Movable rotary drum type composting reactor

A composting reactor and drum-type technology, applied in application, organic fertilizer, fertilization device, etc., can solve the problems of lack of monitoring and control of process parameters, incomplete mixing, high energy consumption, etc., to achieve automatic monitoring and real-time Control, improve ventilation effect, enhance heat and mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

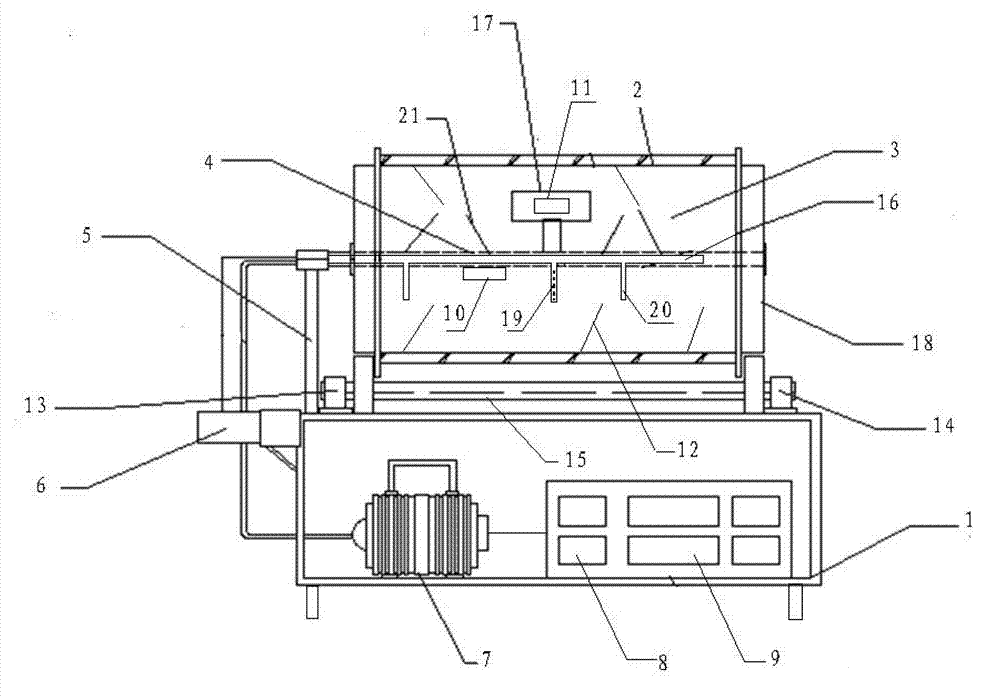

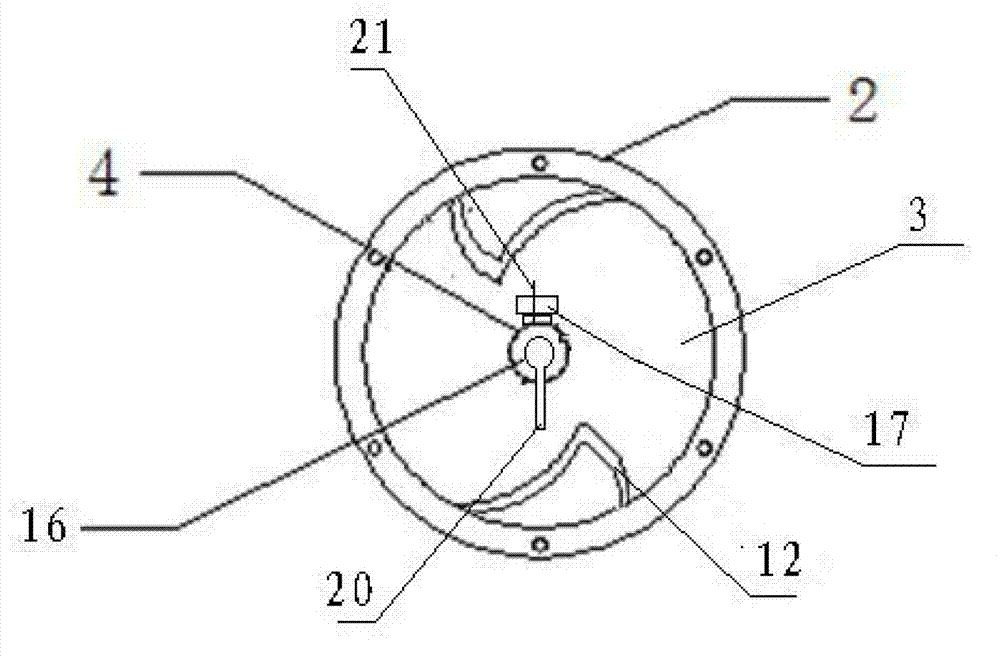

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] like figure 1 , figure 2 Shown, a kind of movable drum type composting reactor of the present invention, this reactor comprises the workbench 1 with movable wheel, horizontal drum 3, center tube 4, motor 6, blower fan 7, data collector 8 and control Terminal 9;

[0019] Wherein, the motor 6, the fan 7, the data collector 8 and the control module 9 are installed on the workbench 1 with movable wheels, and the upper end surface of the workbench 1 is provided with a support 5, a driving wheel 13, and a drive shaft 15 in turn from left to right. And driven wheel 14, one end of driving wheel 13 is connected with the output shaft of motor 6, and the other end is connected with driven wheel 14 by drive shaft 15, and described horizontal drum 3 is erected on the drive shaft 15, and horizontal drum 3 The outer layer is wrapped with an insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com