Sludge high-dry dehydration conditioning method

A sewage treatment plant and sludge technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of inability to realize effective utilization of resources, increase sludge treatment costs, and destroy affinity, so as to achieve effective utilization of resources, The effect of reducing secondary pollution, reducing time and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: the dehydration treatment of sludge

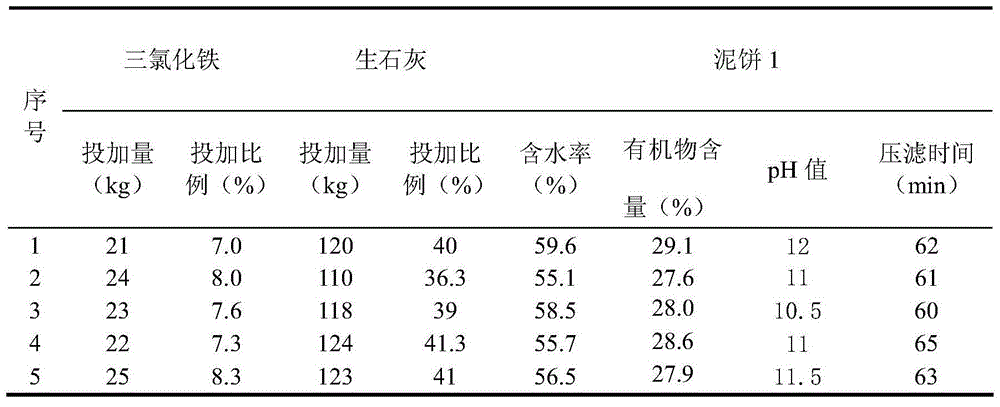

[0012] According to the data disclosed in Table 1, ferric chloride and quicklime were added to the sludge, mixed and stirred, and then the mixture was dehydrated by pressure filtration through a plate-and-frame filter to obtain mud cake 1, wherein, the input of ferric chloride and quicklime The adding ratio is the ratio added to the dry sludge, and the working pressure of the plate and frame filter press is 5.0Mpa.

[0013] Table 1 Experimental data

[0014]

Embodiment 2

[0015] Embodiment 2: the dehydration treatment of sludge

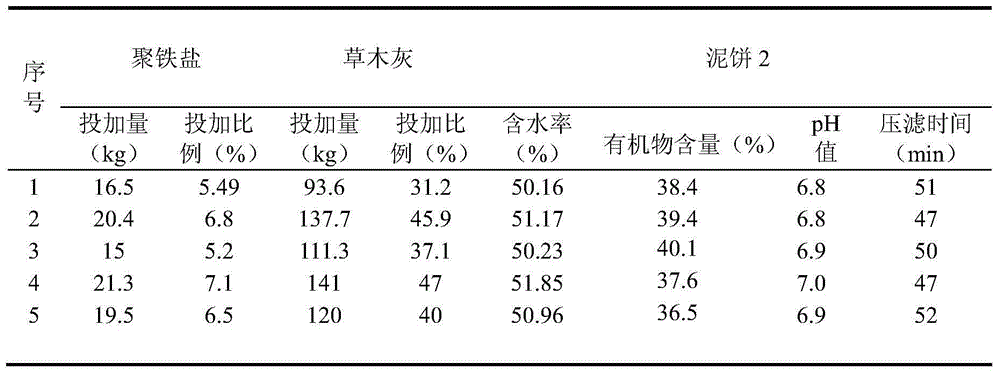

[0016] According to the data disclosed in Table 2, polyferric salt and plant ash are added to the sludge, mixed and stirred, and then the mixture is dehydrated by pressure filtration through a plate and frame filter to obtain mud cake 2, wherein the dosage of polyferric salt and plant ash The working pressure of the plate and frame filter press is 4.0Mpa for the ratio of adding to the dry sludge.

[0017] Table 2 Experimental data

[0018]

[0019] The mud cake 1,2 that obtains in embodiment 1,2 is analyzed and detected, gets the average value of each detection value, specifically as shown in table 3 below, can find out from the table: 1) " polyferric salt+plant ash " as In the conditioner, the calorific value of mud cake 2 increased by 317kcal / kg compared with mud cake 1, and the conditioner of mud cake 2 did not use ferric chloride, which reduced the chlorine content in the mud cake and effectively reduced the am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com