Intelligent plate blank width measurement number identification system

A technology for identifying systems and numbers, applied in character and pattern recognition, measuring devices, instruments, etc., can solve problems such as unmanageable defective products, control and timely processing, and inability to connect board numbers, etc., to avoid Production safety accidents, high-precision width measurement, effects of avoiding deviations and errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

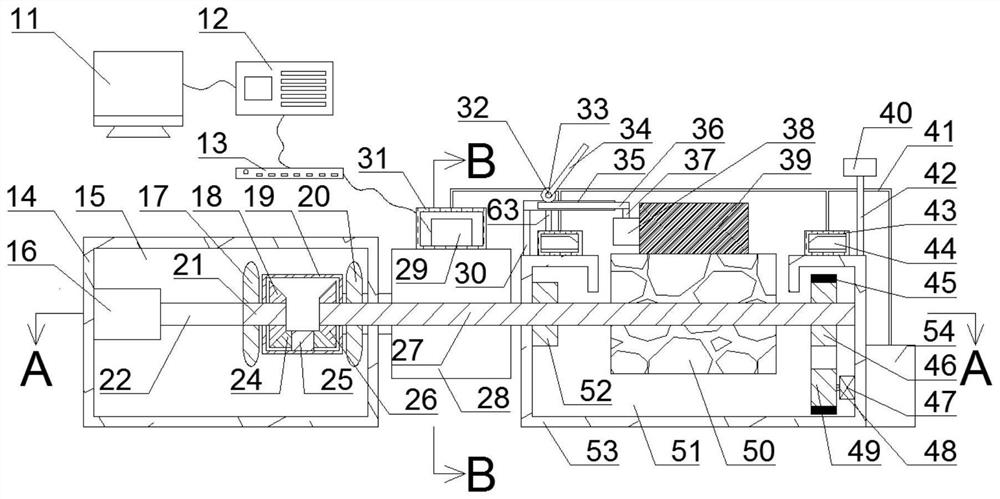

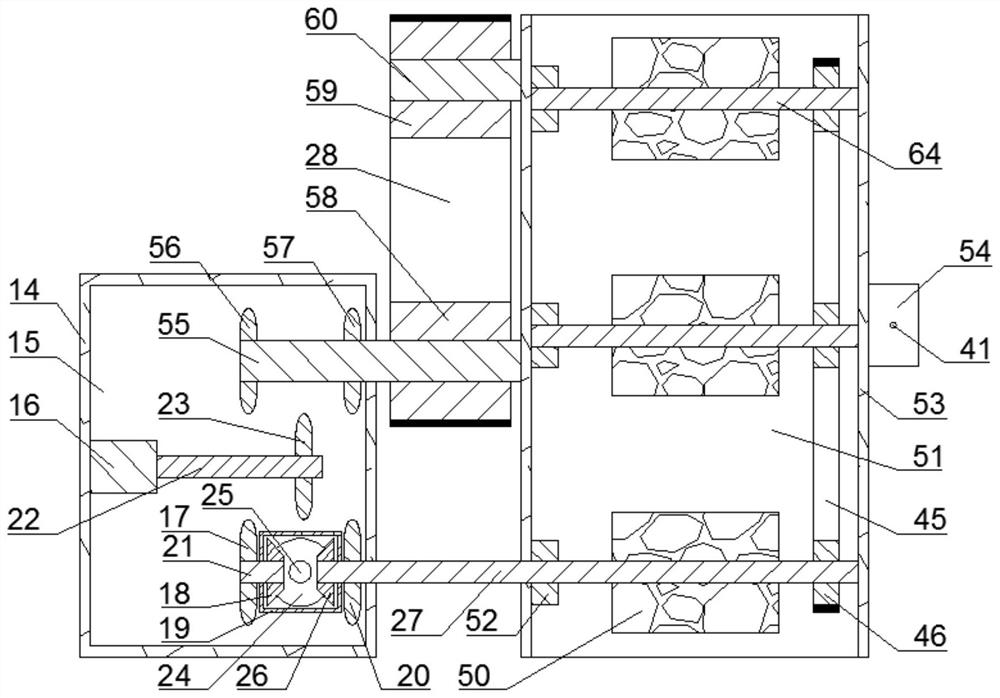

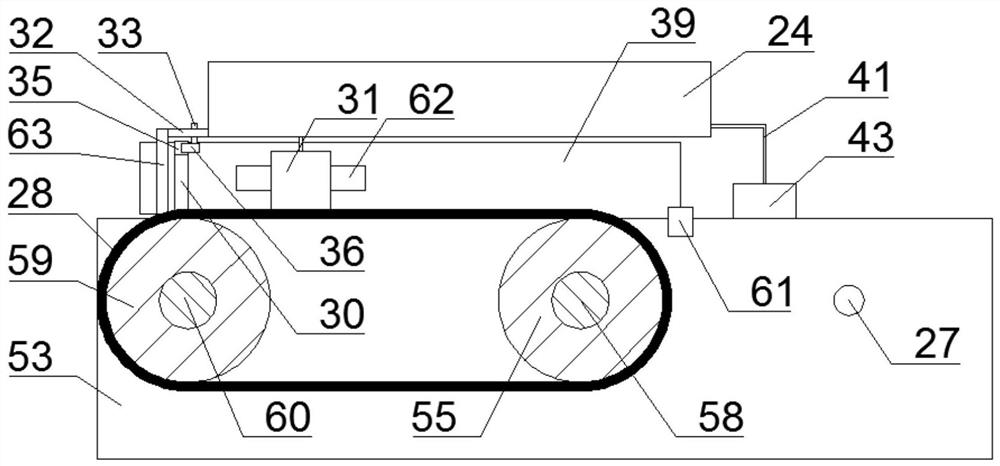

[0021] Combine below Figure 1-3 Describe the specific embodiment of the present invention, the intelligent plate width measurement number recognition system, including a hydraulic cylinder 16 and a first rotating shaft 55, one end of the hydraulic cylinder 16 controls a hydraulic rod 22, and the hydraulic rod 22 is far away from the hydraulic pressure One side of the cylinder 16 is rotated with a first friction wheel 23, and the first rotating shaft 55 is fixed with a second friction wheel 56 and a third friction wheel 57, and the first rotating shaft 55 is far away from the second friction wheel. One end of wheel 56 is fixedly provided with drive pulley 58, and described drive pulley 58 is driven with drive pulley 59 by conveyer belt 28, and described drive pulley 59 is fixedly arranged on the second rotating shaft 60, and described conveyer belt 28 is fixedly provided with The first protective cover 31, the industrial camera 29 is installed in the first protective cover 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com