Brewing method for high-salt liquid-state fermentation soy sauce

A high-salt dilute soy sauce, pouring and fermenting technology, applied in application, food preparation, food science and other directions, can solve the problems of difficult application, cumbersome process, high energy consumption, etc., and achieves reduced production cost, simple process and good flavor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 6650kg of defatted soybeans, screen and remove impurities, mix them with 750kg of bran, add them to a rotary steamer, sprinkle water with a total weight ratio of 73% of the raw materials (percentage by weight), soak for 30 minutes, cook at 120°C for 3 minutes, and quickly Out of the tank and transferred to the ventilated curved bed by conveying equipment, and 2100kg of wheat flakes were mixed in. Turn on the fan to cool to 40°C, and evenly mix in 0.3% by weight of Shanghai Brewed 3.042 Aspergillus oryzae seed koji, transfer to the ventilated koji bed, and cultivate at 30-36°C for 36 hours. Stir 2.5 times of 22% (salt weight percentage) salt water according to the weight ratio of raw materials, and ferment in a glass fiber reinforced plastic fermenter in the natural sun. The bottom of the fermentation tank is laid with non-woven fabric as a false bottom. The thickness of the material and water mixture entering the fermentation tank is 3.0 meters. It is poured every...

Embodiment 2~10

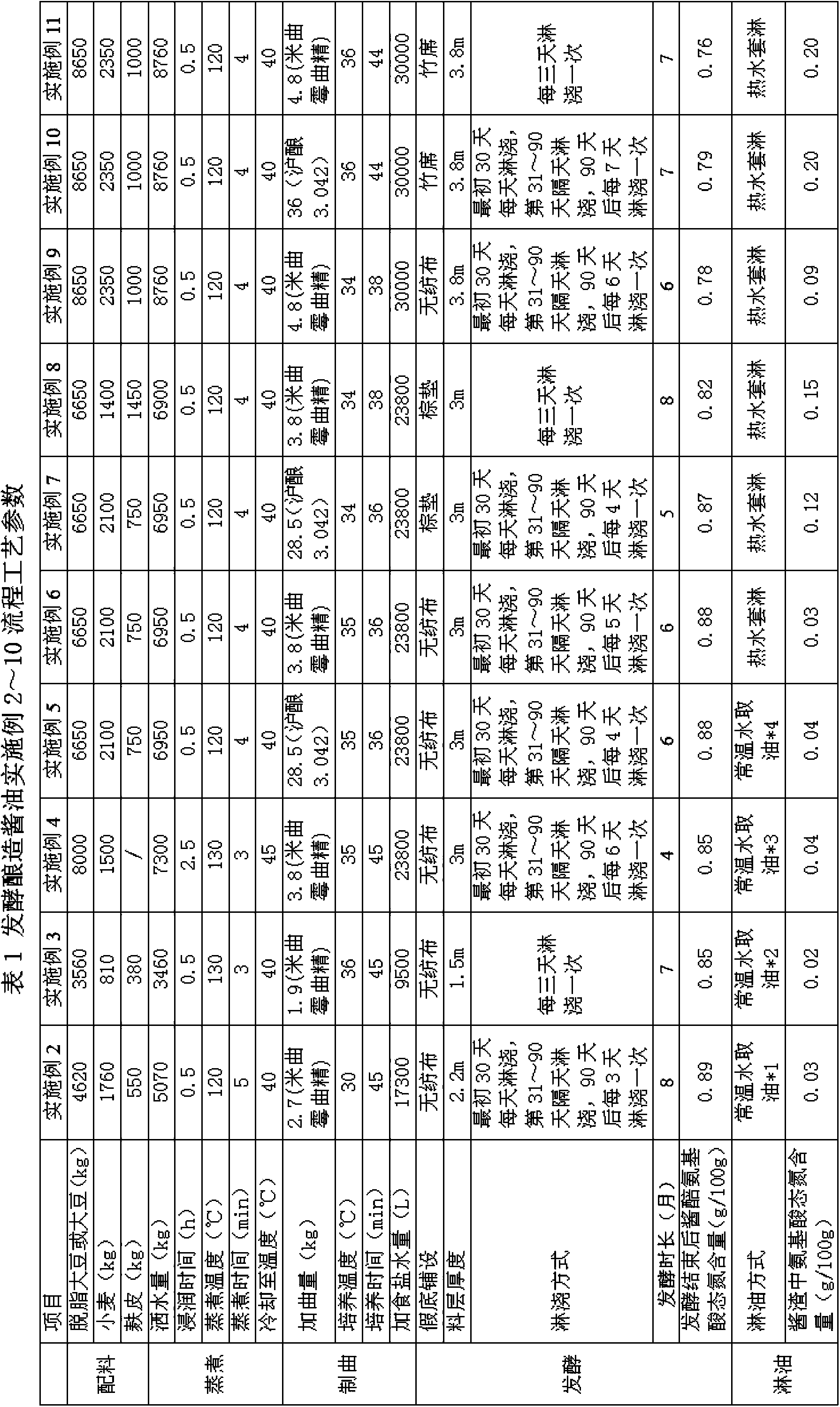

[0041] The implementation process is the same as in Example 1, and the specific process parameters and results are shown in Table 1, and the unspecified items are the same as in Example 1.

[0042]

[0043] Remarks: *1: In this example, the real-time measured temperature of the three oils, four oils, and salt water added before the oil pouring is 5°C;

[0044] *2: In this example, the real-time measured temperature of the three oils, four oils, and salt water added before the oil pouring is 35°C;

[0045] *3: In this example, the real-time measured temperature of the three oils, four oils, and salt water added before the oil pouring is 23°C;

[0046] *4: In this example, the real-time measured temperature of the three oils, four oils, and salt water added before the oil pouring was 12°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com