Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Calorific value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of producing an upgraded bio-oil

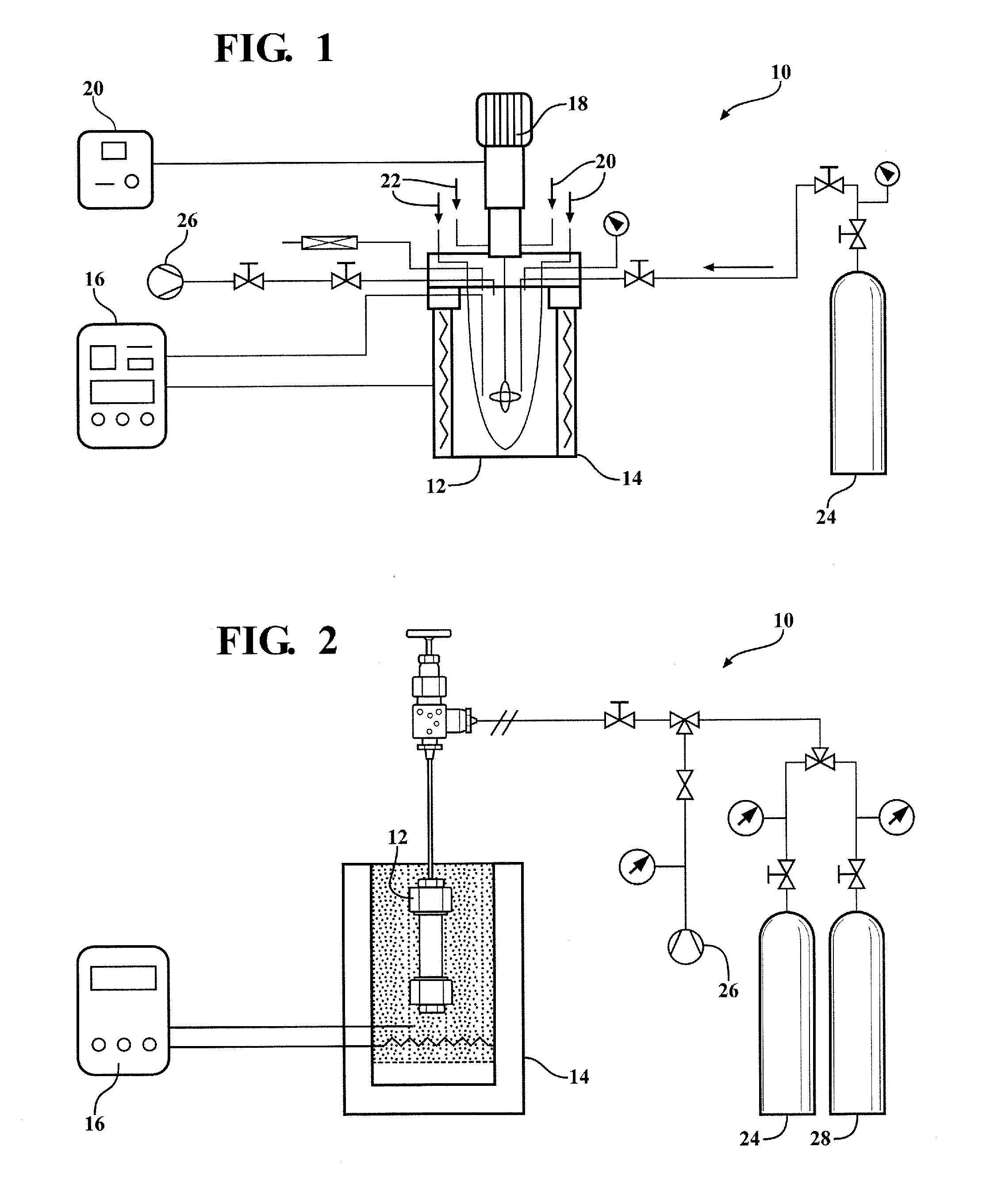

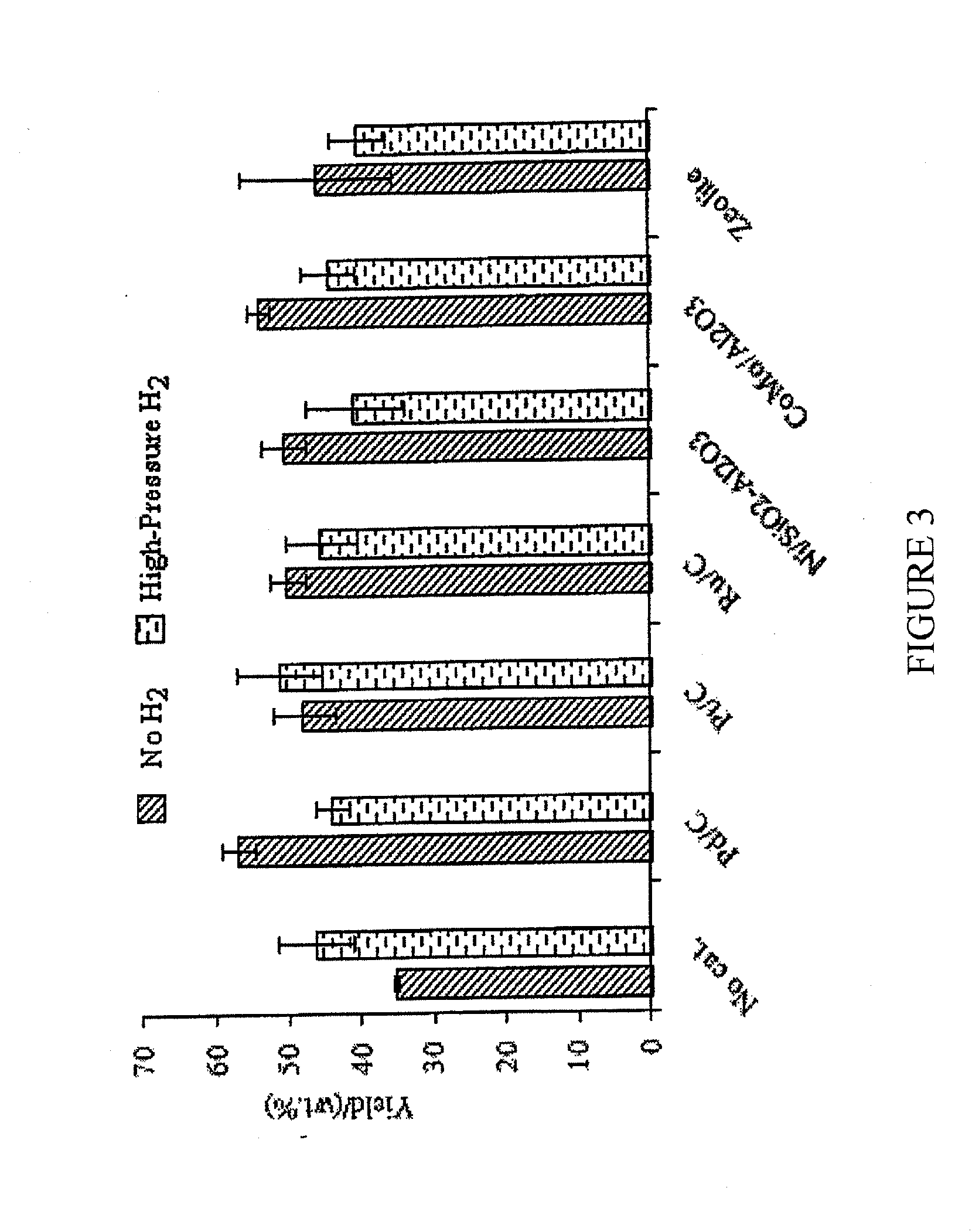

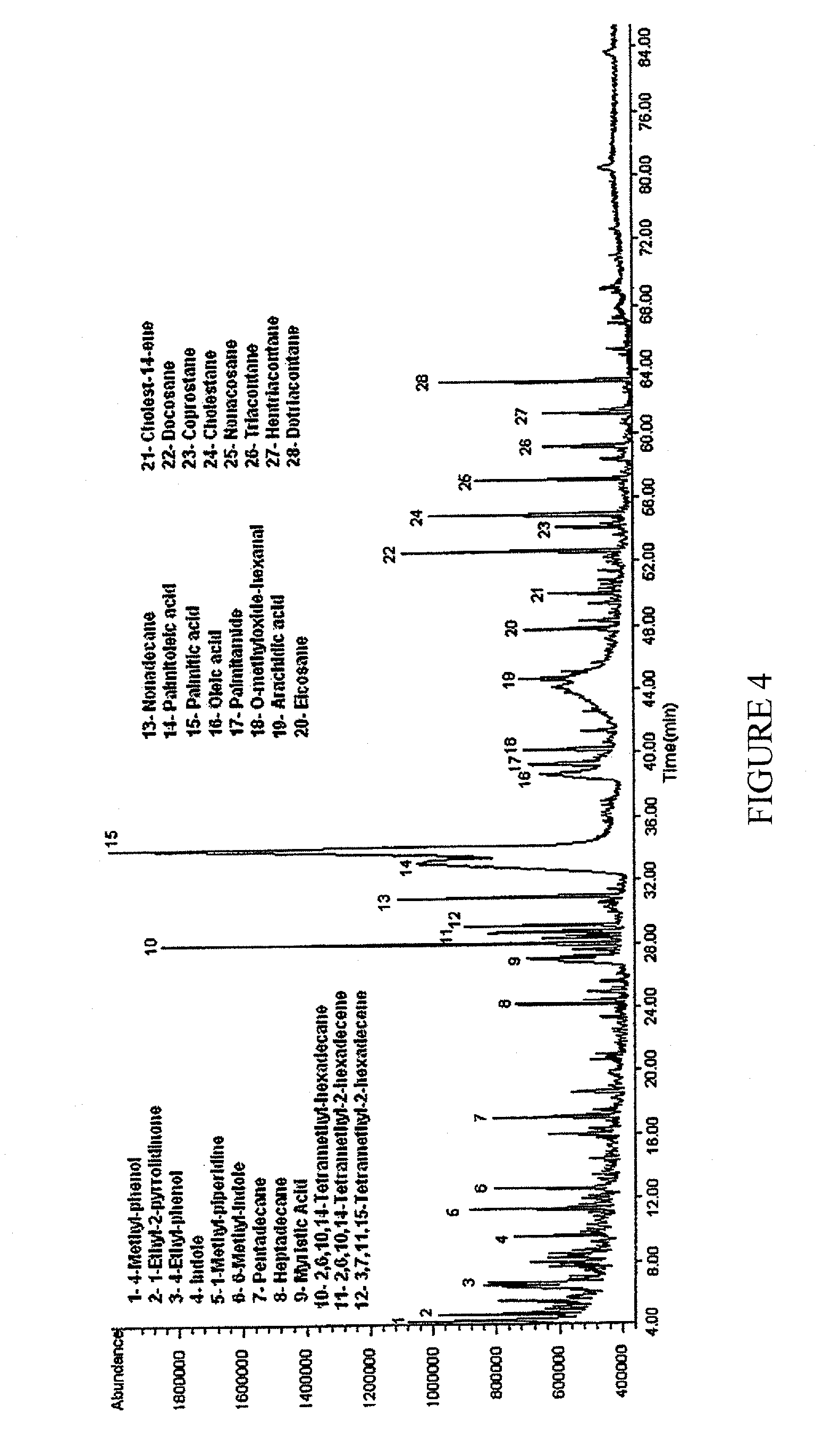

InactiveUS20120055077A1Cost reductionExcellent heating valueLiquid carbonaceous fuelsBio-feedstockBiomassPressure range

A method of producing an upgraded bio-oil from a wet biomass that includes heating the wet biomass at a first temperature and a first pressure for a time period ranging from 10 to 200 minutes to form a crude bio-oil. The first temperature ranges from 200 to 400° C. and the first pressure ranges from 0.1 to 25 MPa, with the proviso that at least a portion of the water present in the wet biomass remains in a liquid phase throughout the step of heating to form the crude bio-oil, and the first temperature and pressure are below super-critical conditions for water. The method also includes heating the crude bio-oil and the water at a second temperature and a second pressure to form the upgraded bio-oil. Some water remains in the liquid phase or in a super-critical fluid phase throughout the step of heating to form the upgraded bio-oil.

Owner:THE RGT OF THE UNIV OF MICHIGAN

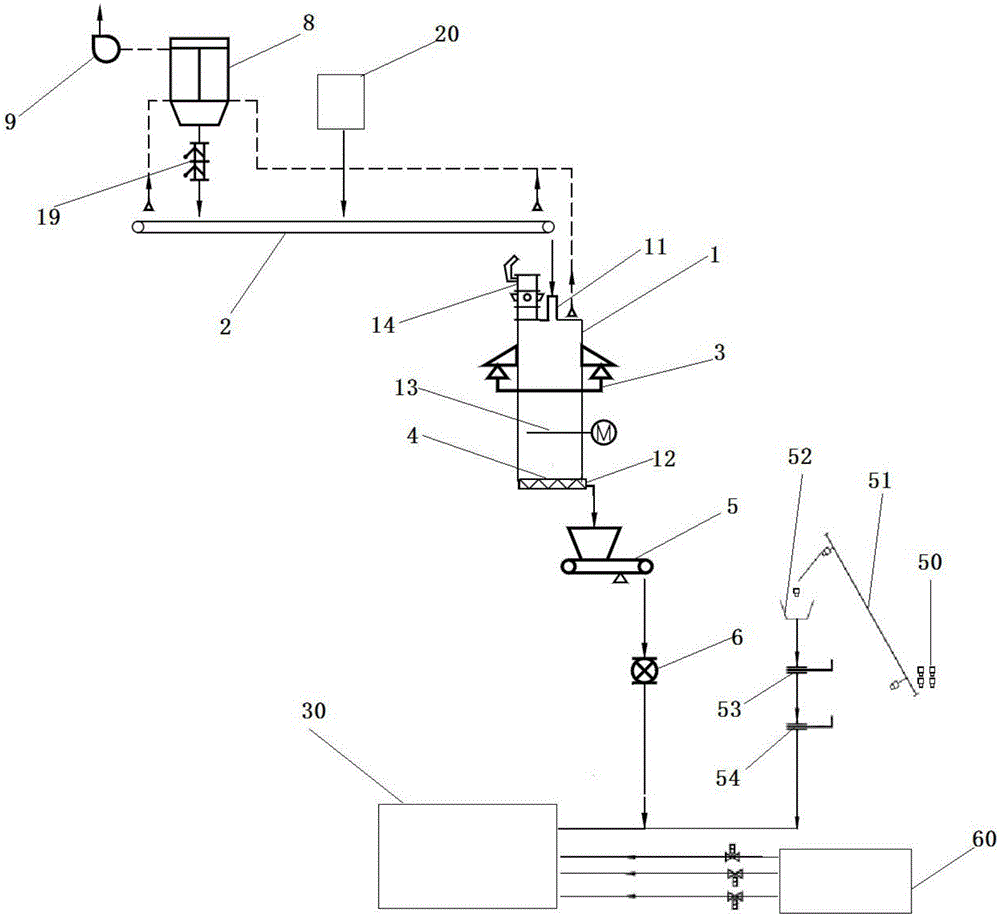

Gradually-expanding premixing porous medium combustor for combusting biomass gasification gas

ActiveCN102418927AReduce the degree of skew instabilityImprove stabilityGaseous fuel burnerPorous mediumLow load

The invention relates to a gradually-expanding premixing porous medium combustor for combusting biomass gasification gas. The combustor is provided with gradually-expanding pipes, wherein a porous medium with catalytic action is filled in each gradually-expanding pipe; a heater is coated outside each gradually-expanding pipe; each gradually-expanding pipe is wholly embedded into a thermal insulating layer; a capacity expansion chamber is formed at an inlet of each gradually-expanding pipe; a tempering prevention piece and a flow equalization plate are arranged in each capacity expansion chamber; and an inlet of each capacity expansion chamber is connected with a premixing tube. Flame deflection and other unstable combustion phenomena can be avoided, flames can be effectively prevented from being blown out of the combustor, the power of the combustor is improved, the working range of the combustor is expanded, and the load and working condition changes of the combustor are met. Moreover, the combustor has a function of adjusting gas flow, and parallel gradually-expanding pipes are prevented from being shut down due to over-low load or prevented from being subjected to over-high load; and the biomass gasification gas can be subjected to super adiabatic combustion in the combustor, the lean flammability limit of fuel is greatly expanded, and the fuel with ultralow heat value can be stably combusted. Meanwhile, the flame area is widened, the combustor contributes to accelerating cracking combustion of tar, and the combustion efficiency is improved.

Owner:SHENYANG INST OF ENG +1

Method for conditioning urban sludge by agent compounding

InactiveCN108083609AImprove dehydration effectCalorific valueSludge treatment by de-watering/drying/thickeningElectrochemical sludge treatmentDewatered sludgeMoisture

The invention discloses a method for conditioning urban sludge by agent compounding. The method comprises (1) adjusting pH through an acid solution, then adding iron powder and activated carbon powderinto sludge, carrying out full stirring mixing, starting an aeration device to condition and transferring a part of substances in the sludge into the liquid phase, (2) adding a persulfate into the sludge conditioned in the previous step, activating the persulfate through ferrous ions, oxidizing to break the sludge so that combined water, adsorbed water, interstitial water and free water in the sludge are partially separated, the dewaterability is improved and SCOD, proteins and polysaccharide in the sludge are increased, and (3) after sludge conditioning, carrying out mechanical dewatering toobtain dewatered sludge. The method can reduce the moisture content of the urban sludge from 97 to 99% to 55 to 60%, greatly reduce the specific resistance and volume of the sludge, greatly improve the combustion calorific value, realize harmlessness, stabilization, reduction and recycling of sludge and has a wide application prospect.

Owner:NANCHANG HANGKONG UNIVERSITY

Aged garbage-primary garbage collaborative incineration method

ActiveCN110131726AAvoid enteringNo waste of resource utilization valueBioreactor/fermenter combinationsWeighing by removing componentResource utilizationComputer science

The invention relates to the field of garbage incineration treatment, and in particular relates to an aged garbage-primary garbage collaborative incineration method. The collaborative incineration method comprises the following steps that the aged garbage is sorted to obtain combustible, the aged garbage combustible and the primary garbage are stored in a partitioned mode, the low calorific valueof the primary garbage and the low calorific value data of the aged garbage can be rapidly obtained by simple classification and determination of the moisture content, and the calorific value data ofthe garbage mixture is obtained according to the blending burning ratio. According to the method, the aged garbage is sorted to ensure that all the components of the aged garbage obtain a proper resource utilization way according to the properties, the combustible matters sorted by the aged garbage and the original garbage are incinerated, and the heat value of the material entering a furnace is optimized, and the quality of the material entering the furnace is improved; and the heating value of the material entering the furnace can be ensured to be within the heat load range borne by a gratefurnace, and the operation condition of a garbage incineration system is optimized.

Owner:CHENGDU XINGRONG RENEWABLE ENERGY CO LTD

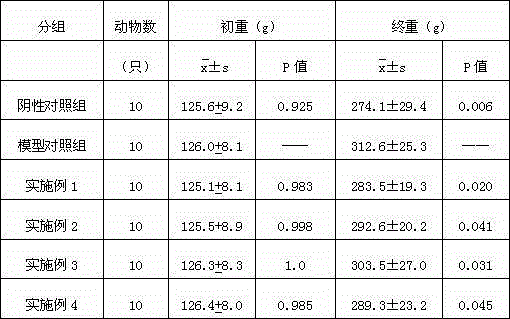

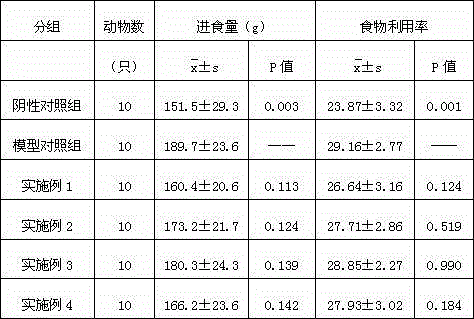

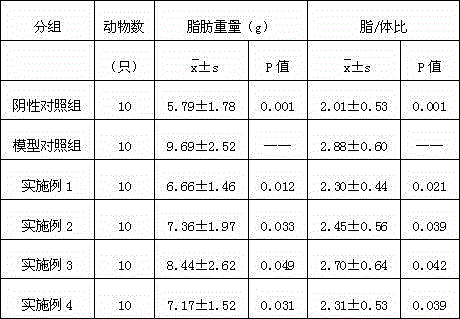

Weight-losing health food

InactiveCN104432068APromote decompositionPromote absorption and metabolismNatural extract food ingredientsFood ingredient functionsBiotechnologyIdeal weight

The invention discloses a weight-losing health food. The weight-losing health food is prepared from the following components in percentage by weight: 10%-28% of lindera strychnifolia leaf extract, 4%-13% of malic acid, 3%-8% of stevioside, 12%-32% of lotus leaf powder, 10%-34% of fruit and vegetable powder and 20%-40% of inulin. The raw materials of the weight-losing health food are scientific in composition, reasonable in cooperation, natural in components and proper in use amount, and the weight-losing health food is convenient to take, has a remarkable weight losing effect and has no obvious side effects, so that the weight-losing health food is the ideal weight-losing health food.

Owner:WEIHAI BAIHE BIOTECH

Method for preparing water coke slurry fuel by using oily water

InactiveCN101886005AEasy to operateReduce energy consumptionLiquid carbonaceous fuelsTreatment costsSewage

The invention relates to a method for preparing a novel environment-friendly water coke slurry fuel by using the resource recycling technology of combining oily water and water coke slurry. The novel environment-friendly water coke slurry fuel comprises the following raw material components in percentage by weight: 62 to 72 percent of petroleum coke powder of which over 80 percent of the petroleum coke powder passes a 200-mesh sieve, 28 to 38 percent of oily water and 0.5 to 1.5 percent of dispersant, wherein the components are mixed and stirred at normal temperature under normal pressure to form high-dispersion stable slurry. The method has the advantages of simple operation, low energy consumption and low cost; the prepared water coke slurry has good fluidity and strong stability, does not need to add a stabilizing agent, fully meets the requirement of a boiler for fuel combustion, realizes the resource recycle of the oily water, reduces the treatment cost of the oily water, and has good market prospect and popularization value.

Owner:SHANDONG UNIV OF SCI & TECH

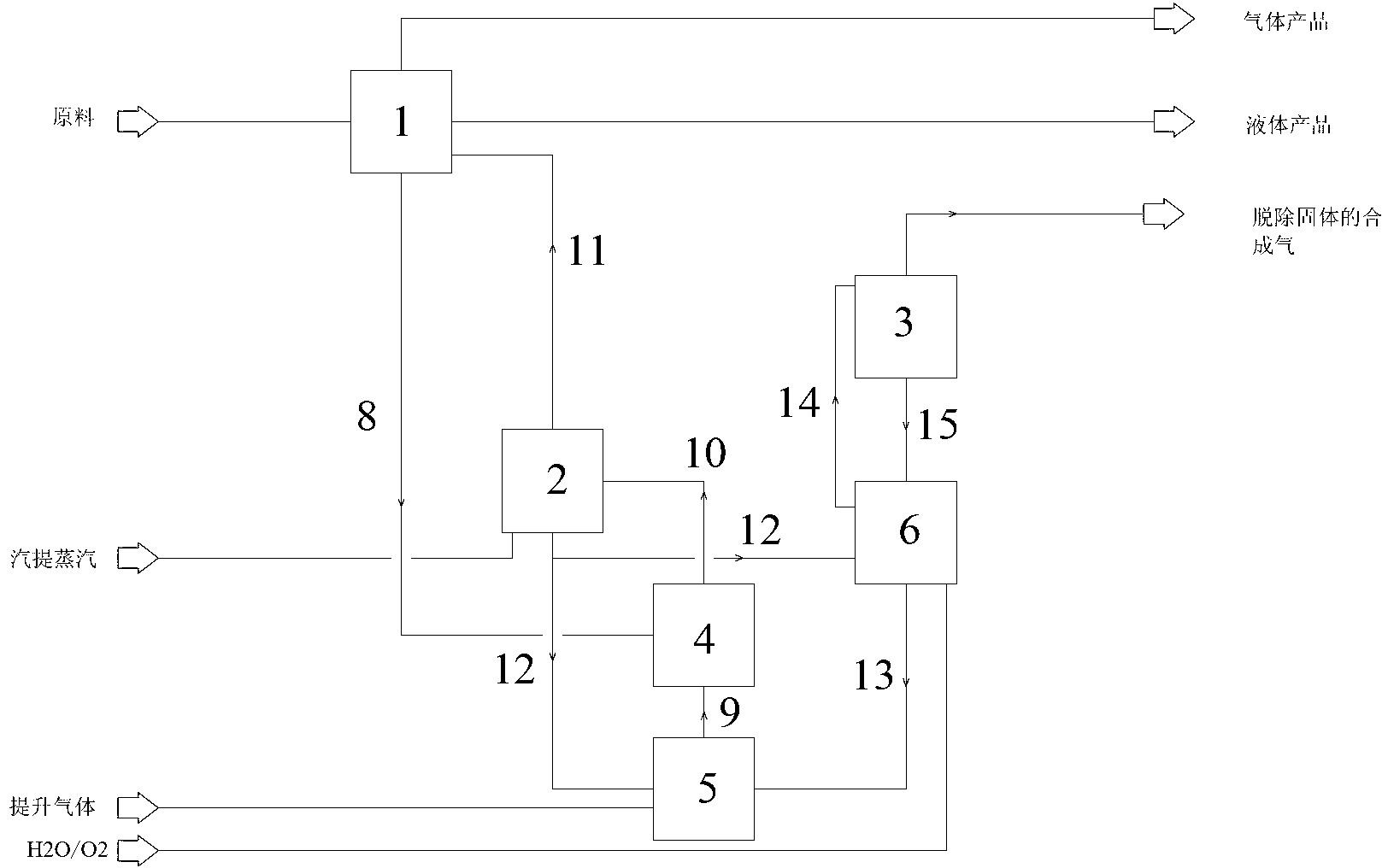

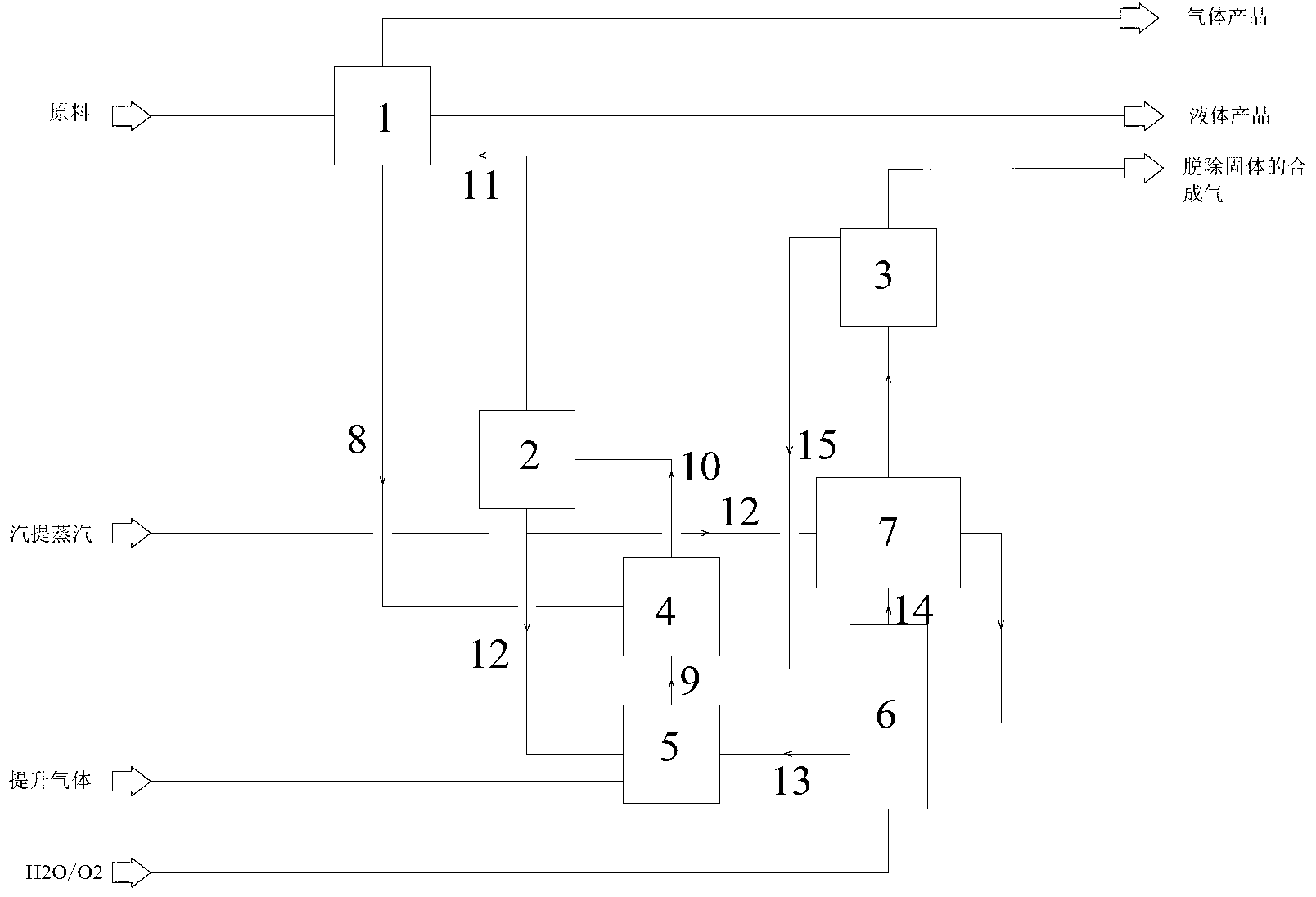

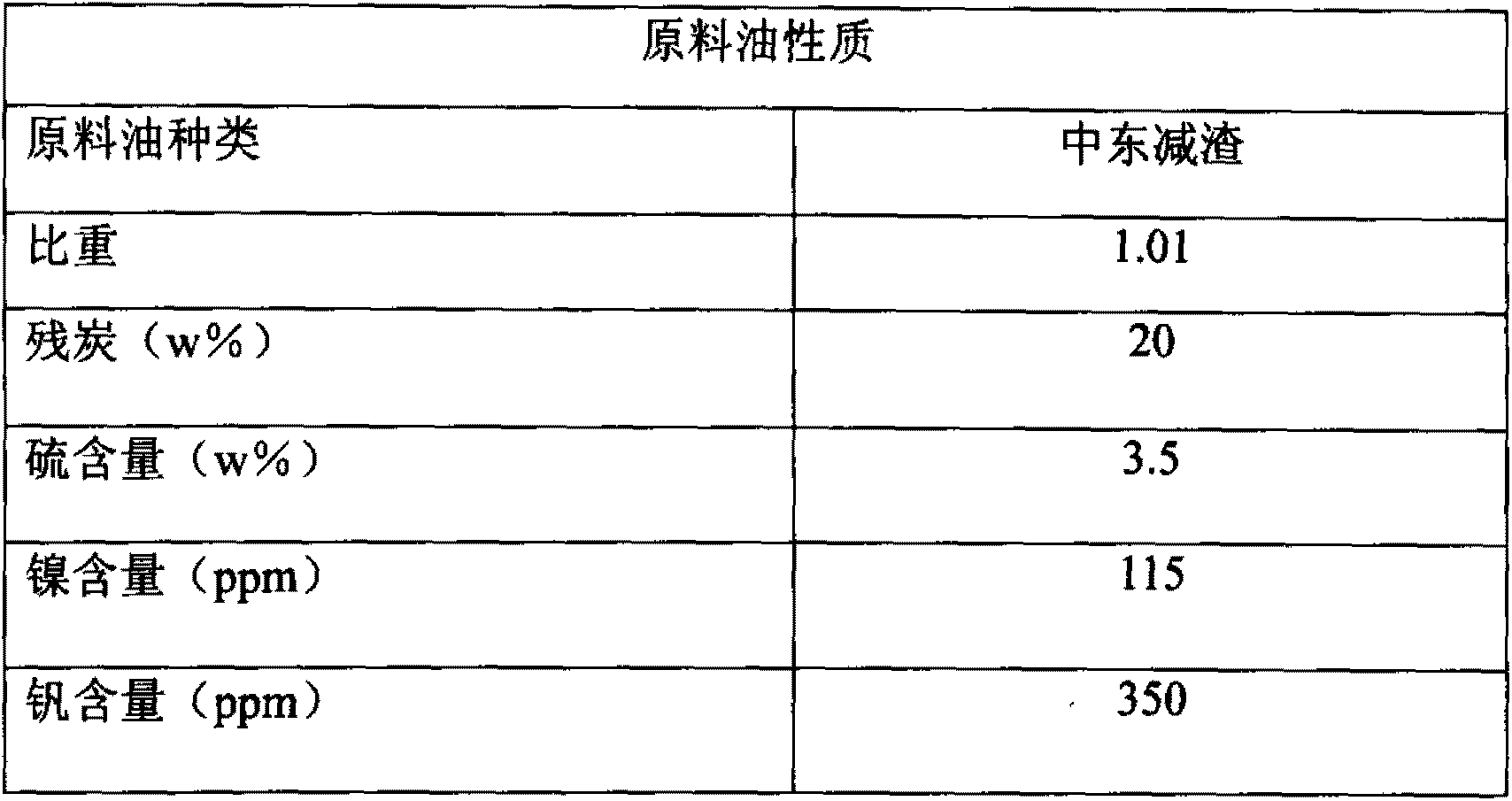

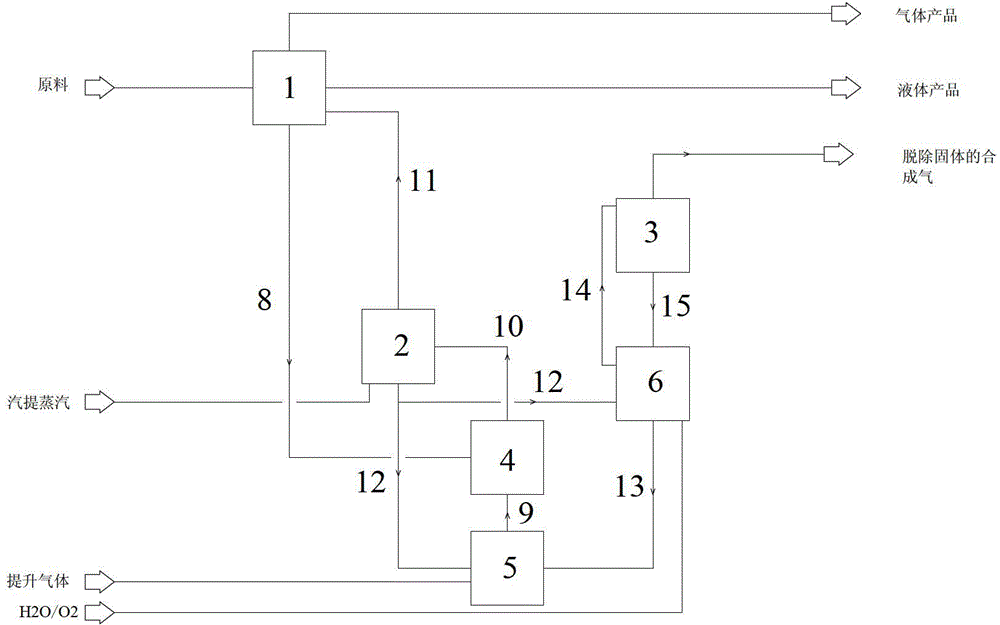

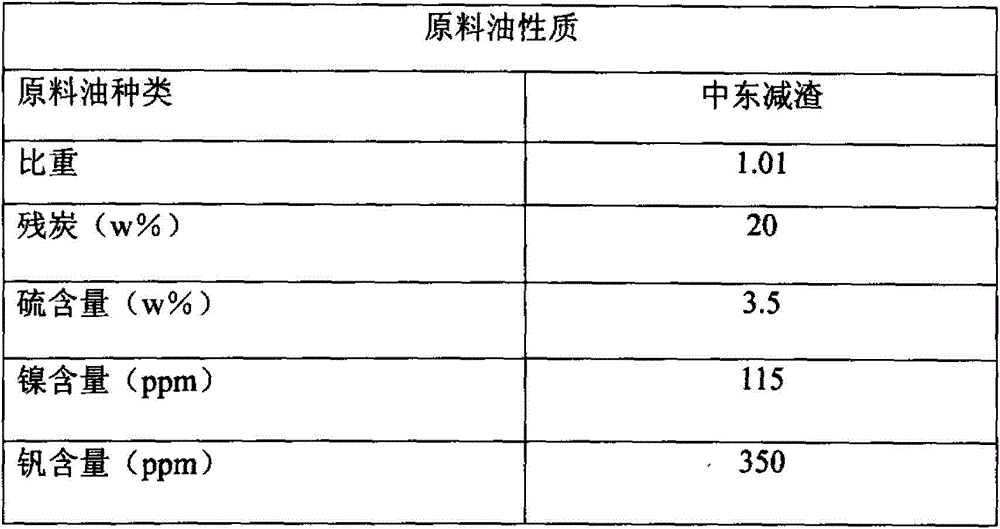

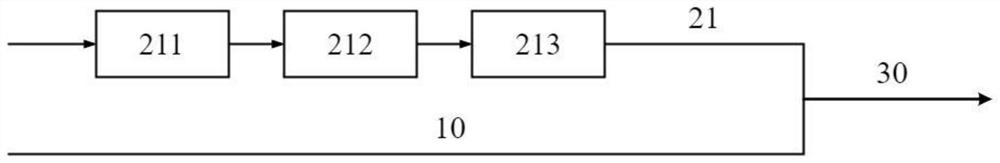

Inferior heavy oil fluidization conversion technology

ActiveCN103224808ALow calorific valueQuality improvementTreatment with plural serial stages onlyGranular/pulverulent flues gasificationSyngasThermal energy

The invention relates to an inferior heavy oil fluidization conversion technology. The inferior heavy oil fluidization conversion technology comprises that raw material oil is treated by a fractionating tower, then enters into a lifting pipe reactor, undergoes a contact reaction with coke carriers from a coke carrier mixer, then enters into a first gas-solid separation device and is separated; the separated reaction oil gas is fed into the fractionating tower and is subjected to product division; the coke carriers with coke is stripped and is divided into two parts, one of the two parts is fed into the coke carrier mixer, then is mixed with the high-temperature coke carriers from a vaporizer and then is fed back to the lifting pipe reactor, and other one of the two parts is fed into the vaporizer, contacts with oxygen-containing gas and water vapor and undergoes a gasification reaction; the produced synthetic gas is separated by a second gas-solid separation device, is fed into a follow-up section, and is subjected to heat recovery and conversion; and the vaporized coke carriers are fed into the coke carrier mixer and is mixed with the coke carriers with the coke. Compared with the prior art, the inferior heavy oil fluidization conversion technology has the advantages of simple process, low investment, strong raw material adaptability, good product distribution and good environmental benefits.

Owner:SHANGHAI HOTO PETROCHEM ENG

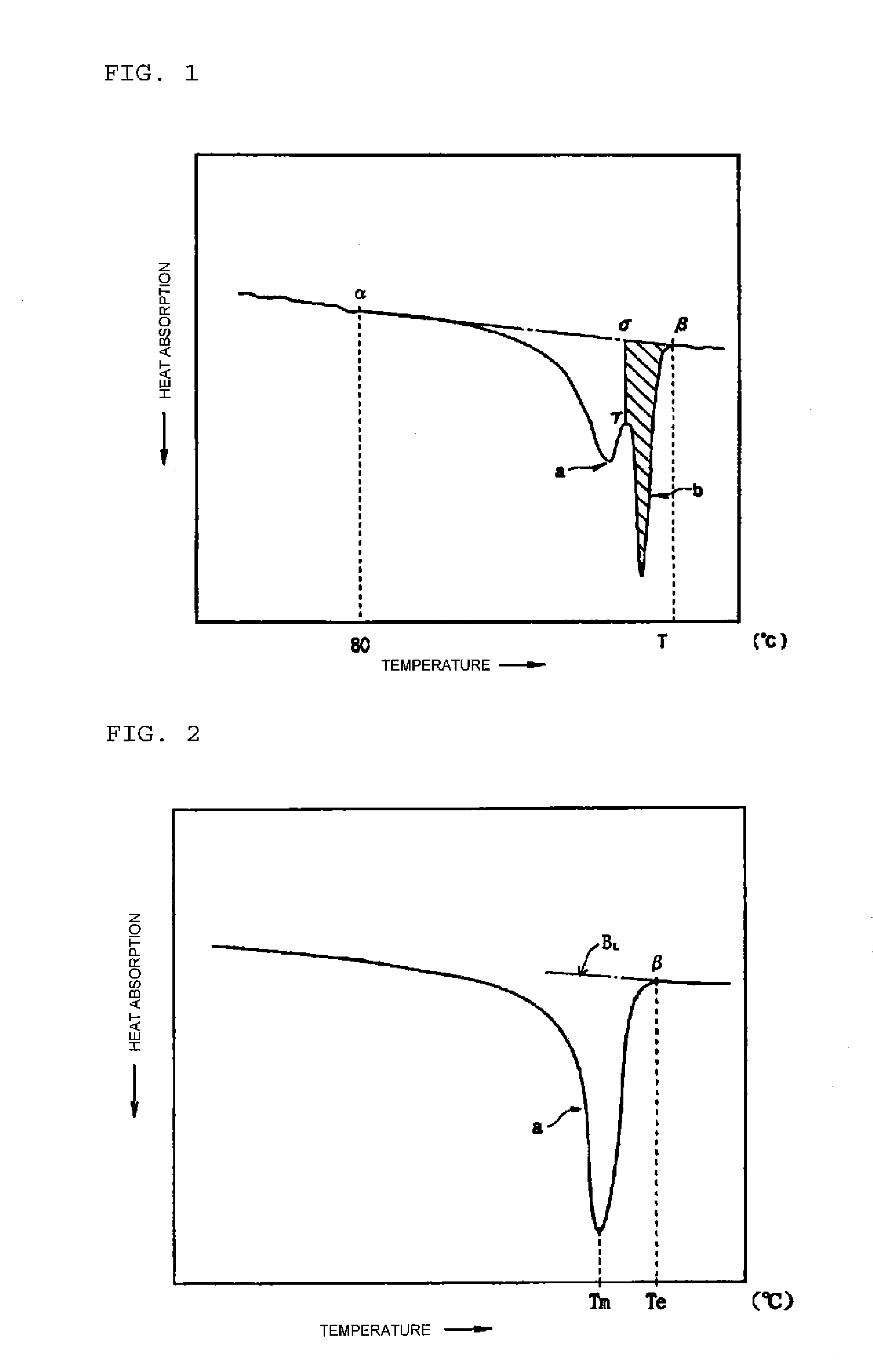

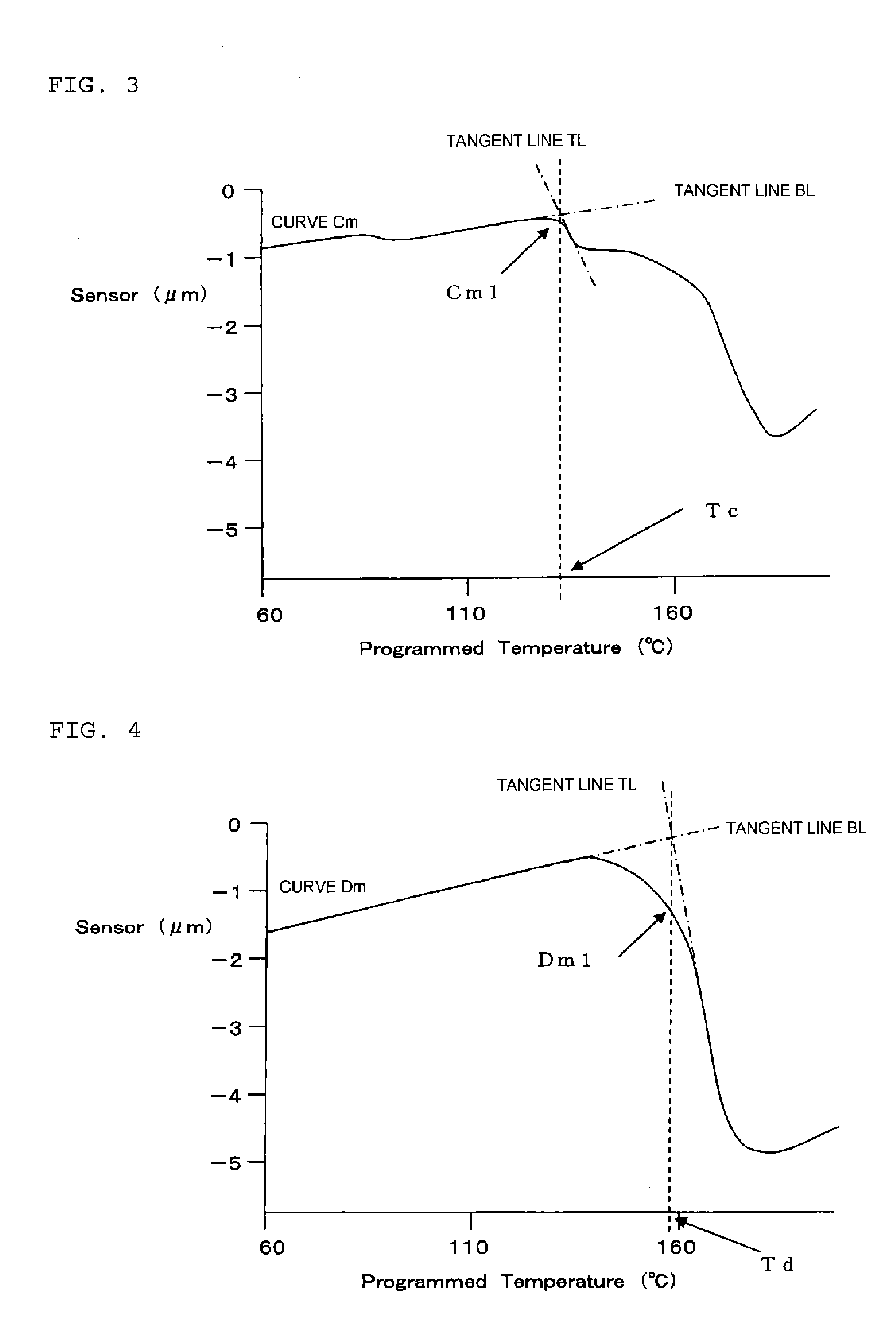

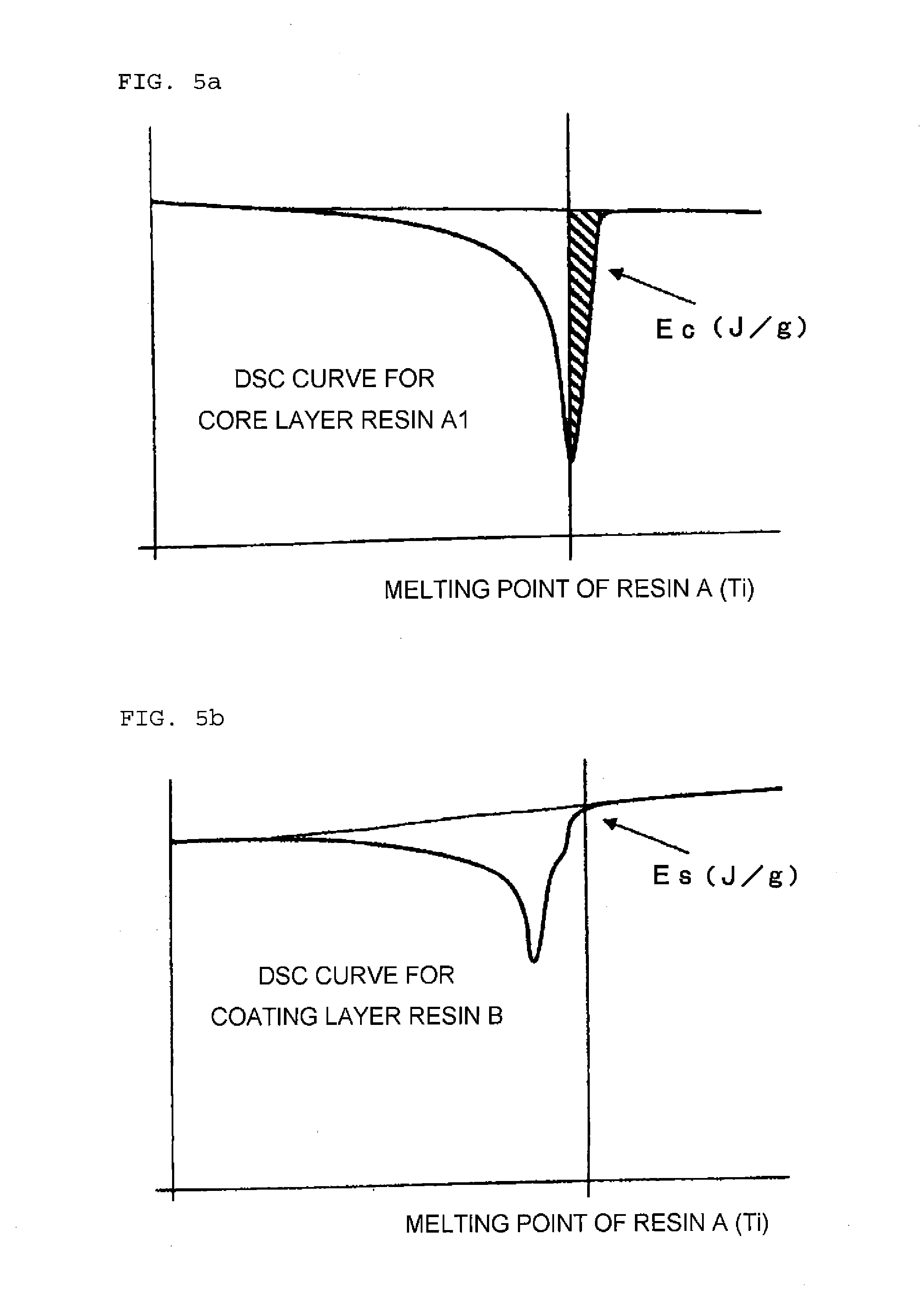

Expanded polypropylene resin beads and expanded bead molding

ActiveUS8518540B2Rigid enoughImprove mechanical propertiesLiquid surface applicatorsSynthetic resin layered productsSteam pressureHeat resistance

Multilayer expanded polypropylene resin beads that are heat moldable at low steam pressure and can provide an expanded mold with sufficient rigidity and heat resistance. The beads are formed from a polypropylene resin and a coating layer formed from a different polypropylene resin. The multilayer expanded resin beads can be molded in-mold at a steam pressure lower than the steam pressure for molding single-layer expanded beads made from the polypropylene resin which forms the core layer. The coating layer to core layer resin weight ratio in the multi-layer resin beads is not less than 0.001 and not greater than 0.040 and the expansion ratio of the expanded beads, the average value of the thickness of the coating layer of the expanded beads, calculated based on the coating weight ratio of the multi-layer resin beads, is not less than 0.1 μm and not greater than 3.0 μm.

Owner:JSP CORP

Alcohol-powered novel environment-friendly fuel and manufacturing method thereof

InactiveCN102827648AHigh calorific valueImprove performanceLiquid carbonaceous fuelsAlcoholNew energy

The invention discloses an alcohol-powered novel environment-friendly fuel and a manufacturing method of the fuel. The fuel is a liquid fuel produced by ester exchange reaction with methanol or ethanol as a raw material under the catalysis of an additive. The formula of per cent of fuel contains 80-85% of alcohol (methanol or ethanol), 2% of additive and not more than 18% of water, wherein the additive contains 0.5% of solvent oil, 0.1% of isopropanol, 0.1% of ethylamino alcohol, 0.8% of acetone, 0.4% of glycerol and 0.1% of sulfonated oil. The production manner comprises the steps of: preparing the additive by mixing, uniformly stirring the alcohol, the additive and water, and standing for 4h, wherein the fuel can be used after inspection by sampling to be qualified. The fuel is suitable for guesthouses, restaurants, plants schools and households to be used as a clean environment-friendly fuel serving a new energy.

Owner:ZHEJIANG HECHENG ENERGY

A kind of natural compound sweetener and preparation method thereof

The invention discloses a natural compound sweetening agent and a preparation method thereof. The preparation method comprises the following steps of dissolving erythritol, a momordica grosvenori extract and stevioside into water; concentrating at temperature of 55 to 95 DEG C; crystallizing at pressure of -0.06 to -0.1MPa under the temperature of 50 to 70 DEG C; drying; and granulating to obtain the natural compound sweetening agent, wherein 97.8 to 99.9% of erythritol is added, and the sum of added momordica grosvenori extract and stevioside reaches 0.1 to 2.2% in mass percentage of raw materials. The sweetening agent prepared by the preparation method is high in purity, uniform in particle size and density, uniform in color and stabile in performance.

Owner:HILL PHARMA

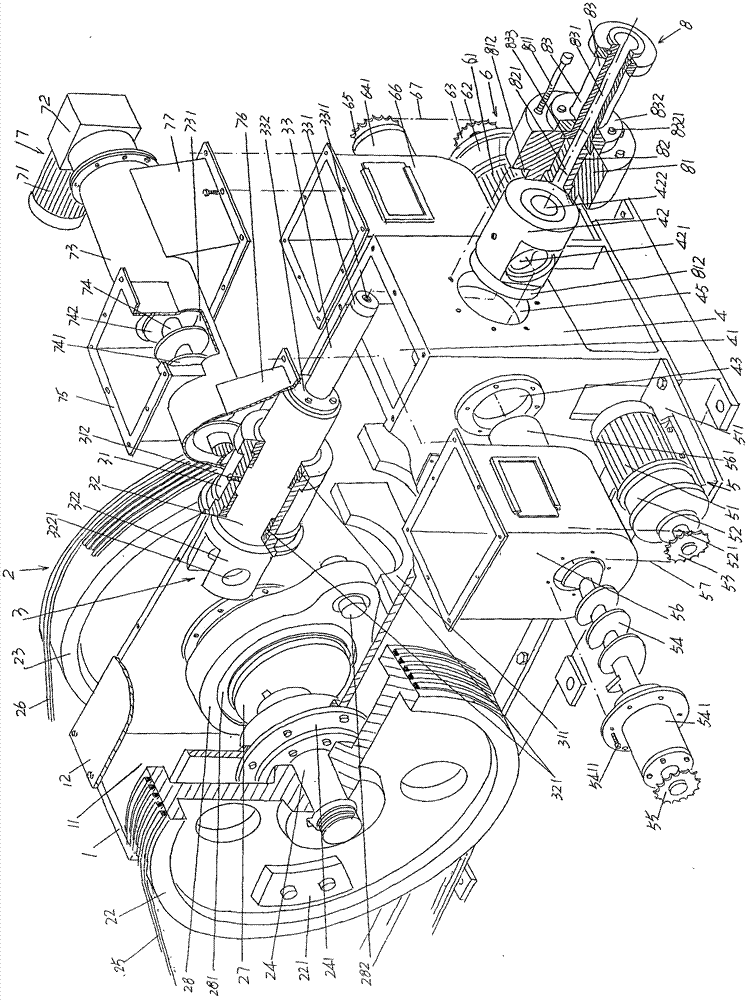

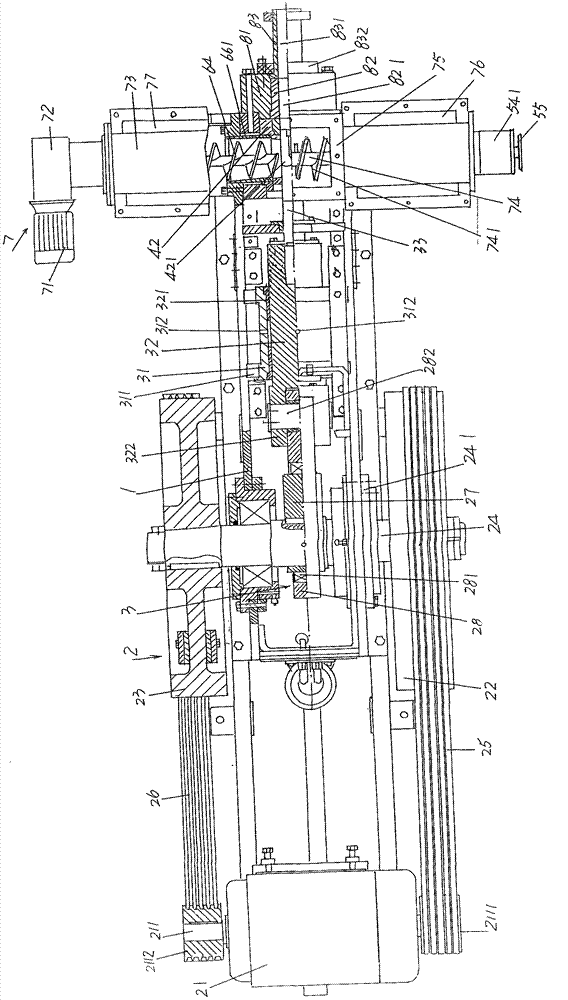

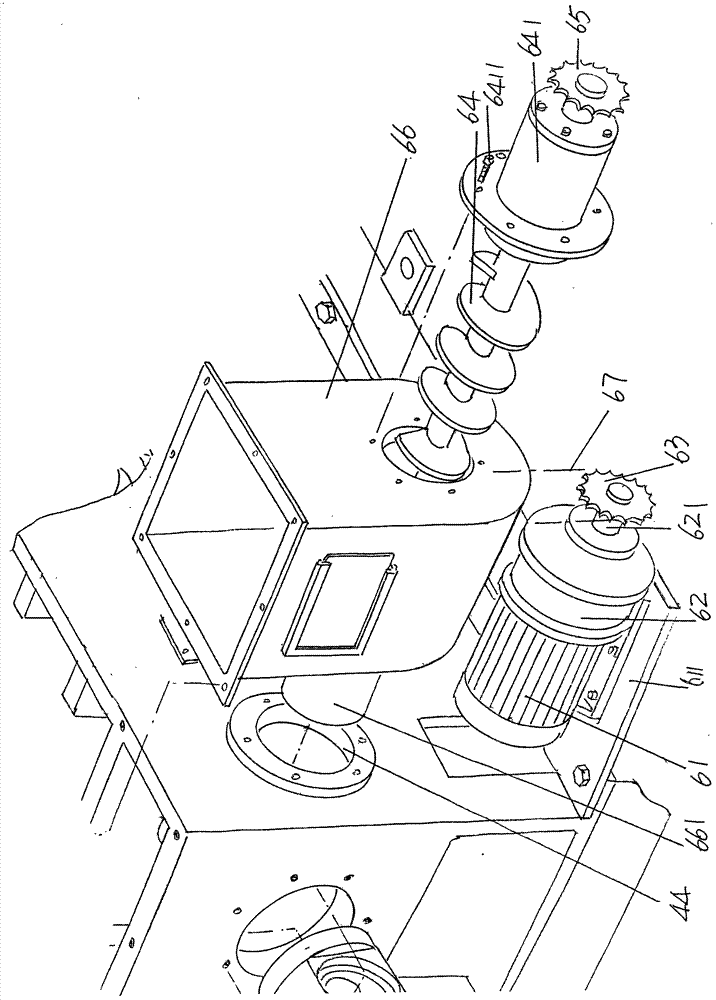

Biomass fuel moulding machine

InactiveCN102205664BMeet mass production requirementsHigh calorific valueShaping pressBiofuelBiomass fuels

The invention relates to a biomass fuel moulding machine, belonging to the technical field of fuel moulding machinery. The biomass fuel moulding machine comprises a rack, a power transmission mechanism arranged on the rack, an extruding mechanism which is arranged on the rack and is connected with the power transmission mechanism, a material collection tank fixed on the rack, a first material collection mechanism arranged at one side of the material collection tank, a second material collection mechanism arranged at the other side of the material collection tank, a feeding mechanism which is matched and connected with the first material collection mechanism and is also matched and connected with the second material collection mechanism and a solid material guiding mechanism which is fixedon the material collection tank and corresponds to a punch hole, wherein the material collection tank is internally provided with a four-way sleeve, the four-way sleeve is provided with a charging through hole and the punch hole, and the extruding mechanism is matched with the punch hole. The biomass fuel moulding machine provided by the invention has the advantages that: the biomass fuel moulding machine has ideal compactness and intensity, thus being beneficial to improving the heat value and being beneficial to transportation and storage; the moulding efficiency is good, thus the requirement for realizing batch production of solid biomass fuel can be met; and the overall structure configuration is reasonable, and the operation requirement is low, thus being easy to use and maintain.

Owner:CHANGSHU HUAJI BOILER MFG

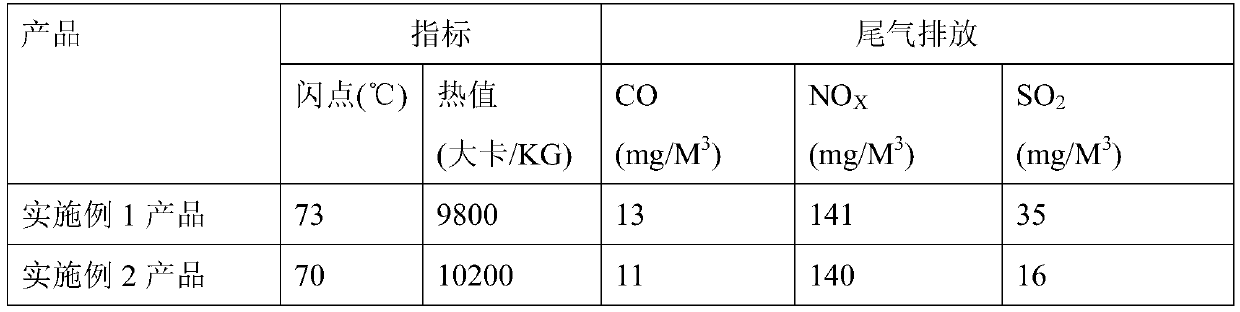

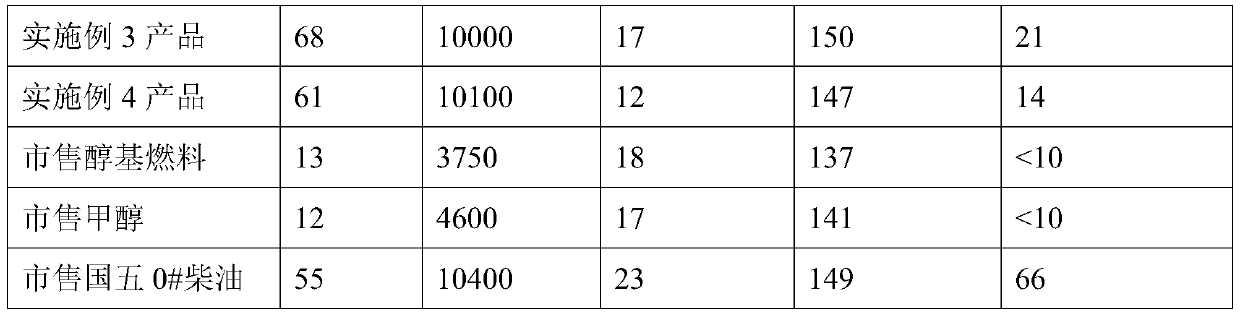

Fuel for catering stove and preparation method of fuel

InactiveCN110437891AReduce sulfur contentReduce maintenance timesBiofuelsLiquid carbonaceous fuelsWaxAtmospheric pollutants

The invention relates to a fuel for a catering stove and a preparation method of the fuel. The fuel for the catering stove comprises the following components in percentage by weight: 20-40% of Fischer-Tropsch synthetic wax, 30-50% of waste grease, 10-20% of biodiesel and 5-10% of polyoxymethylene dimethyl ether. The problems that alcohol-based fuel is low in flash point and heat value, a stove needs to be modified, tail gas emission pollutants are high in the combustion process of diesel oil and other fuel, black smoke exists, carbon deposit exists, and the price is high are solved. The fuel for the catering stove is extremely low in sulfur content, can be stably combusted in the catering stove, and is high in heat value, free of dust emission, black smoke and carbon deposition during combustion and low in atmospheric pollutant emission, so that the cleaning frequency of a stove hearth and the maintenance frequency of the stove are reduced.

Owner:泰州鑫百益能源有限公司

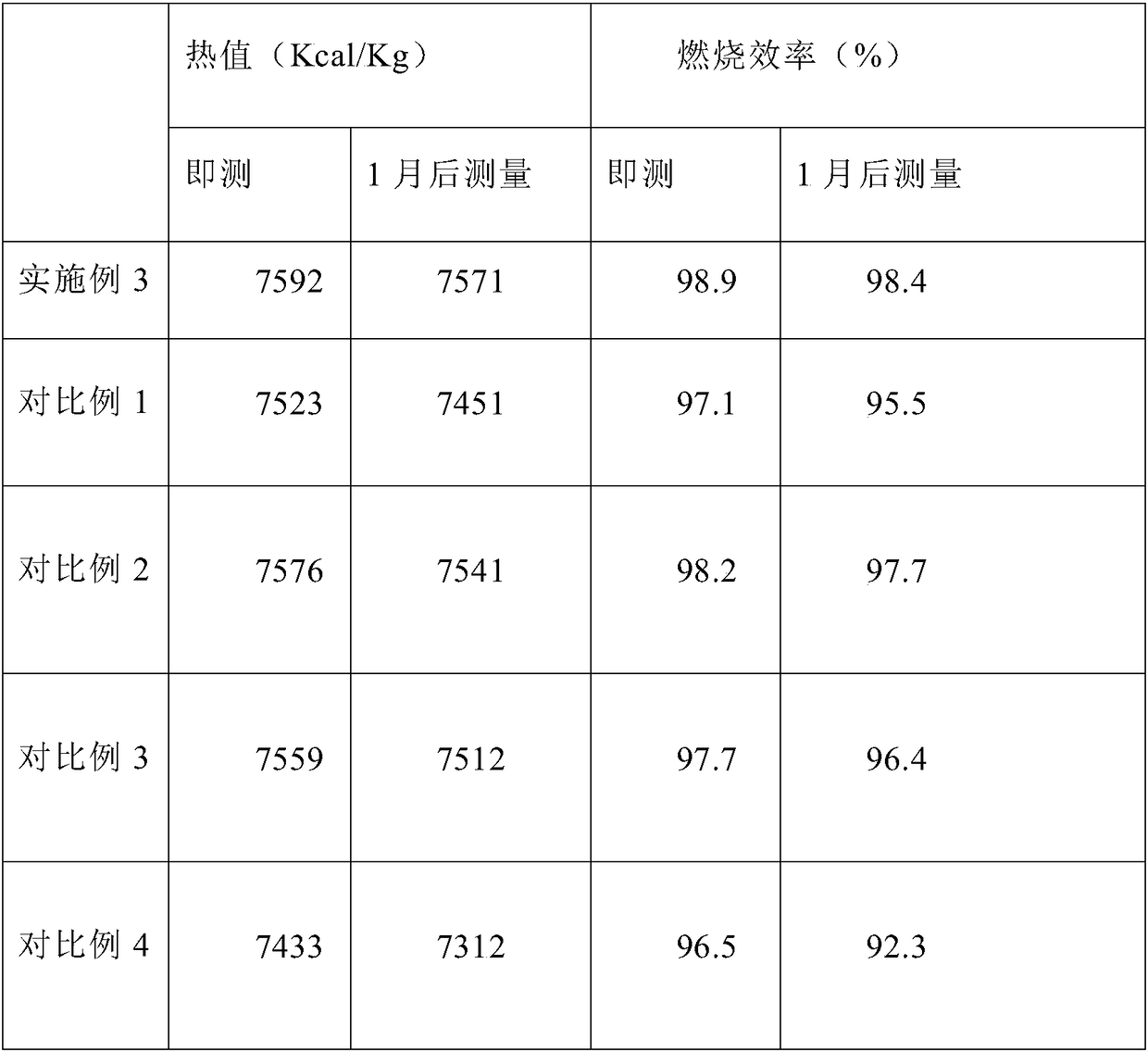

Coal-fired catalyst as well as preparation method and application thereof

ActiveCN111298805AIncrease burn rateImprove burnout rateSolid fuelsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystAlkali metal oxide

The invention relates to the technical field of coal energy, in particular to a coal-fired catalyst as well as a preparation method and application thereof. The coal-fired catalyst is prepared from the following raw materials in percentage by weight: 10-13% of inorganic acid, 3-6% of a catalytic component, 0.3-0.5% of a sulfur-fixing component and the balance of a solvent, and the catalytic component is selected from one or more of alkali metal oxide, transition metal oxide and rare earth metal oxide. According to the coal-fired catalyst provided by the applicant, by controlling the types andthe use amounts of the coal-fired catalysts, the coal combustion rate and burn-off rate can be increased, and the heat value generated by coal combustion can be increased; and by controlling the proportion of the coal-fired catalyst and the inorganic acid, catalytic components can be promoted to be adsorbed in coal, the utilization rate of the catalyst can be increased, and the application range of the coal-fired catalyst can be expanded. The coal-fired catalyst can be applied to multiple technical fields such as cement production or coal power.

Owner:吉林省惠净环保有限公司

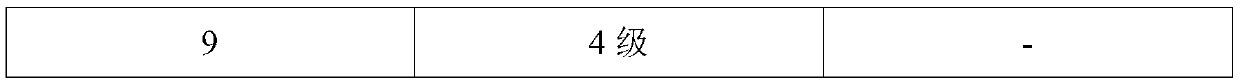

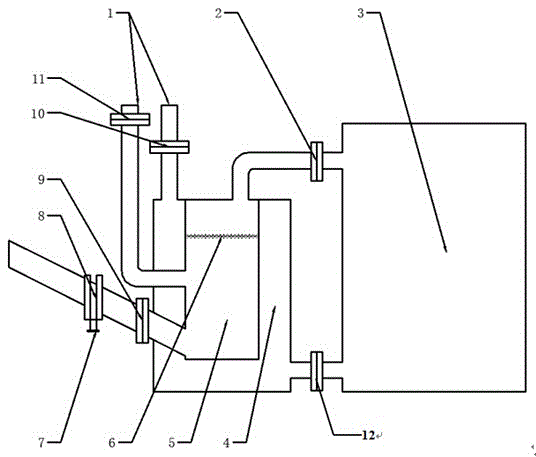

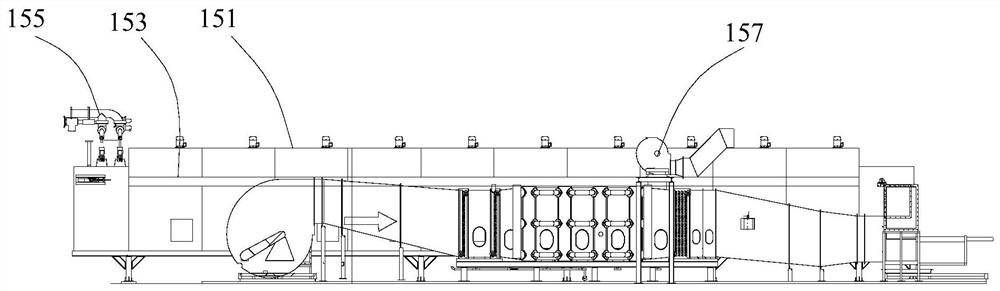

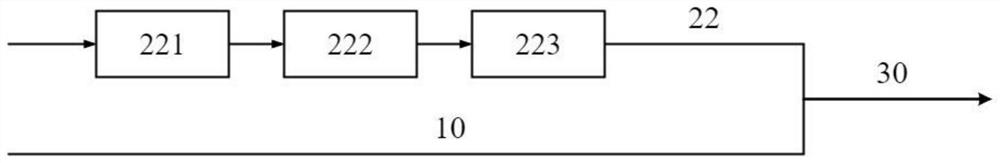

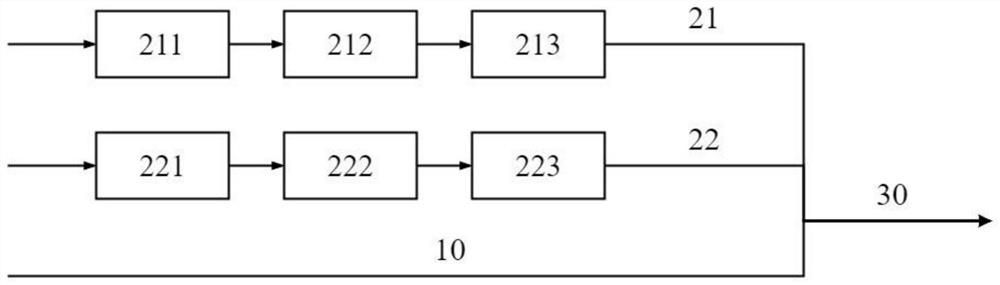

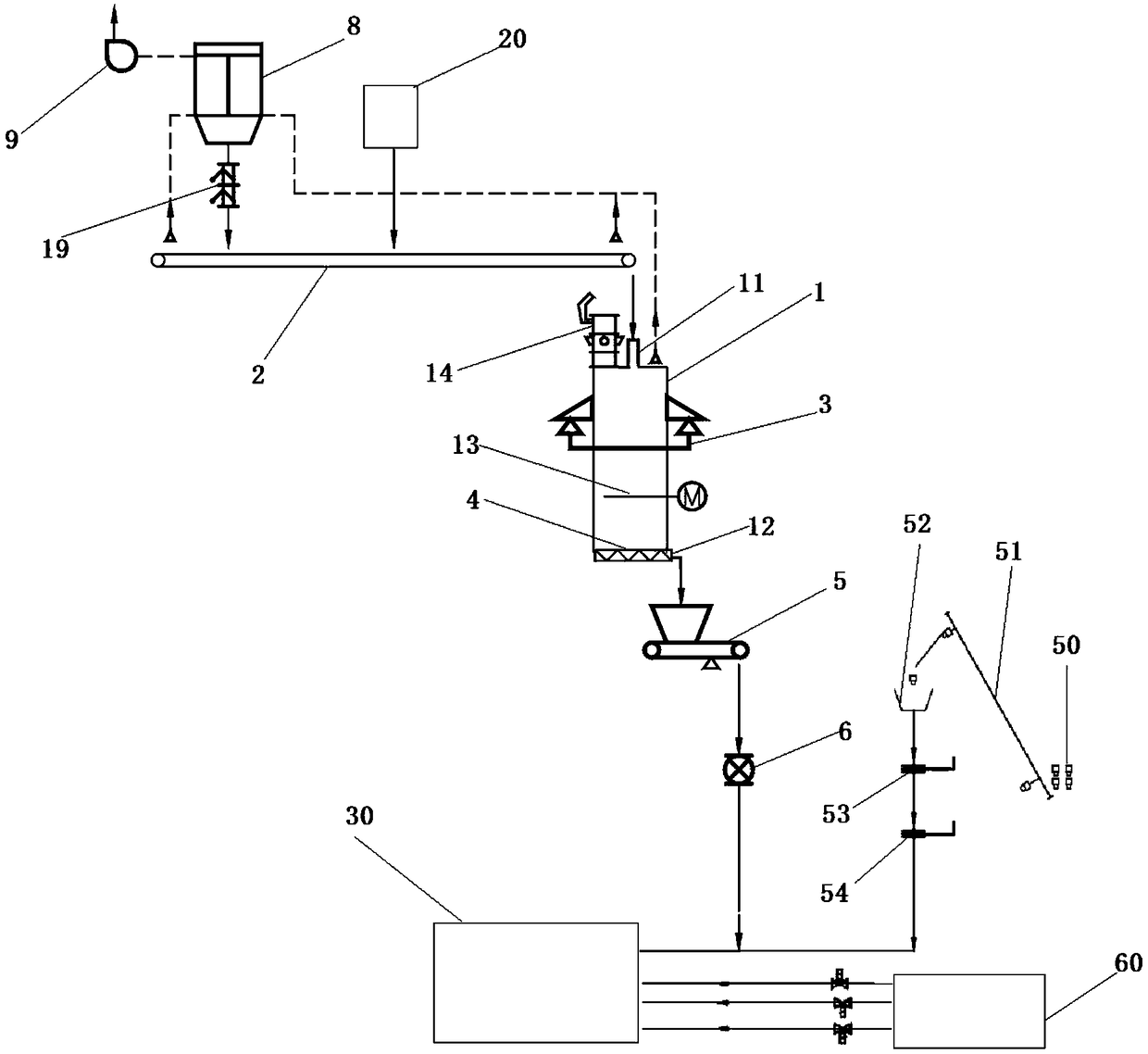

Continuous and sealed feeding system for classified incineration of hazardous waste

ActiveCN106402903APrecise control of process parametersGuaranteed uptimeIncinerator apparatusLiquid stateIncineration

The invention discloses a continuous and sealed feeding system for classified incineration of hazardous waste. The feeding system comprises a bulk material feeding sub-system, a bagged material feeding sub-system and a liquid material feeding sub-system, and the bulk material feeding sub-system, the bagged material feeding sub-system and the liquid material feeding sub-system are used for conveying bulk materials, bagged materials and liquid-state hazardous waste to an incinerating device correspondingly in a continuous and sealed mode. By means of the continuous and sealed feeding system, hazardous waste can be conveniently subjected to heat value detection and chemical proportioning, and therefore process parameters in the incinerating device can be accurately controlled, and stable, safe and efficient operation of the incinerating device is guaranteed.

Owner:北控安耐得环保科技发展常州有限公司

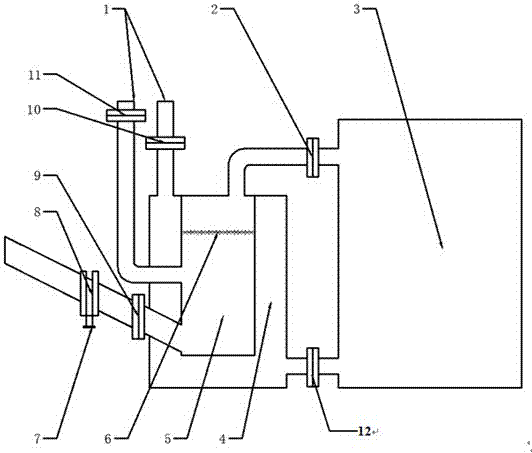

Gradually-expanding premixing porous medium combustor for combusting biomass gasification gas

ActiveCN102418927BReduce the degree of skew instabilityImprove stabilityGaseous fuel burnerCombustorPorous medium

The invention relates to a gradually-expanding premixing porous medium combustor for combusting biomass gasification gas. The combustor is provided with gradually-expanding pipes, wherein a porous medium with catalytic action is filled in each gradually-expanding pipe; a heater is coated outside each gradually-expanding pipe; each gradually-expanding pipe is wholly embedded into a thermal insulating layer; a capacity expansion chamber is formed at an inlet of each gradually-expanding pipe; a tempering prevention piece and a flow equalization plate are arranged in each capacity expansion chamber; and an inlet of each capacity expansion chamber is connected with a premixing tube. Flame deflection and other unstable combustion phenomena can be avoided, flames can be effectively prevented from being blown out of the combustor, the power of the combustor is improved, the working range of the combustor is expanded, and the load and working condition changes of the combustor are met. Moreover, the combustor has a function of adjusting gas flow, and parallel gradually-expanding pipes are prevented from being shut down due to over-low load or prevented from being subjected to over-high load; and the biomass gasification gas can be subjected to super adiabatic combustion in the combustor, the lean flammability limit of fuel is greatly expanded, and the fuel with ultralow heat value can be stably combusted. Meanwhile, the flame area is widened, the combustor contributes to accelerating cracking combustion of tar, and the combustion efficiency is improved.

Owner:SHENYANG INST OF ENG +1

Method for preparing high-efficiency biomass fuel by using graphene

The invention discloses a method for preparing a high-efficiency biomass fuel by using graphene. The method comprises a first step of adding 26-28 parts of modified graphene powder into a mixed solution of 20 parts of tetrahydrofuran and 80 parts of absolute ethyl alcohol, carrying out ultrasonic dispersion for 15-25 min, then adding 34-38 parts of a pretreated base material and 6-12 parts of algae-lysing microorganism particles, increasing a stirring rotation speed to 75-85 r / min, carrying out stirring for 35-45 min, then adding 3-5 parts of oleic acid and 2-4 parts of rosin, and continuing stirring for 15-25 min so as to obtain a premix. According to the method for preparing the high-efficiency biomass fuel by using graphene in the invention, graphene is used as the base material for thebiomass fuel and cooperatively used with other auxiliary material; and research results show that the combustion performance and stability of the biomass fuel are significantly improved.

Owner:安徽兆拓新能源科技有限公司

A device and process for producing bio-oil by hydrothermal liquefaction of microalgae extracted from power plants

ActiveCN105647594BImprove qualityReduce energy consumptionLiquid carbonaceous fuelsPtru catalystProcess engineering

The invention belongs to the field of energy utilization, and relates to a device and technique for preparing biological oil by microalgae hydrothermal liquefaction by using power plant steam turbine extraction steam. The power plant steam turbine extraction steam is high-temperature high-pressure steam, and the quaternary extraction steam is used for hydrothermal liquefaction reaction of microalgae. The quaternary extraction steam of the steam turbine is divided into two streams, one stream is directly introduced into an inner interlayer of a high-pressure autoclave, and other stream is introduced into an outer interlayer of the high-pressure autoclave as a heat source. In the microalgae hydrothermal liquefaction reaction, the microalgae and ethanol are proportionally fed, a reticular filter layer is arranged inside the high-pressure autoclave, and an HZSM-5 catalyst is arranged. The steam of the power plant steam turbine after applying part of work is fully utilized, the pressure and temperature of the steam are utilized in the technique for preparing biological oil by microalgae hydrothermal liquefaction reaction, the conventional hydrothermal liquefaction technique is improved, the electric heating is utilized to reach the solvent critical value, and abundant energy consumption is lowered, thereby lowering the cost for preparing the biological oil, improving the oil preparation efficiency and enhancing the oil product.

Owner:JIANGSU UNIV

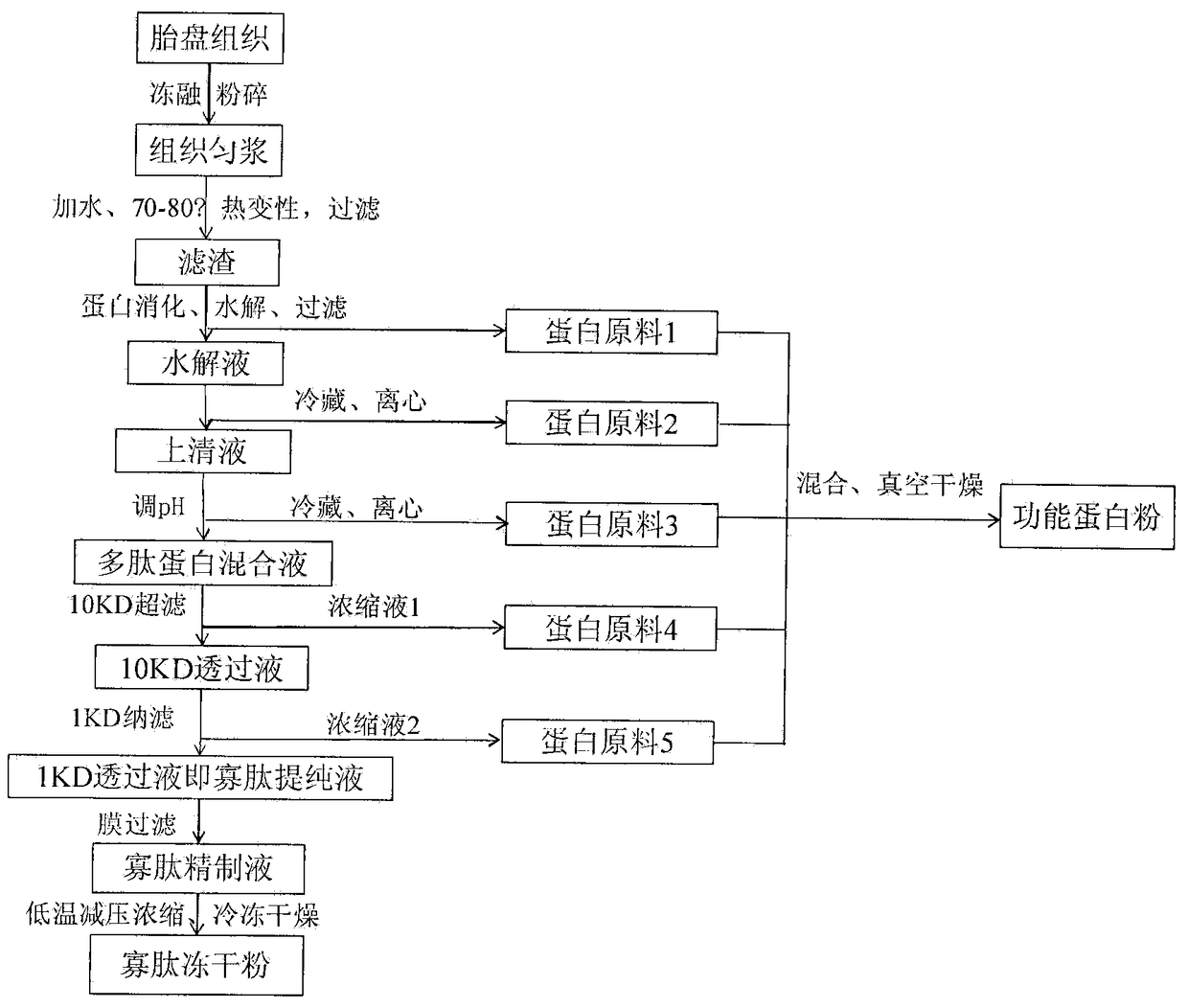

Placenta oligopeptide probiotic composite preparation and preparation method thereof

InactiveCN108157974AGood thermal stabilityImprove lipid metabolismLactobacillusBifidobacteriumNutrientPlacenta extract

The invention relates to a placenta oligopeptide probiotic composite preparation and a preparation method thereof. The composite preparation consists of main raw materials of animal (pig, cattle and sheep) placenta extract oligopeptide and probiotics, as well as medical auxiliary materials. The specific preparation method comprises the following steps of extracting placenta oligopeptide from healthy animal placentas through a series of integrated technologies of hydrolyzing, ultrafiltration, nano-filtration, freeze drying and the like, then weighing the following raw materials in percentage byweight of 35-70% of placenta oligopeptide freeze-dried powder, 5-20% of probiotic freeze-dried powder, 2-10% of sodium alginate, 15-20% of starch and 8-15% of fructo-oligosaccharide, performing sufficient and uniform mixing to obtain granules, directly bagging the granules or enabling capsules to be filled with the granules. According to the placenta oligopeptide probiotic composite preparation disclosed by the invention, the animal placenta extract oligopeptide and the probiotics are perfectly combined, and the placenta oligopeptide and the probiotics exert synergistic effects, so that the balance of intestinal microecology can be adjusted, the intestinal tract environment is purified, digestion and absorption of nutrient substances by organisms are promoted, the immune function of the organisms can be strengthened, and the placenta oligopeptide probiotic composite preparation is a purely-natural composite immune adjustment agent.

Owner:王景仙

Device and technique for preparing biological oil by microalgae hydrothermal liquefaction by using power plant extraction steam

ActiveCN105647594AImprove qualityReduce energy consumptionLiquid carbonaceous fuelsEngineeringHigh pressure

The invention belongs to the field of energy utilization, and relates to a device and technique for preparing biological oil by microalgae hydrothermal liquefaction by using power plant steam turbine extraction steam. The power plant steam turbine extraction steam is high-temperature high-pressure steam, and the quaternary extraction steam is used for hydrothermal liquefaction reaction of microalgae. The quaternary extraction steam of the steam turbine is divided into two streams, one stream is directly introduced into an inner interlayer of a high-pressure autoclave, and other stream is introduced into an outer interlayer of the high-pressure autoclave as a heat source. In the microalgae hydrothermal liquefaction reaction, the microalgae and ethanol are proportionally fed, a reticular filter layer is arranged inside the high-pressure autoclave, and an HZSM-5 catalyst is arranged. The steam of the power plant steam turbine after applying part of work is fully utilized, the pressure and temperature of the steam are utilized in the technique for preparing biological oil by microalgae hydrothermal liquefaction reaction, the conventional hydrothermal liquefaction technique is improved, the electric heating is utilized to reach the solvent critical value, and abundant energy consumption is lowered, thereby lowering the cost for preparing the biological oil, improving the oil preparation efficiency and enhancing the oil product.

Owner:JIANGSU UNIV

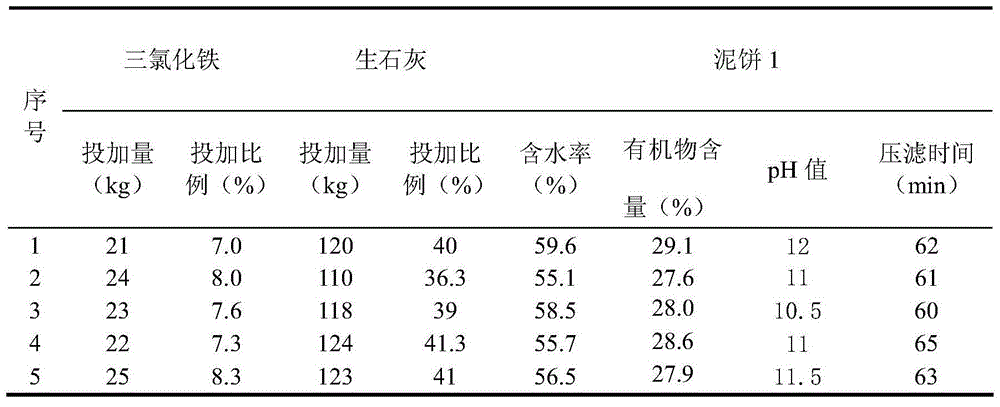

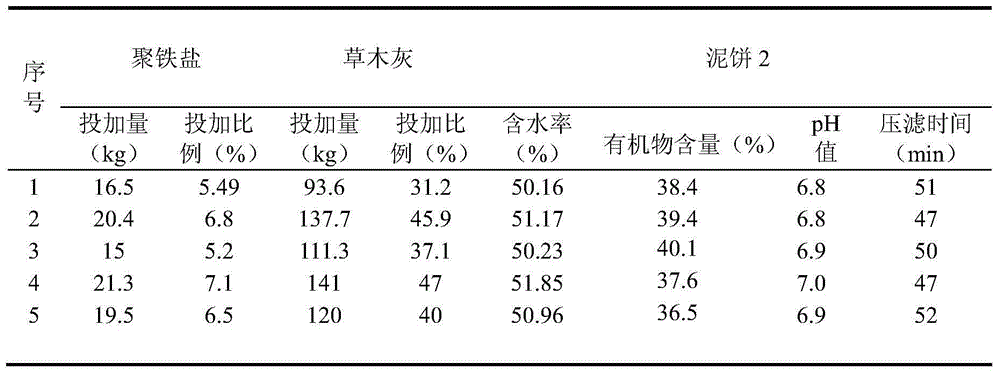

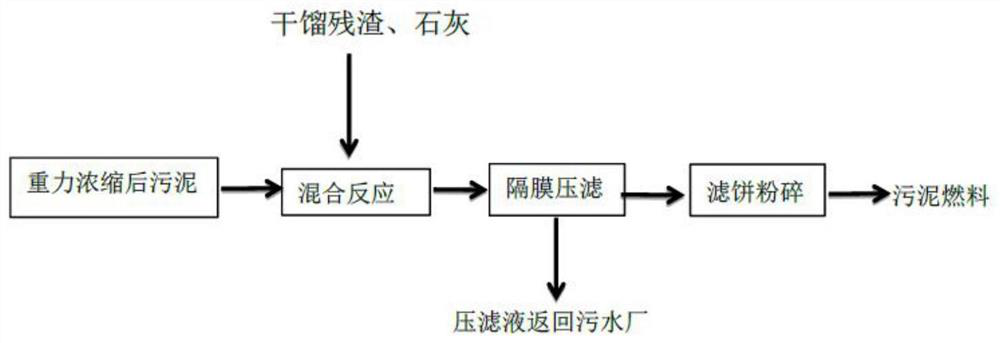

Sludge high-dry dehydration conditioning method

InactiveCN104788001ALower specific resistanceEfficient use ofSludge treatment by de-watering/drying/thickeningDry weightSludge

The invention discloses a sludge high-dry dehydration conditioning method. The sludge high-dry dehydration conditioning method comprises the following steps: preparing sludge, polymer ferric salt and plant ashes according to a ratio of parts by weight of 1000:(5-7):(30-50), mixing and stirring the materials, and mechanically filter pressing and dehydrating the mixture to obtain mud cakes, wherein the sludge is from a sewage treatment plant, the moisture content of the sludge ranges from 90% to 99%; the ratio of parts by weight of 1000:(5-7):(30-50) is based on the absolute dry weight of the sludge. The polymer ferric salt and the plant ashes are used as conditioning agents to condition and modify the sludge, so that the cost is low; the moisture content of the mud cakes after dehydration is about 50%, and meets the follow-up treatment requirement; furthermore, the aspects of organic content, calorific value and pH value of the mud cakes are improved.

Owner:安徽省通源环境节能股份有限公司

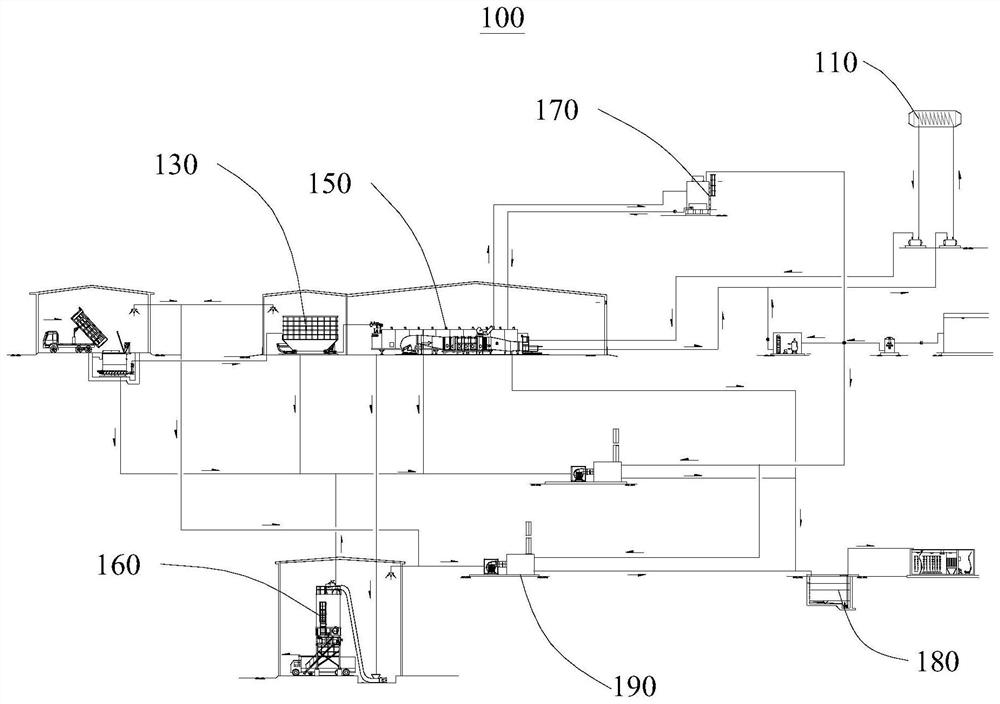

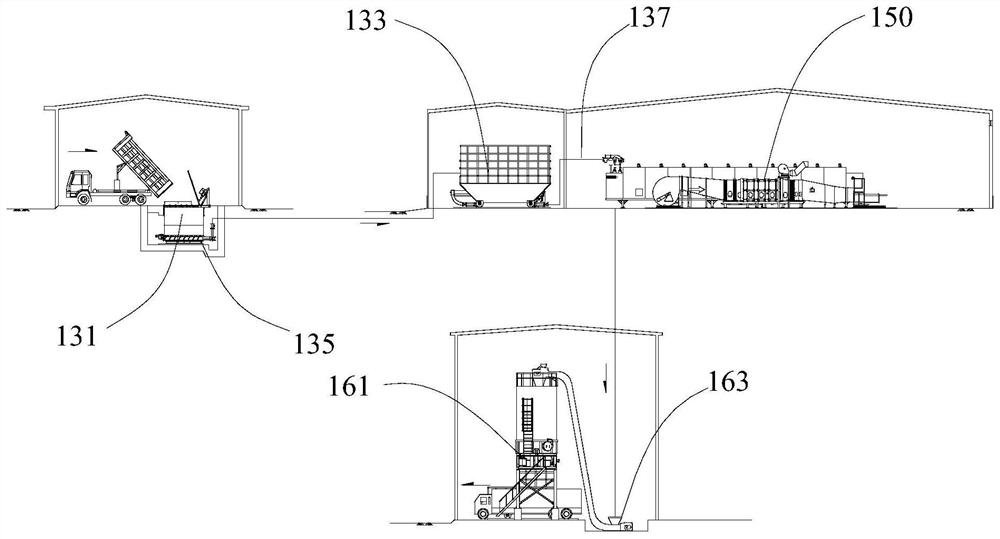

Municipal sludge drying treatment system

PendingCN112551854AEasy to storeReduce moisture contentSludge treatment by de-watering/drying/thickeningFlue gasSludge

The invention provides a municipal sludge drying treatment system, and relates to the technical field of sludge treatment. The municipal sludge drying treatment system comprises flue gas heat exchangeequipment, wet material storage and conveying equipment, a sludge drying machine and dry material storage and conveying equipment, waste heat in industrial flue gas is recycled through the flue gas heat exchange equipment, and heat is transferred to the sludge drying machine, the sludge drying machine utilizes the heat to dry municipal sludge, the dried municipal sludge is conveyed to the dry material storage and conveying equipment to be stored, drying operation is carried out through waste heat in industrial flue gas, energy is recycled, energy is saved, meanwhile, the content of harmful organisms in soil can be reduced in the drying process, the moisture content of the dried municipal sludge is greatly reduced, the size of the dried municipal sludge is greatly reduced, reduction and harmlessness are achieved, in addition, the dried sludge is convenient to transport and store and good in heat value and soil texture, the dried sludge can be used as fuel, fertilizer and the like to bereused, and recycling of the municipal sludge is achieved.

Owner:核工业西南勘察设计研究院有限公司

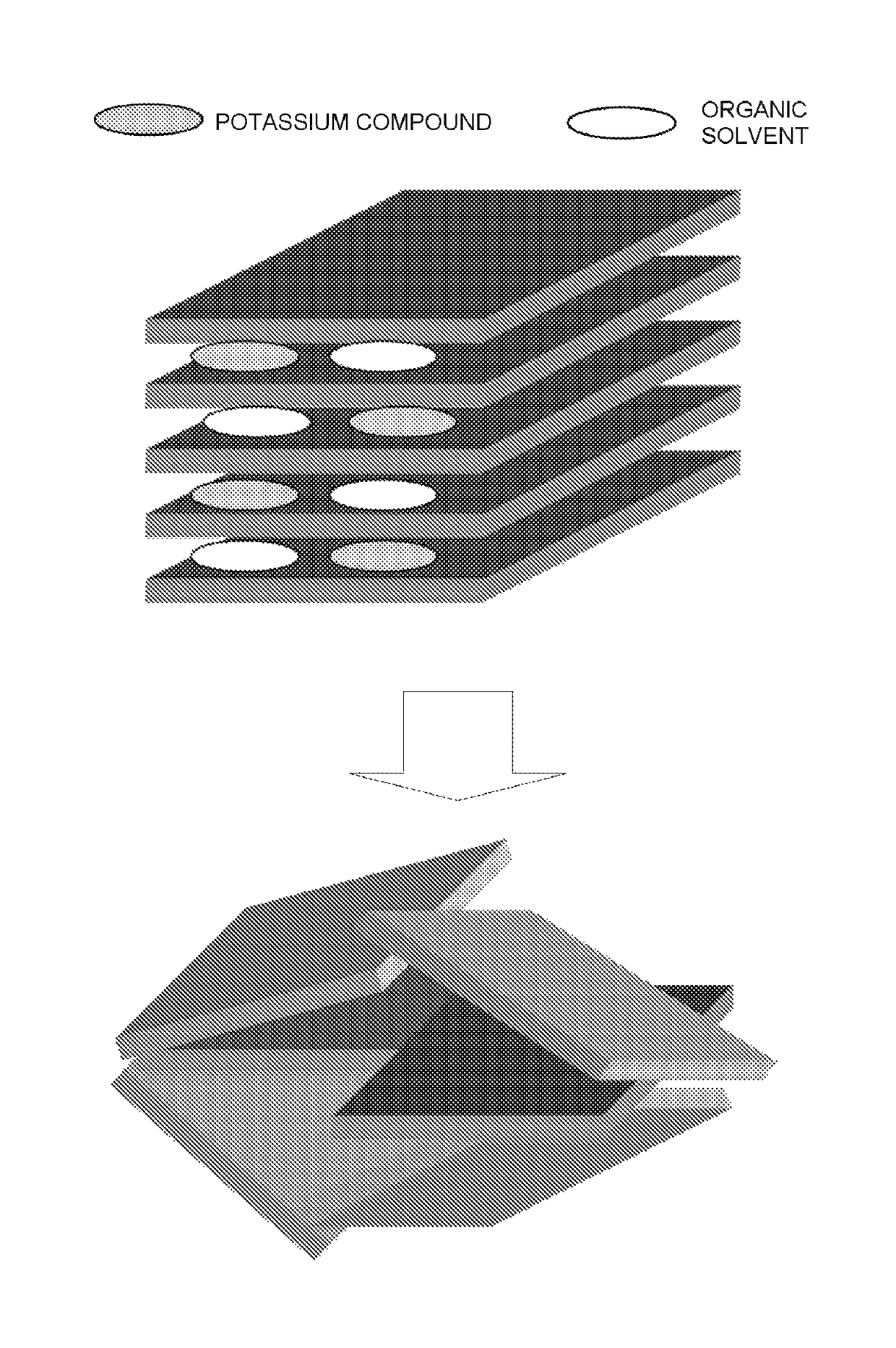

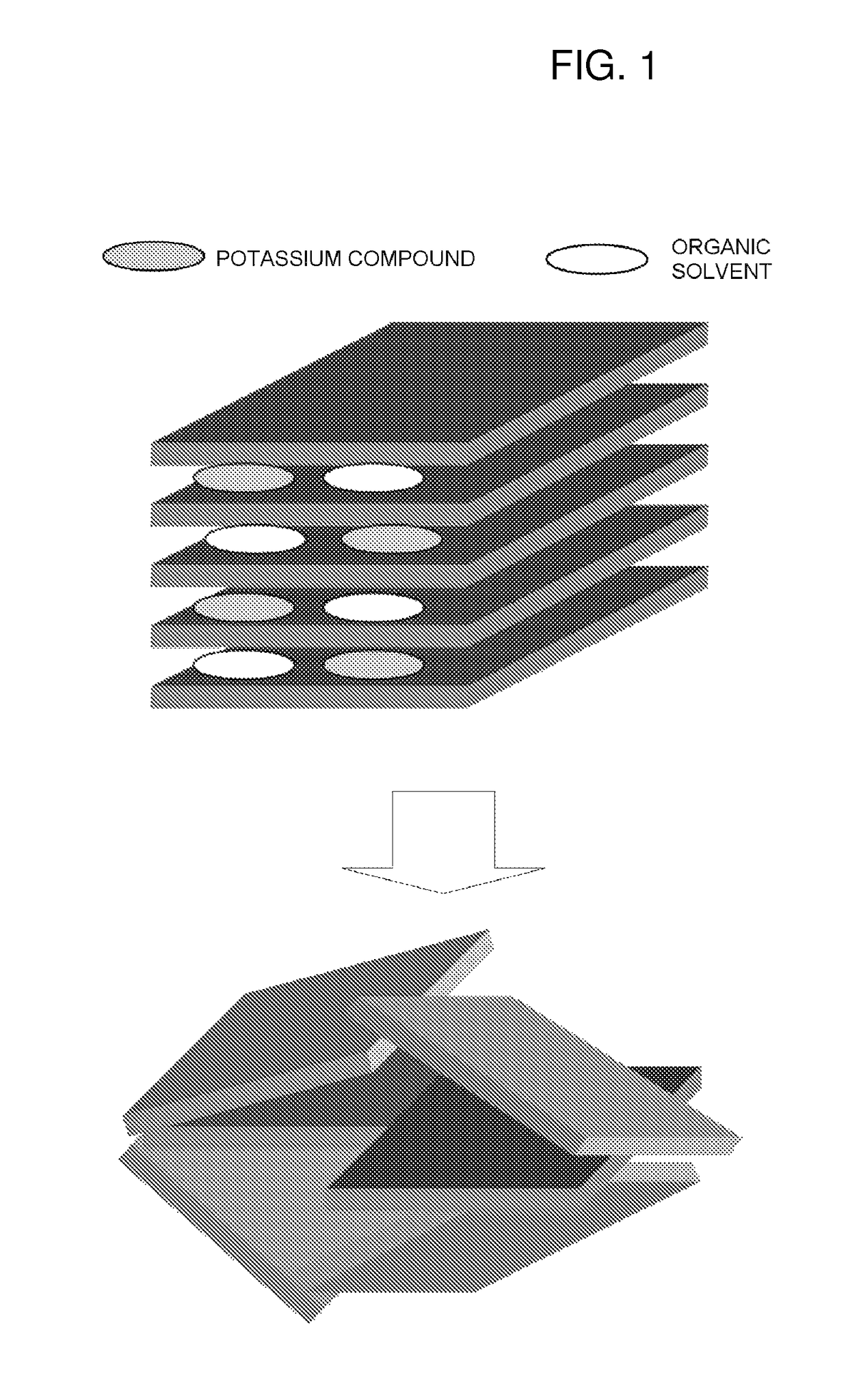

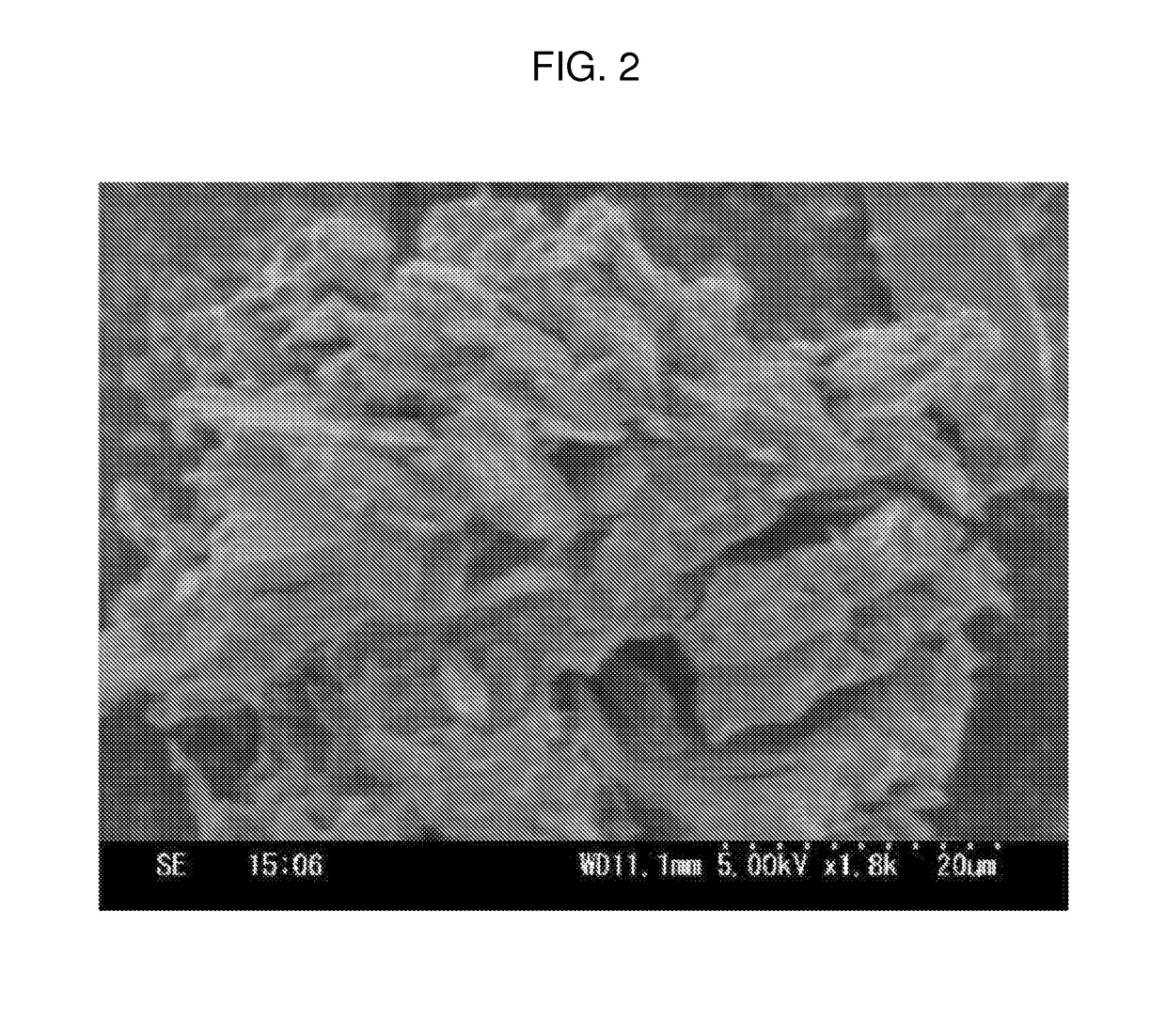

Method for producing vacuum insulation material

ActiveUS9664330B2Improve insulation effectCalorific valueThermal insulationClimate change adaptationOrganic solventClay minerals

A method for producing a vacuum insulation material includes producing a core by molding a core starting material composition, containing a talc-based clay mineral, a potassium compound and an organic solvent, into a predetermined shape to yield a core molded body, and firing the core molded body at a temperature that is lower than the melting point of the talc-based clay mineral. The core is vacuum-packaged with a gas barrier packaging material, to thereby produce a vacuum insulation material.

Owner:FUJI ELECTRIC CO LTD

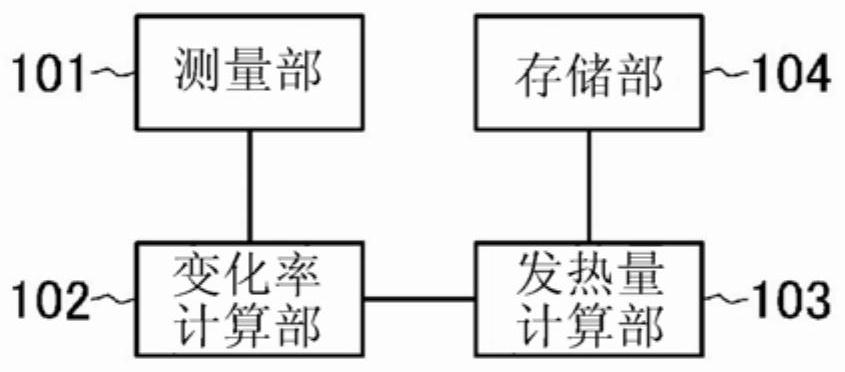

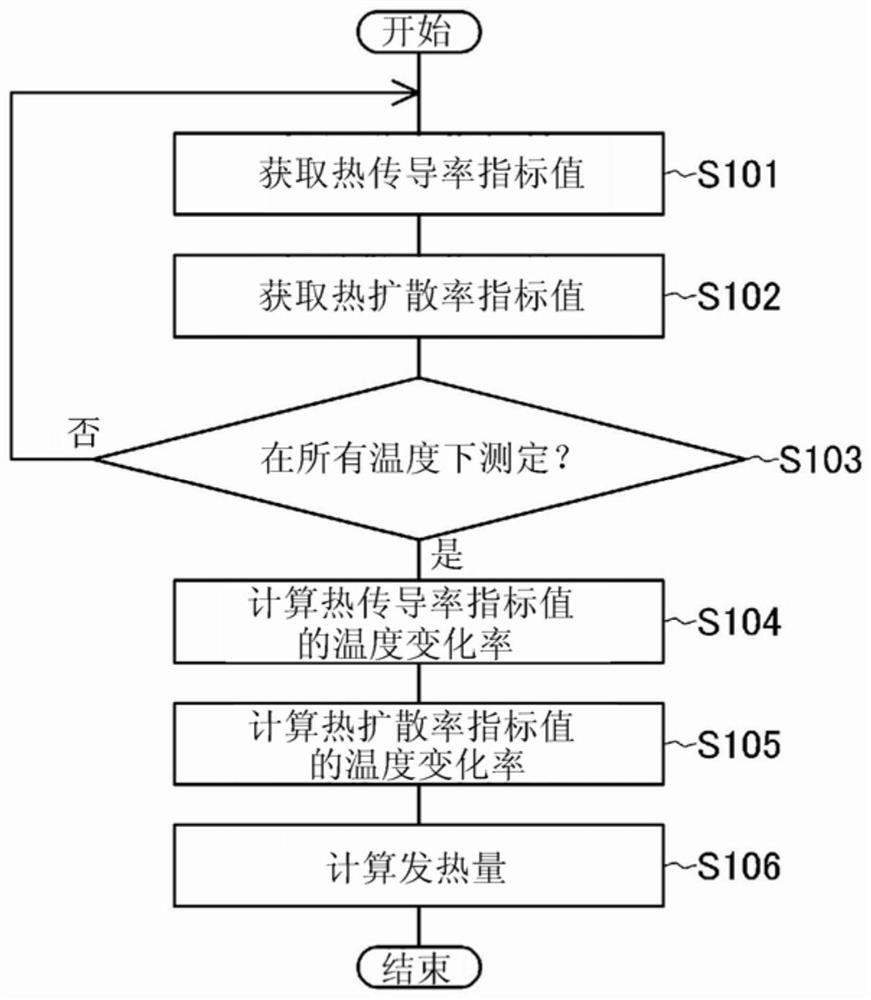

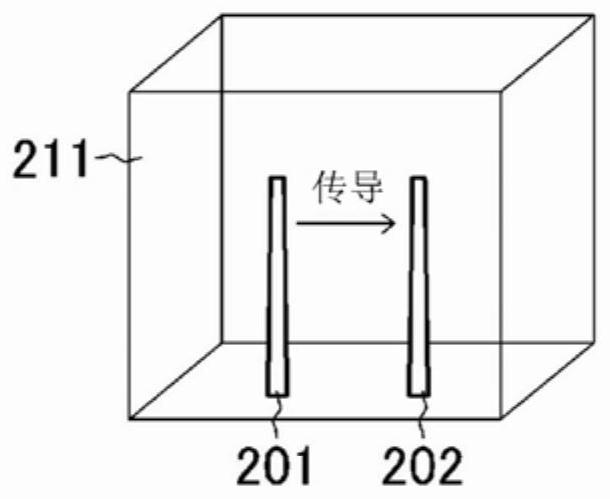

Apparatus and method for measuring calorific value

ActiveCN109564178BCalorific valueMaterial thermal conductivityMaterial heat developmentThermal diffusivityHeat measurement

Obtain a first value as an index of thermal conductivity and a second value as an index of thermal diffusivity of the fuel gas to be measured at a first temperature, a second temperature, and a third temperature that are different from each other by the measurement unit (101). , use the rate of change calculating part (102) to obtain the temperature change rate κ of the first value between the first temperature and the second temperature measured by the measuring part (101) 1 , the temperature change rate κ of the first value between the second temperature and the third temperature 2 , the temperature change rate α of the second value between the first temperature and the second temperature 1 , the temperature change rate α of the second value between the second temperature and the third temperature 2 , using the calorific value calculation unit (103) to pass κ 1 , κ 2 、α 1 、α 2 As an explanatory variable, the calorific value calculation formula using the calorific value as the target variable calculates the calorific value of the fuel gas.

Owner:YAMATAKE HONEYWELL CO LTD

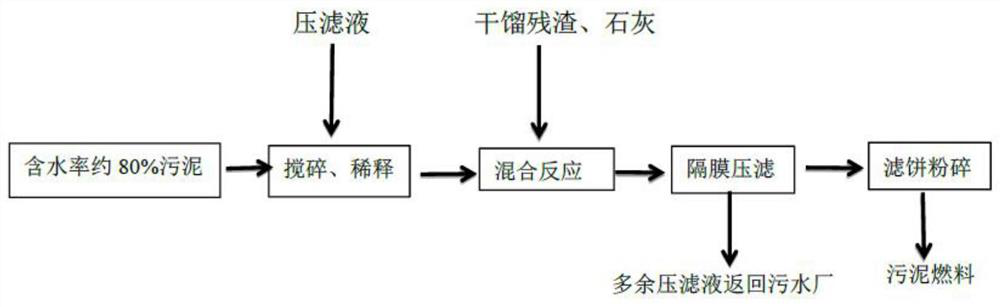

A kind of sludge dehydrating agent and its application method for reducing the moisture content of sludge and utilizing it as a resource

The invention belongs to the technical field of sludge treatment, and specifically relates to a sludge dehydrating agent, which is composed of lime and carbonization residue; the particle size of the carbonization residue is 30-500 μm, the hydrophobic angle is 91-97°, and the specific surface area is 220 ~300m 2 / g. The invention also provides a method for reducing the water content of the sludge and utilizing the sludge as a resource based on the sludge dewatering agent. The present invention innovatively finds that the dry distillation residue and lime with the particle size, hydrophobic angle and specific surface area have synergy in sludge dehydration, which can synergistically reduce the specific resistance of sludge and effectively improve the dewatering performance of sludge. Not only that, but also The calorific value of the treated sludge can be increased, so that the treated sludge can be directly used as solid fuel to realize high-value utilization.

Owner:长沙坚诺环境科技有限公司

A kind of method utilizing inulin to prepare fructan and gluconic acid

Owner:HUNAN XINLI BIOLOGICAL SCI & TECH +1

Inferior heavy oil fluidization conversion technology

ActiveCN103224808BLow calorific valueQuality improvementTreatment with plural serial stages onlyGranular/pulverulent flues gasificationThermal energySyngas

The invention relates to an inferior heavy oil fluidization conversion technology. The inferior heavy oil fluidization conversion technology comprises that raw material oil is treated by a fractionating tower, then enters into a lifting pipe reactor, undergoes a contact reaction with coke carriers from a coke carrier mixer, then enters into a first gas-solid separation device and is separated; the separated reaction oil gas is fed into the fractionating tower and is subjected to product division; the coke carriers with coke is stripped and is divided into two parts, one of the two parts is fed into the coke carrier mixer, then is mixed with the high-temperature coke carriers from a vaporizer and then is fed back to the lifting pipe reactor, and other one of the two parts is fed into the vaporizer, contacts with oxygen-containing gas and water vapor and undergoes a gasification reaction; the produced synthetic gas is separated by a second gas-solid separation device, is fed into a follow-up section, and is subjected to heat recovery and conversion; and the vaporized coke carriers are fed into the coke carrier mixer and is mixed with the coke carriers with the coke. Compared with the prior art, the inferior heavy oil fluidization conversion technology has the advantages of simple process, low investment, strong raw material adaptability, good product distribution and good environmental benefits.

Owner:SHANGHAI HOTO PETROCHEM ENG

Converter gas mixing device and method

PendingCN113293258AWell mixedSimple structureTransportation and packagingMixer accessoriesThermodynamicsCombustion

The invention provides a converter gas mixing device and a method. The mixing device comprises a converter gas branch pipe, a mixed gas pressure regulating unit, a mixed gas branch pipe and a mixed gas main pipe. The mixed gas pressure regulating unit is connected with the mixed gas branch pipe; and the converter gas branch pipe and the mixed gas branch pipe are respectively and independently connected to the mixed gas main pipe. The method comprises the following steps of (1) detecting the content of CO in converter gas; (2) determining the mixing ratio of mixed gas according to the CO content obtained in the step (1); and (3) mixing the mixed gas subjected to pressure regulation with the converter gas. The invention constructs the reasonable and efficient converter gas mixing device, the mixed gas with the proper variety and mixing ratio is determined according to the CO content of the converter gas, the combustion rate and heat value of the fuel are improved,the extensibility of combustion flame is increased, the calcination requirement of a rotary kiln is met, and the product quality of the rotary kiln is stabilized.

Owner:承德燕北冶金材料有限公司

Fuel oil composition

The invention relates to a fuel oil composition suitable for bunker fuel oil industry, industrial generation, civil boilers and the like. The fuel oil composition comprises the following materials: 10-60 parts by weight of heavy oil residues as petroleum byproducts, 5-50 parts by weight of low-temperature coal tar, 5-53 parts by weight of light fuel oil and 2-20 parts by weight of diesel oil or absorber oil. A fuel oil finished product prepared from the fuel oil composition has the advantages of good cleanness and stability, low abrasion and corrosion effects on combustion equipment and favorable storage stability.

Owner:锦州港船舶燃料供应有限责任公司

Hazardous waste incineration classification continuous closed feeding system

ActiveCN106402903BPrecise control of process parametersGuaranteed uptimeIncinerator apparatusLiquid stateIncineration

The invention discloses a continuous and sealed feeding system for classified incineration of hazardous waste. The feeding system comprises a bulk material feeding sub-system, a bagged material feeding sub-system and a liquid material feeding sub-system, and the bulk material feeding sub-system, the bagged material feeding sub-system and the liquid material feeding sub-system are used for conveying bulk materials, bagged materials and liquid-state hazardous waste to an incinerating device correspondingly in a continuous and sealed mode. By means of the continuous and sealed feeding system, hazardous waste can be conveniently subjected to heat value detection and chemical proportioning, and therefore process parameters in the incinerating device can be accurately controlled, and stable, safe and efficient operation of the incinerating device is guaranteed.

Owner:北控安耐得环保科技发展常州有限公司

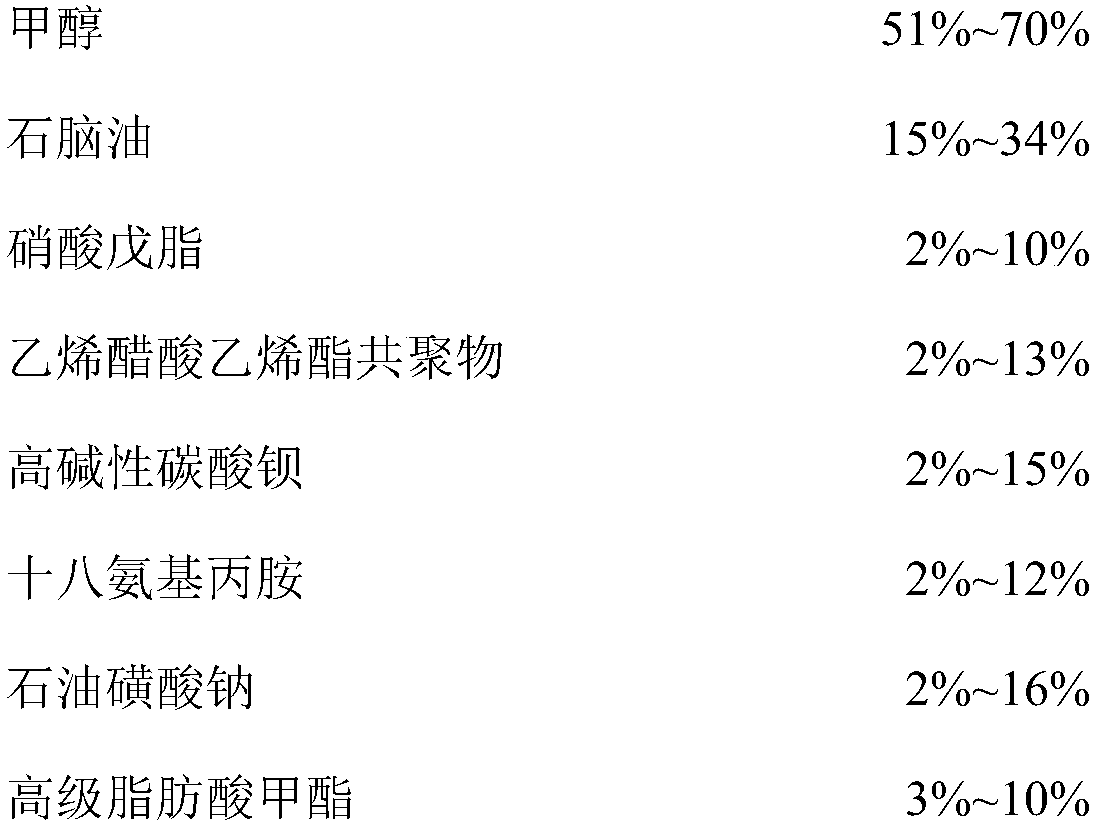

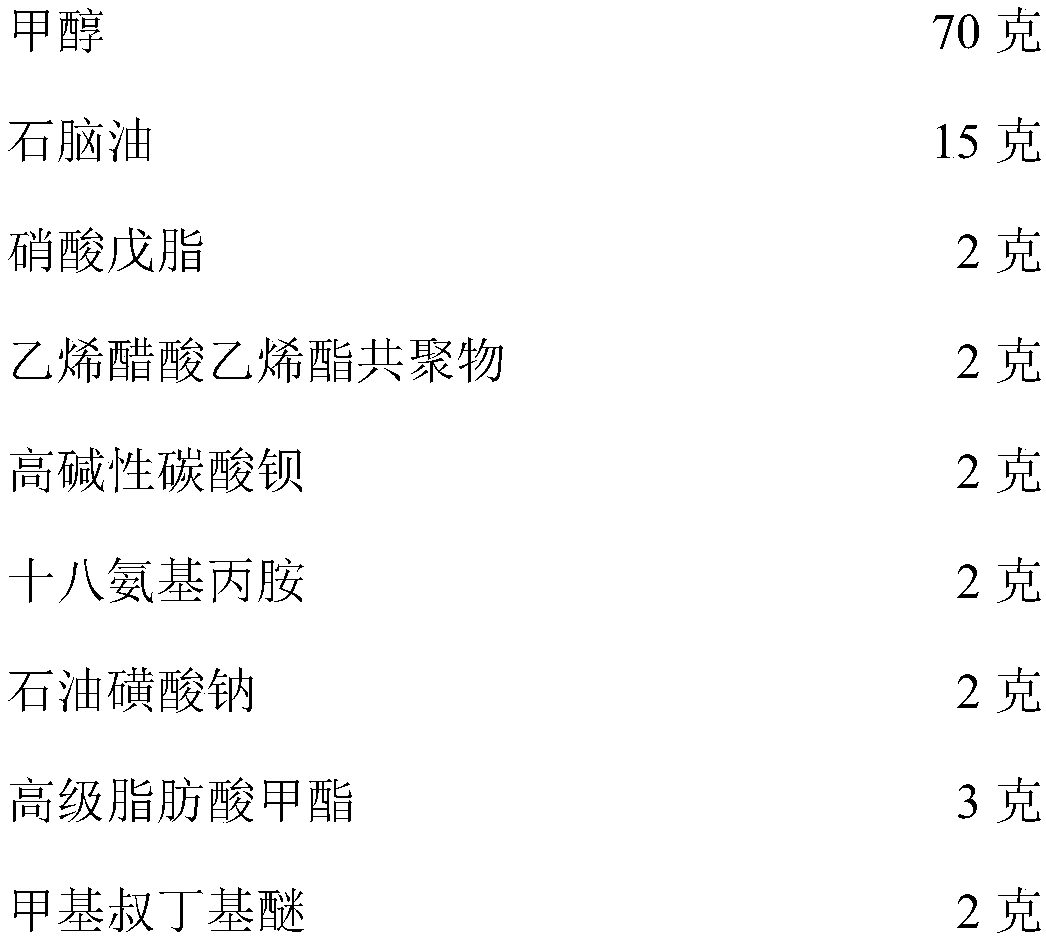

High-performance methanol engine fuel

InactiveCN108456566ACalorific valueProblem improvement with low calorific valueLiquid carbonaceous fuelsNew energyPropylamine

The invention discloses a high-performance methanol engine fuel and belongs to the technical field of energy chemistry. The invention aims at providing the high-performance methanol engine fuel with ahigher heat value. The formula of the high-performance methanol engine fuel is characterized by being prepared from methanol, naphtha, amyl nitrate, ethylvinylacetate, high alkalinity barium carbonate, stearyl propylamine, petroleum sodium sulfonate, long-chain fatty acid methyl ester and methyl tertiary-butyl ether. A product disclosed by the invention is mainly applied to an engine of a methanol power vehicle of new energy vehicles. According to the high-performance methanol engine fuel disclosed by the invention, by adopting a variety of excellent auxiliaries, the stability of the methanolfuel is enhanced, ignition is easier and the combustion effect is better; more importantly, the big problem of lower heat value of the methanol fuel is improved; by means of testing, the product disclosed by the invention has a heat value of 1350.75KJ / mol which is far superior to like products in the existing technology. (The heat value of the methanol fuel in the existing technology is normally726.55 KJ / mol).

Owner:肇庆创奇者新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com