Cold rolling production monitoring system and monitoring method thereof

A DCS system and roll technology, applied in the field of cold rolling production, can solve the problems of bearing lock, production failure shutdown, economic loss, etc., and achieve the effect of prolonging service life, improving rationality and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

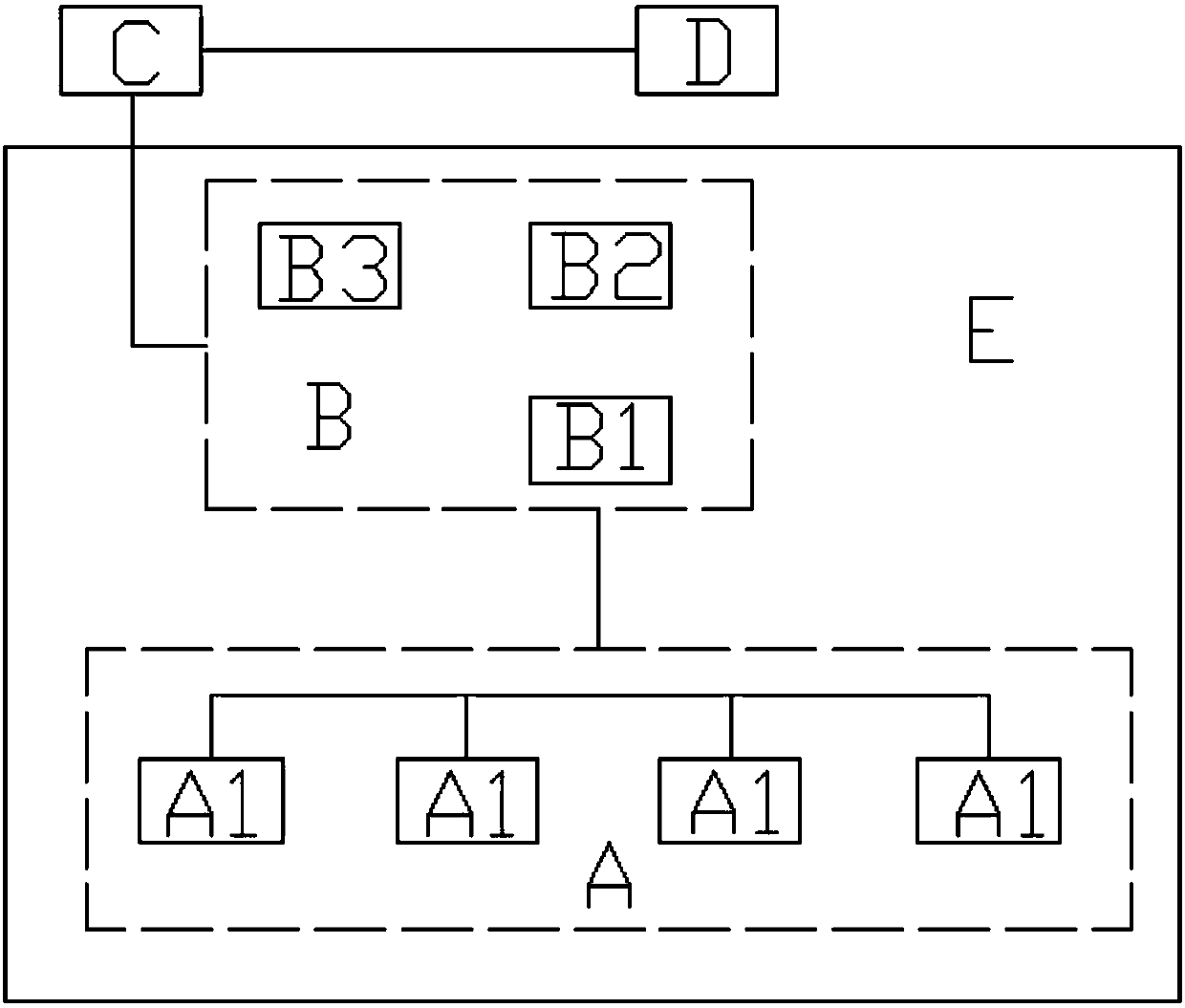

[0014] Such as figure 1 As shown, the roll online temperature measurement system provided by the present invention includes an acquisition unit E, an on-site display unit C, and an on-site DCS system D. The acquisition unit includes a temperature detection part A and a signal processing part B. Among them, the temperature detection part includes the temperature sensor A1, which is installed and fixed through the oil and gas recovery hole of the bearing seat, and is used to detect the temperature of oil and air in the oil and gas recovery of the bearing seat in real time; the signal processing part includes the signal receiving module B1, the signal processing module B2 and the signal Sending module B3, the signal receiving module is used to receive the real-time temperature detected by the temperature sensor; the signal processing module is used to analyze and process the temperature; the signal sending module is used to analyze and process the signal processing module The fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com