Ultrasonic water gate removing machine

An ultrasonic and nozzle technology, applied in the field of ultrasonic nozzle removal machine, can solve the problems of inaccurate fracture size, product drop, secondary welding, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

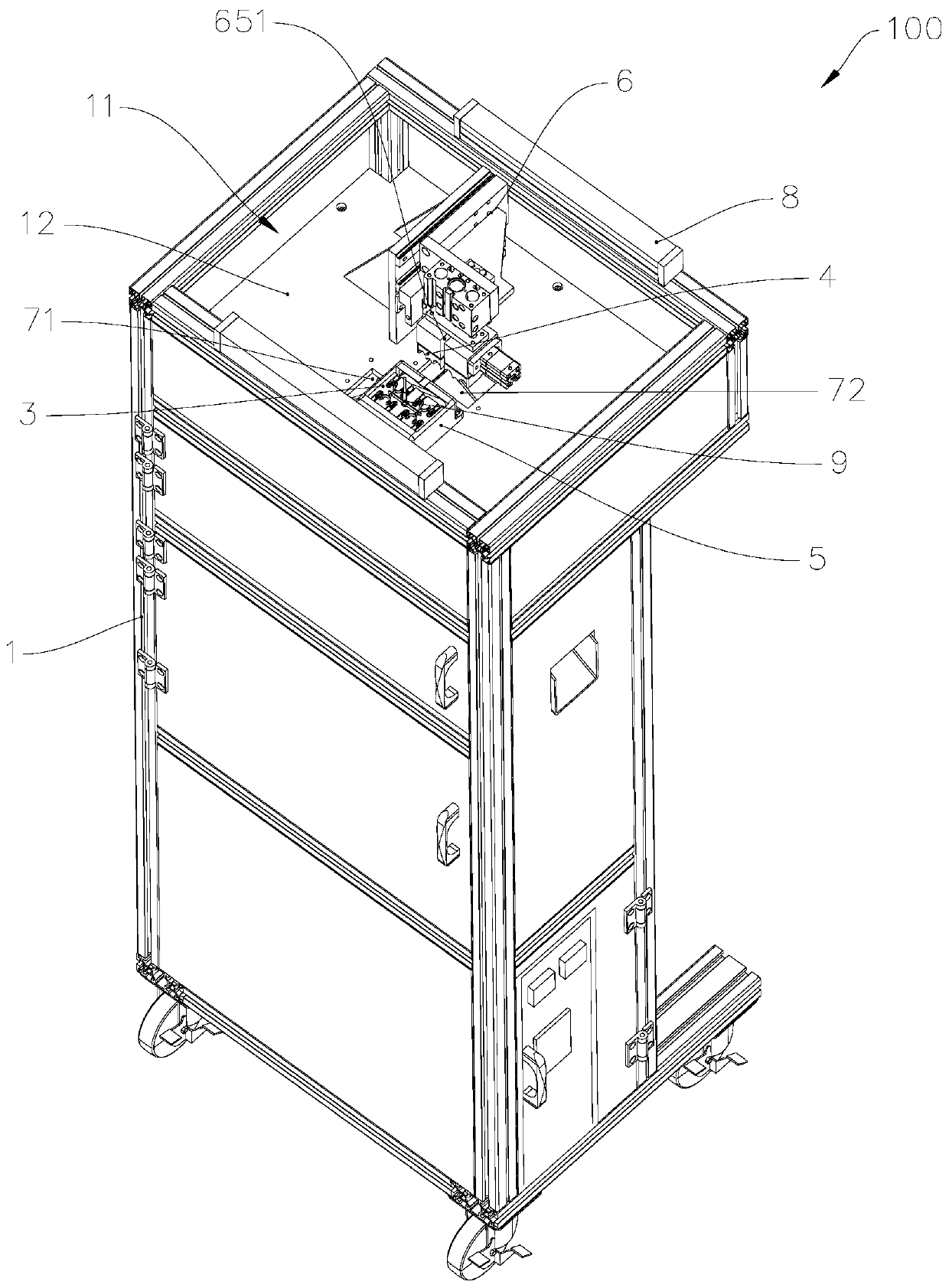

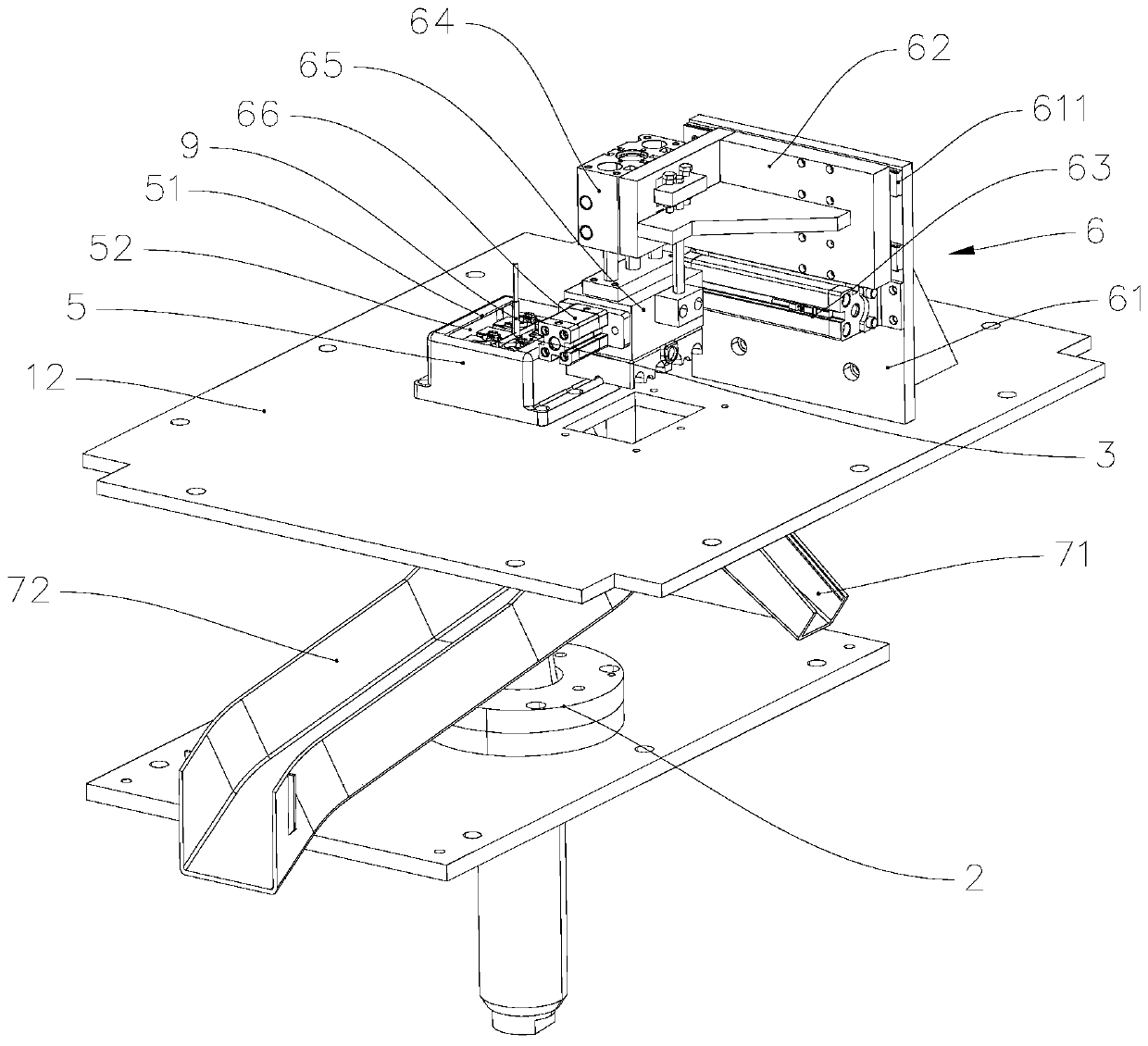

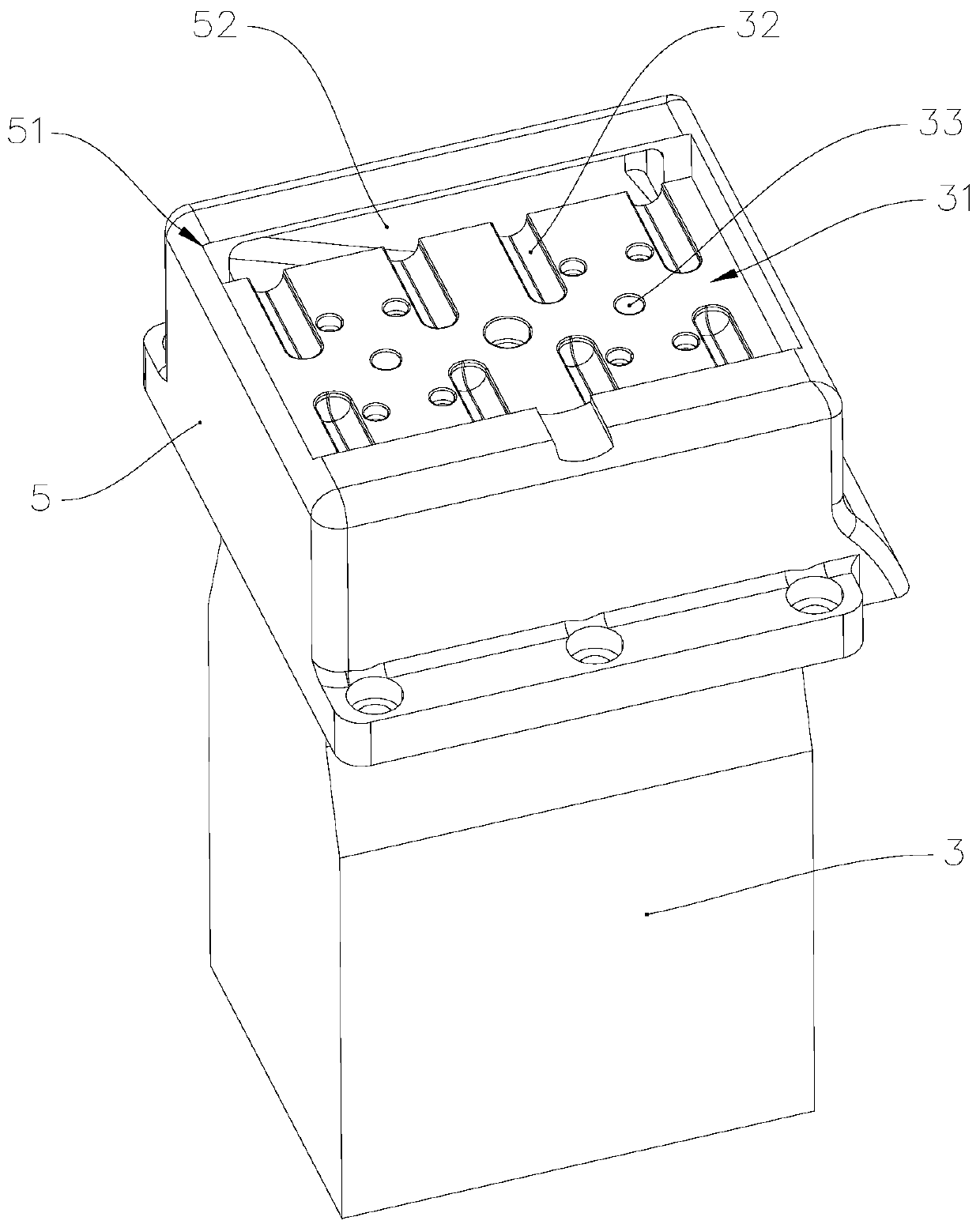

[0041] refer to figure 1 and figure 2 , The ultrasonic water outlet machine 100 includes a frame 1, an ultrasonic vibrator 2, a vibration seat 3, a cooling mask 4, a diversion shell 5, a driving device 6, a second slide 71, a third slide 72 and a safety grating 8.

[0042] Among them, the frame 1 has a processing chamber 11, the vibrating seat 3, the cooling mask 4, the diversion shell 5 and the driving device 6 are all arranged in the processing chamber 11, and the safety grating 8 is arranged at the mouth of the processing chamber 11. The safety grating 8 is used for real-time signal feedback to the control system connected with it, so that when a foreign object penetrates into the processing chamber 11 during the ultrasonic water removal machine 100 processing the workpiece 9, the safety grating 8 can be in time. Send a feedback signal to the control system connected with it, so that the control system controls the ultrasonic water outlet machine 100 to suspend operation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com