Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53results about How to "Avoid production safety accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

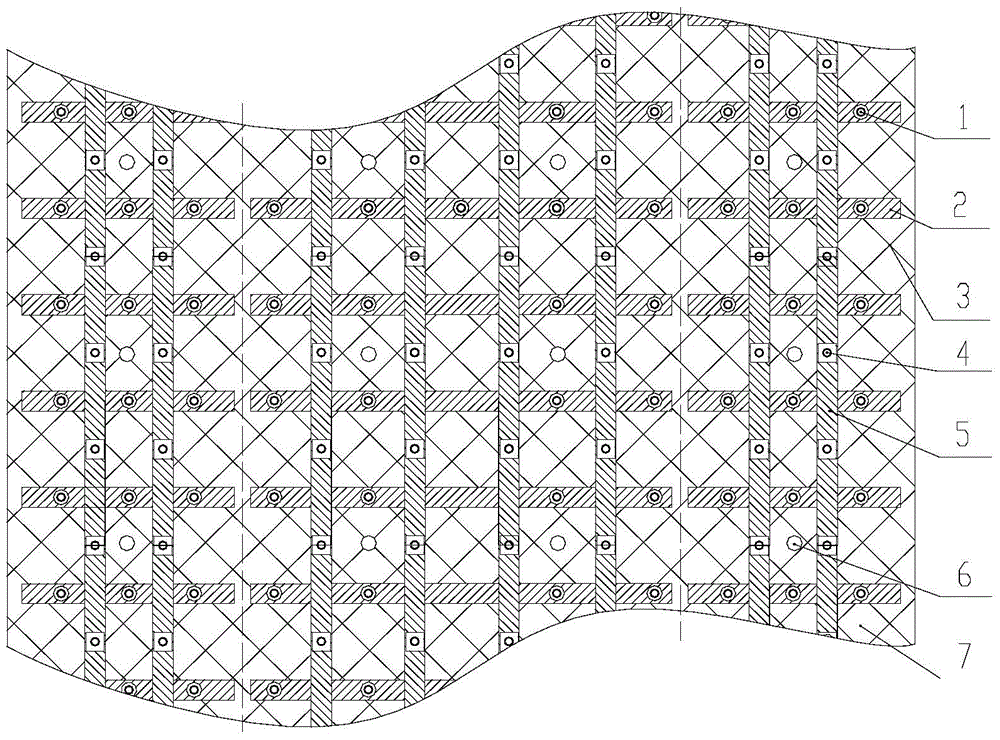

Impact ground pressure preventing method of full seam gateway

ActiveCN104806265AImproved anti-shock performanceEven by forceUnderground chambersBlastingSupporting systemEngineering

The invention provides an impact ground pressure preventing method of a full seam gateway. The method is that an impact preventing support consisting of energy absorbing steel beams and energy absorbing anchor rod ropes is added on the basis of the general support composed of an iron wire net, a steel belt and an anchor rod, wherein the energy absorbing steel beams are lengthways distributed at intervals along the gateway, comprising two layers of steel plates, and energy absorbing boxes which are fixed at intervals between the two layers of steel plates; gateway surrounded rock in a propping plate and two sides is drilled and grouted, so that the gateway surrounded rock can damp the impact; two bottom corners of the gateway within the advance influence range of a workface are blasted to release pressure. According to the method, the general support, the impact preventing support, the surrounded rock modification and the blasting and pressure release of the bottom corners of the gateway are synchronously carried out to form a point-line-face-body 3D distribution type energy absorbing and impact preventing system; the incident stress wave can be reduced through the support system, and the reflecting stress wave of the gateway surface can be reduced; the modified loose surrounded rock mass can greatly reduce the influence of the impact energy on the support structure; the four measures supplement each other and synergistically interacted, so that the impact ground pressure preventing capacity of the gateway can be greatly improved.

Owner:LIAONING TECHNICAL UNIVERSITY

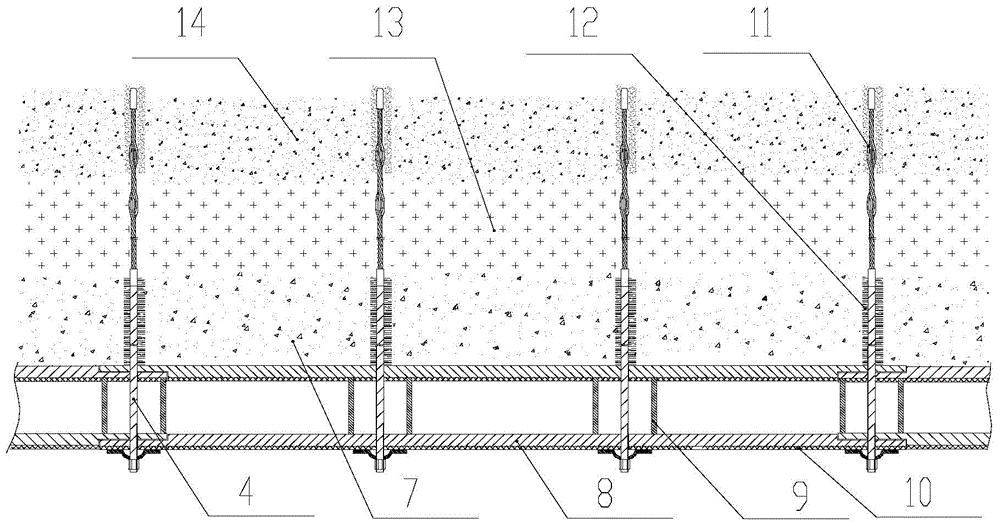

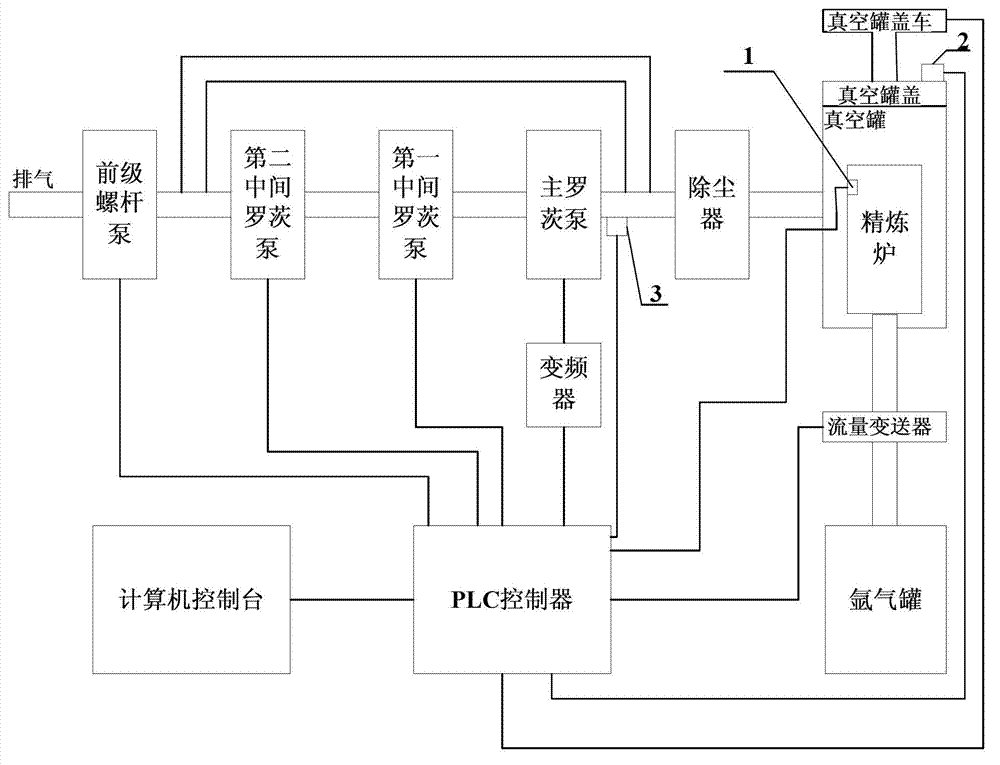

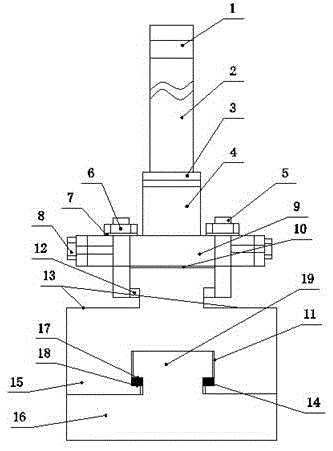

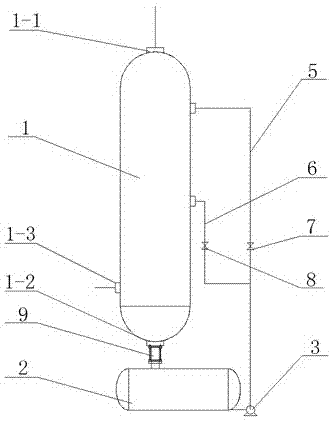

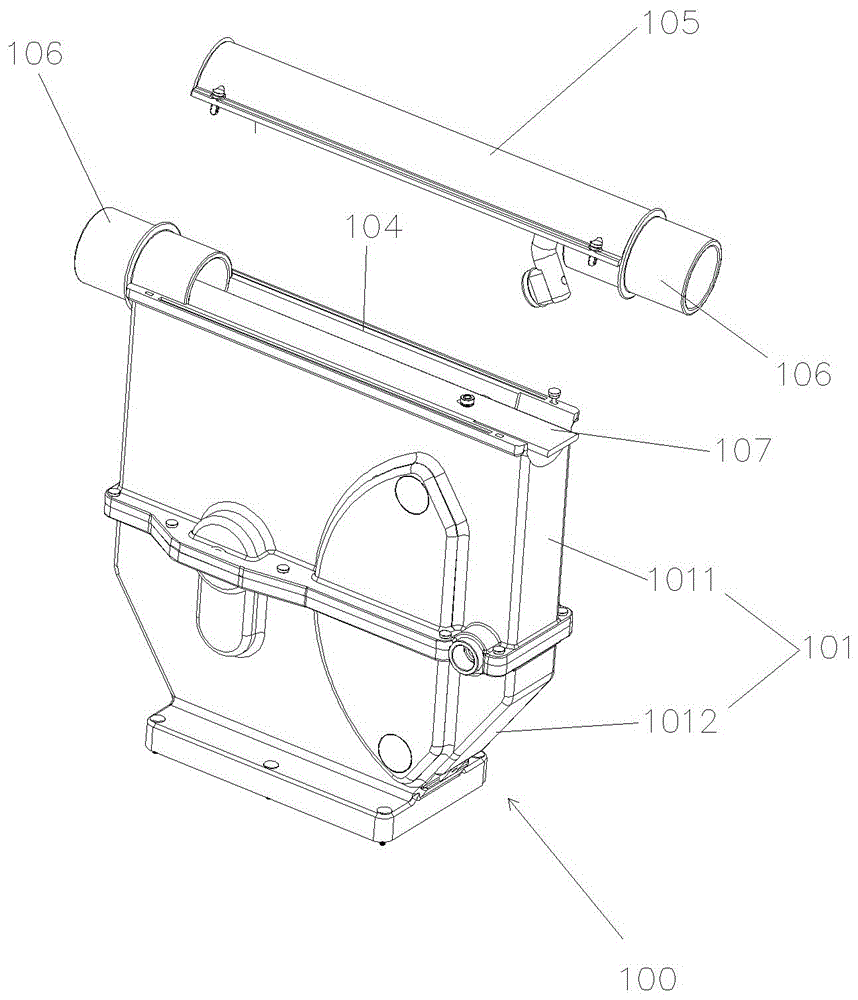

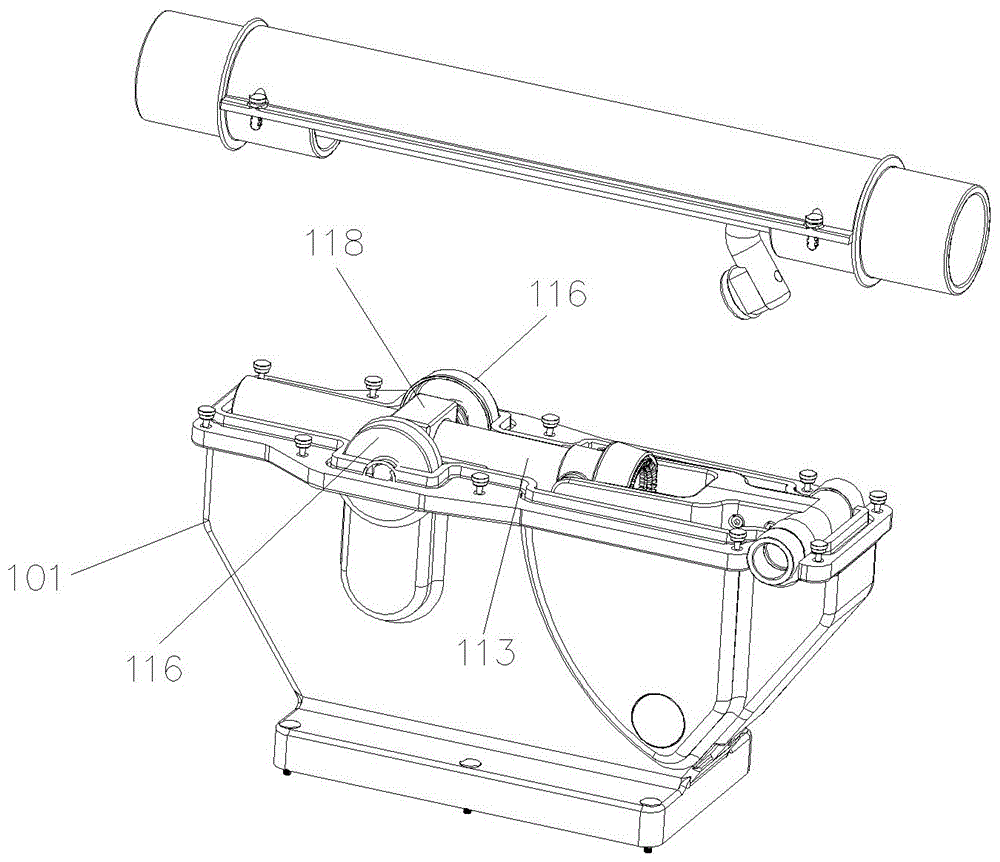

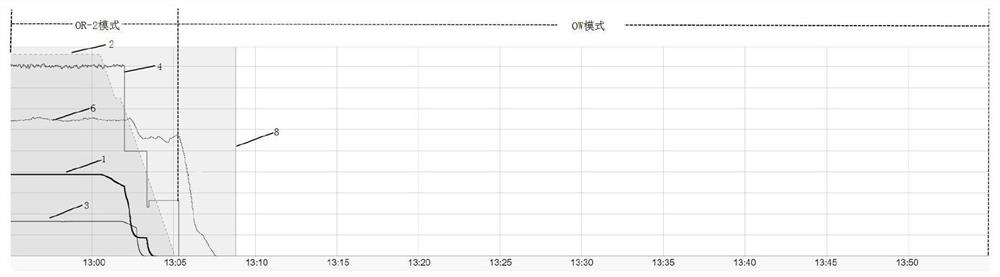

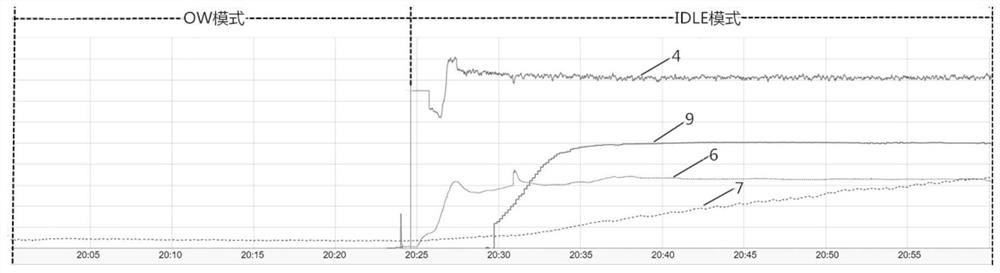

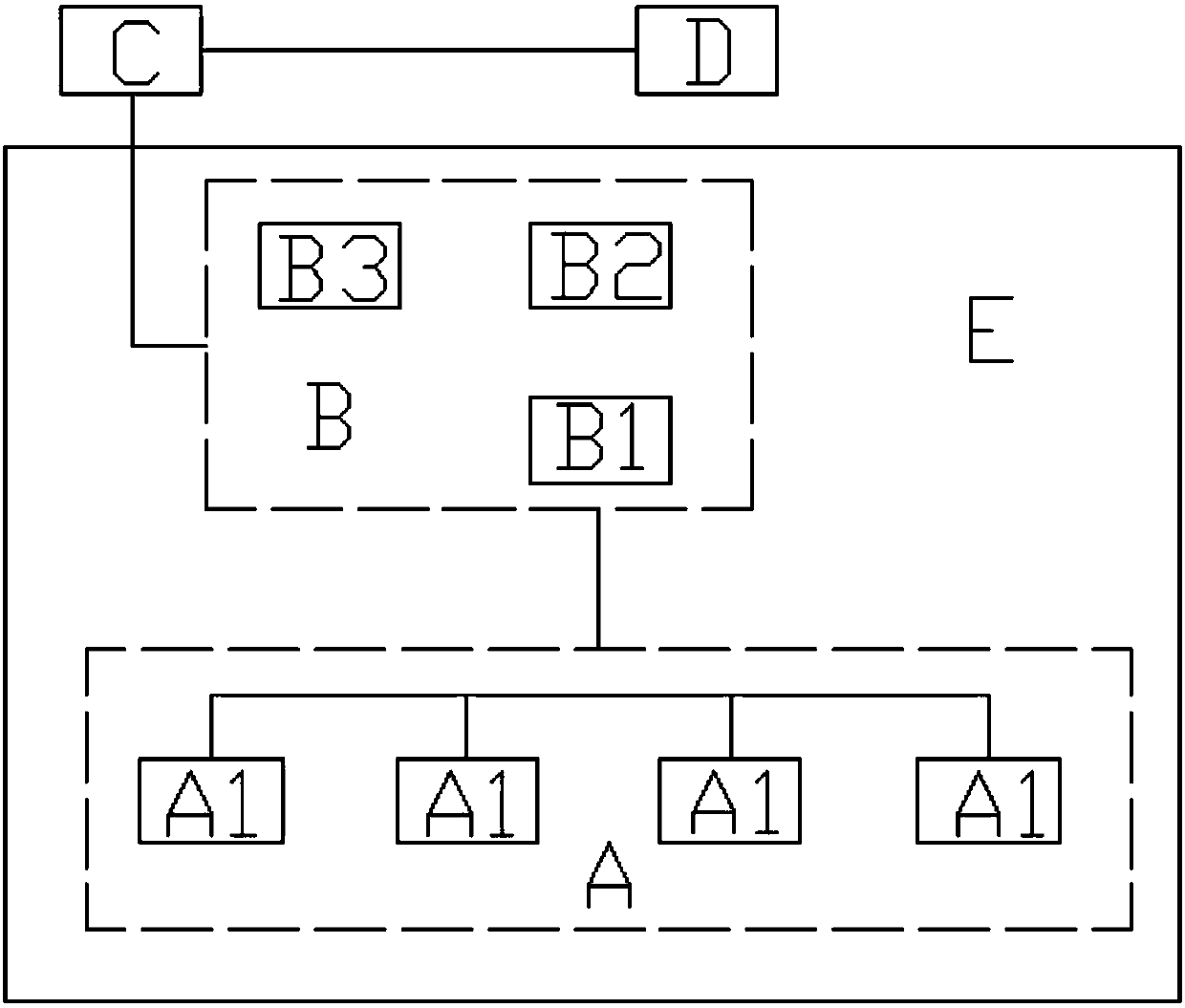

Molten steel vacuum refining system based on mechanical pump group

The invention discloses a molten steel vacuum refining system based on a mechanical pump group. The system comprises a vacuum tank, a deduster, a roots pump group and a pre-screw pump, wherein the roots pump group comprises a main roots pump, a first middle roots pump and a second middle roots pump; the deduster is also directly connected with the pre-screw pump through a pipeline; the bottom of the vacuum tank is connected with an argon system; the system also comprises a controller; the first middle roots pump, the second middle roots pump and the pre-screw pump are all electrically connected with the controller; the main roots pump is electrically connected with the controller through a frequency converter; a liquid level sensor is arranged at the upper part of the inner wall of a refining furnace of the vacuum tank; the liquid level sensor is electrically connected with the controller; a vacuum degree measuring device is mounted on a pipeline between the deduster and the main roots pump; and the vacuum degree measuring device is connected with the controller. The system disclosed by the invention can perform automatic control to realize stable liquid surface of the molten liquid in the refining furnace of the vacuum tank to prevent steel overflow, thereby avoiding production safety accident.

Owner:什邡市三裕锻件有限公司

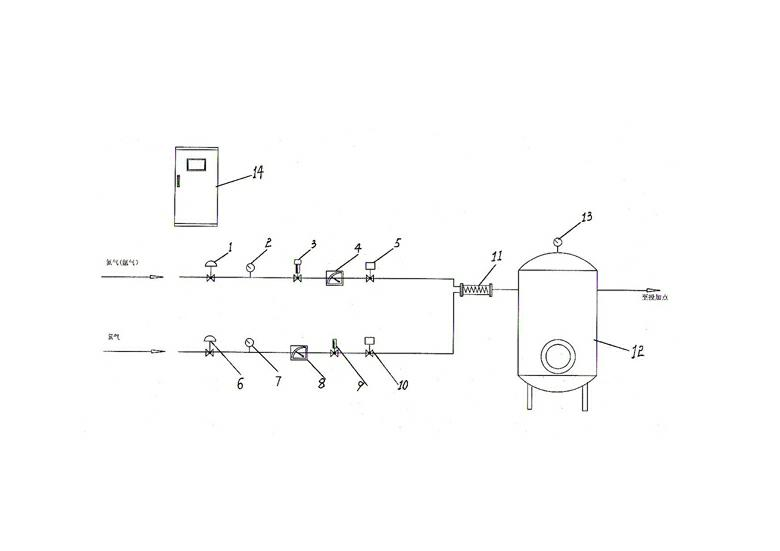

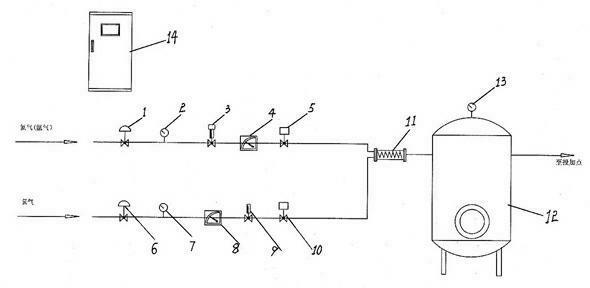

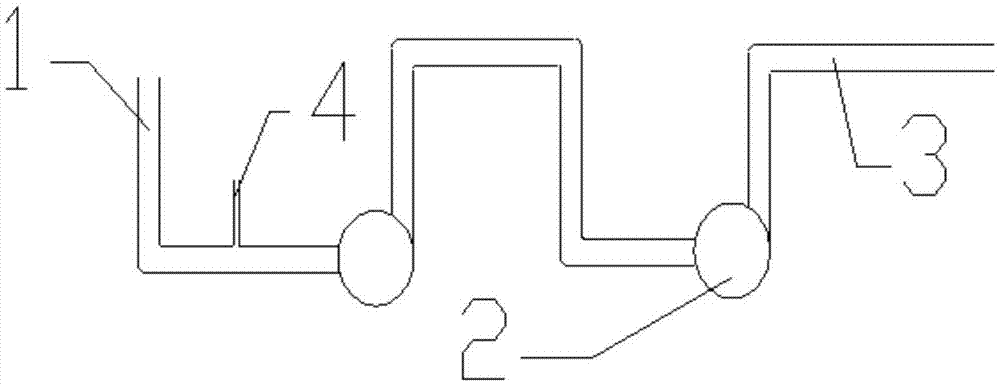

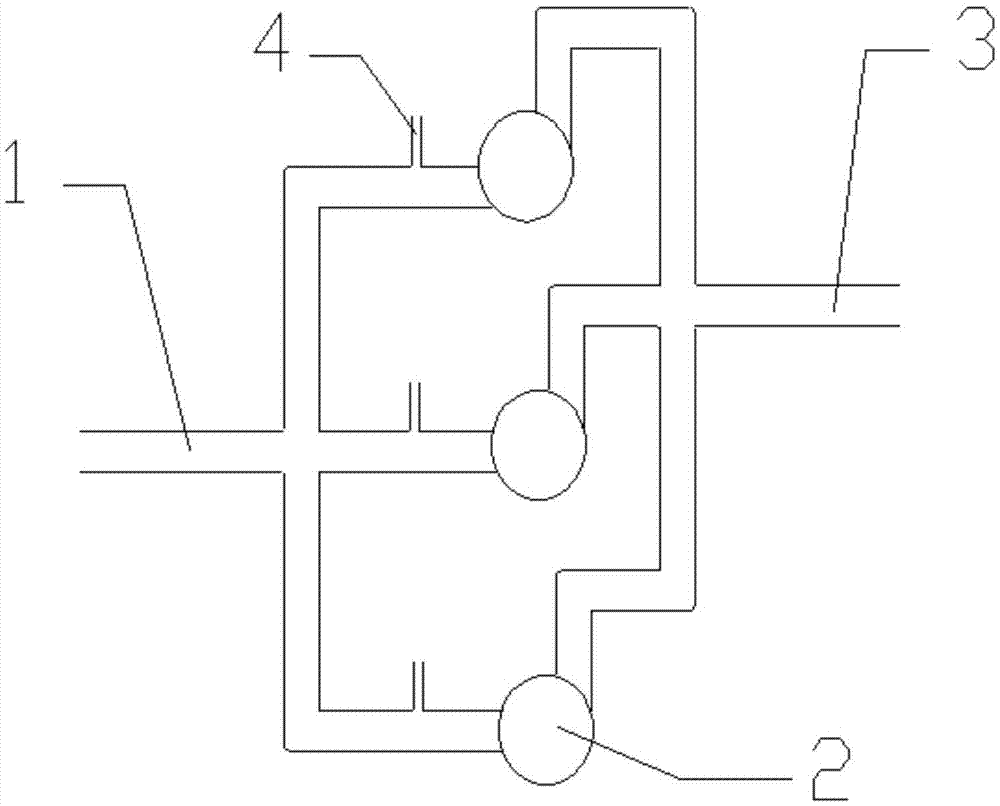

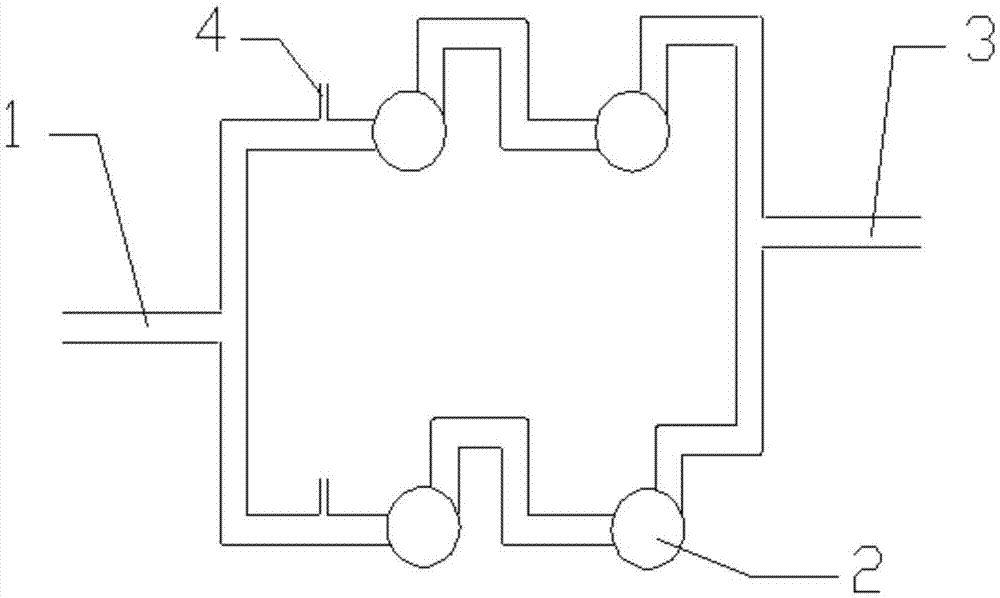

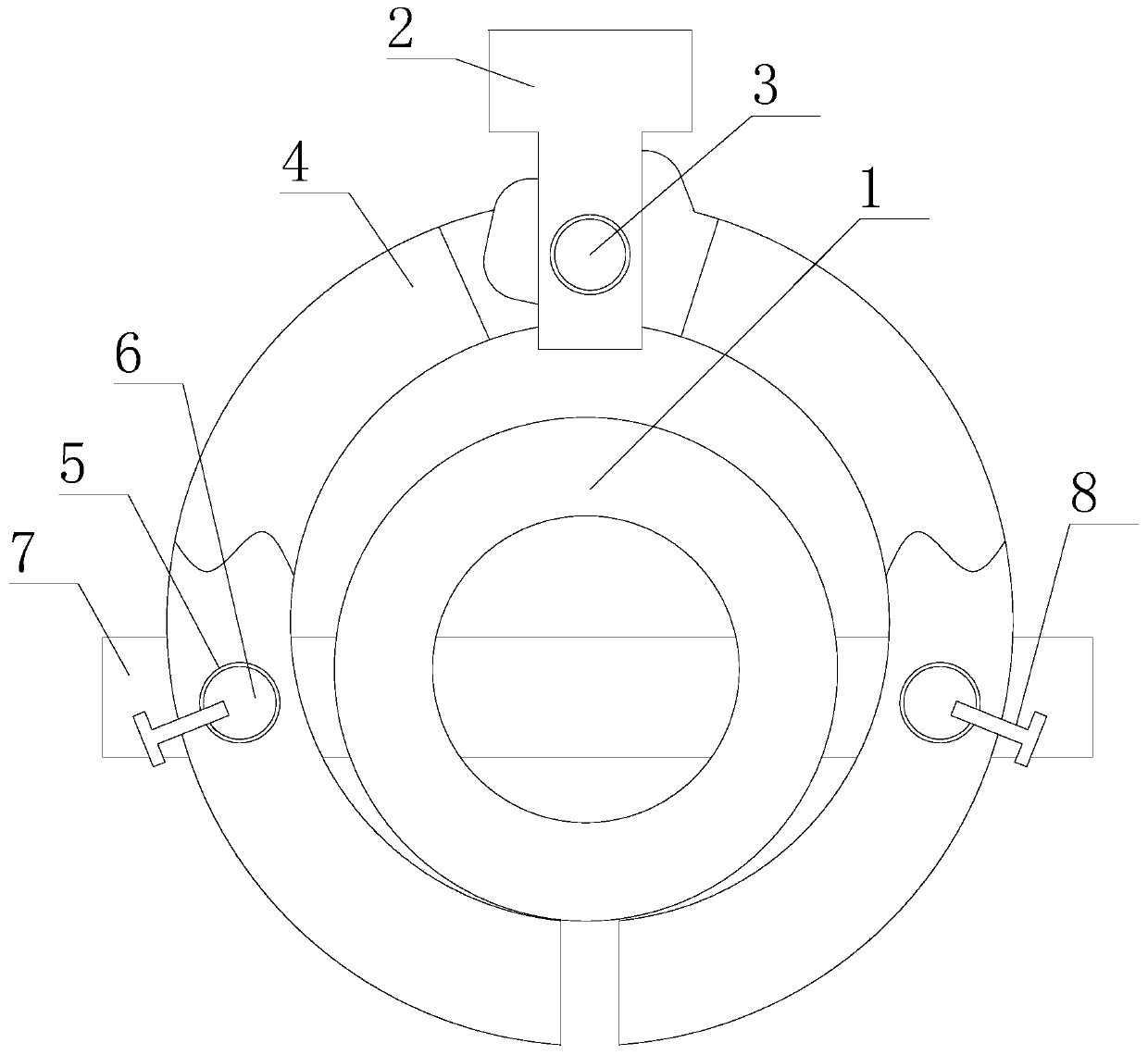

Nitrogen/chlorine (argon/chlorine) mixing and proportioning system and operation method thereof

InactiveCN102600759AImprove the ratio accuracyExtended service lifeMixer accessoriesMixing gases with gases/vapoursProgrammable logic controllerProcess engineering

The invention relates to a nitrogen / chlorine (argon / chlorine) mixing and proportioning system and an operation method thereof, aiming to overcome the defect that the manual nitrogen / chlorine (argon / chlorine) mixing and proportioning process in the prior art is completed by manual operation rather than automatic operation and is low in proportioning precision and high in operation risk. The nitrogen / chlorine (argon / chlorine) mixing and proportioning system comprises nitrogen (argon) gas running equipment, chlorine gas running equipment, a nitrogen and chlorine (argon and chlorine) mixer, a mixed gas storage tank and a PLC (programmable logic controller) control cabinet, wherein tail ends of the nitrogen (argon) gas running equipment and the chlorine gas running equipment are connected with the nitrogen and chlorine (argon and chlorine) mixer together, the nitrogen and chlorine (argon and chlorine) mixer is further connected with the mixed gas storage tank for a feeding point, a pressure sensor is arranged on the mixed gas storage tank, the PLC control cabinet is connected with all the equipment, and intelligent management and operation is realized by an internal control and management system. The nitrogen / chlorine (argon / chlorine) mixing and proportioning system and the operation method thereof have the advantages that automatic proportioning operation can be realized, operators can keep away from dangerous sources, the proportioning precision is increased, the service life of the equipment is prolonged, the service pressure of the system is stabilized, and leakage caused by long-term overhigh pressure load for the end equipment is avoided.

Owner:刘树伟

Oilfield injection-production parameter optimization and adjustment method based on fault stability evaluation

InactiveCN106096308AAvoid production safety accidentsData processing applicationsSpecial data processing applicationsOil wellFault block

The invention discloses an oilfield injection-production parameter optimization and adjustment method based on fault stability evaluation. The method includes the following steps that 1, a fault pressure-bearing limit is predicted; 2, the current balance formation pressure is calculated; 3, the original formation pressure is calculated; 4, the current balance formation pressure is compared with the fault pressure-bearing limit, if the current balance formation pressure is smaller than the fault pressure-bearing limit, a fault is stable, production pressure can be increased properly, and oil well productivity is increased; if the current balance formation pressure is larger than the fault pressure-bearing limit, the fault is in an unstable state, and injection-production parameter adjustment is required to be conducted in fault blocks on the two sides of the fault respectively according to the injection-production parameter optimization and adjustment method in the fault blocks. Based on prediction about the critical pressure required for fault stability maintenance, an oilfield water injection parameter optimization and adjustment method is improved, and the situation that fault activation caused by abnormally high formation pressure gives rise to production safety accidents is avoided.

Owner:NORTHEAST GASOLINEEUM UNIV

Anti-static membrane based on graphene and preparation method of membrane

InactiveCN106279732ALow resistivityWith radiation protectionThermoplastic polyurethaneStatic performance

An anti-static membrane based on graphene is prepared from, by mass, 100 parts of base material, 1.5-6 parts of 1,6-diisocyanatohexane, 1-2 parts of N-dimethylethanolamine, 1-10 parts of nano graphene particle, 1-3 parts of dispersing agent and 0.5-3 parts of waterproof agent. The base material is one of polyurethane resin, thermoplastic polyurethane elastomer, polyether sulfone resin and polytetrafluoroethylene. Due to excellent anti-static performance of the anti-static membrane based on graphene, the membrane can be widely applied to textile fabrics, meets the wearing requirements of people for dryness and comfort, and has the strong efficient anti-static, heat-storage, thermal, antibacterial, anti-acarid and anti-radiation effects.

Owner:KUNSHAN HUAYANG NEW MATERIAL

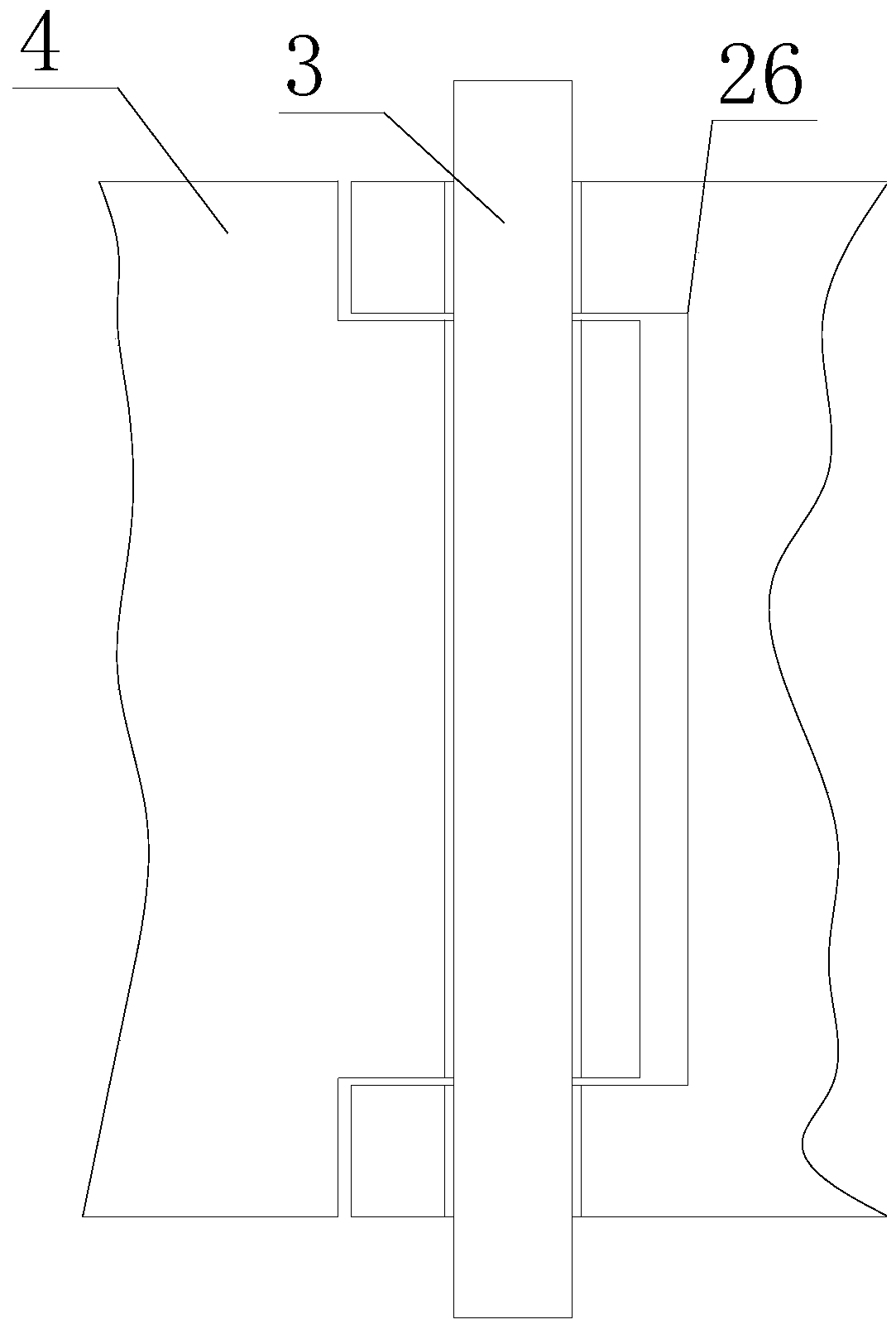

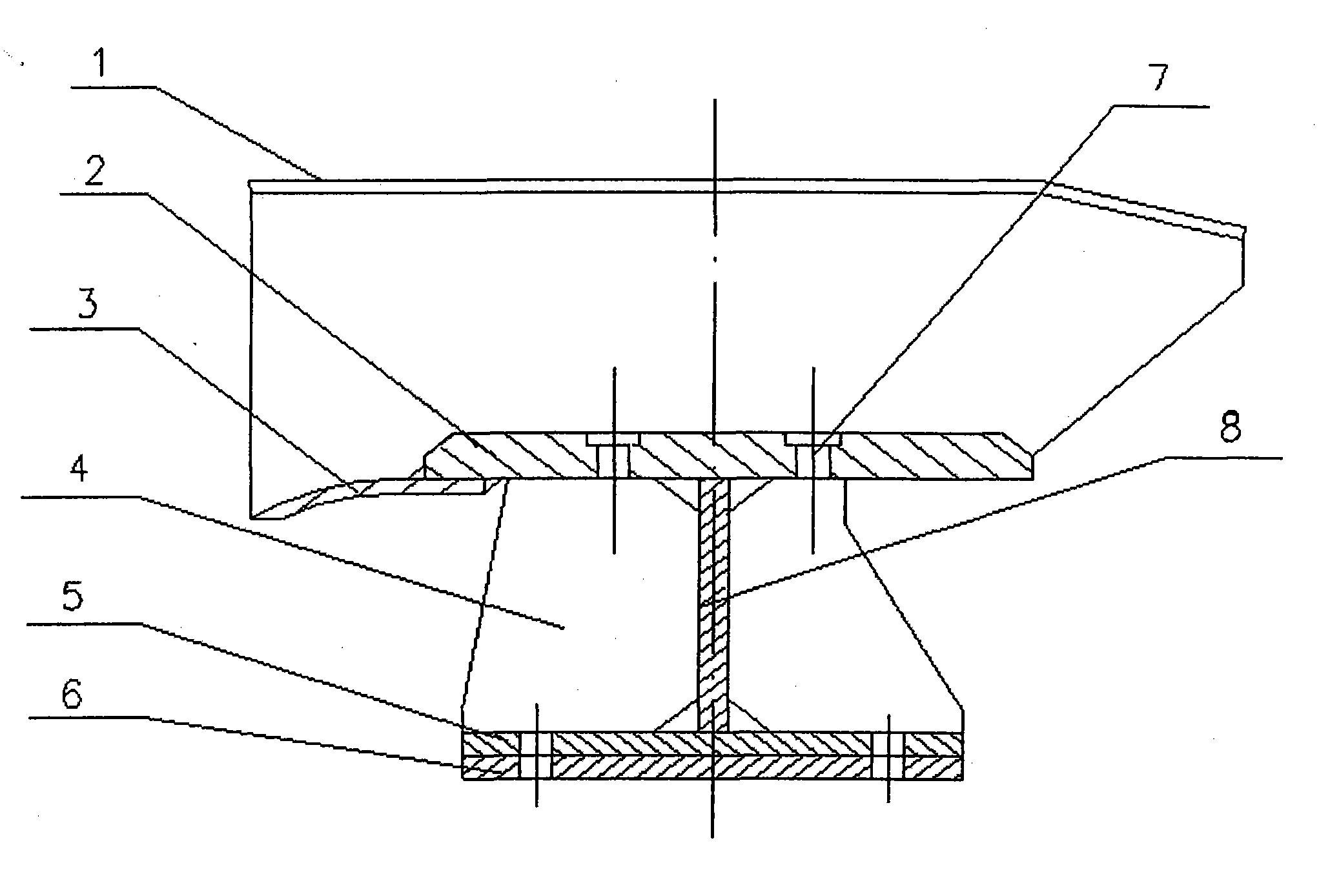

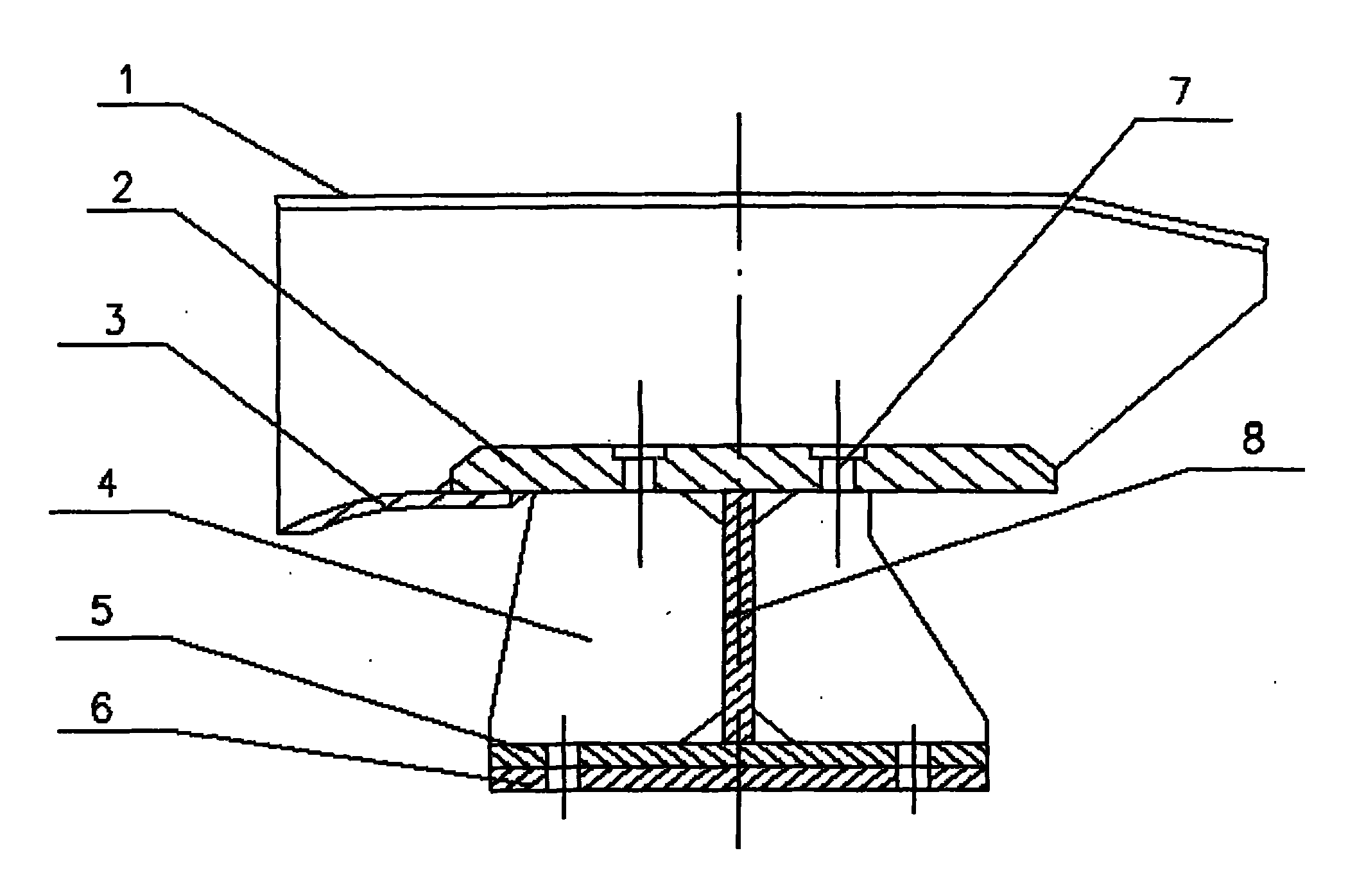

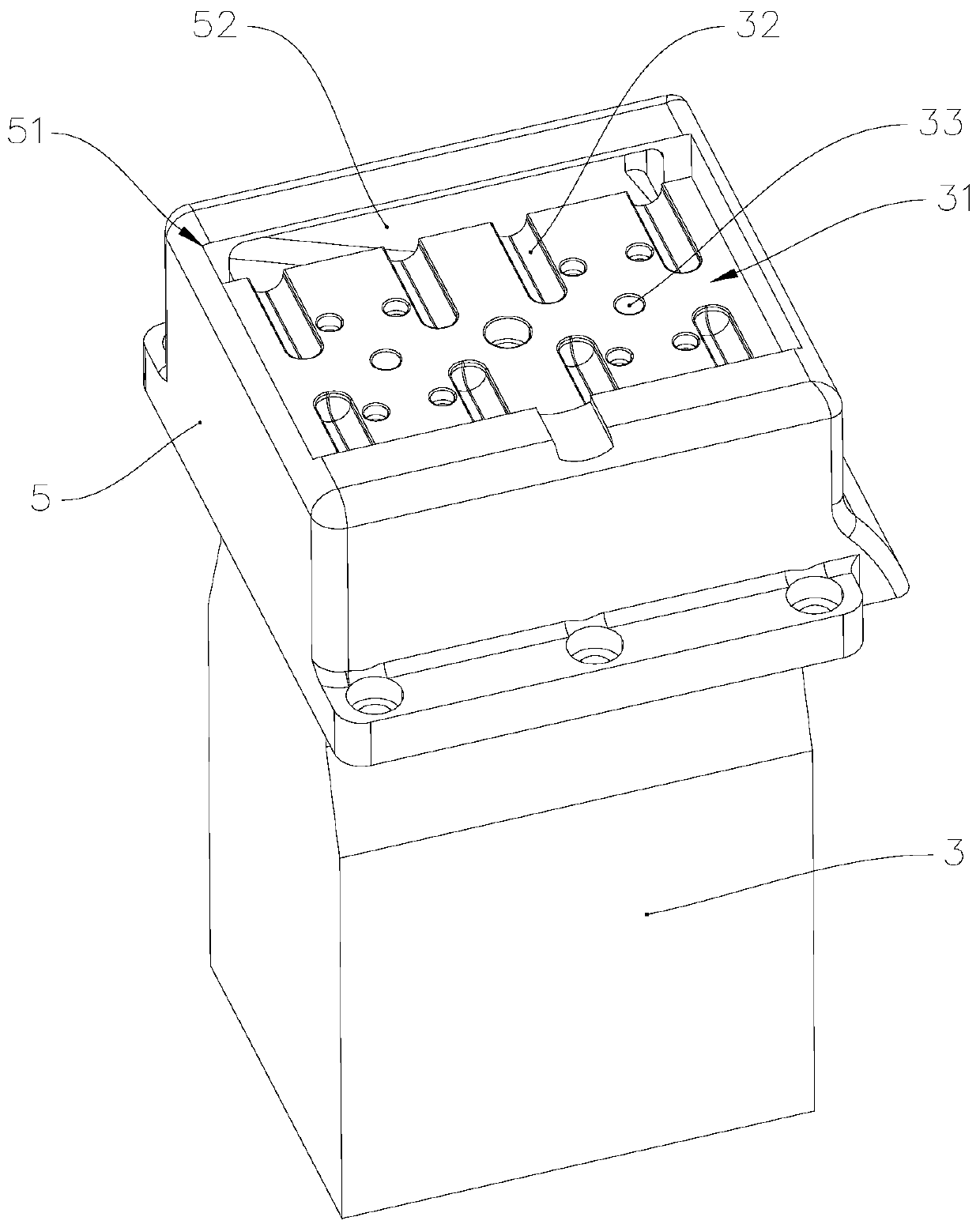

Prebaking aluminum cell anode set structure

The invention discloses a prebaking aluminum cell anode set structure which comprises a mechanical steel claw base plate. A connection portion of a mechanical steel claw and a carbon block is arranged below the mechanical steel claw base plate. A novel anode carbon block is connected to the portion below the connection portion of the mechanical steel claw and the carbon block. An upper carbon block T-shaped connection convex head is arranged on the novel anode carbon block. The two sides of the upper carbon block T-shaped connection convex block are provided with T-shaped connection convex head force-bearing shoulders. The bottom of the upper carbon block T-shaped connection convex head is provided with a lower carbon block T-shaped connection groove used in cooperation with the upper carbon block T-shaped connection convex head. The bottom of the lower carbon block T-shaped connection groove is provided with a T-shaped connection groove hook force-bearing shoulder. An old anode carbon block is connected to the portion below the novel anode carbon block. The prebaking aluminum cell anode set structure has the advantages that no residue anode is generated, the utilization rate of the anode carbon block is improved from 70-80% traditional to 100%, the production cost of electrolytic aluminum can be lowered, the service life of the steel claw is long, the working conditions of the electrolytic cell are stable, electrical losses are low, the novel anode carbon block and the old anode carbon block are rapidly and conveniently connected, heat energy is saved, connection is firm, and the electrical conduction effect is good.

Owner:周俊和 +1

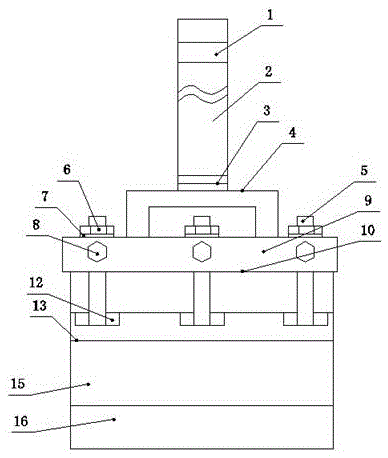

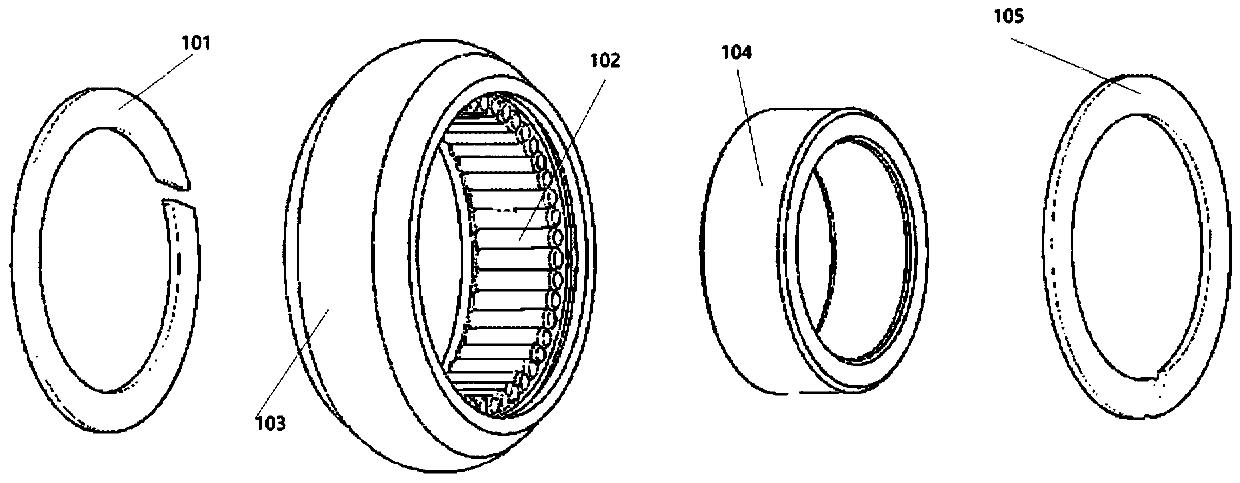

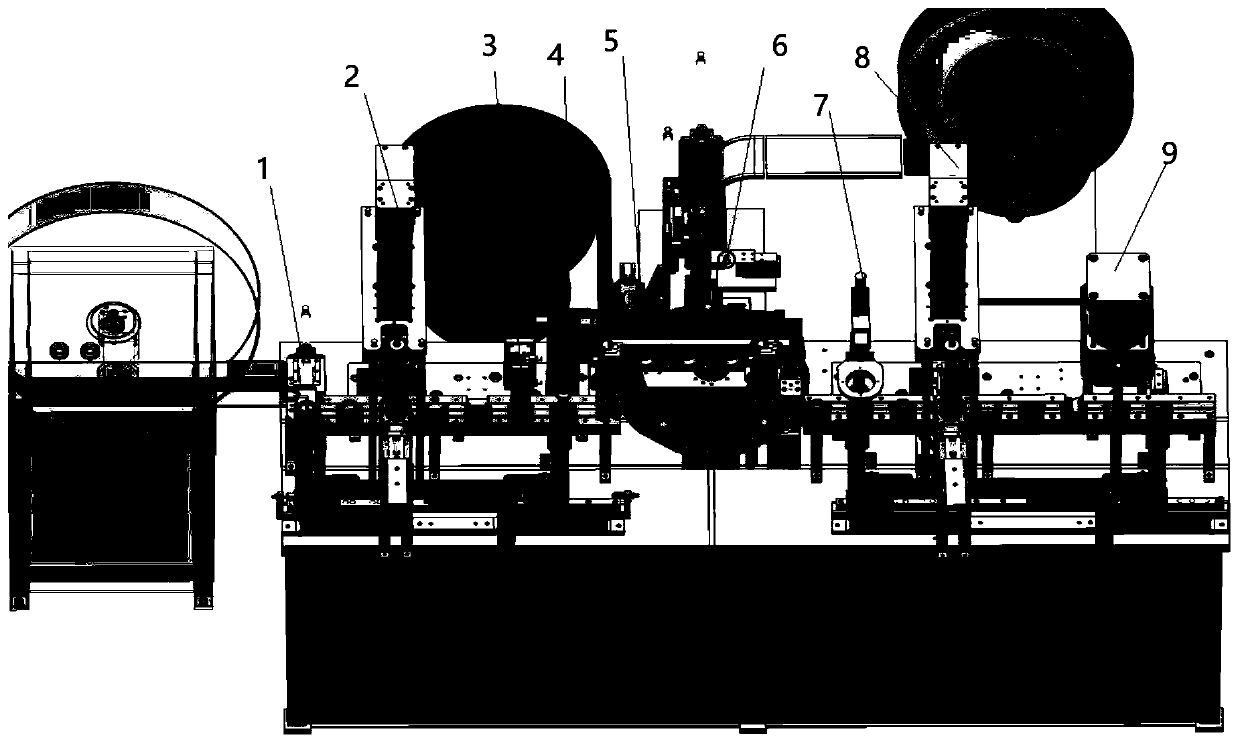

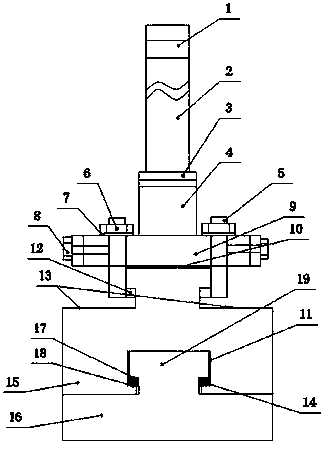

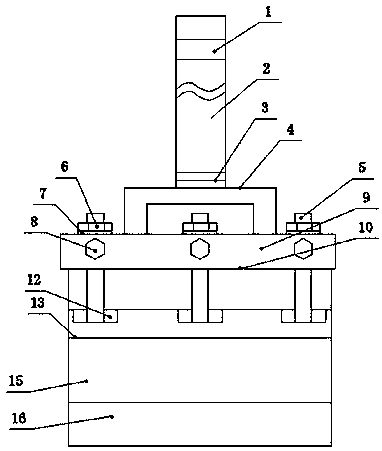

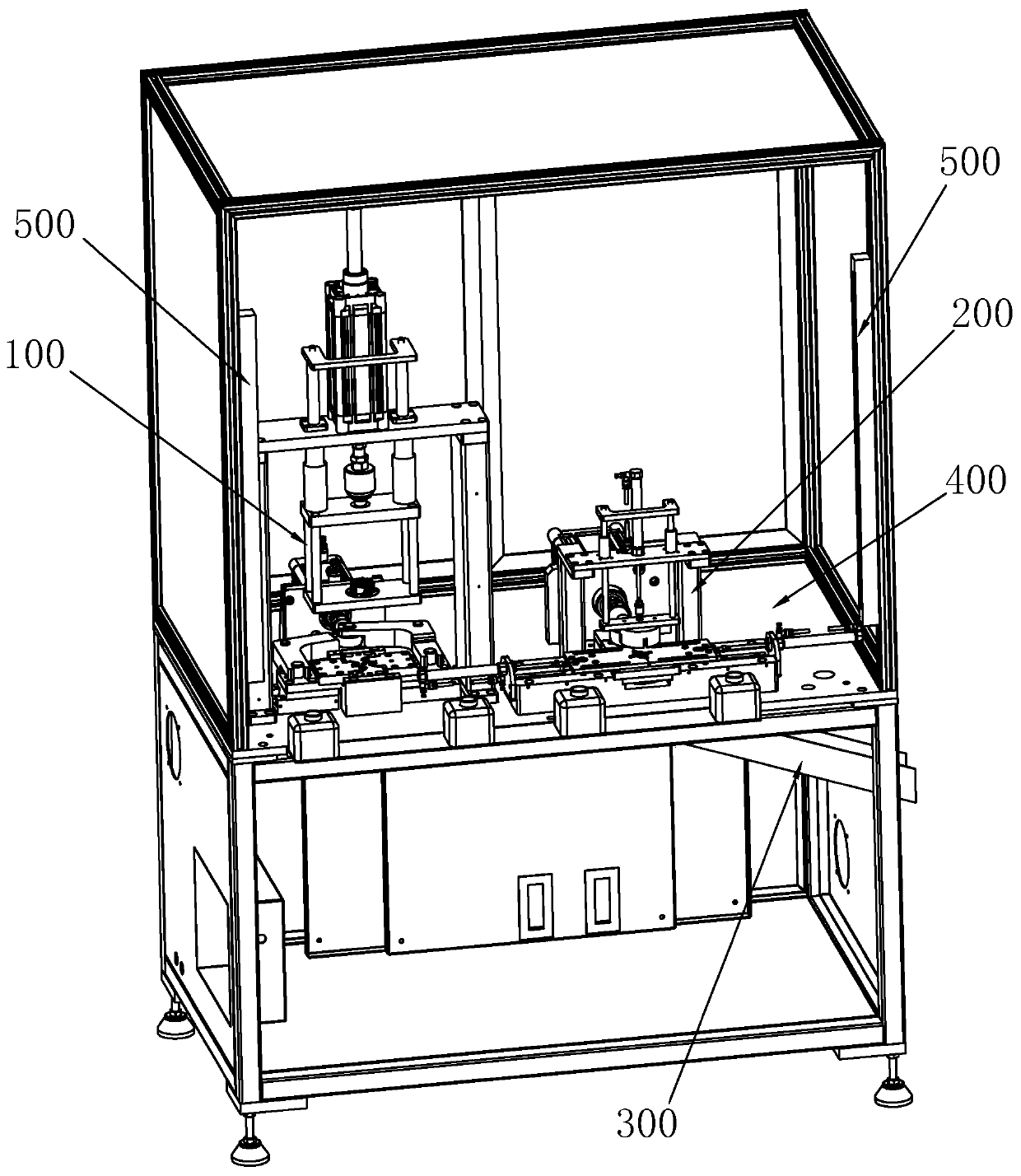

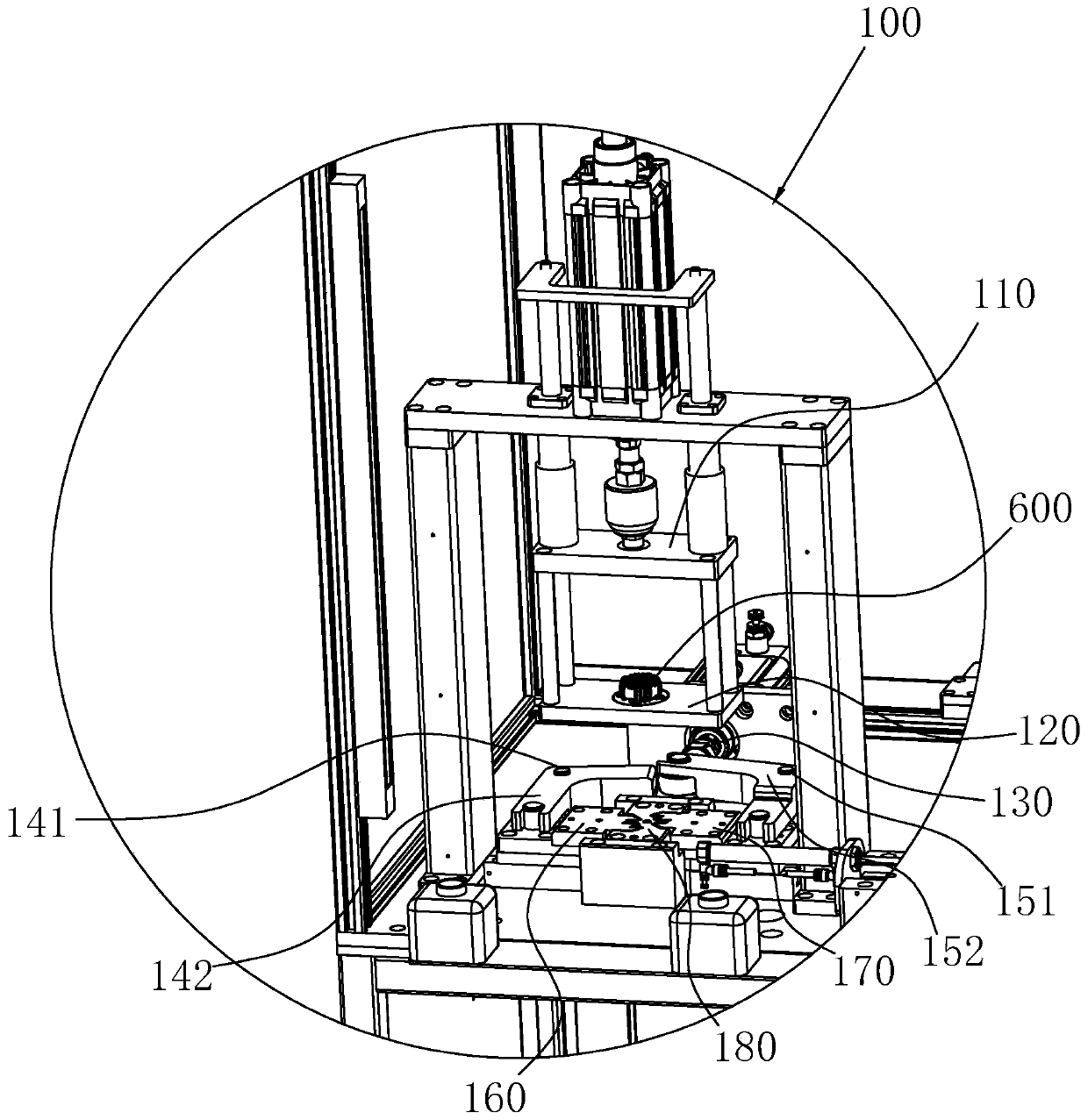

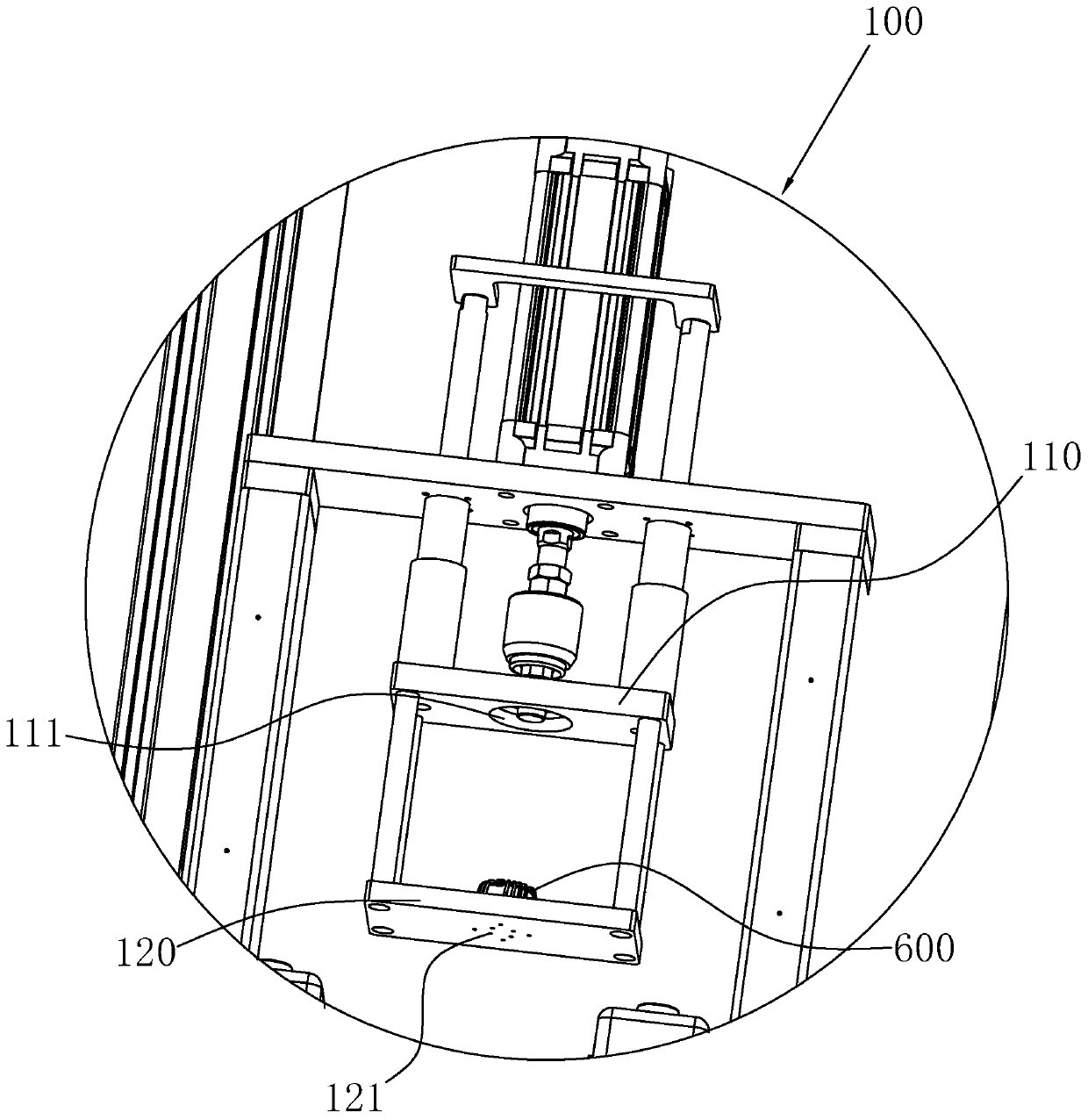

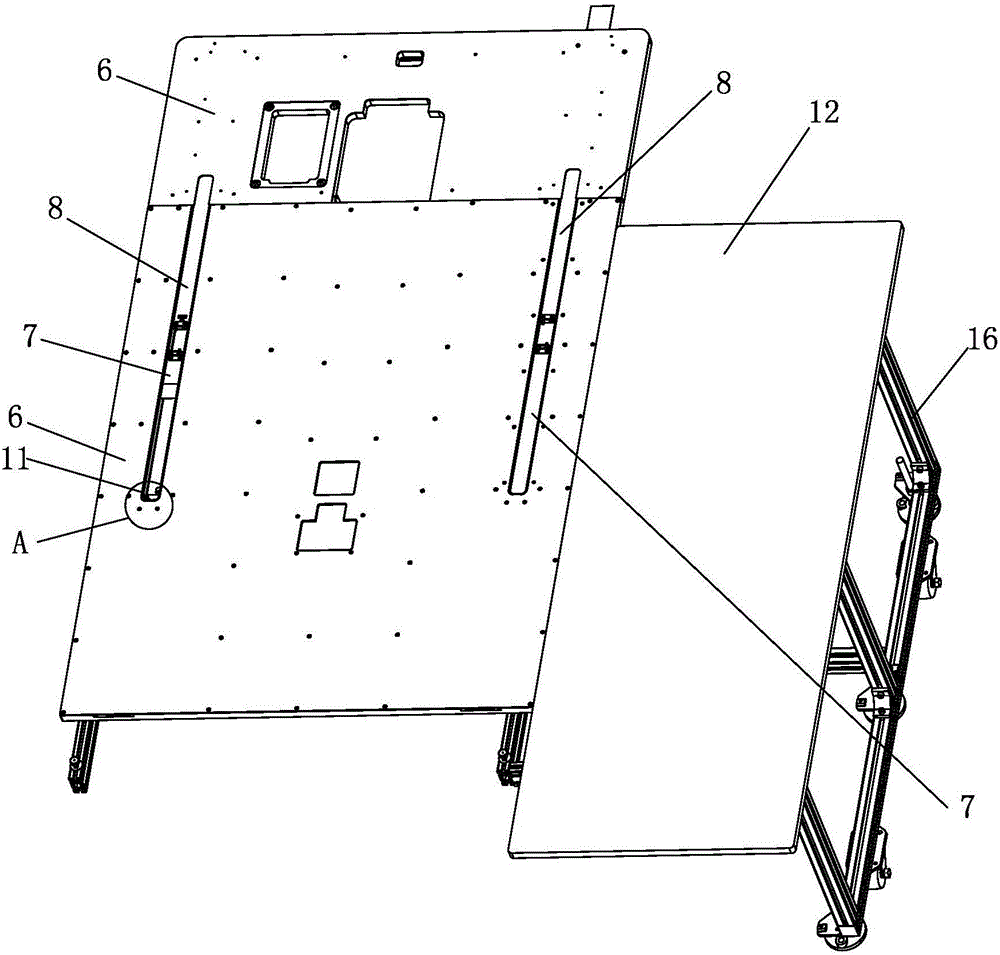

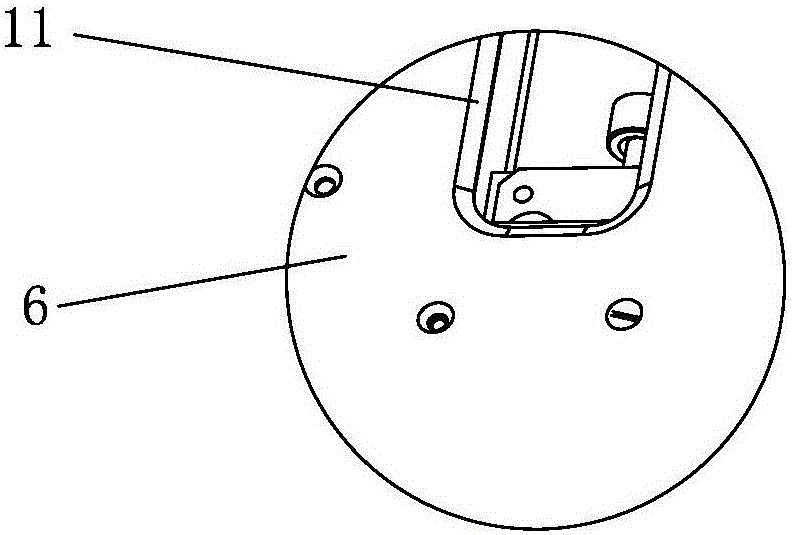

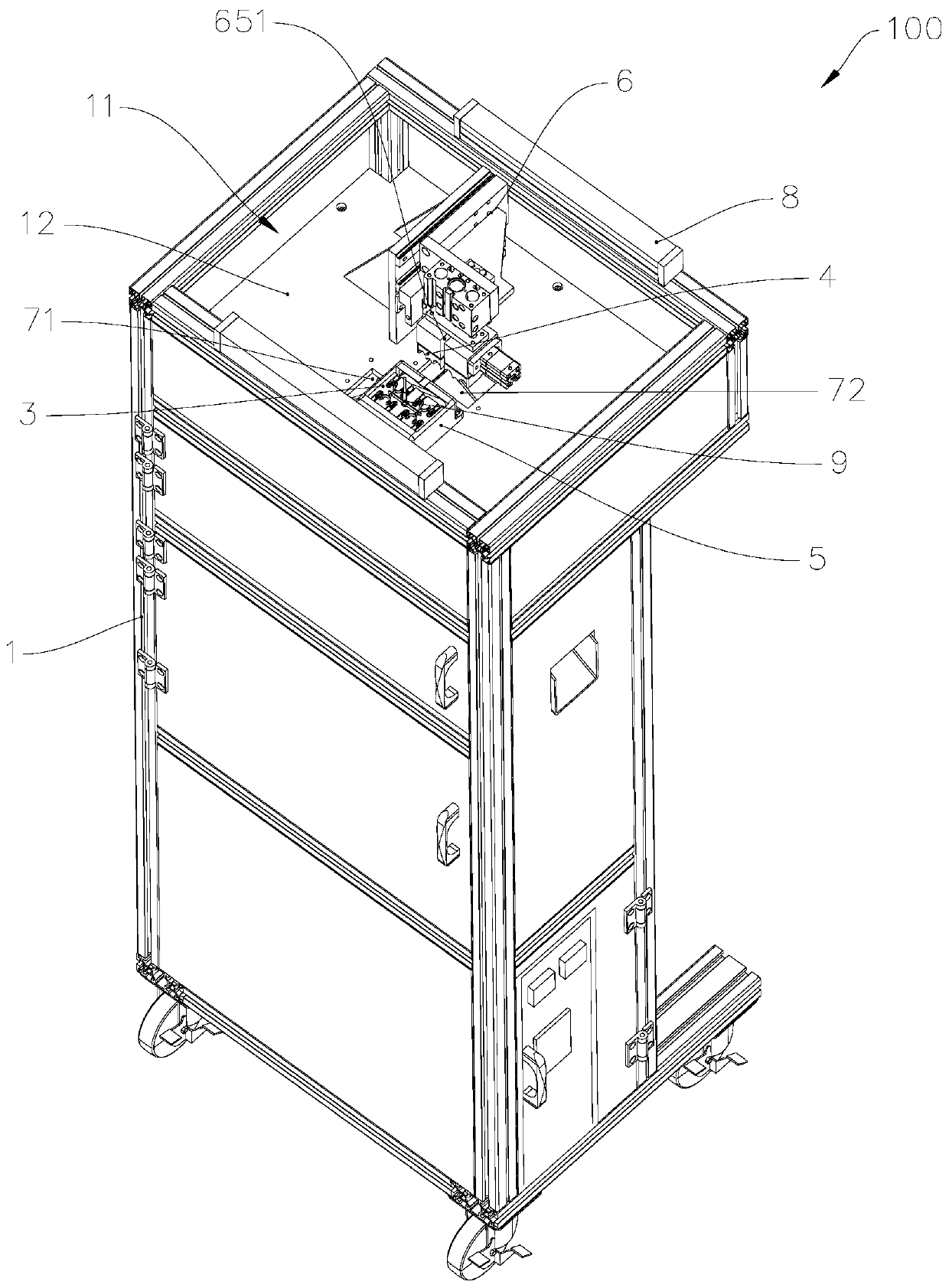

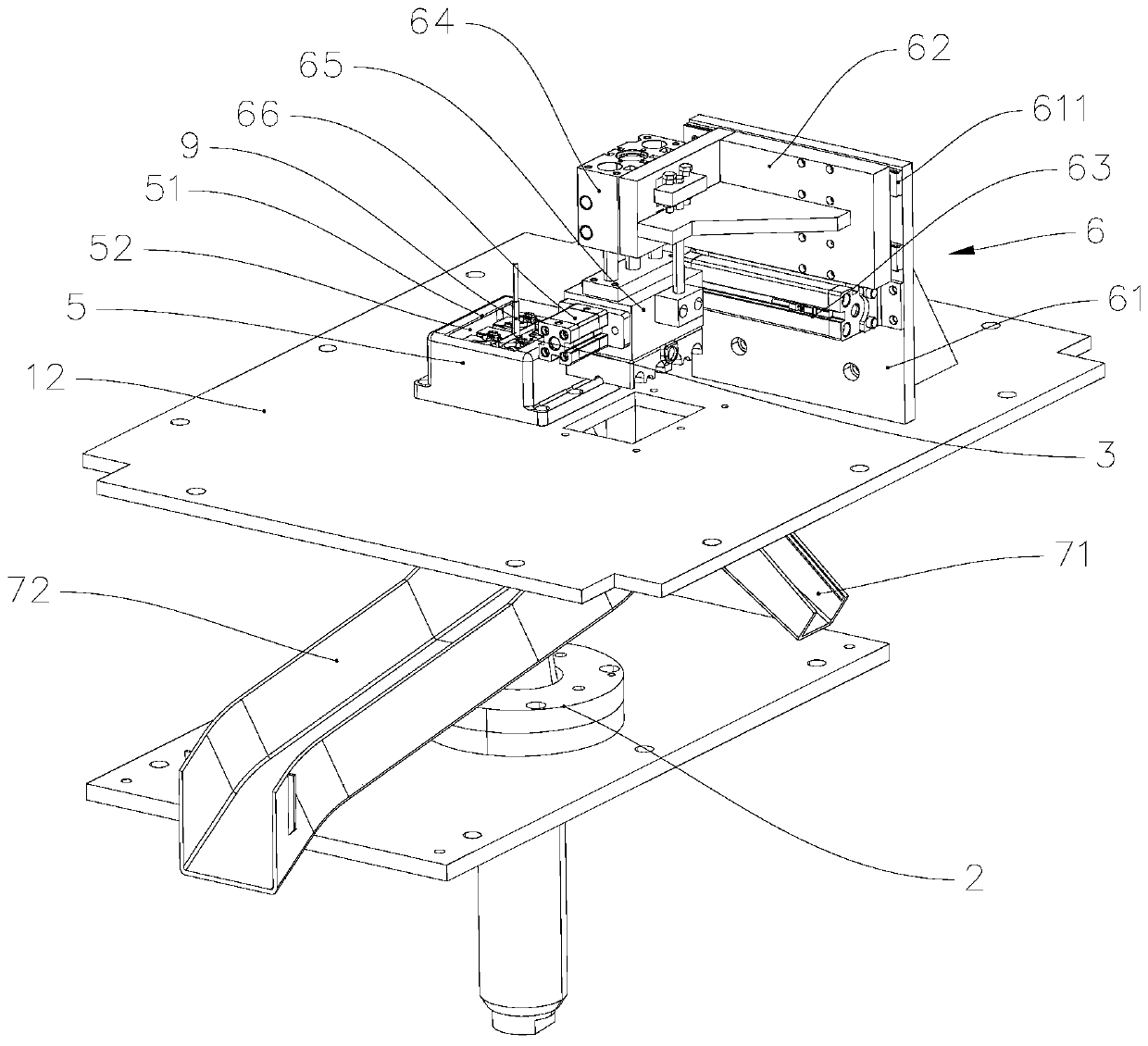

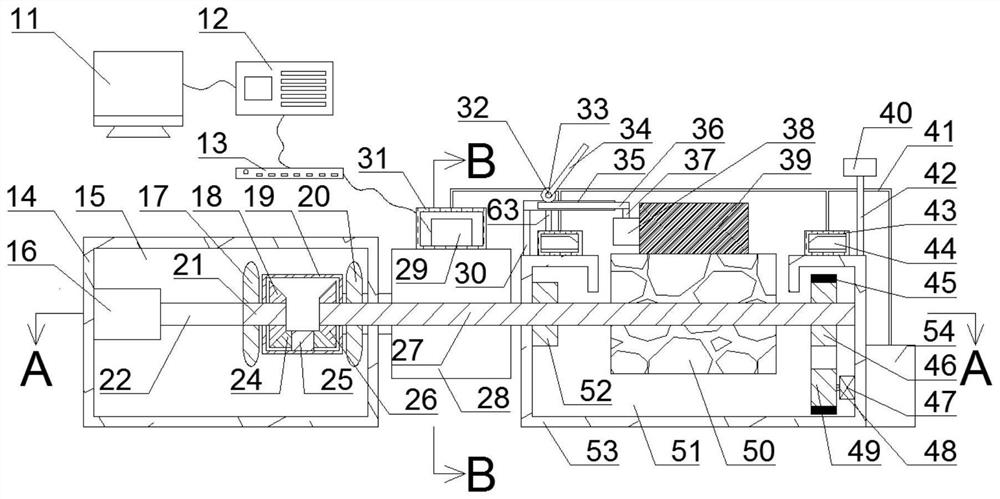

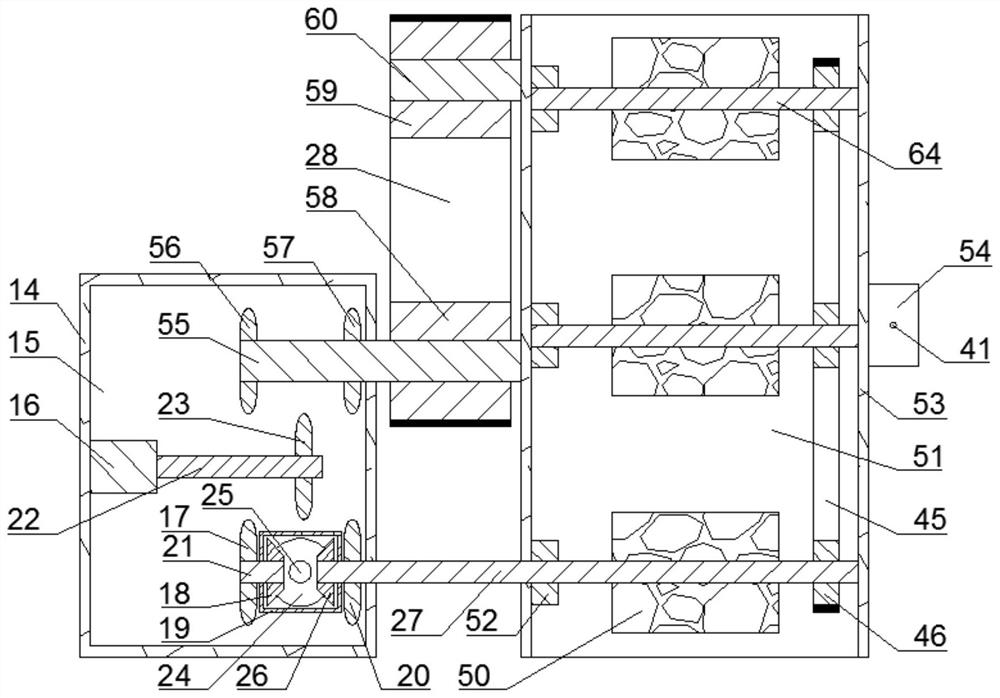

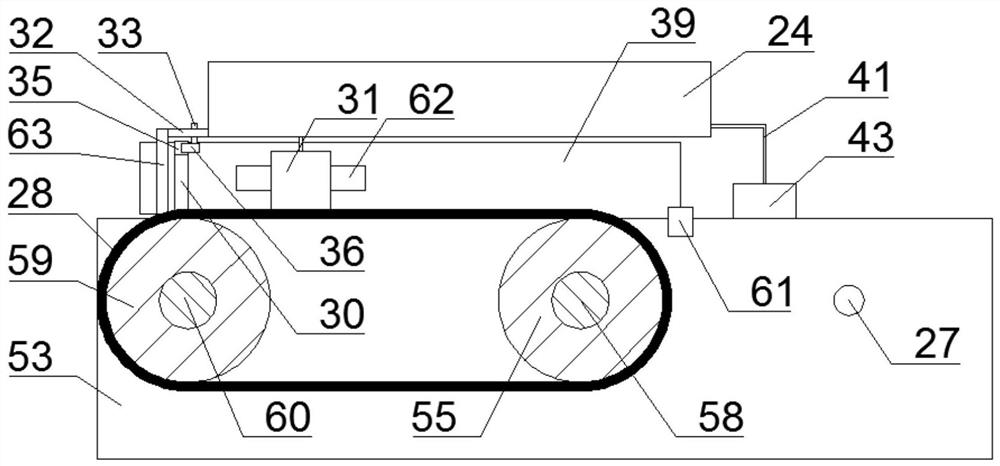

Full-automatic assembling device for outer ring double-flange needle bearing

PendingCN110814736AReduce turnoverReduce labor intensityAssembly machinesBearing componentsNeedle roller bearingLogistics management

The invention discloses a full-automatic assembling device for an outer ring double-flange needle bearing. The full-automatic assembling device mainly comprises an upper outer ring station, a needle pressing check ring station A, a turnover station, a grease smearing station, an inner ring pressing station, a needle mounting station, a needle number detection station, a needle pressing check ringstation B and a secondary needle pressing check ring station which are sequentially arranged end to end. According to the full-automatic assembling device, the original multiple processes, one processand one equipment are coordinated to complete product machining, the mode that one person serves one machine and multiple stations are achieved, an intelligent camera is additionally arranged to detect the product quality, logistics circulation is reduced, the labor intensity is reduced, the reliability is improved, the site and labor cost can be saved, and the assembling efficiency is improved;all parts adopt an automatic feeding mode, so that production safety accidents are avoided; the production procedure of the full-automatic assembling device for the bearing is 10 seconds per piece, and 2268 thousand bearings can be produced per year; and 2520 bearings can be automatically produced per shift by the equipment, and the production efficiency is improved by 500% according to the original process that 500 bearings are mounted per person per shift.

Owner:WANXIANGQIANCHAO CO LTD +1

Regeneration and recycling technology for acid copper chloride etching waste liquid

InactiveCN105441950AAvoid production safety accidentsReduce energy consumptionAcid etchingCopper chloride

The invention discloses a regeneration technology for acid copper chloride etching waste liquid. The regeneration technology includes the steps of carrying out replacement and filtering, washing filter residues, preparing regeneration mixed liquid, and carrying out oxidation to form regeneration etching sub-liquid. According to the regeneration technology, toxic chlorine is not used, ingredients in the acid etching waste liquid can be sufficiently recycled, and a large amount of redundant chemical waste liquid is not generated. The invention further provides a recycling technology for the acid copper chloride etching waste liquid. The recycling technology includes the steps of replacement, filtering, filter residue washing and oxidation recycling. According to the recycling technology, toxic chlorine is not used, and a recycled solution with ferric trichloride as a main ingredient can serve as a wastewater treatment raw material to be recycled; and recycled copper can be directly reused.

Owner:叶涛

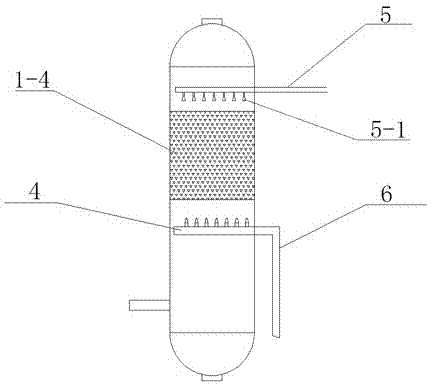

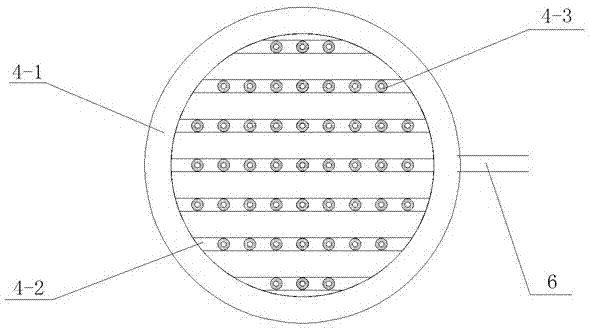

Alkaline liquid absorption tower with filling backwashing device

PendingCN107569994ARealize the problem of clogging the tower bodyIncrease the cross-sectional areaDispersed particle separationInorganic saltsLiquid storage tank

The invention discloses an alkaline liquid absorption tower with a filling backwashing device. The alkaline liquid absorption tower comprises an absorption tower, an alkaline liquid storage tank, a circulating pump and a backwashing circulating system, wherein the absorption tower is internally provided with a filling layer; a tail gas inlet is formed in a side wall of a tower body located below the filling layer; the absorption tower is provided with a tail gas outlet at the top and an alkaline liquid outlet at the bottom; the alkaline liquid storage tank is arranged below the absorption tower and is connected with the alkaline liquid outlet; an outlet formed in the bottom of the alkaline liquid storage tank is connected with an inlet end of the circulating pump; the backwashing circulating system comprises an alkaline liquid inlet pipeline, a backwashing pipeline and a backwashing device. The device disclosed by the invention has the advantages of relatively small investment and simple structure; the problem that inorganic salt in filling is crystallized in the absorption tower can be solved relatively well, the absorption effect of the absorption tower is improved and the pollution, caused by tail gas, on the environment is avoided.

Owner:YUZHOU WEILITE CHEM

A prebaked aluminum electrolytic cell anode group structure

The invention discloses a prebaking aluminum cell anode set structure which comprises a mechanical steel claw base plate. A connection portion of a mechanical steel claw and a carbon block is arranged below the mechanical steel claw base plate. A novel anode carbon block is connected to the portion below the connection portion of the mechanical steel claw and the carbon block. An upper carbon block T-shaped connection convex head is arranged on the novel anode carbon block. The two sides of the upper carbon block T-shaped connection convex block are provided with T-shaped connection convex head force-bearing shoulders. The bottom of the upper carbon block T-shaped connection convex head is provided with a lower carbon block T-shaped connection groove used in cooperation with the upper carbon block T-shaped connection convex head. The bottom of the lower carbon block T-shaped connection groove is provided with a T-shaped connection groove hook force-bearing shoulder. An old anode carbon block is connected to the portion below the novel anode carbon block. The prebaking aluminum cell anode set structure has the advantages that no residue anode is generated, the utilization rate of the anode carbon block is improved from 70-80% traditional to 100%, the production cost of electrolytic aluminum can be lowered, the service life of the steel claw is long, the working conditions of the electrolytic cell are stable, electrical losses are low, the novel anode carbon block and the old anode carbon block are rapidly and conveniently connected, heat energy is saved, connection is firm, and the electrical conduction effect is good.

Owner:周俊和 +1

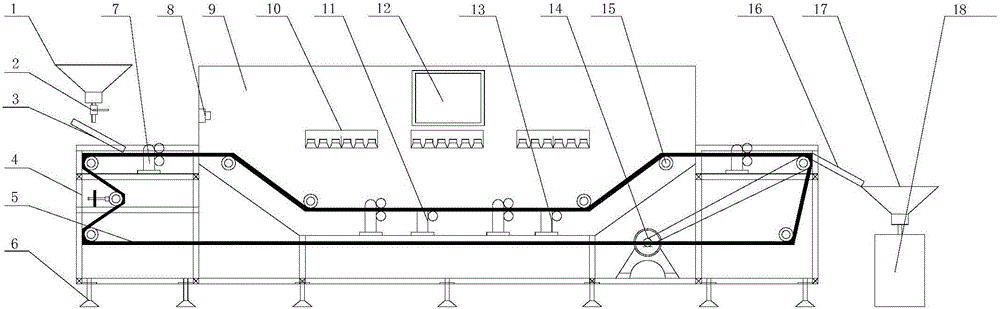

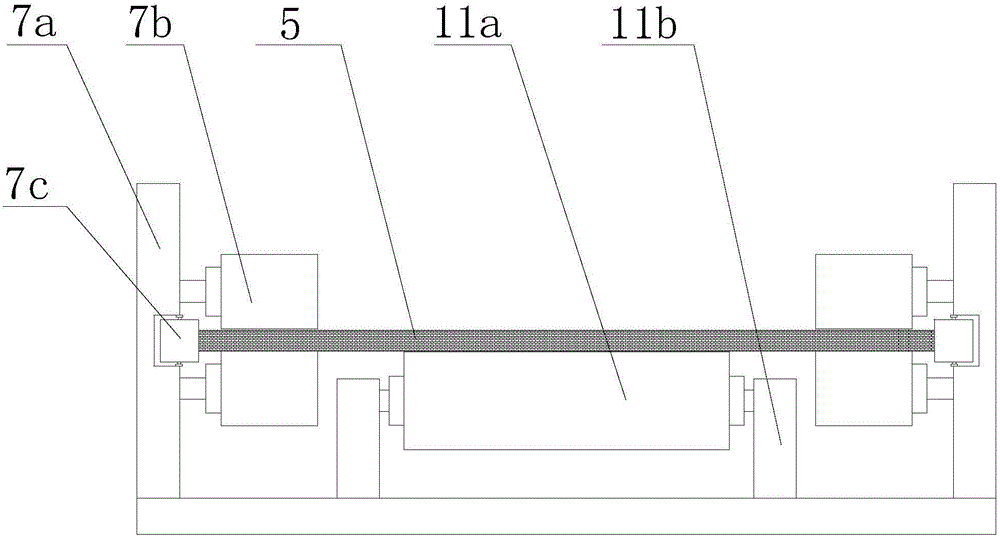

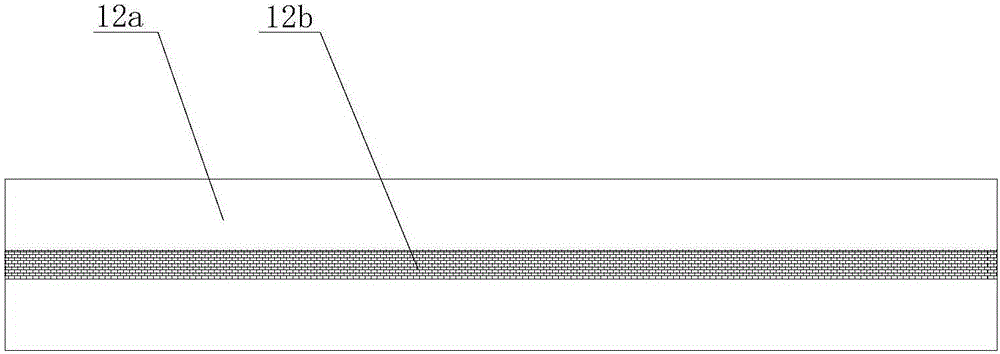

Medicinal material scattering preventing device in traditional Chinese medicinal material microwave drying process

InactiveCN105836466AAvoid failureGuaranteed uptimeConveyorsCharge manipulationMedicinal herbsStructural engineering

The invention relates to a medicinal material scattering preventing device in the traditional Chinese medicinal material microwave drying process. The medicinal material scattering preventing device comprises a rack, a metal box, a conveying belt and roller sets. The metal box is arranged in the middle portion of the rack. The conveying belt is arranged on the rack and penetrates the metal box. The multiple roller sets are arranged in the operation direction of the conveying belt. The medicinal material scattering preventing device further comprises a microwave generator and anti-deflection set racks. The microwave generator is arranged in the metal box. The anti-deflection set racks are arranged on the two sides of the conveying belt. A lug plate frame of the anti-deflection set rack on each side is provided with two anti-deflection wheels, wherein the two anti-deflection wheels are arranged above and below the conveying belt and used for clamping the conveying belt. The lug plate frame on each side is further provided with anti-clamping wheels, wherein the anti-clamping wheels are arranged between the corresponding two anti-deflection wheels, and the axis of each anti-clamping wheel is perpendicular to the axis of the corresponding anti-deflection wheel. An anti-deflection device of a belt conveyor is suitable for being used in a microwave dryer and has the advantages of being stable in running, low in fault rate and long in service life.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE +1

Cloth winding device with automatic winding structure for textile industry

The invention relates to the technical field of cloth winding, in particular to a cloth winding device with an automatic winding structure for the textile industry. The device comprises a winding device body, wherein the winding device body comprises a shell, a control panel is fixedly mounted on the right side wall of the shell, a support is fixedly connected to the front side of the shell, a cloth roller is movably connected to the interior of the shell, a sliding groove is formed in the front side wall of the inner side of the shell, a fixing structure is installed in the winding device body and comprises an outer cylinder, the outer cylinder is fixedly connected to the side wall of the shell, a telescopic rod is movably installed in the outer cylinder, and the top end of the telescopic rod is movably connected with a rotating rod. According to the winding device, a cloth head can be stably fixed to a cloth winding drum, when the cloth winding drum rotates, the cloth head can be automatically wound around the cloth winding drum, the preparation work time is saved, winding is tighter, and the practicability of the device is improved.

Owner:御金(广东)机械科技有限公司

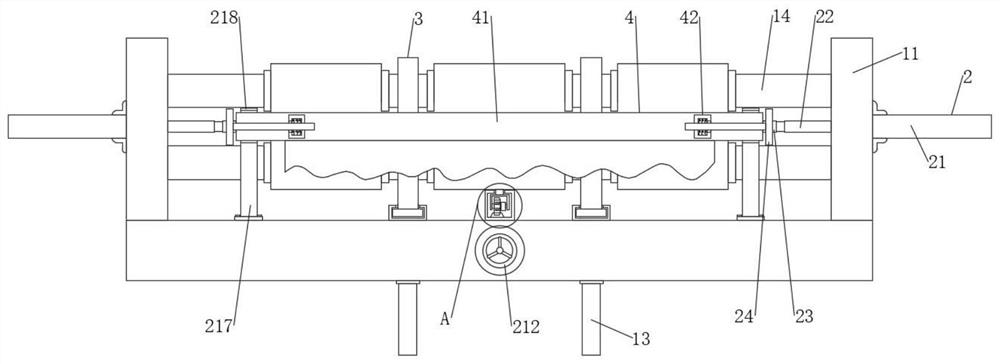

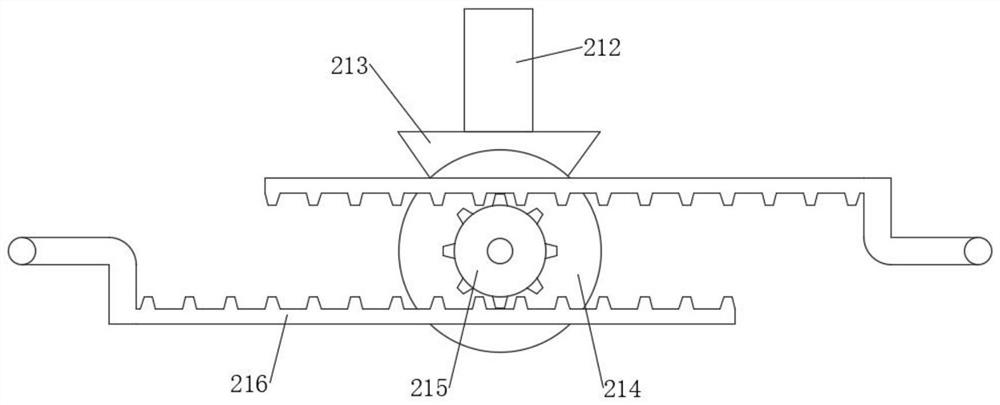

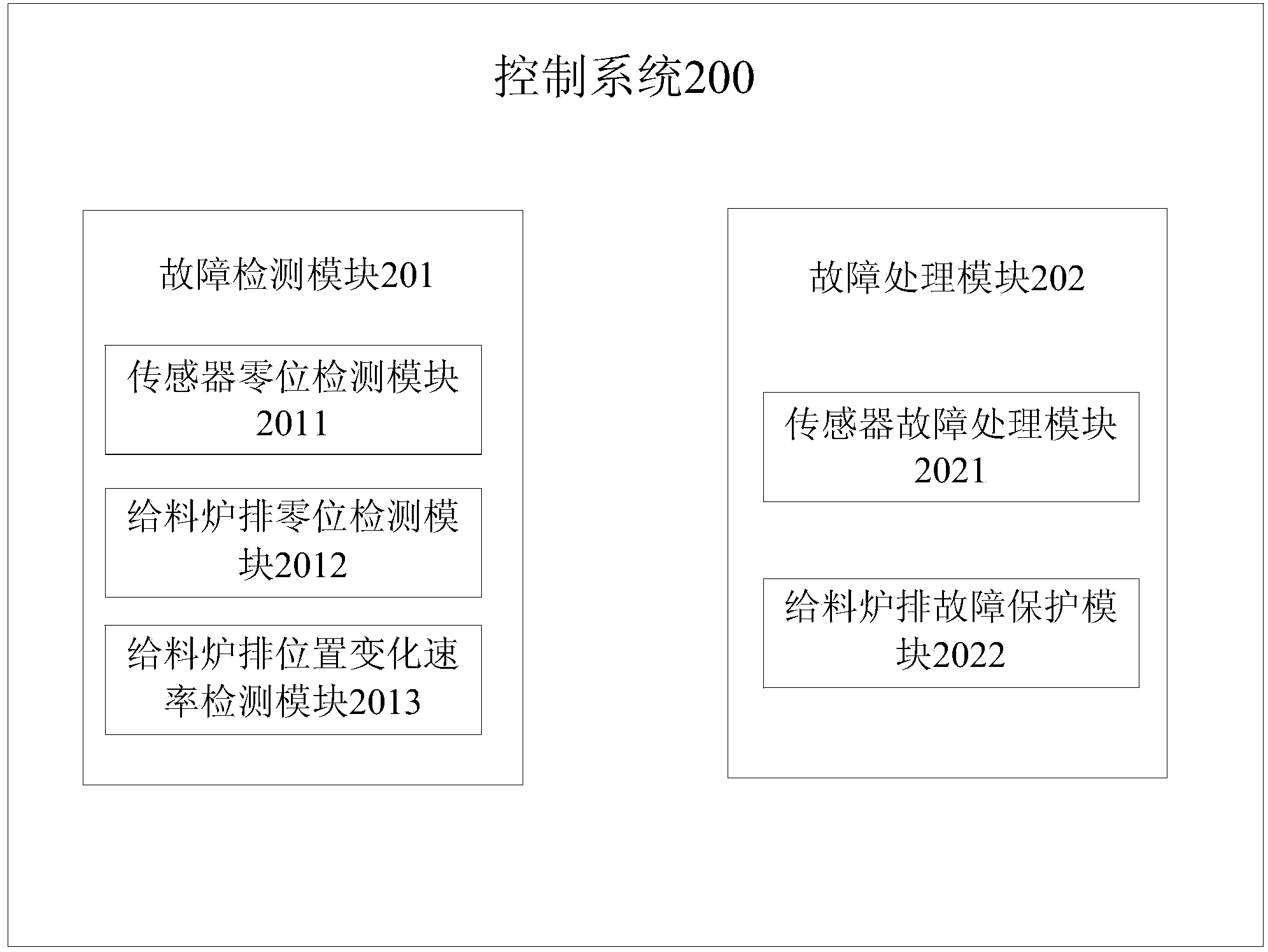

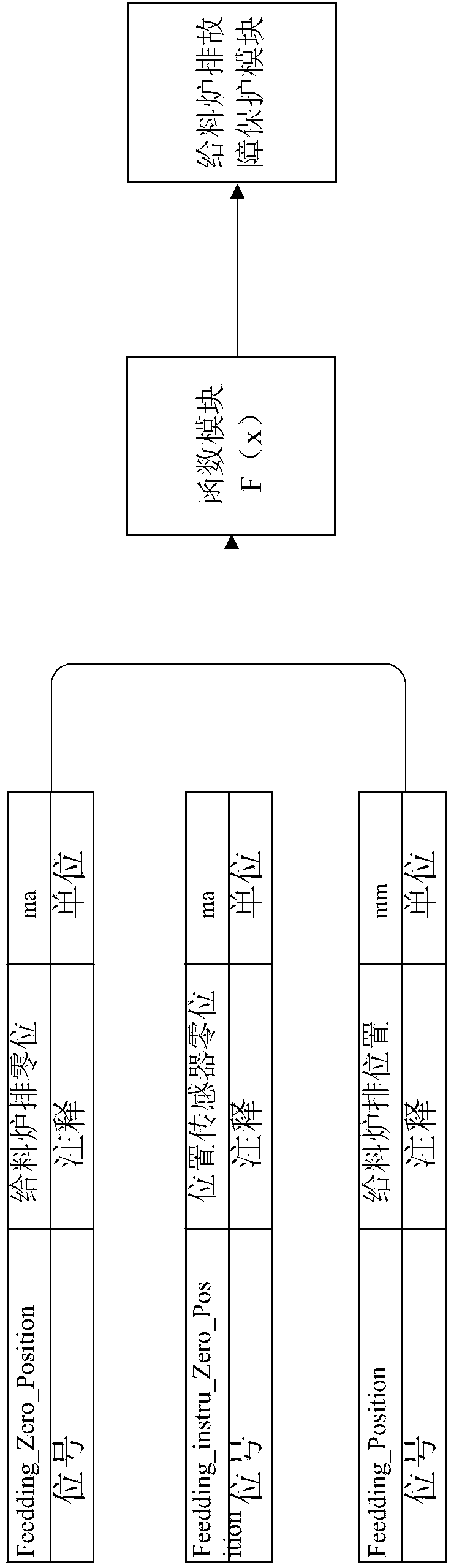

Control system and method for feeding protection of feeding grate

InactiveCN104110686AAvoid production safety accidentsGuaranteed uptimeIncinerator apparatusStopped workControl system

The invention provides a control system and method for feeding protection of a feeding grate. The control system comprises a fault detecting module and a fault handling module, wherein the fault detecting module is used for detecting faults of a sensor of the feeding grate; the fault handling module is used for controlling the feeding grate on the basis of the detected faults, so that the feeding grate stops working. By the adoption of the control system and method, production safety accidents caused by error running of the feeding grate in a rubbish incinerator can be avoided successfully, normal proceeding of production is guaranteed, and good economic benefits are generated.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION CHINA +2

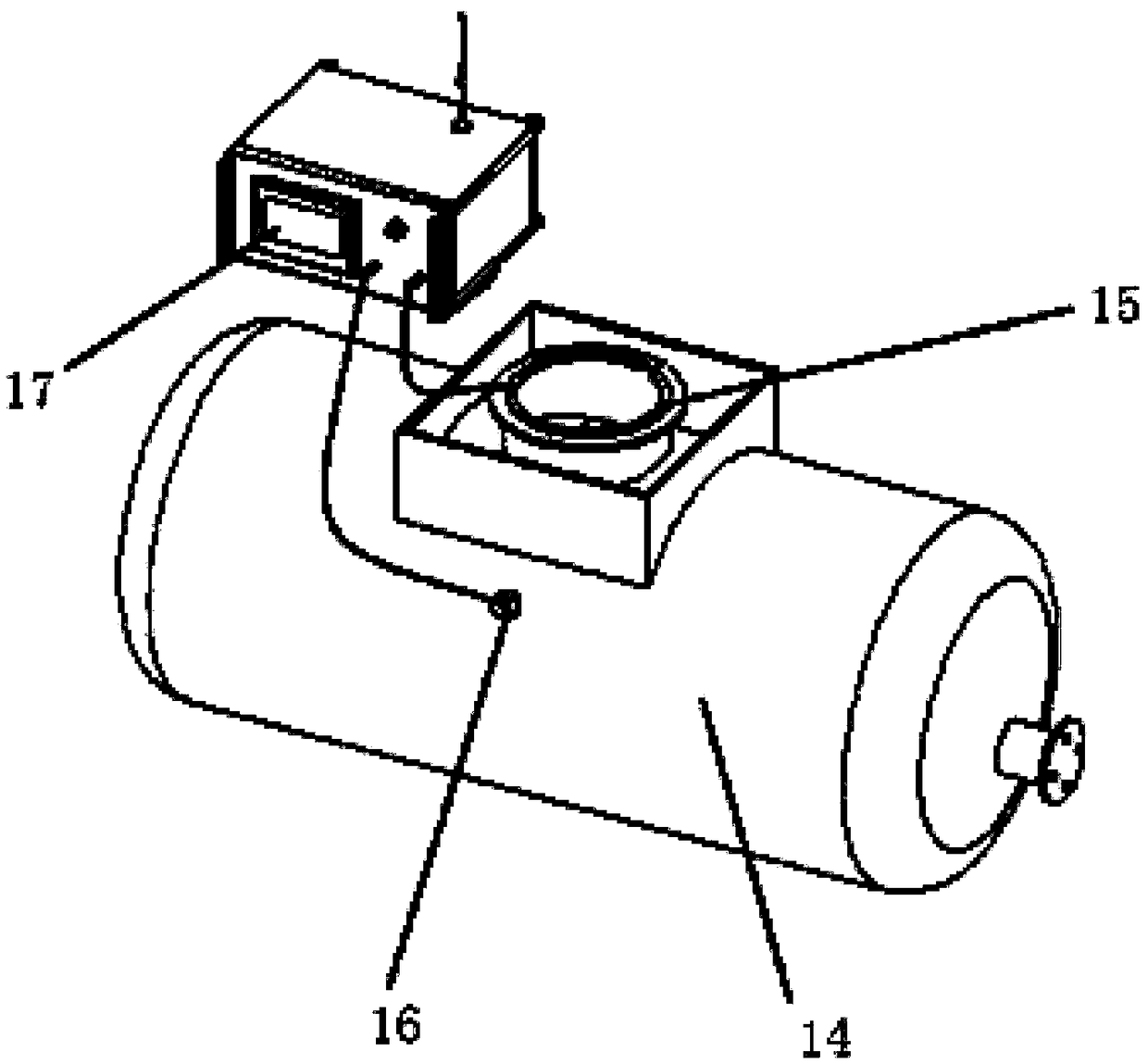

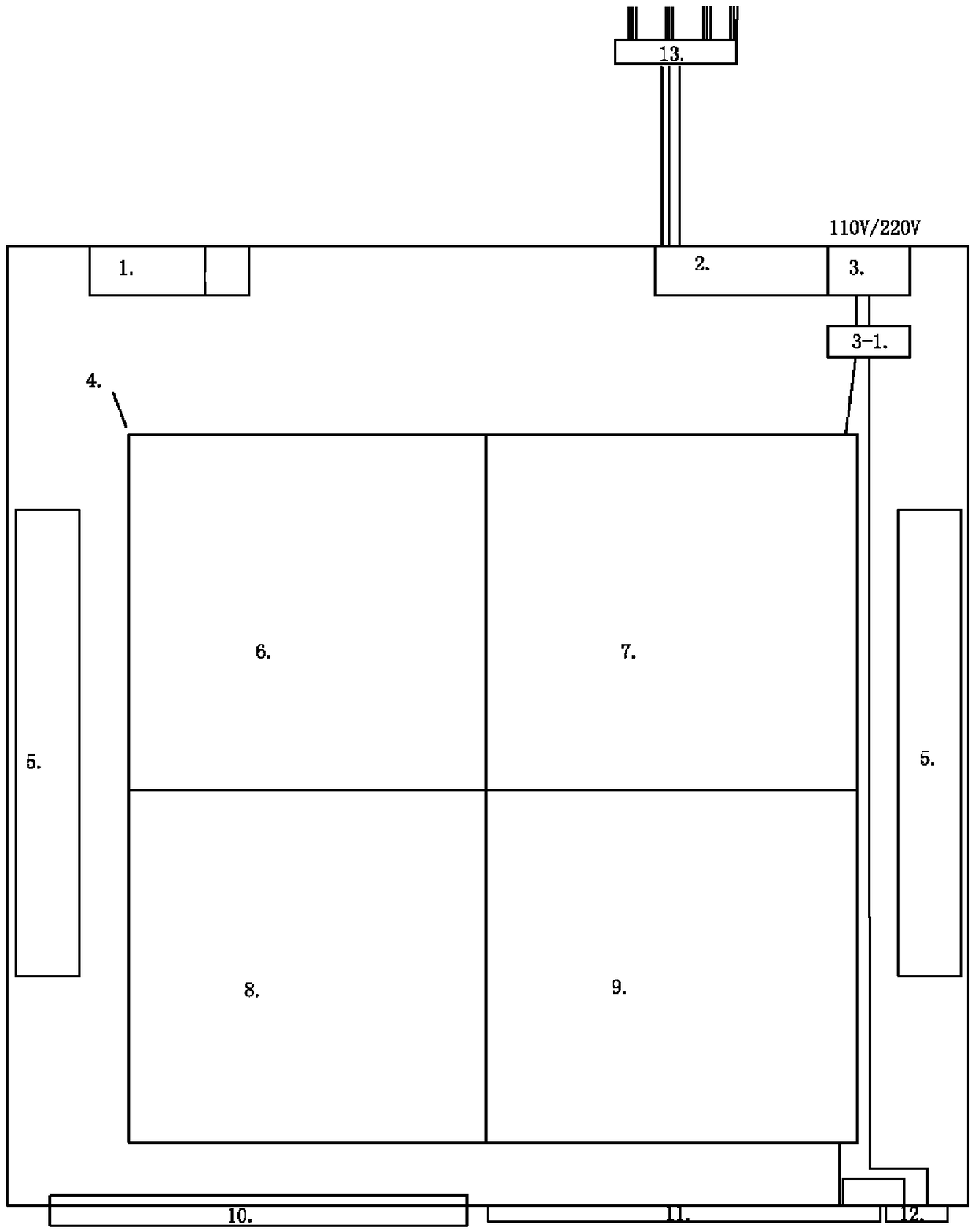

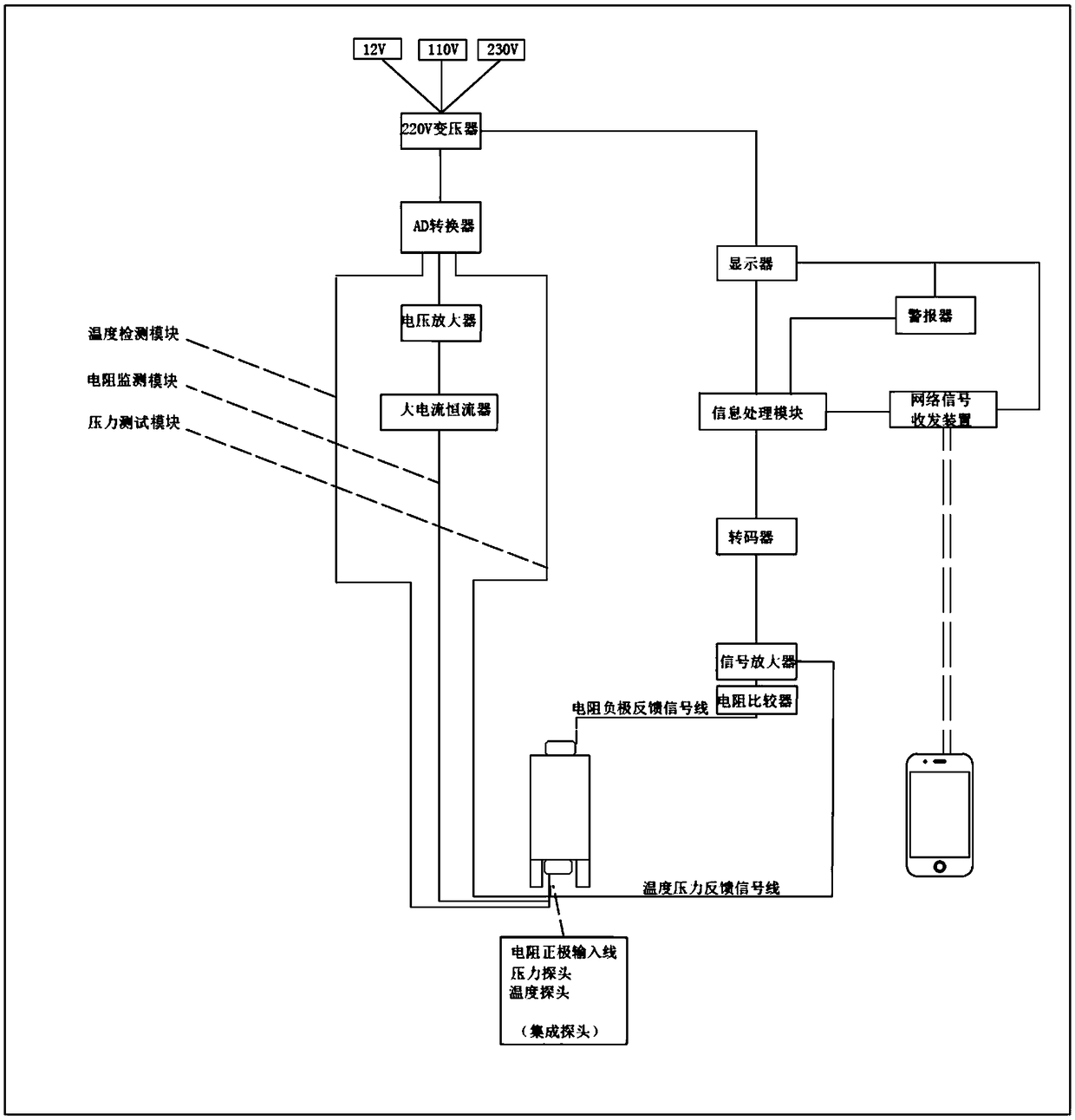

Online resistance temperature and pressure monitoring early-warning instrument

PendingCN108761206AShort response timeLow equipment loss and repair costsResistance/reactance/impedenceTransceiverData lines

The invention discloses an online resistance temperature and pressure monitoring early-warning instrument. The online resistance temperature and pressure monitoring early-warning instrument comprisesa box body; a signal transceiver device, a data line socket, a power module, a display module, a button module and a key module are arranged on the box body; a main board is arranged inside the box body; and the main board includes a resistance monitoring module, a temperature monitoring module, a pressure monitoring module, and an information processing module. The invention integrates the monitoring and early-warning device for a storage tank through the organic combination of hardware and software, combines with the instant messaging device such as the mobile phone to realize real-time online monitoring of a storage tank system, and can immediately issue an alarm before the storage tank is about to leak;, the problem can be fed back to the relevant personnel's mobile phone in the firsttime through the built-in communication software, thus minimizing the response time and minimizing the equipment loss and the maintenance cost. The invention can improve the safety and reliability ofthe storage tank, can effectively avoid the leakage of the storage tank and the like, and prevent the occurrence of production safety accidents.

Owner:江苏瑞能防腐设备有限公司

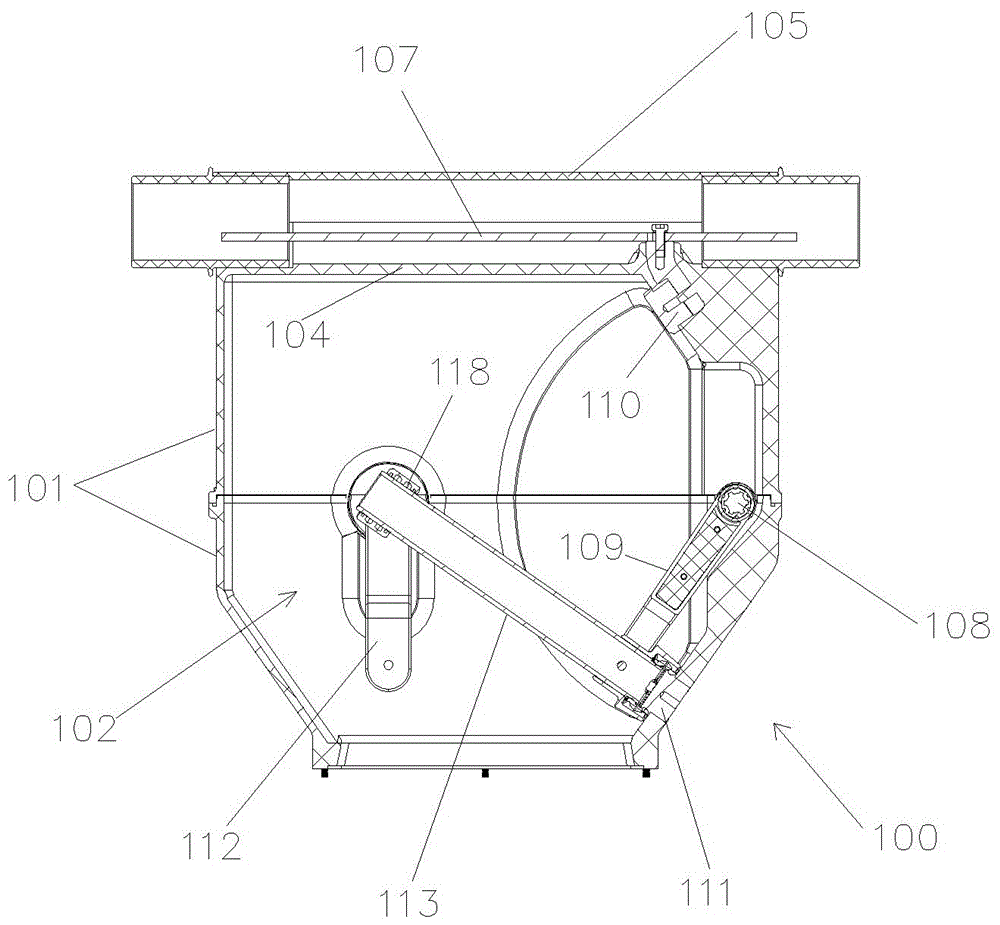

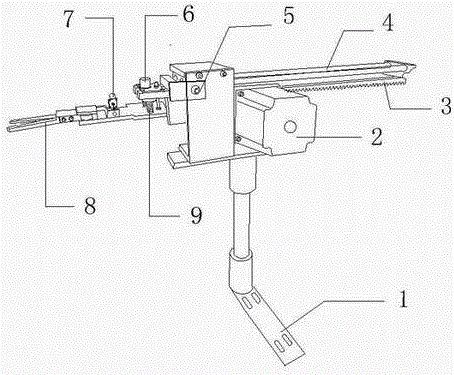

Coil reshaping and pin shearing machine

PendingCN109926526AEasy to put inImprove consistencyManufacturing dynamo-electric machinesEngineeringWaste material

The invention discloses a coil reshaping and pin shearing machine. A reshaping mechanism, a pin shearing mechanism and a waste material groove are included; the reshaping mechanism comprises a clamp assembly used for clamping pins of a coil, and a reshaping assembly arranged above the clamp assembly liftably; the reshaping assembly comprises a lower positioning plate and an upper positioning plateused for jointly clamping the coil; the upper positioning plate is provided with a first groove matched with the coil in shape; the lower positioning plate is provided with first passing holes for the pins of the coil to pass through; the pin shearing mechanism comprises a first positioning assembly and a scissor assembly; the first positioning assembly comprises a supporting plate and a pressingplate arranged above the supporting plate liftably; the supporting plate is provided with second passing holes for the pins of the coil to pass through; the scissor assembly is arranged below the second passing holes; and the waste material groove is arranged below the scissor assembly. The consistency of the product shape after coil reshaping and pin shearing is improved, the production efficiency is further improved, and production safety accidents are avoided.

Owner:ZHUHAI ANZHUO ROBOT AUTOMATION CO LTD

Three position isolating switch

ActiveCN104934256BTo achieve the requirement of full insulationAvoid production safety accidentsAir-break switch detailsOperation safetyElectrical and Electronics engineering

The invention discloses a three-position switch. The three-position switch comprises an insulating box, a three-position regulating mechanism and a three-position operating mechanism, wherein the three-position regulating mechanism is arranged in the insulating box; the three-position regulating mechanism is controlled by the three-position operating mechanism and capable of switching among a switching-on position, an isolating position and a grounding position; a bus fixing structure for fixing a bus is arranged on the top of the insulating box; the bus fixing structure comprises a bus slot with two open end parts and an insulating cover; the bus slot is formed in the top of the insulating box; the insulating cover is arranged above the bus slot and used for sealing the bus slot; and a bus which is connected with the three-position regulating mechanism is arranged between the bus slot and the insulating cover. According to the three-position switch, the three-position isolating switch and the bus are connected together, and the bus is arranged between the bus slot and the insulating cover, so that the but is not required to expose outsides, thereby realizing full-insulation requirements, being capable of being used in various occasions, preventing a production safety accident in operation, and guaranteeing operation safety.

Owner:SUCTRN TECH

Control method and device suitable for foamed slag furnace condition in iron bath smelting reduction

The invention provides a control method and device suitable for the foamed slag furnace condition in iron bath smelting reduction. The method includes the following steps that firstly, according to the changes of the secondary combustion rate of coal gas, the calorific value of coal gas, the semi-coke content of smoke, the thermal load of a water cooled wall, the carbon content of molten iron, thecarbon powder content of slag, the slag density and the slag component index in iron bath smelting reduction production, whether foamed slag is generated or not is judged; secondly, if the foamed slag is generated, on the basis of existing production parameters, by increasing the ratio of the coal injection amount to the ore injection amount, the quaternary alkalinity of the slag is controlled to0.7-1.10, and the normal production of the furnace condition is recovered; and if the foamed slag is not generated, the production continues according to the existing production parameters. By meansof the method, accurate judgment of the foamed slag is achieved, rapid recovery of the normal production is achieved by controlling the production parameters, and the production efficiency is improved. By means of the method, the judgment basis and the recovery method of the the foamed slag furnace condition in iron bath smelting reduction are quantified, and the current blank of the production technology in the field is filled.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

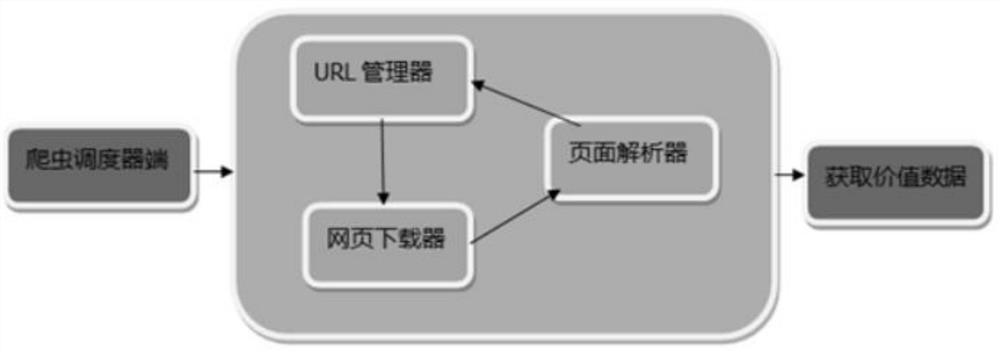

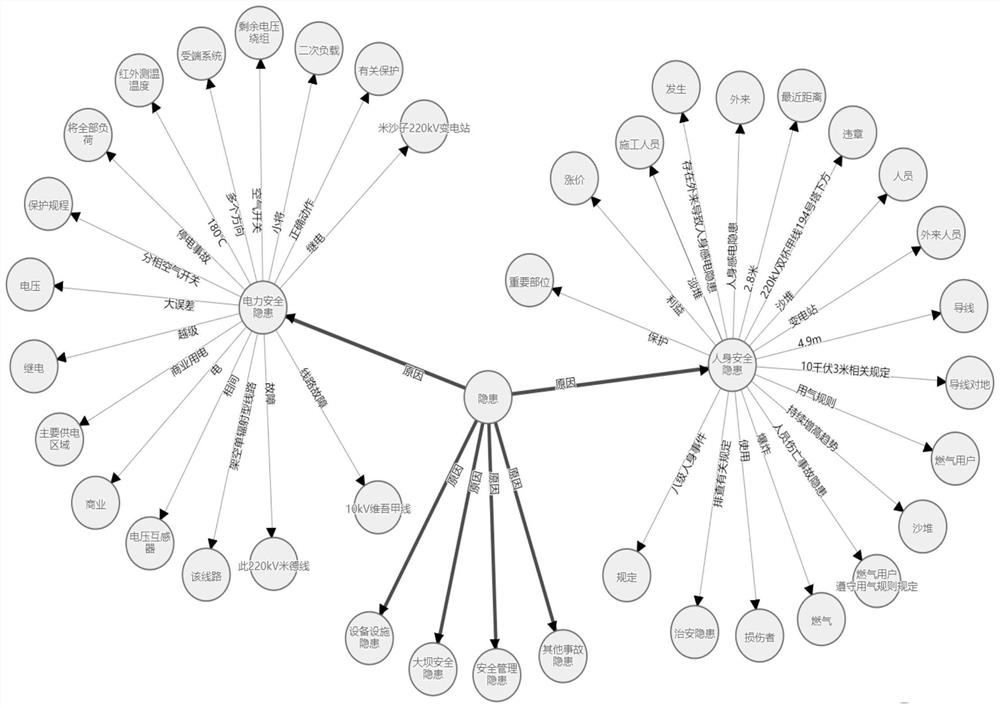

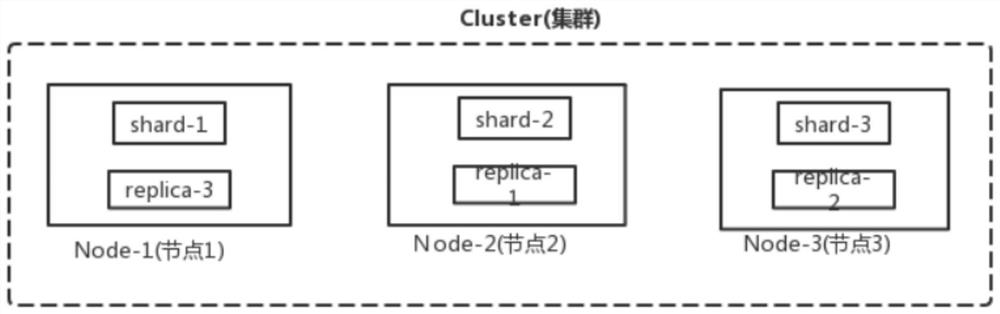

Electric power safety production hidden danger pre-control method based on knowledge graph

PendingCN114328819AEasy to analyzeAccurate analysisWeb data indexingNatural language data processingSafety knowledgeEngineering

An electric power safety production hidden danger pre-control method based on a knowledge graph comprises the steps that a related electric power production safety hidden danger knowledge sample set is extracted through a natural language preprocessing technology, and information is preprocessed through a feature extraction algorithm; constructing a power production safety knowledge model based on the knowledge graph; the generated accident potential safety hazard and safety information record relation knowledge base is stored in an Elasticsearch database; and training the continuously input processed power production safety information candidate set through a deep learning technology, obtaining a knowledge reasoning network chain by using a trained model, putting the obtained training result set into a power production safety record knowledge base for matching one by one, and performing knowledge reasoning analysis to obtain an analysis result. According to the invention, the efficiency of potential safety hazard information management can be improved, pre-control and prevention of potential hazard events are realized, personal safety in the production operation process is ensured, and production safety accidents are avoided.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

Hoisting and transporting device for aluminum plate coil

ActiveCN110835046AAvoid production safety accidentsLoad-engaging elementsClassical mechanicsStructural engineering

Owner:安徽坤源铝业有限公司

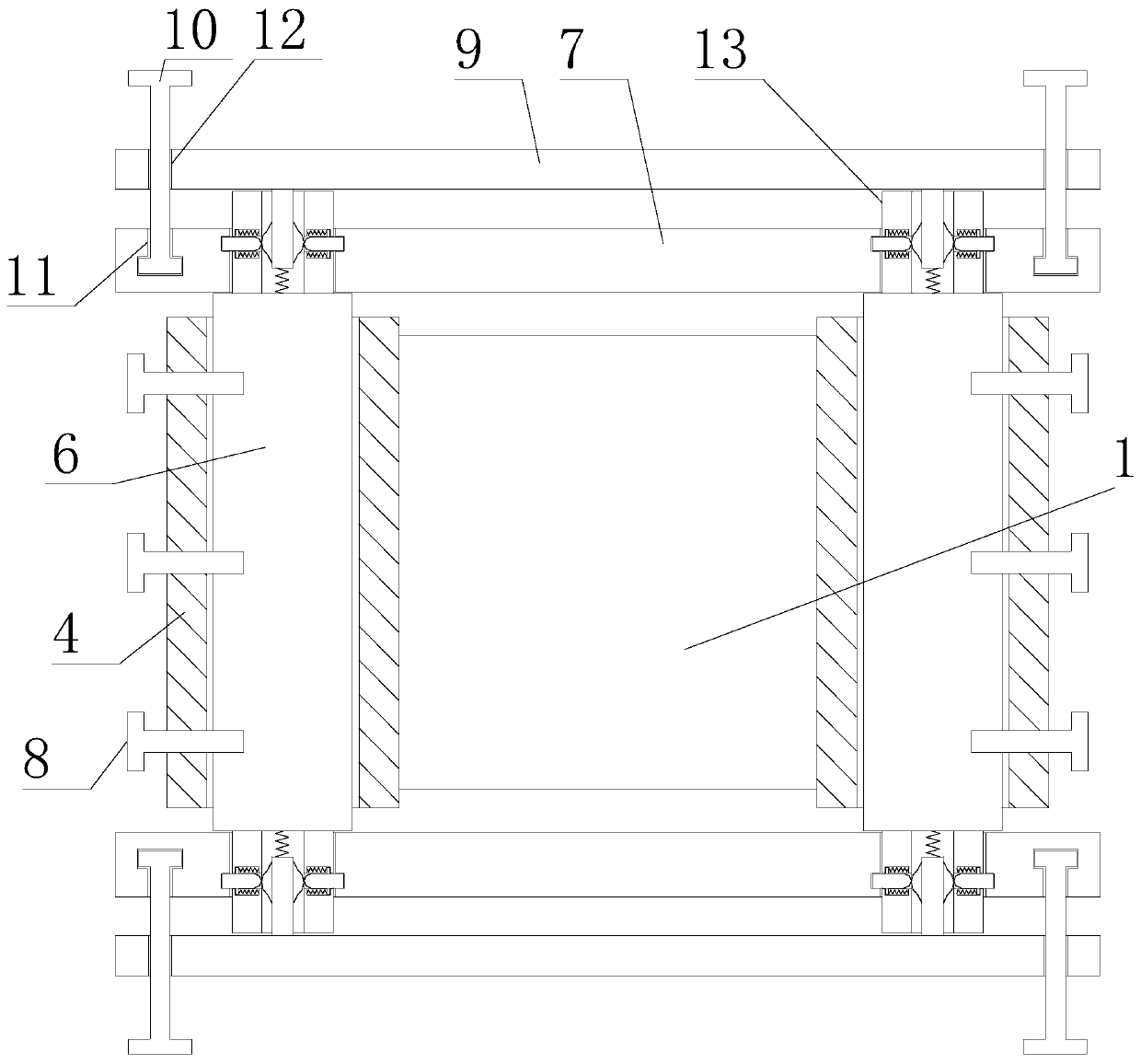

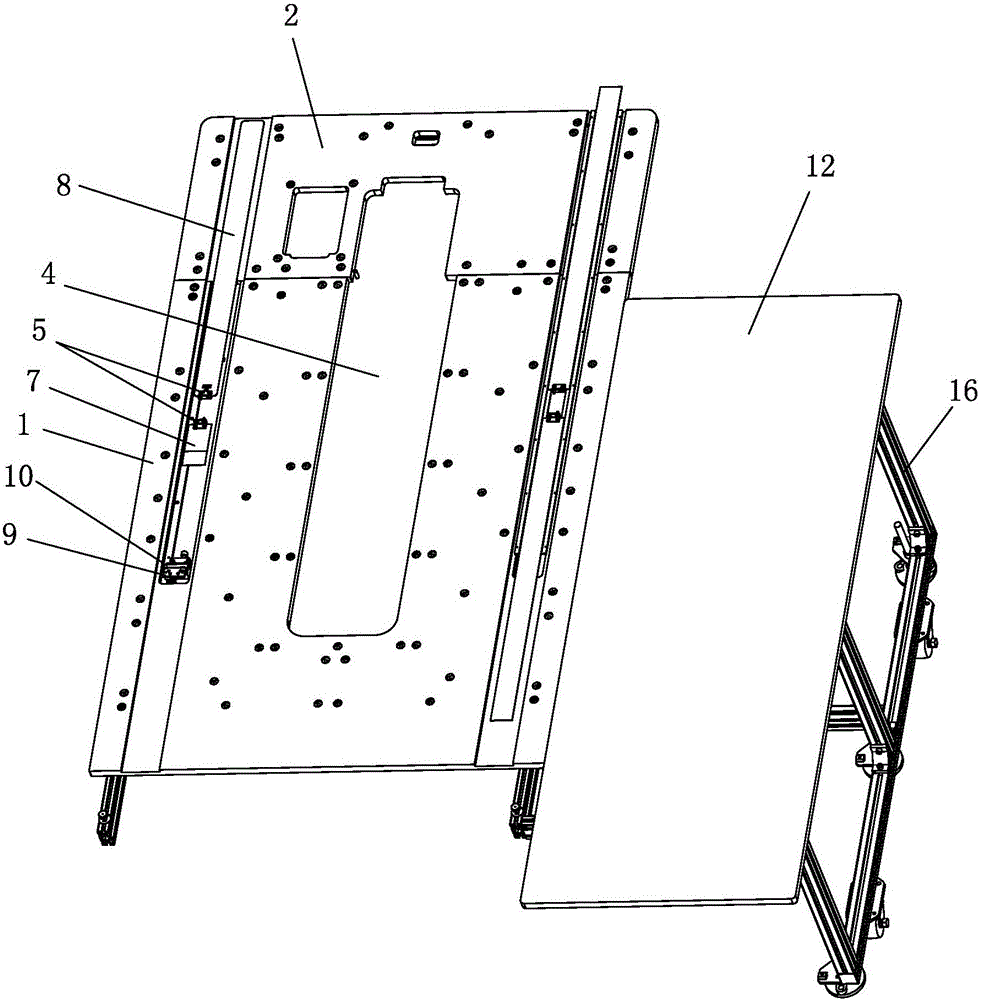

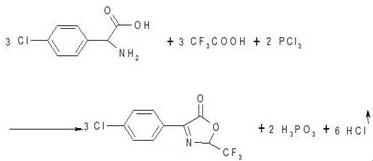

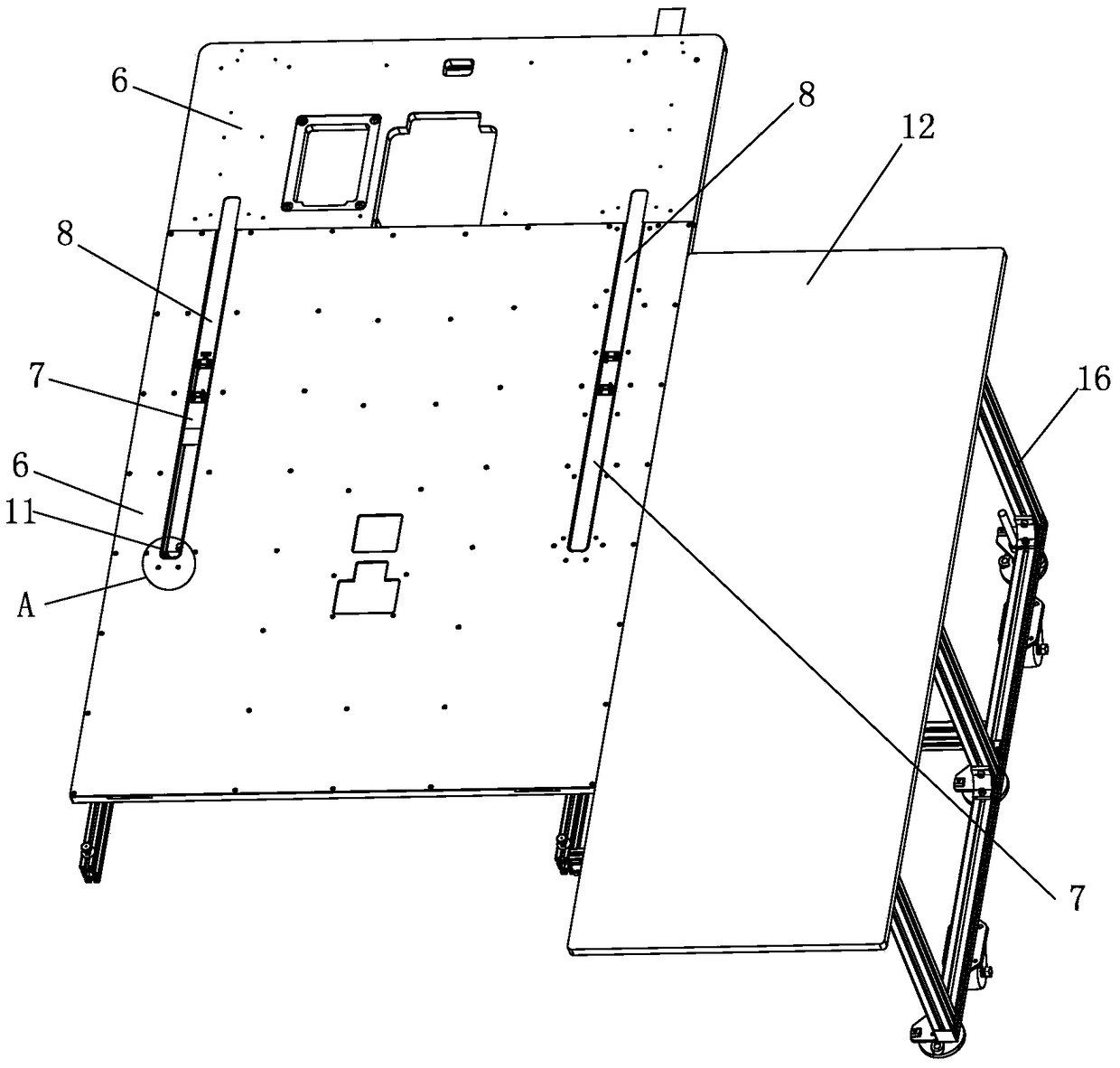

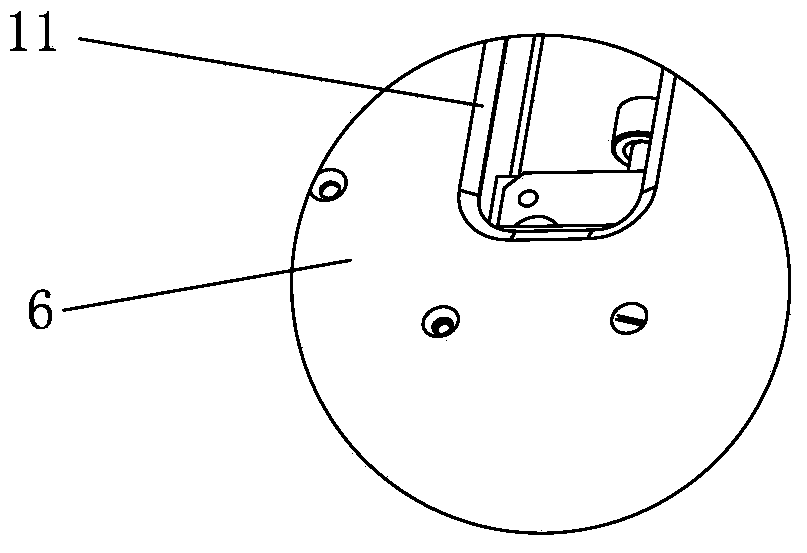

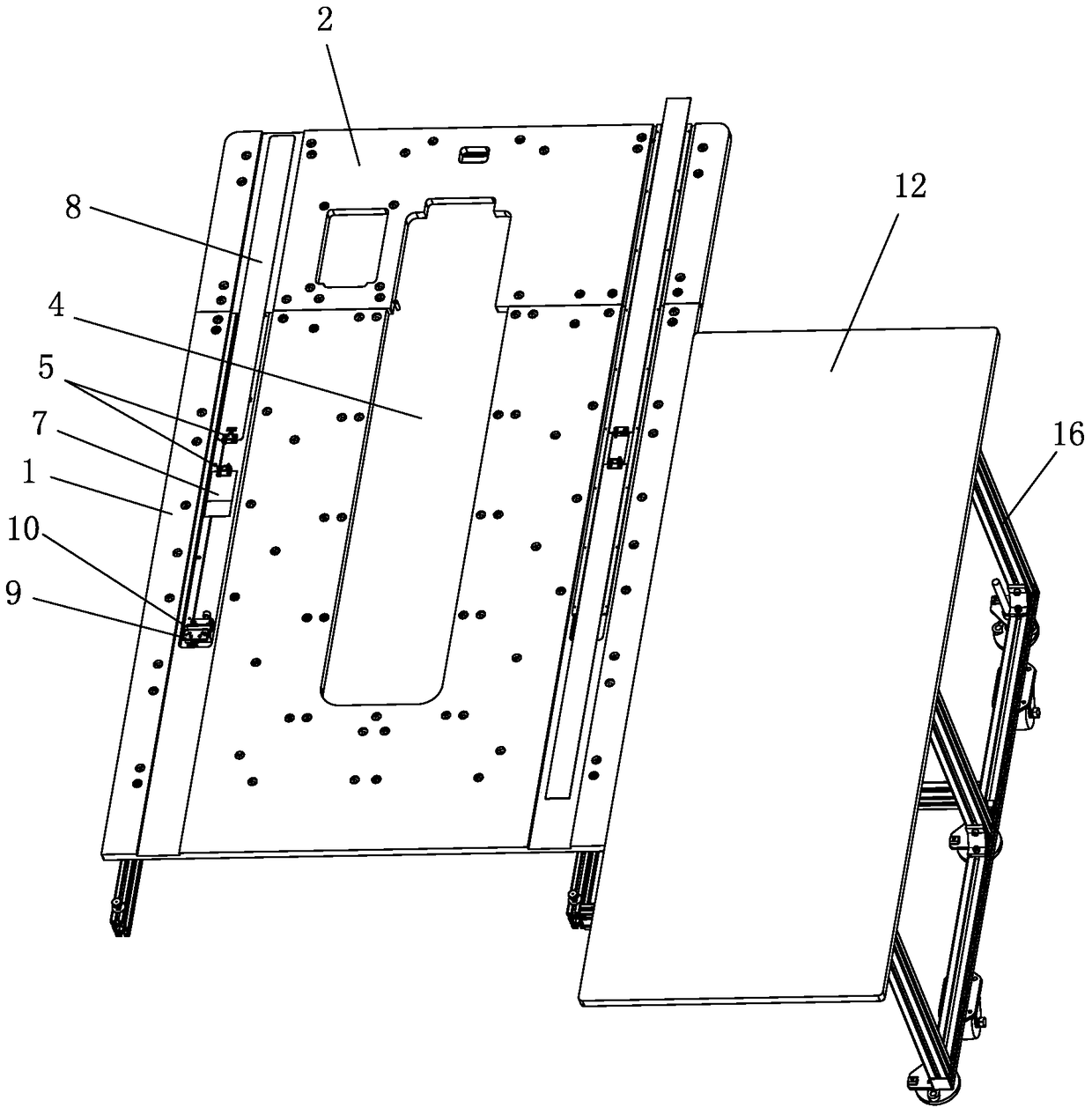

Novel sewing table structure

The invention belongs to the technical field of sewing machine accessories and especially provides a novel sewing table structure. The novel sewing table structure comprises a base plate, a back base plate connected to the rear of the base plate, a handpiece mounting hole arranged on the base plate and the back base plate, two slide ways arranged on the base plate of the left and right sides of the handpiece mounting hole. The slide ways extend to the back base plate. Each of the slide ways is provided with two slide plates reciprocating along the slide way. Each adjacent end of the two slide plates is provided with a mounting base. The two slide plates are connected to a moving crossbar by the mounting bases. By use of the novel sewing table structure, the number of seams is greatly reduced and pressure frames or form boards can be unhinderedly operated. The novel sewing table structure is easy in assembly and debugging and has few assembly parts, bringing great convenience for the subsequent maintenance users. By use of the novel sewing table structure, labor-hour is saved.

Owner:BULLMER ELECTROMECHANICAL TECH

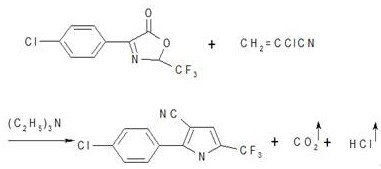

Method for producing chlorfenapyr intermediate pyrrole by replacing acetonitrile with solvent DMF

PendingCN112608268ASolve technical problemsImprove production efficiencyOrganic chemistryPyrroleEnvironmental chemistry

The invention provides a method for producing chlorfenapyr intermediate pyrrole by replacing acetonitrile with a solvent DMF. The solvent DMF is used for replacing acetonitrile. The method for producing the chlorfenapyr intermediate pyrrole by replacing acetonitrile with the solvent DMF comprises the following steps: extraction replacement, heat preservation reaction and condensation desolvation. The method has the beneficial effects that the reaction temperature of the pyrrolation cyclization reaction for preparing the intermediate is increased to 80 DEG C, the yield is increased to 90% or above in a breakthrough manner, the consumed solvent amount is reduced by more than 30%, the production cost is reduced by about 86%, the production cost is greatly reduced, and the production burden of enterprises is reduced.

Owner:李通

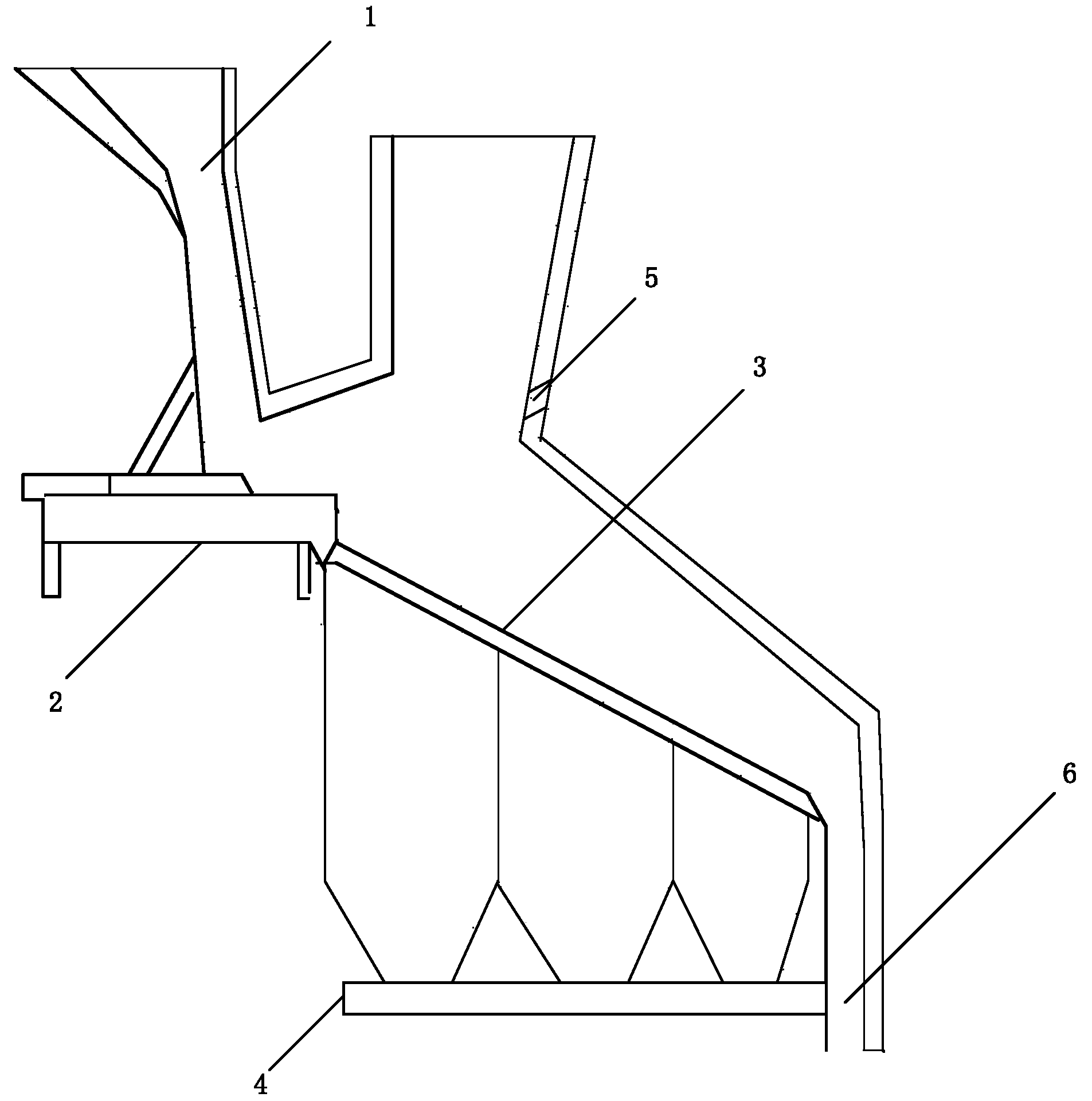

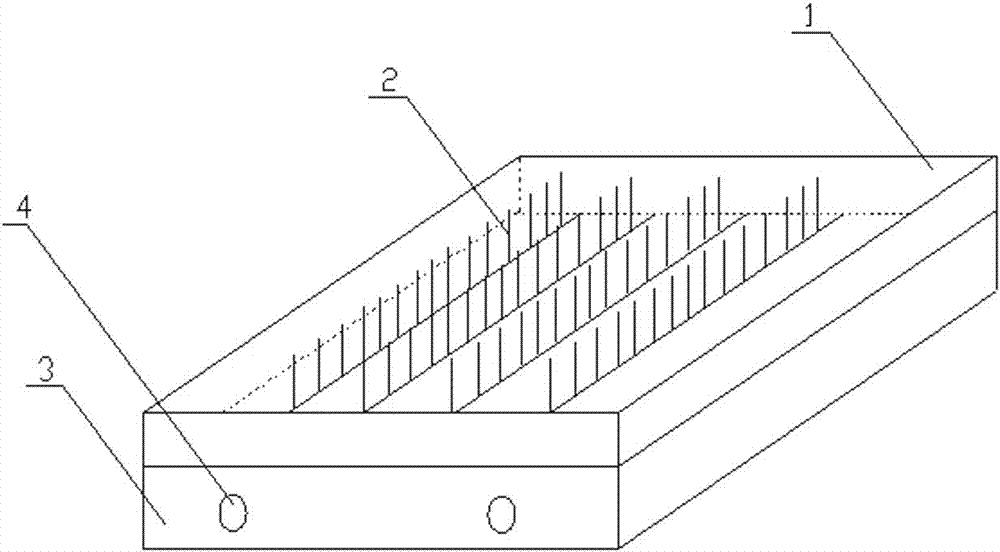

Ore conveying belt device of plate-type ore feeder

Owner:TAIYUAN IRON & STEEL GROUP

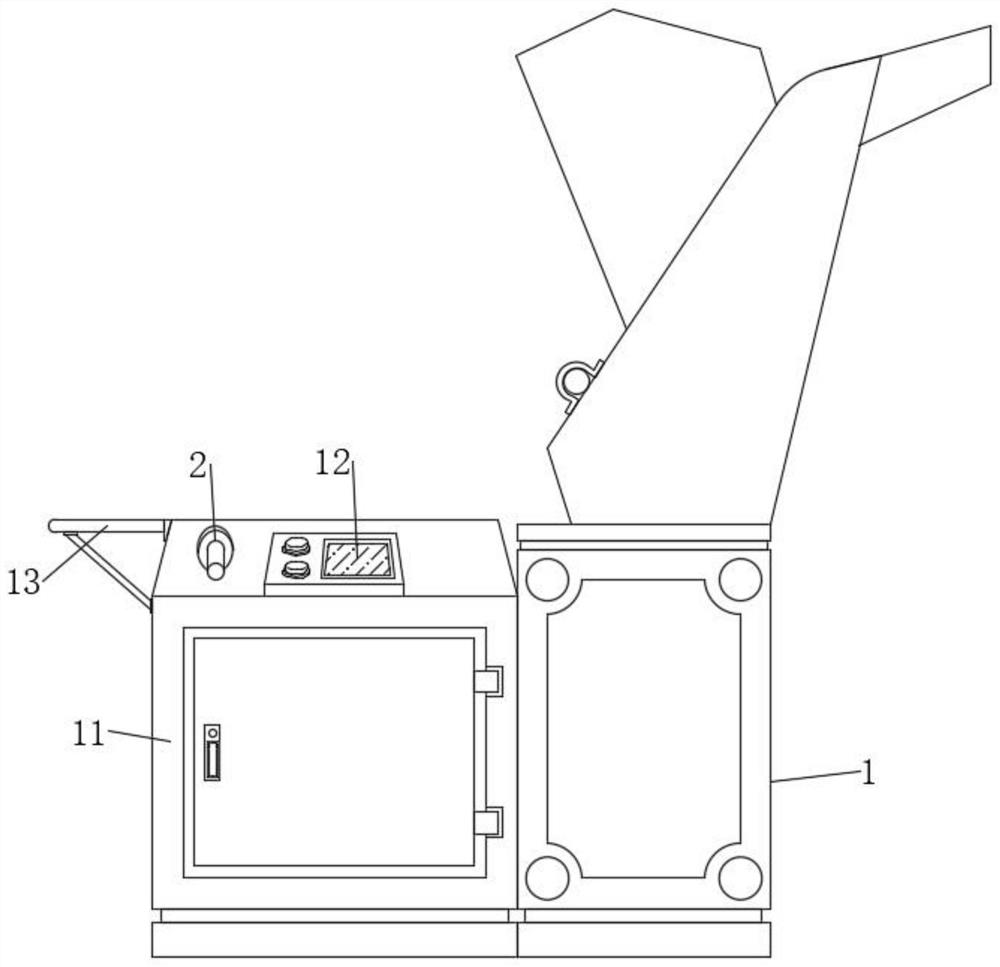

Ultrasonic water gate removing machine

The invention provides an ultrasonic water gate removing machine. The ultrasonic water gate removing machine comprises a rack, an ultrasonic vibrator, a vibrating base, a cooling face cover and a driving device. The ultrasonic vibrator is fixedly mounted on the rack. The vibrating base is fixedly mounted on the ultrasonic vibrator. The top of the vibrating base is provided with a carrying position. The carrying position is provided with discharge grooves. The top of the vibrating base is separably covered with the cooling face cover. The cooling face cover is provided with an air inlet hole, air outlet holes and an air flow channel. The air flow channel communicates with the air inlet hole and the air outlet holes. The air outlet holes face the discharge grooves. The driving device is mounted on the rack. The execution end of the driving device is fixedly connected with the cooling face cover. The driving device can drive the cooling face cover to move relative to the vibrating base. The ultrasonic water gate removing machine has the advantages of being suitable for cutting thick water gates and capable of avoiding secondary fusion welding, flanging or wire drawing in the cutting process.

Owner:SUNWAY PLASTIC INJECTION MOLD ZHUHAI

A device and method for removing s impurities in yellow phosphorus by directional solidification through full melting

ActiveCN112813503BLow costPrevention of Accidental Leakage and DeflagrationAfter-treatment apparatusPolycrystalline material growthHazardous substanceElectric machine

The invention relates to a device and method for removing S impurities in yellow phosphorus through directional solidification through full melting, which includes a vertical heating device and a yellow phosphorus carrier, and also includes an annular cooler, and the annular cooler is located above the vertical heating device And it fits closely with the top of the vertical heating device. The yellow phosphorus carrier passes through the annular cooler from top to bottom and is inserted into the vertical heating device. The top of the yellow phosphorus carrier is hung on the motor shaft, and the motor is connected to the vertical slide. On the rail, a liquid level maintaining device is arranged on the upper part of the device, and the liquid level maintaining device is connected to the vertical heating device through a hose. The method and device melt all the materials to be removed, then let the materials solidify gradually from one end, use the difference in the segregation coefficient of impurities to enrich the impurities at both ends of the material, and finally remove the two ends of the material. The sulfur impurity removal rate in phosphorus is over 95%. The method and device have good sulfur removal effect, simple device, easy production, high safety, and no harmful substance discharge.

Owner:贵州威顿晶磷电子材料股份有限公司

Head device for automatically clamping glass tubes on automatic tube-feed bottle-making machine

ActiveCN105110611AOptimizing automated production processesEasy to operateGlass reforming apparatusComputer moduleDrive motor

The invention relates to the field of automatic tube-feed bottle-making machines, particularly a head device for automatically clamping glass tubes on an automatic tube-feed bottle-making machine. The head device is characterized in that an L-shaped support base is connected with a stepping drive motor on a support base backing plate; the stepping drive motor is connected with a rack; a U-shaped plate is provided with an infrared sensor switch; a precise guide shaft is fixed to the U-shaped plate through a shaft sleeve; a precise guide shaft fixed module and the rack are connected into an integral body; a V-shaped clamp is connected with a push-up electromagnet and a spring connecting piece; the V-shaped clamp is composed of two iron bars of which the front ends are processed into a V shape, and the tail end of each iron bar is provided with meshed gears; and a pushdown-type electromagnet is fixed to a connecting mother board of the V-shaped clamp. The technical scheme can optimize the automatic production process, reduce the manual operation procedures and labor intensity and enhance the work efficiency. The head device avoids production safety accidents, and saves the cost on human resources, financial resources and the like when being used instead of consumable tongs.

Owner:湖北利康医用材料股份有限公司

A method for protecting the steel water jacket at the anode furnace mouth and the flue mouth, and the steel water jacket

ActiveCN104964569BExtended service lifeAvoid production safety accidentsFurnace coolingSteel jacketRefractory

A method for protecting a steel water jacket at an anode furnace mouth and a flue mouth includes changing and installing, making a mould, casting, and igniting and heating up. A new type of steel water jacket, comprising a steel water jacket body and a steel water jacket inlet and outlet water pipe mouth, and a steel water jacket also includes an iron mold and a welding catch. The molten steel jacket at the anode furnace mouth is protected by refractory materials, which isolates the copper water or slag, and prevents the accident of the molten steel jacket being washed and leaked; to anti-corrosion effect.

Owner:YUNNAN TIN

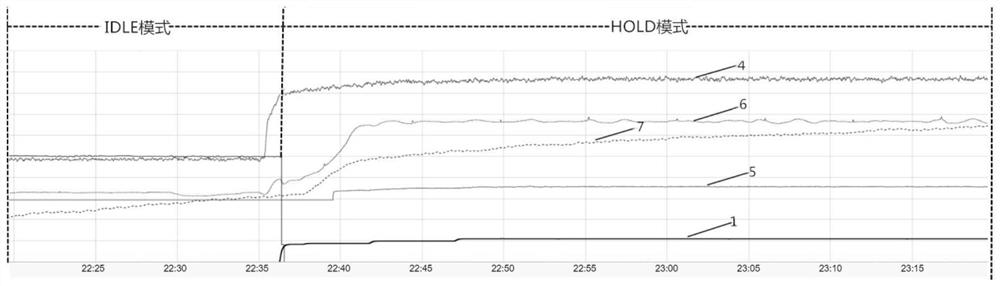

Cold rolling production monitoring system and monitoring method thereof

InactiveCN109101000AAvoid production safety accidentsAvoid economic lossThermometer detailsTotal factory controlBiochemical engineeringMonitoring system

The invention provides a cold rolling production monitoring system and a monitoring method thereof, and relates to the technical field of cold rolling production, and in particular to the cold rollingproduction monitoring system and the monitoring method thereof. The cold rolling production monitoring system comprises a collection unit, an onsite display unit and an onsite DCS system, the collection unit comprises a temperature detection part and a signal processing part, the temperature detection part is connected with the onsite display unit through the signal processing part, and the onsite display unit is connected to the onsite DCS system. The cold rolling production monitoring system provided by the invention has the positive effects of improving the use rationality of the equipmentand the safety and economical efficiency of the operation, prolonging the service life of the equipment, and improving the working efficiency.

Owner:山东冠洲股份有限公司

Intelligent plate blank width measurement number identification system

PendingCN113686247AAccurate ReflexesReduce manual operationsCharacter and pattern recognitionUsing optical meansHydraulic cylinderLaser ranging

The invention discloses an intelligent plate blank width measurement number identification system which comprises a hydraulic cylinder and a first rotating shaft, wherein one end of the hydraulic cylinder controls a hydraulic rod. According to the intelligent plate blank width measurement number identification system, an industrial camera and a laser range finder are used for recognizing and measuring the plate blank number and width on a roller shaft, so as to replace a traditional production mode of manual copying and recording, manual operation is reduced and labor cost is saved through remote monitoring, automatic identification of plate blank production numbers and measurement of plate blank widths, meanwhile, high-precision number identification and high-precision width measurement are achieved, deviation and errors caused by personal quality are avoided, the plate blank number is continuously and automatically identified, the width is continuously and automatically measured, the state of the plate blank is monitored in real time, and the state is matched with background big data, so that unqualified plate blanks in the production process can be found in the first time, timely treatment and comprehensive regulation are realized, and subsequent possible production safety accidents are avoided.

Owner:湖南福华信息工程有限公司

A new seam structure

The invention belongs to the technical field of sewing machine accessories and especially provides a novel sewing table structure. The novel sewing table structure comprises a base plate, a back base plate connected to the rear of the base plate, a handpiece mounting hole arranged on the base plate and the back base plate, two slide ways arranged on the base plate of the left and right sides of the handpiece mounting hole. The slide ways extend to the back base plate. Each of the slide ways is provided with two slide plates reciprocating along the slide way. Each adjacent end of the two slide plates is provided with a mounting base. The two slide plates are connected to a moving crossbar by the mounting bases. By use of the novel sewing table structure, the number of seams is greatly reduced and pressure frames or form boards can be unhinderedly operated. The novel sewing table structure is easy in assembly and debugging and has few assembly parts, bringing great convenience for the subsequent maintenance users. By use of the novel sewing table structure, labor-hour is saved.

Owner:BULLMER ELECTROMECHANICAL TECH

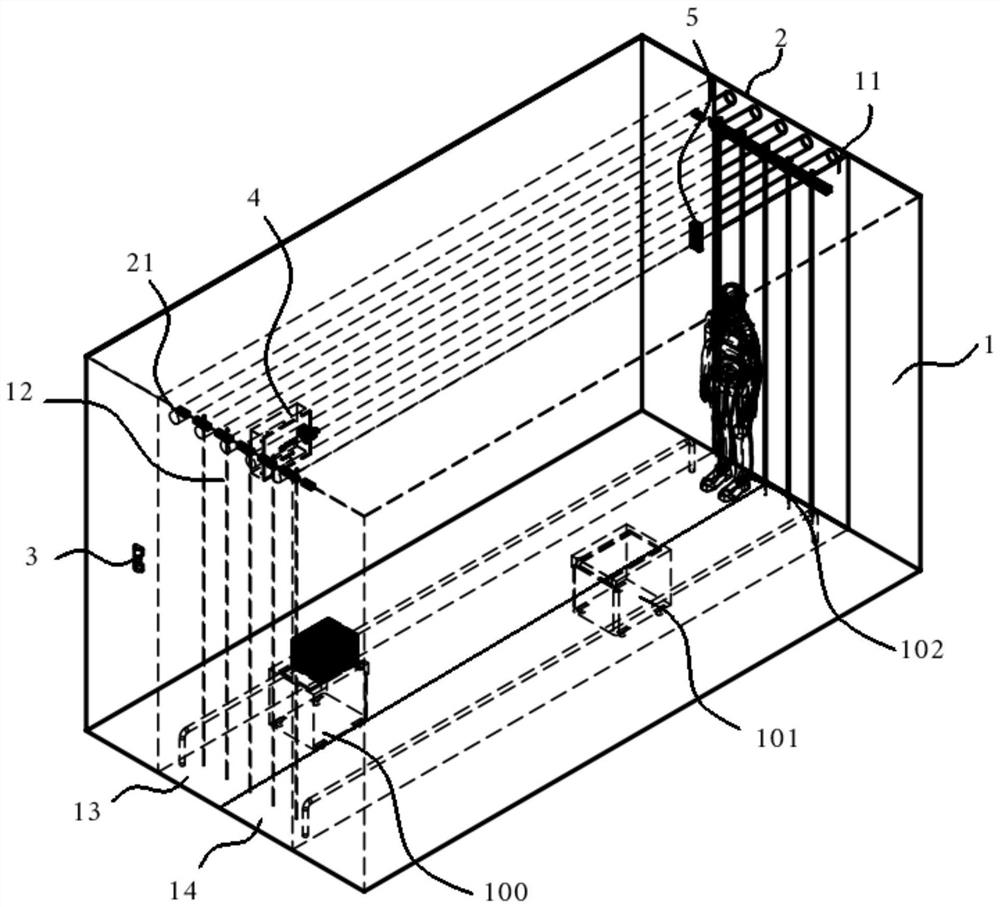

Detection channel and passing method

PendingCN113867304AAvoid collisionSimple detection structureElectric/hybrid propulsionProgramme total factory controlEngineeringLaser sensor

The invention belongs to the technical field of production workshop AGV logistics, and discloses a detection channel and a passing method; the detection channel comprises a channel body, a laser sensing device and a sound-light alarm device, wherein two ends of the channel body are respectively provided with a first outlet and a second outlet for allowing passing objects to enter or leave; the laser sensing device comprises a plurality of laser sensor groups which are uniformly arranged above the channel body in the width direction of the channel body, and the laser sensing device is used for detecting the width of a passing object; the sound-light alarm device is in communication connection with the laser sensing device, and when the width of the passing objects passing in the opposite directions is larger than the width of the channel body, the sound-light alarm device sends out an alarm signal. The detection channel can be used for a plurality of passing objects to pass together, the existing building layout of a production workshop is not changed, the transformation period is short, the cost is low, and the space utilization rate of the production workshop is high; furthermore, the passing method is applied to the detection channel, and the collision of passing objects passing in opposite directions is avoided, so that the passing efficiency is improved, and production safety accidents are prevented.

Owner:BOZHON PRECISION IND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com