Belt conveyor with telescopic head

A belt conveyor and head technology, which is applied in the field of belt conveyors, can solve problems such as low operating efficiency and equipment collision accidents, and achieve the effects of simple structure, stable operation, and improved operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

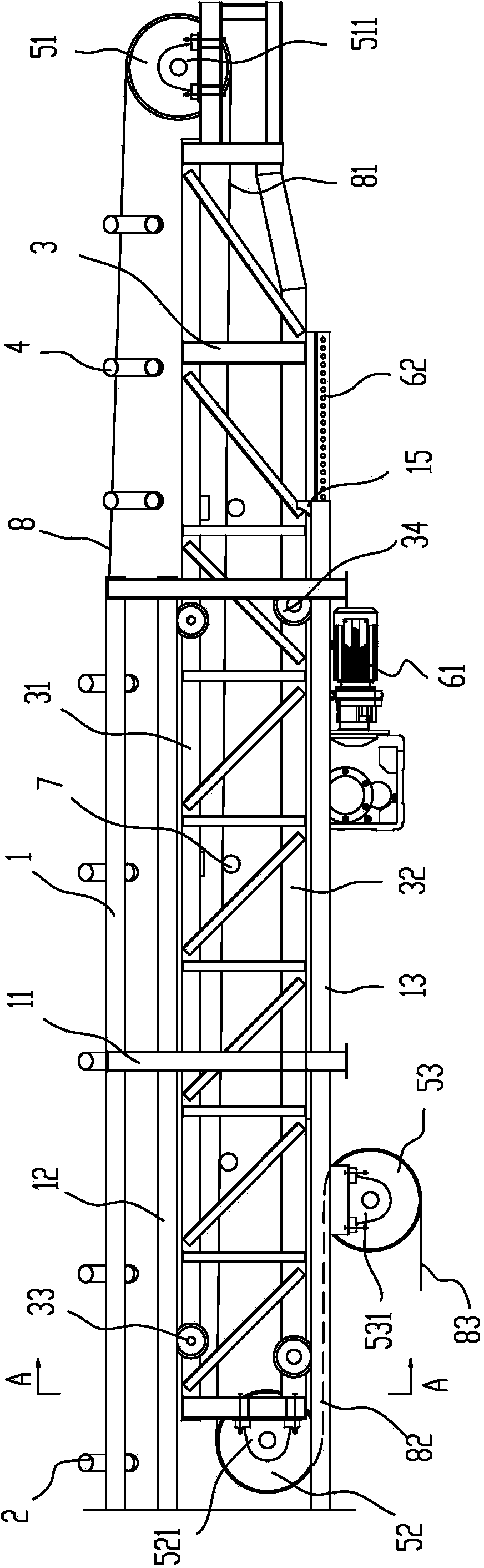

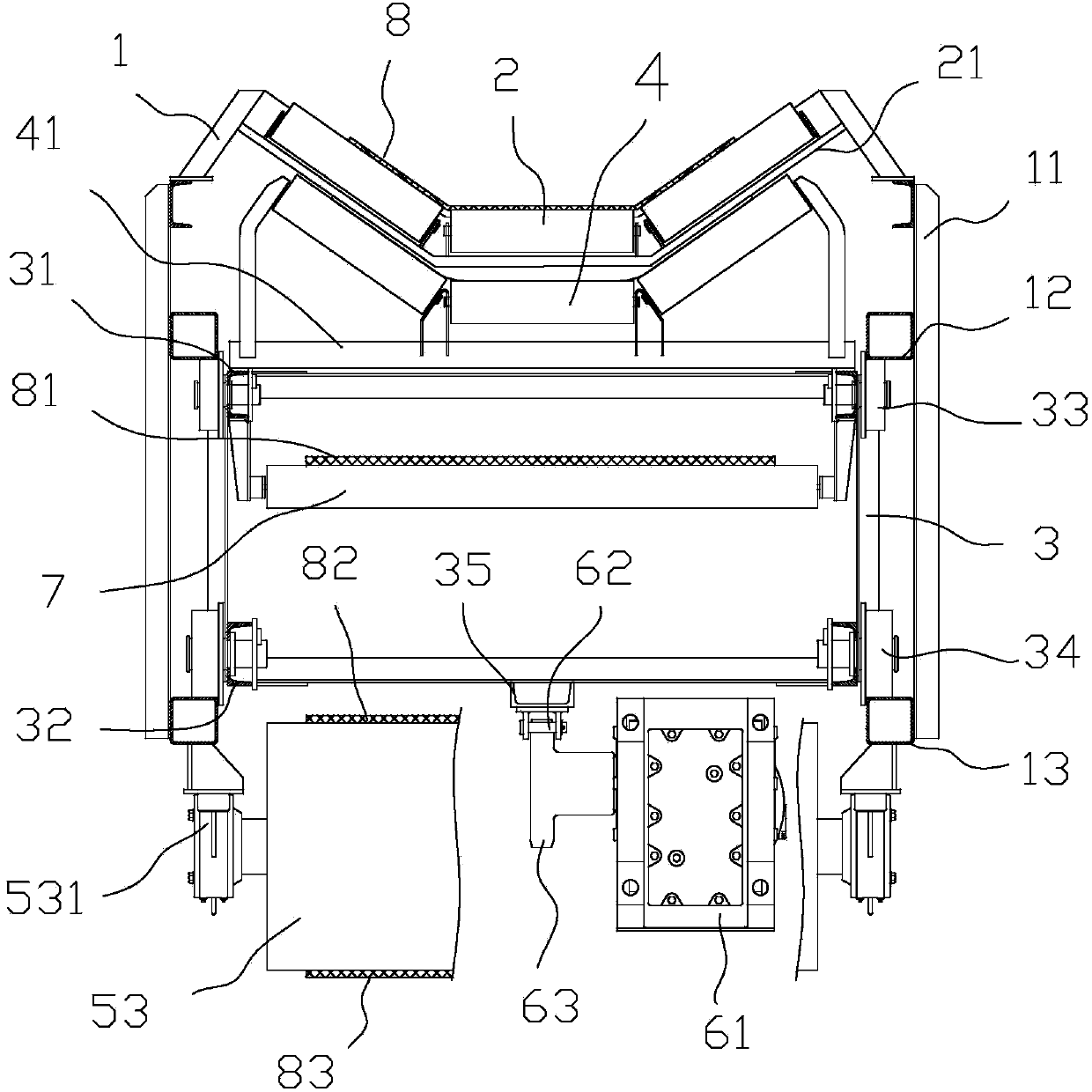

[0016] The detailed structure of the present invention is as figure 1 with figure 2 Shown:

[0017] The trough-shaped idler roller 2 is fixed above the truss body 1 through a support base 21 . The truss body 1 is respectively fixed with upper and lower guide rails 12, 13 at the upper and lower ends of the inner sides of the columns 11 on both sides, and the upper and lower guide rails 12, 13 are made of square steel.

[0018] The vehicle frame 3 is in the shape of a square frame, and a pair of upper and lower beams 31 and 32 are respectively arranged on both sides of the upper and lower ends of the vehicle frame 3 .

[0019] The upper end of the frame 3 is fixed with a trough-shaped load-bearing roller 4, which is fixed on the upper beams 31 on both sides of the top of the frame 3 through the base 41, and the height of the load-bearing roller 4 is lower than the load-bearing roller 2 at the upper end of the truss body 1. The supporting base 21. When the tail of the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com