Gas chromatography detection method in caprolactam production process

A technology of gas chromatography and caprolactam, which is applied in the field of gas chromatography detection in the production process of caprolactam, can solve the problems of poor separation and analysis effect, and achieve the effect of improving separation effect and detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

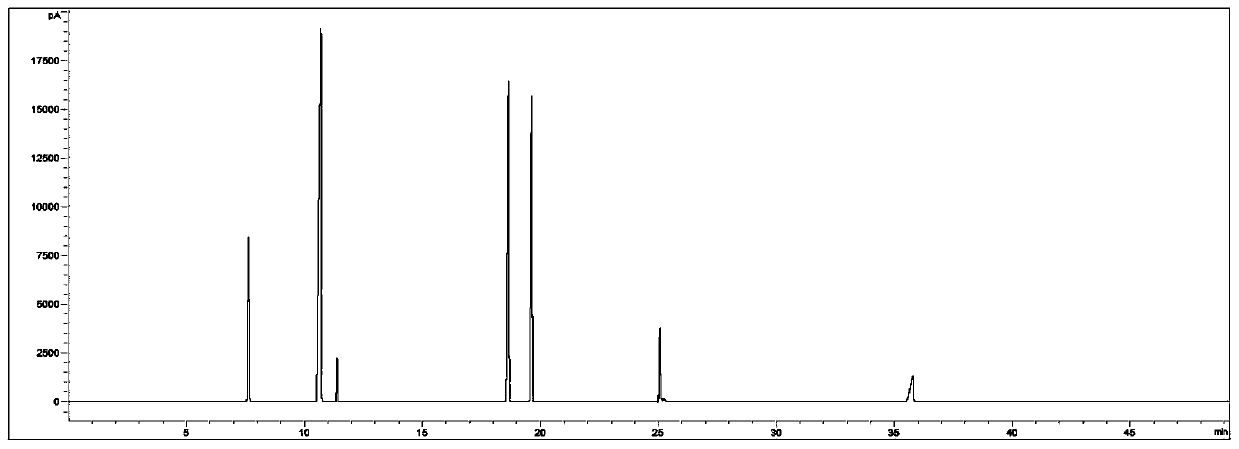

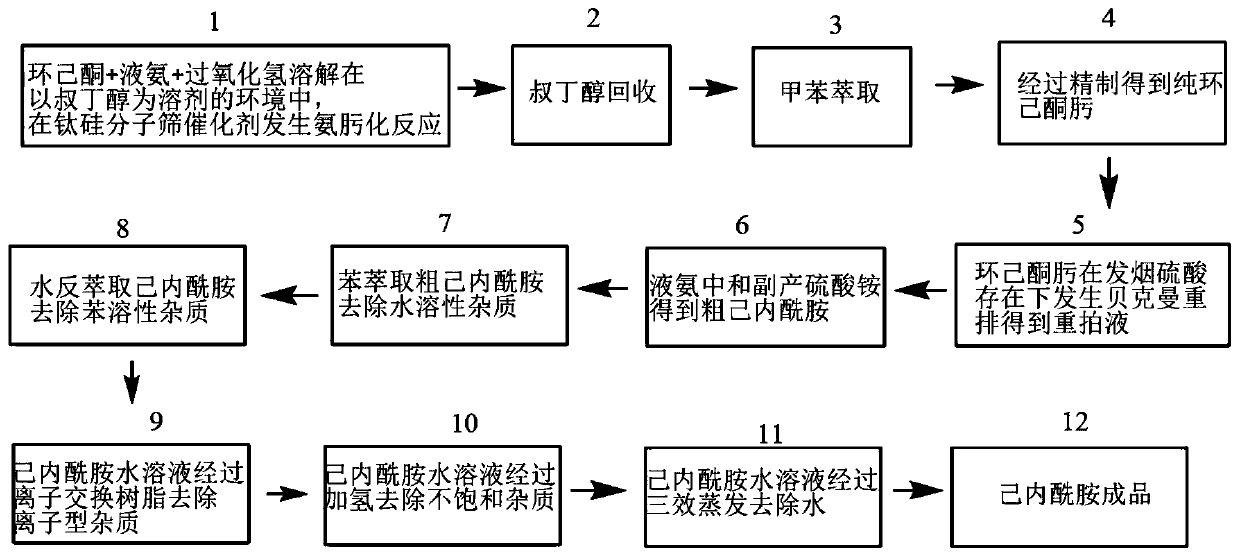

[0054] No. 1 quality control point in the production process of caprolactam, that is, at image 3 At the end of the shown step 1), the sample in the caprolactam production process is detected, which is composed of several types of tert-butanol, toluene, cyclohexanone, cyclohexanol, benzene, cyclohexanone oxime, and caprolactam.

[0055] Injection vaporization temperature: 300°C; temperature program: start at 30°C at 5°C / min to 200°C for 10 minutes; carrier gas flow rate: 2mL / min, column liquid film: Carbowax; column length: 60m; inner diameter: 0.52 mm; film thickness: 0.5 μm. The resulting chromatogram is figure 1 shown.

Embodiment 2

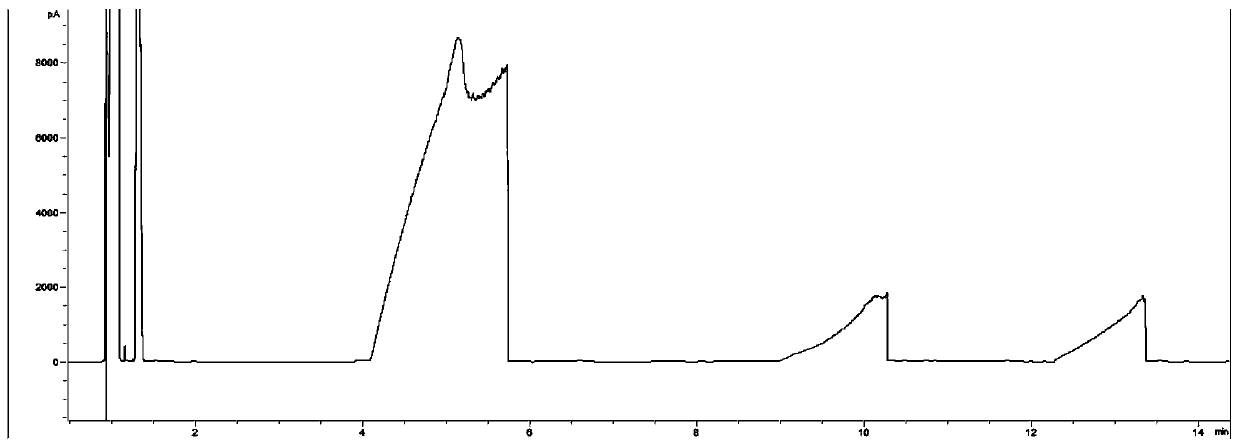

[0057] No. 1 quality control point in the production process of caprolactam, that is, at image 3 At the end of the shown step 1), the sample in the caprolactam production process is detected, which is composed of several types of tert-butanol, toluene, cyclohexanone, cyclohexanol, benzene, cyclohexanone oxime, and caprolactam.

[0058] Injection vaporization temperature: 300°C; temperature program: start at 30°C at 5°C / min to 200°C for 10 minutes; carrier gas flow rate: 2mL / min, column liquid film: DB-FFAP; column length: 60m; inner diameter : 0.52mm; film thickness: 0.5μm.

Embodiment 3

[0060] No. 1 quality control point in the production process of caprolactam, that is, at image 3 At the end of the shown step 1), the sample in the caprolactam production process is detected, which is composed of several types of tert-butanol, toluene, cyclohexanone, cyclohexanol, benzene, cyclohexanone oxime, and caprolactam.

[0061] Injection vaporization temperature: 300°C; temperature program: start at 30°C at 5°C / min to 200°C for 10 minutes; carrier gas flow rate: 2mL / min, column liquid film: CP Wax 58CB; column length: 30m; inner diameter : 0.52mm; film thickness: 0.5μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com