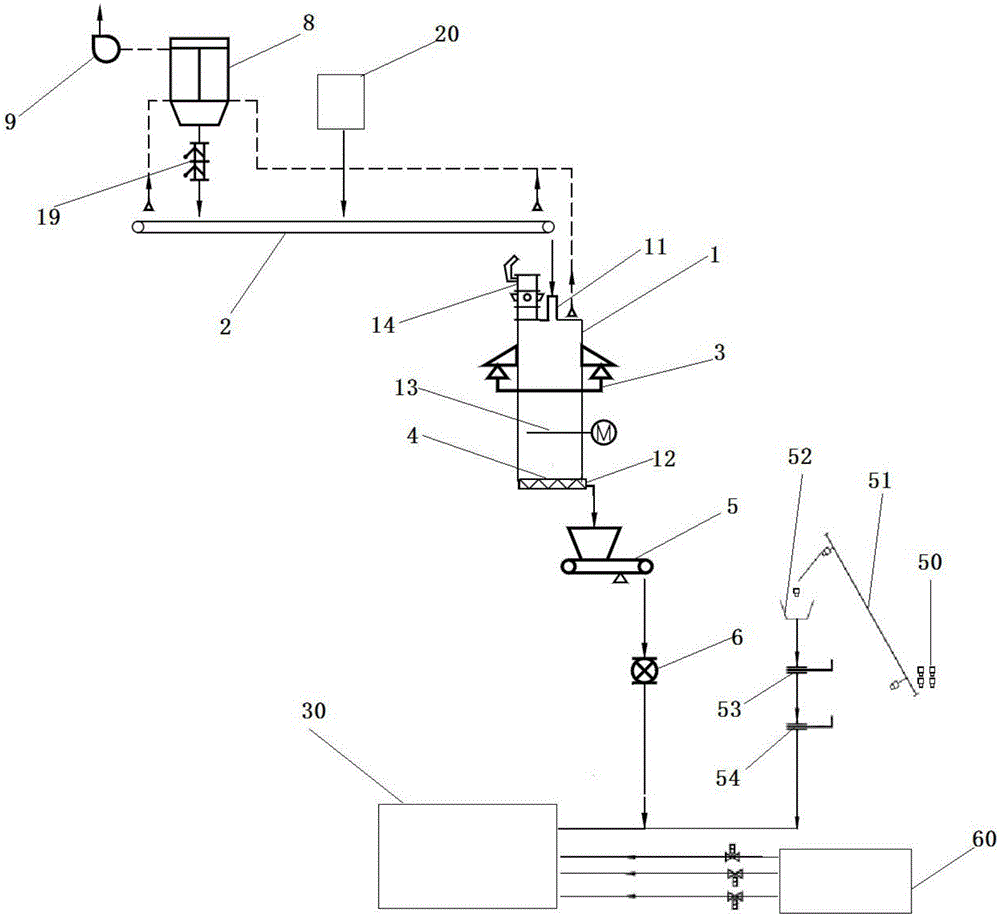

Continuous and sealed feeding system for classified incineration of hazardous waste

A technology of feeding system and waste, applied in combustion types, incinerators, combustion methods, etc., can solve the problems of air pollution, disordered incineration conditions in the kiln, explosion in the inner pit, etc., and achieve the effect of stable and efficient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The hazardous waste incineration classification continuous closed feeding system of the present invention will be described in detail below in conjunction with the accompanying drawings. Those skilled in the art should understand that the embodiments described below are only illustrative illustrations of the present invention, and are not intended to limit it in any way.

[0019] In order to facilitate the compatibility and safe transportation of various materials, in the present invention, the hazardous waste to be treated is divided into three categories in advance: bulk material, bagged material and liquid material. The calorific value and chemical properties of the same type of material are similar. Among them, bulk materials mainly refer to block or granular solids with a particle size of less than 50ⅹ50ⅹ80mm. The bagged material is used to load special hazardous waste in sealed packaging. This kind of substance is characterized by its relatively active chemical pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com