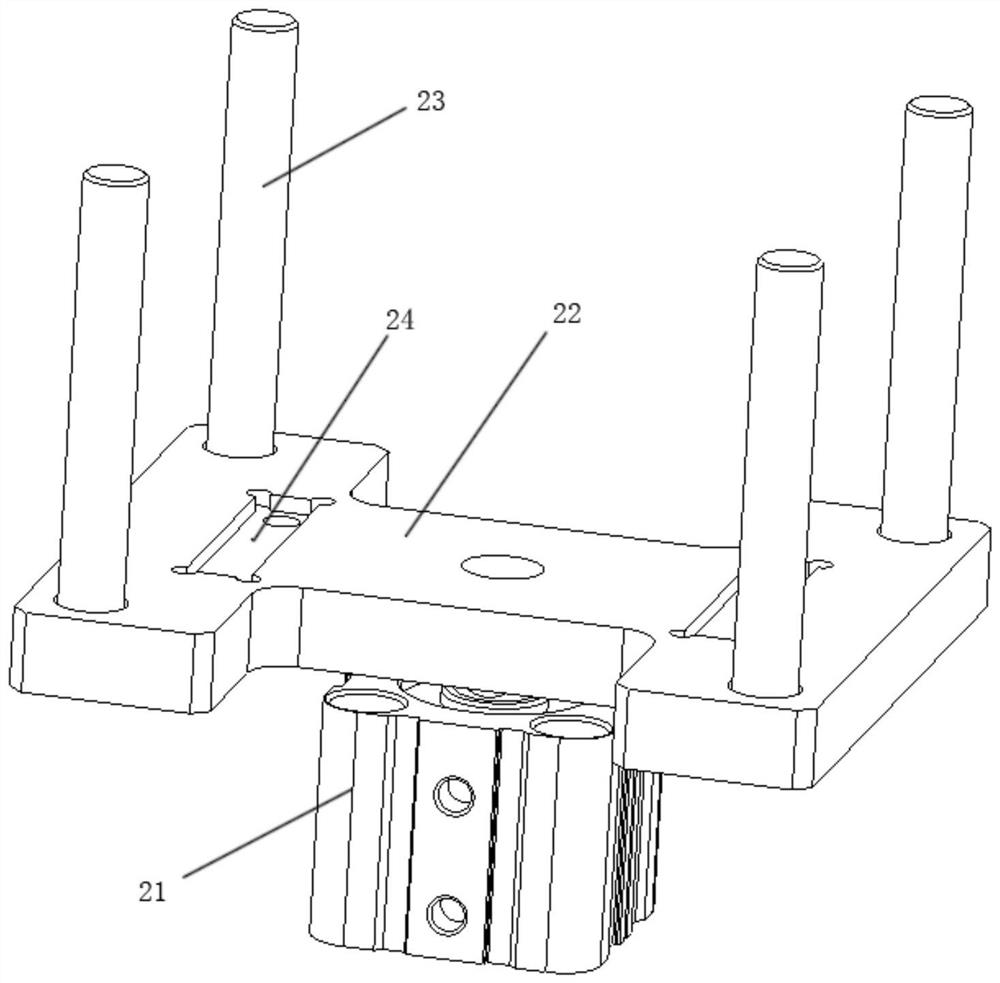

A bearing ring processing device

ActiveCN108655752BLow Carbide GradeHigh grain sizeOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention discloses a bearing ring machining device. The bearing ring machining device comprises a feeding device, a turning device, a cutting device, a cold expanding device and a heat treatmentdevice. The feeding device comprises a storage box, an ejection device and a conveying device. The ejection device is arranged at the bottom of the storage box. The conveying device is arranged at thetop of the storage box and is provided with a through hole. The through hole is parallel to the ground, and an electric friction wheel is arranged in the through hole. A rotary bearing is arranged onthe outer side of the electric friction wheel. The turning device is arranged on the side face of the feeding device. The cutting device is arranged between the turning device and the conveying device. The cold expanding device is arranged below the turning device. The heat treatment device is arranged below the cold expanding device. By adoption of the bearing ring machining device, the problemsof low bearing ring machining efficiency and poor bearing ring machining precision of the prior art are solved; and the bearing ring machining device has the characteristics of being simple in structure and convenient to use.

Owner:常熟缘阳机械制造有限公司

Anhydrous dyeing process and production line of high-end environment-friendly PU leather base cloth

ActiveCN109914055AImprove qualityStrong and goodMechanical cleaningPressure cleaningProduction lineRoom temperature

The invention provides an anhydrous dyeing process and production line of high-end environment-friendly PU leather base cloth. The process includes the following step that greige cloth is sequentiallyand continuously subjected to cloth feeding, desizing, water washing, drying, rolling at room temperature, drying, color development and cropping. The process improves many problems caused by batch production of traditional leather base cloth with a dyeing cylinder. The anhydrous dyeing process and production line of high-end environment-friendly PU leather base cloth are ideal in design, each link is operated separately and independently, a production mode of an assembly line is formed, the production efficiency is greatly improved, and 50% labor can be saved. The water consumption is small,operation is performed just at room temperature, energy conservation and environment protection are achieved, energy consumption of dyeing is basically equal to zero, the dyeing rate is high, the prepared PU leather base cloth is high in strength, has no color difference, and the product quality is excellent. Meanwhile, the labor intensity of workers is reduced, operation is more convenient, flying nap, a dirty floor and dirty water can be effectively controlled, and the production environment in a workshop can be cleaner.

Owner:福建格利尔印染有限公司

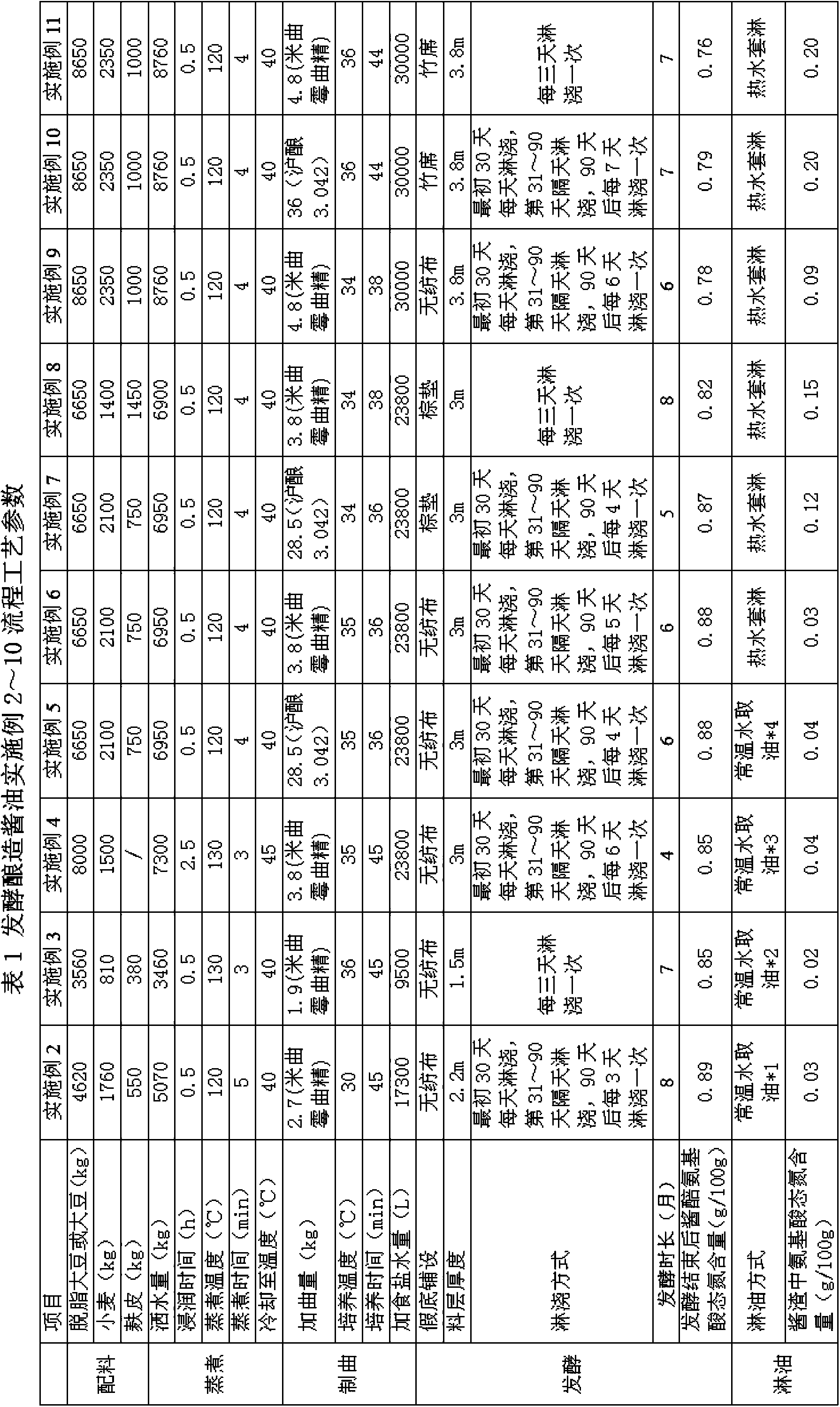

Brewing method for high-salt liquid-state fermentation soy sauce

The invention discloses a brewing method for a high-salt liquid-state fermentation soy sauce. The brewing method comprises the following steps of: preparing materials, stewing the materials, producing a starter, fermenting and spraying oil, wherein the steps of fermenting and spraying oil are carried out in a glass steel can. The fermenting specifically comprises the following processes of: adding the materials which are treated by the steps of preparing materials, stewing the materials and producing the starter to a saline solution, weight of which is 2-3 times that of the materials; adding the mixture to the glass steel can which is paved with a false substrate at the bottom, controlling the thickness of the fermentation layer to 1.5m-3.8m, and spraying and fermenting for 4-8 months. The spraying and fermenting specifically comprises the following processes of: spraying every day at the initial 30 days of the fermenting; spraying every two days from the 31st day to the 90th day; spraying every 3-7 days after the 90th day, wherein each spraying time is 3 minutes to 10 minutes, and the flow rate is 20kg / min to 40kg / min. According to the brewing method disclosed by the invention, the environment is sealed in the fermentation process, and is sanitary and safe. The process for fermenting and spraying oil in a same fermentation tank are simpler, efficient and low in production cost; and the production environment is clean and sanitary for being beneficial to saving energy and reducing emission. Besides, the produced soy sauce is good in flavor and bright in color.

Owner:四川清香园调味品股份有限公司

Sheet-shaped sheet metal part laser cutting auxiliary device

PendingCN113492260APrecise positioningClean production environmentLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a sheet-shaped sheet metal part laser cutting auxiliary device. The sheet-shaped sheet metal part laser cutting auxiliary device comprises a positioning assembly, a jacking assembly, a guide cleaning assembly, a material pushing assembly and a support assembly, wherein the positioning assembly is used for providing a positioning platform to position a workpiece; the jacking assembly is used for jacking the positioning assembly upwards to guide and position the workpiece; the guide cleaning assembly is used for providing a material feeding channel and cleaning waste materials in the cutting process; the material pushing assembly is arranged on one side of the guide cleaning assembly to be used for providing a waste material separation effect; and the positioning assembly and the jacking assembly are installed in the support assembly, furthermore, the positioning assembly is installed on the jacking assembly, and the guide cleaning assembly is installed at the upper end of the support assembly. According to the sheet-shaped sheet metal part laser cutting auxiliary device, a multifunctional structure integrating the functions of material feeding and discharging, positioning, cutting, cleaning, material stirring and separating and the like of laser cutting is integrated, the production efficiency is effectively improved, furthermore, positioning is more convenient, and the applicability is wide.

Owner:铭镭激光智能装备(河源)有限公司

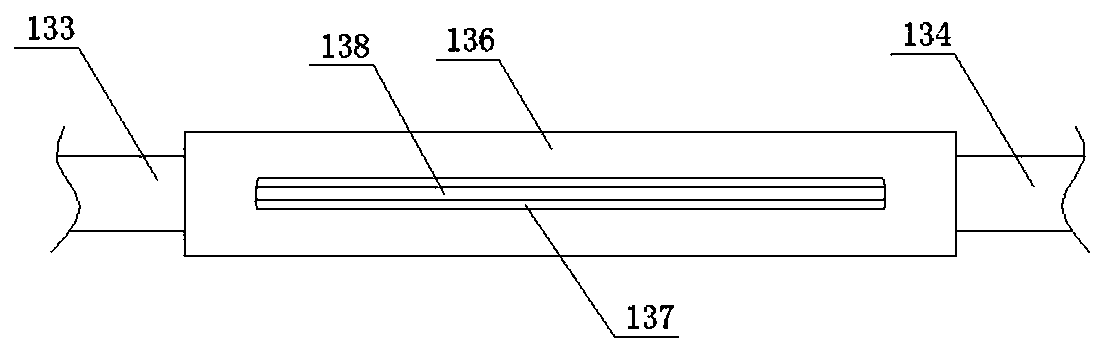

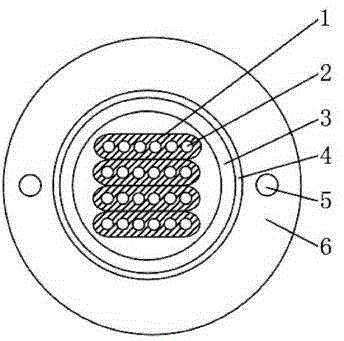

Layer-stranded ribbon fiber cable for electric power or communication

The invention belongs to the field of fiber cable technology, in particular to a layer-stranded ribbon fiber cable for electric power or communication. The ribbon fiber cable comprises multiple loose tubes outside a reinforcing piece and a small filling rope in an outer gap of every two adjacent loose tubes. The loose tubes and the small filling ropes are provided with a protection layer outside. The exterior of the protection layer is coated by a sheath layer in an extrusion molding manner. The fiber cable is characterized in that multiple fiber cable ribbons are arranged in each of the loose tubes; each of the fiber cable ribbons is provided with multiple optical fibers and multiple fiber cable ribbon resin coating the whole optical fibers; there is no other visible filling matter except for the fiber cable ribbons in gaps of the loose tubes; and there is no visible filling material in gaps formed by the loose tubes, the reinforcing piece, the small filling ropes and the protection layer. The beneficial effects are that the fiber cable ribbons have quite high water resisting performance; cost of the fiber cable is quite low; the fiber cable is quite environmentally-friendly and light; detection and construction are quite convenient to perform; and production environment is quite clean.

Owner:孙海东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com