Electric push rod used for solar photo-thermal power generation

A technology of electric push rods and photothermal power generation, which is applied in the direction of electric components, circuits, electromechanical devices, etc., can solve the problems that electric push rods are prone to negative pressure, etc., and achieve the effects of improving service life, reducing energy consumption losses, and reducing burdens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

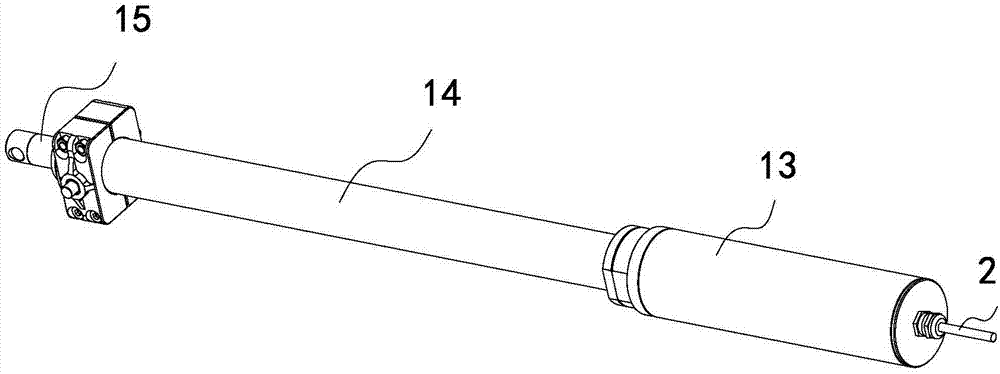

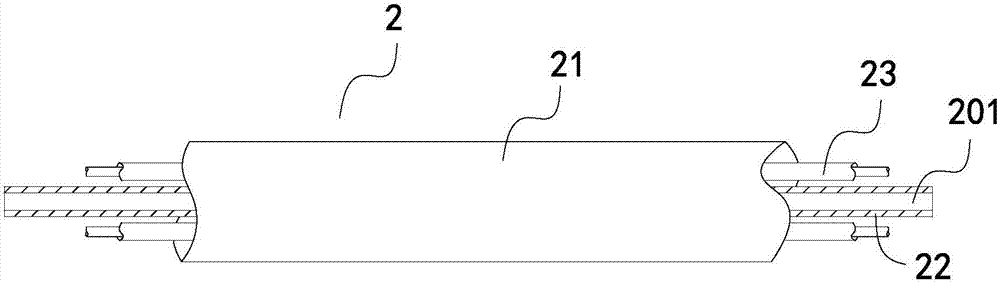

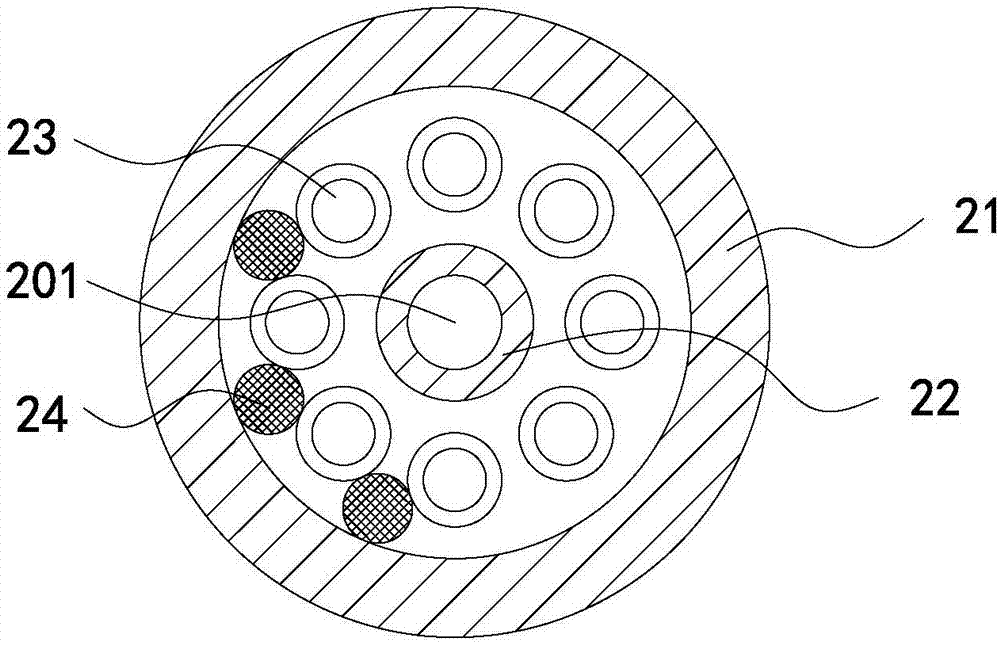

[0061] Such as Figure 1 to Figure 15 As shown, this embodiment shows an electric push rod for solar thermal power generation. This embodiment is mainly used in solar thermal power generation technology to drive heliostats. The electric push rod in this embodiment, its The main structure includes a motor 10, the motor 10 is connected with a drive screw 11, the drive screw 11 is connected with a nut 12, the motor 10 is installed in a base 13, the base 13 is fixedly connected with an outer tube 14, and the nut 12 is fixedly connected There is an inner tube 15. When the motor 10 drives the drive screw 11 to rotate, the nut 12 and the drive screw 11 move relative to each other. Specifically, it reciprocates between two positions on the drive screw 11. For the nut 12, it is Reciprocating motion between an initial position and limit positions. Overall, the relative movement between the inner tube 15 and the outer tube 14 is achieved, and the outermost end of the inner tube 15 is us...

Embodiment 2

[0102] Such as Figure 16 As shown, the difference between this embodiment and Embodiment 1 is that there is no hollow conduit in this embodiment, and the core wire 23 inside the cable 2 in this embodiment includes a core wire sleeve 231, and the outside of the core wire sleeve 231 is provided with ribs 232, after the ribs 232 are set, the core wires 23 will not be tightly fitted, but a certain gap will be generated, and at the same time, a certain gap will also be generated between the core wire 23 and the inner wall of the sheath 21, and these gaps will naturally form The ventilation channel 201 .

Embodiment 3

[0104] The difference between this embodiment and Embodiment 1 is that there is no fixed seat in this embodiment, the photoelectric sensor is directly fixed on the base, and the touch panel is also installed on the base, and is installed in a sliding fit with the base. The structure is to set a chute on the base, let the touch plate slide and install in the chute, after the photoelectric sensor is installed on the base, cover it with a protective cover to prevent oil, of course, the protective cover is also set accordingly There is a first opening as in embodiment 1, for the trigger projection to stretch in or out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com