Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Solve the problem of negative pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

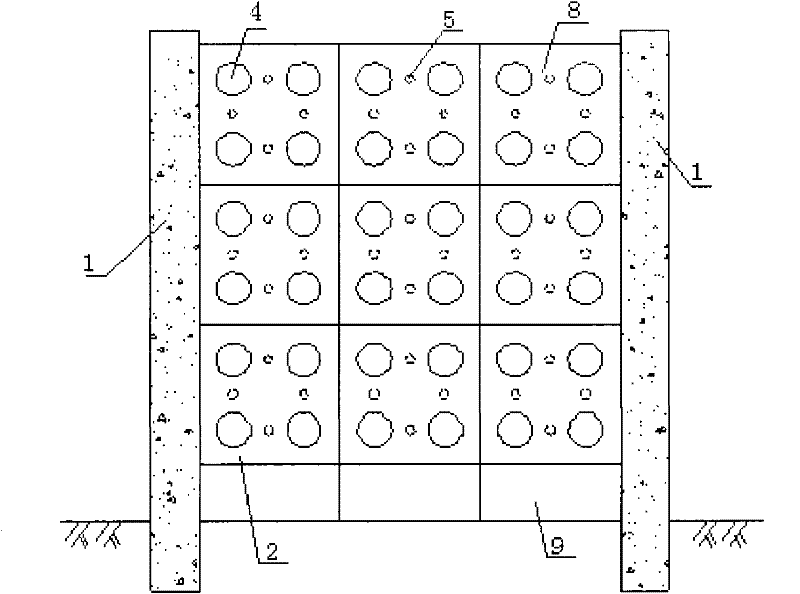

Wind-proofing sand-blocking device

InactiveCN101871199AStable structureRealize industrial productionProtective constructionEngineeringWire mesh

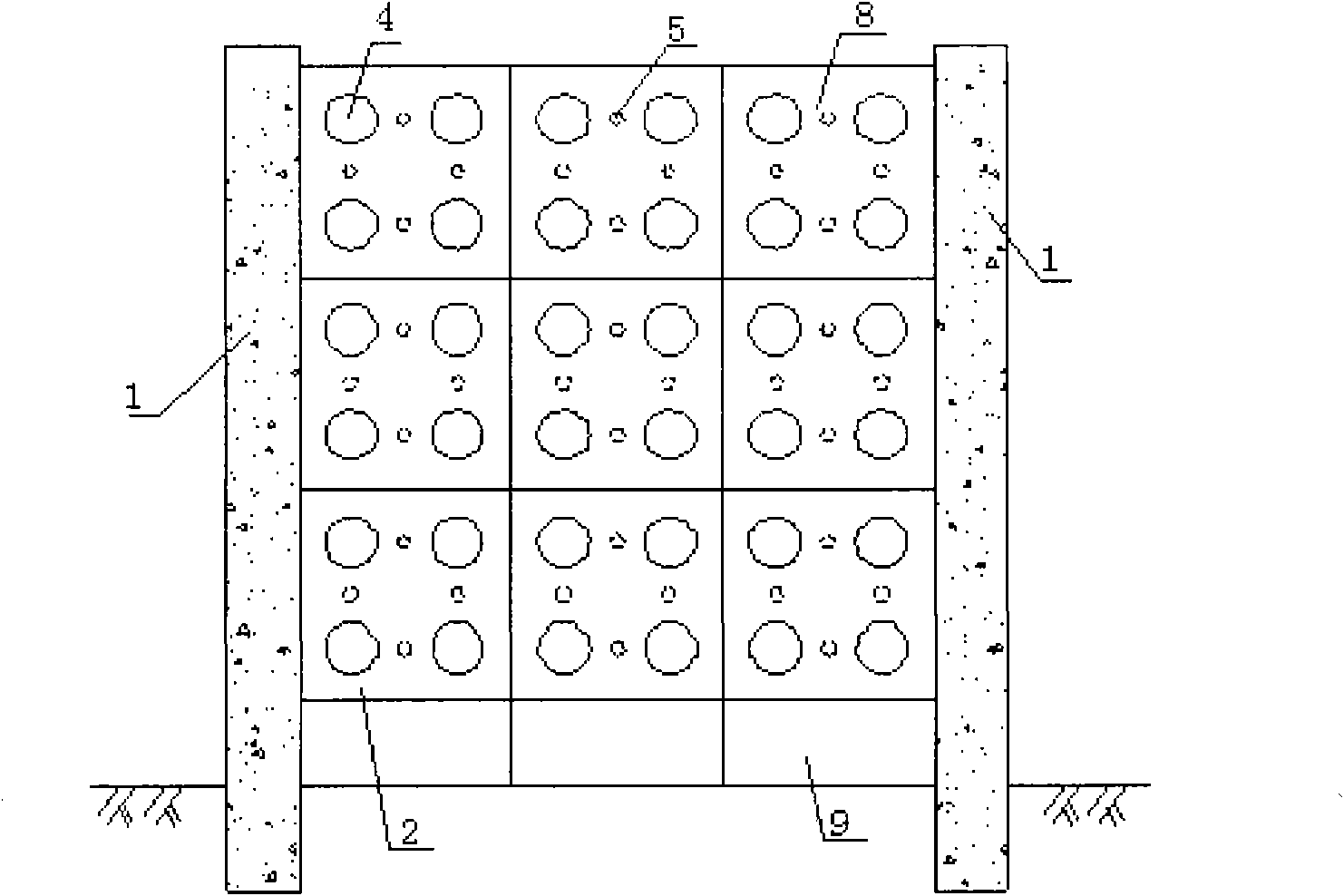

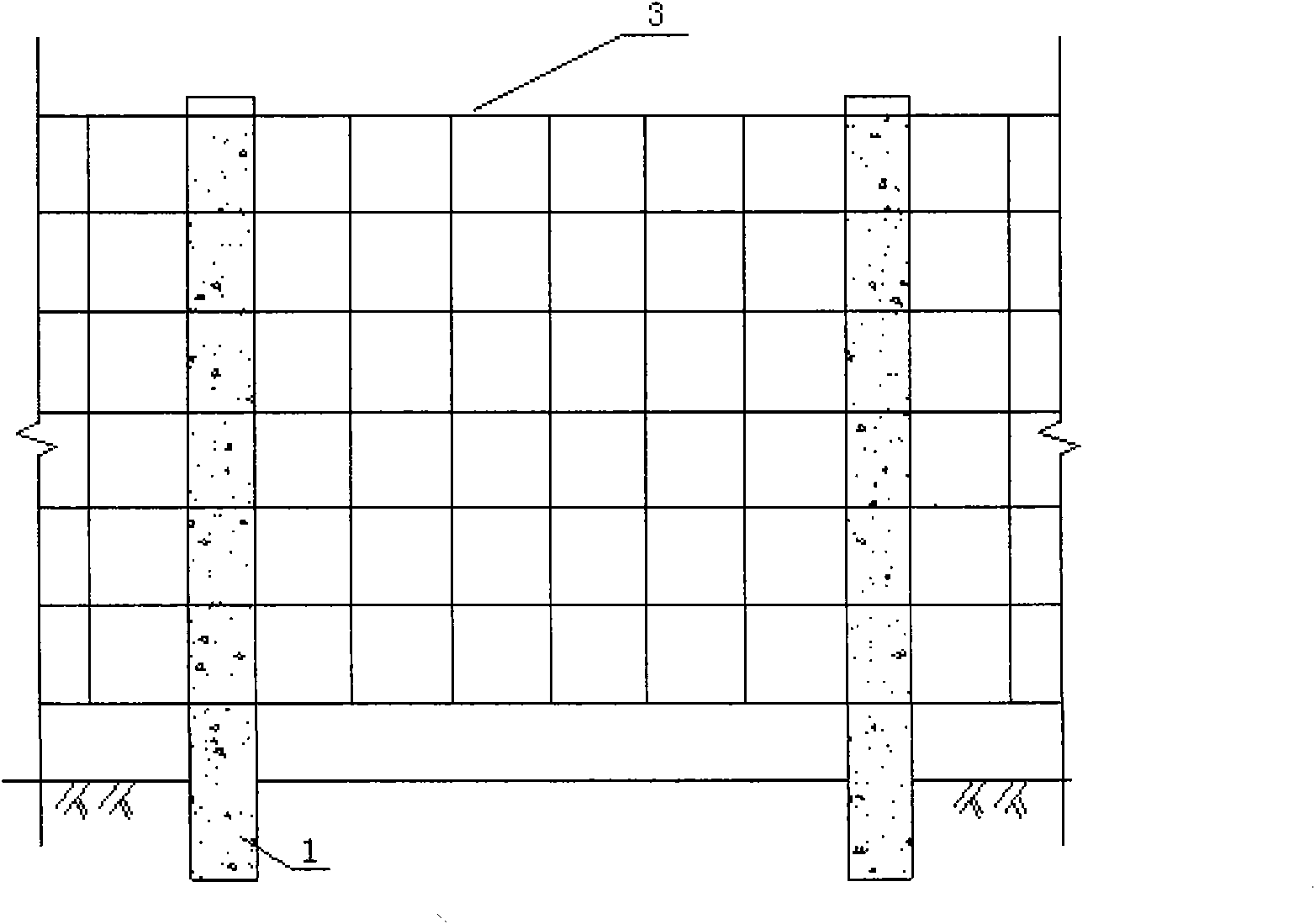

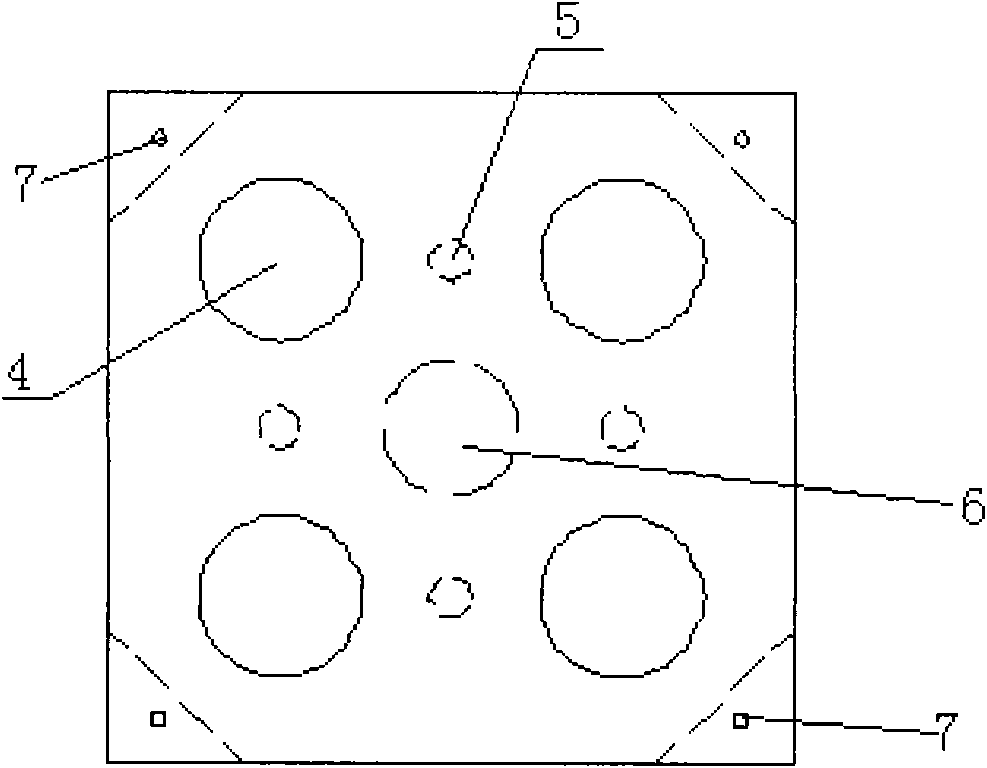

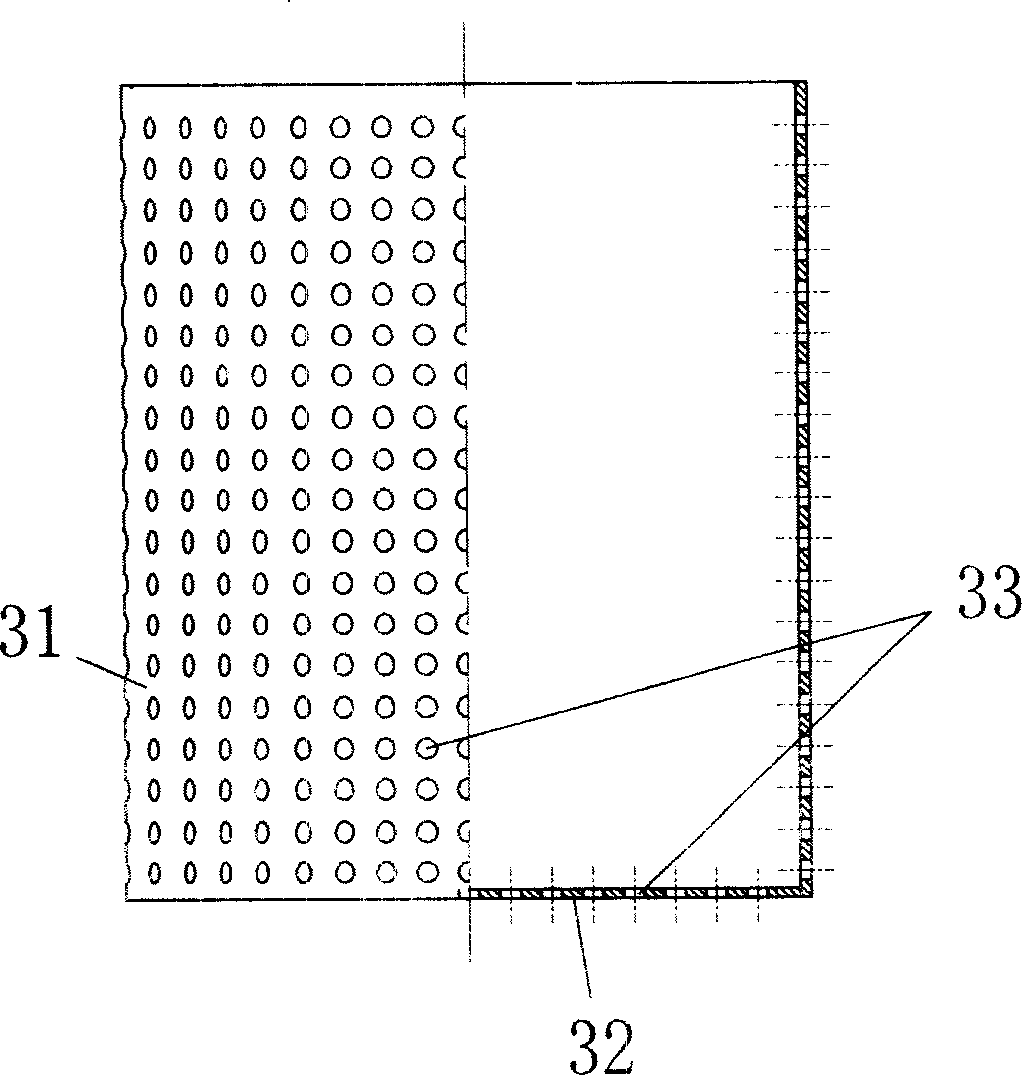

The invention discloses a wind-proofing sand-blocking device for preventing sand from affecting or damaging railways and other facilities. The wind-proofing sand-blocking device comprises a vertical column buried on the ground and a wind-blocking ball provided with through holes, wherein an anti-corrosion steel wire mesh is fixed on the vertical column, and the wind-blocking wall is fixed on the iron wire mesh. The wind-blocking wall comprises a plurality of wind-blocking monomers which are combined together; each wind-blocking monomer is a rectangular double-sided sandwich structure consisting of a windward side and leeward side, wherein the thickness of a hollow sandwich layer is 5 to 15cm; the windward side and leeward side of the wind-blocking monomer are respectively and symmetrically provided with at least one through hole; and holes on the windward side of the monomer and holes on the leeward side thereof are not on the same axis, the ration of the diameter of the holes of the windward side to that of the holes of the leeward side is 8:1 to 1:1, and the windward side and the leeward side are separated by a strut.

Owner:NORTHWEST RES INST CO LTD OF C R E C

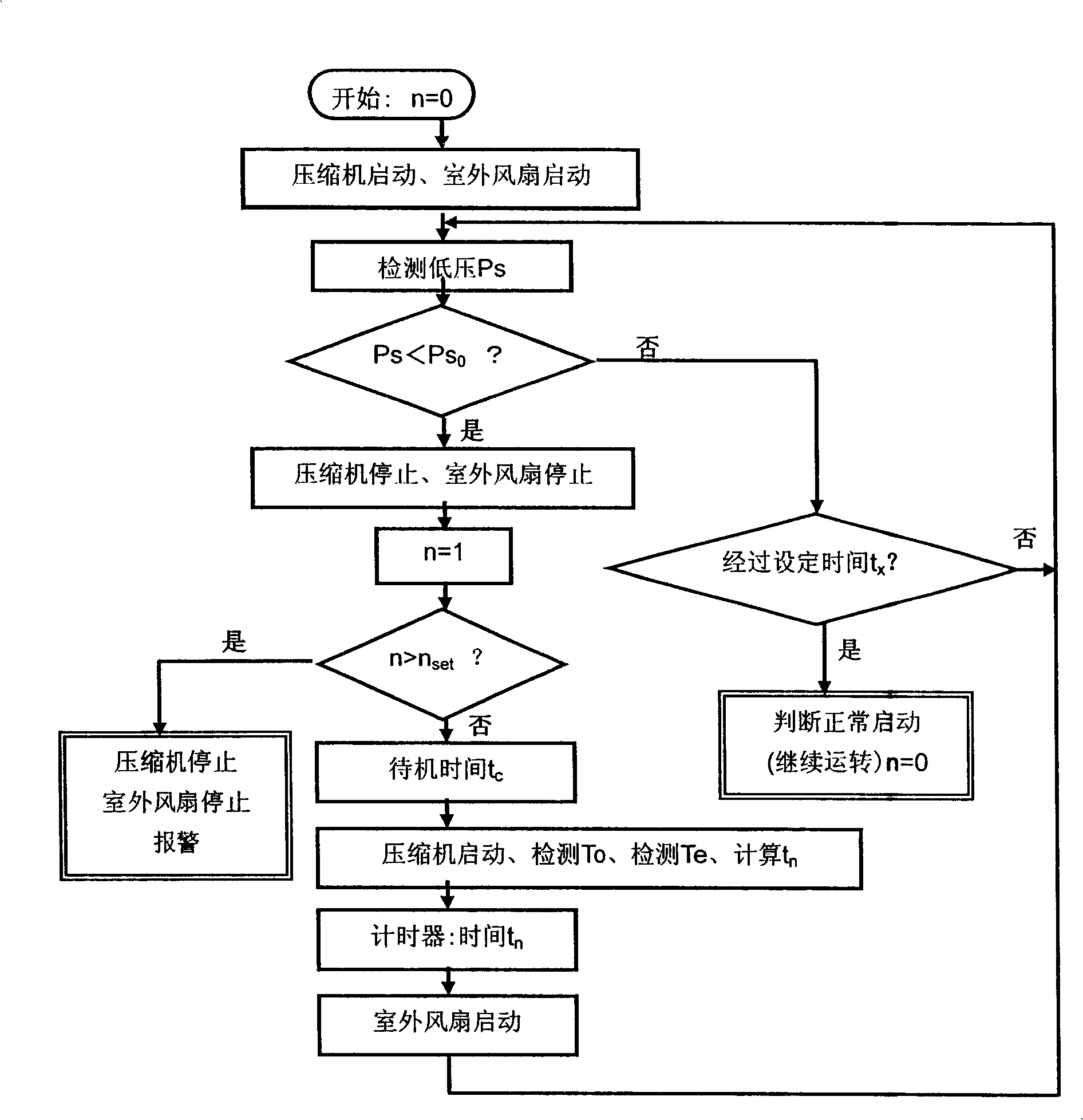

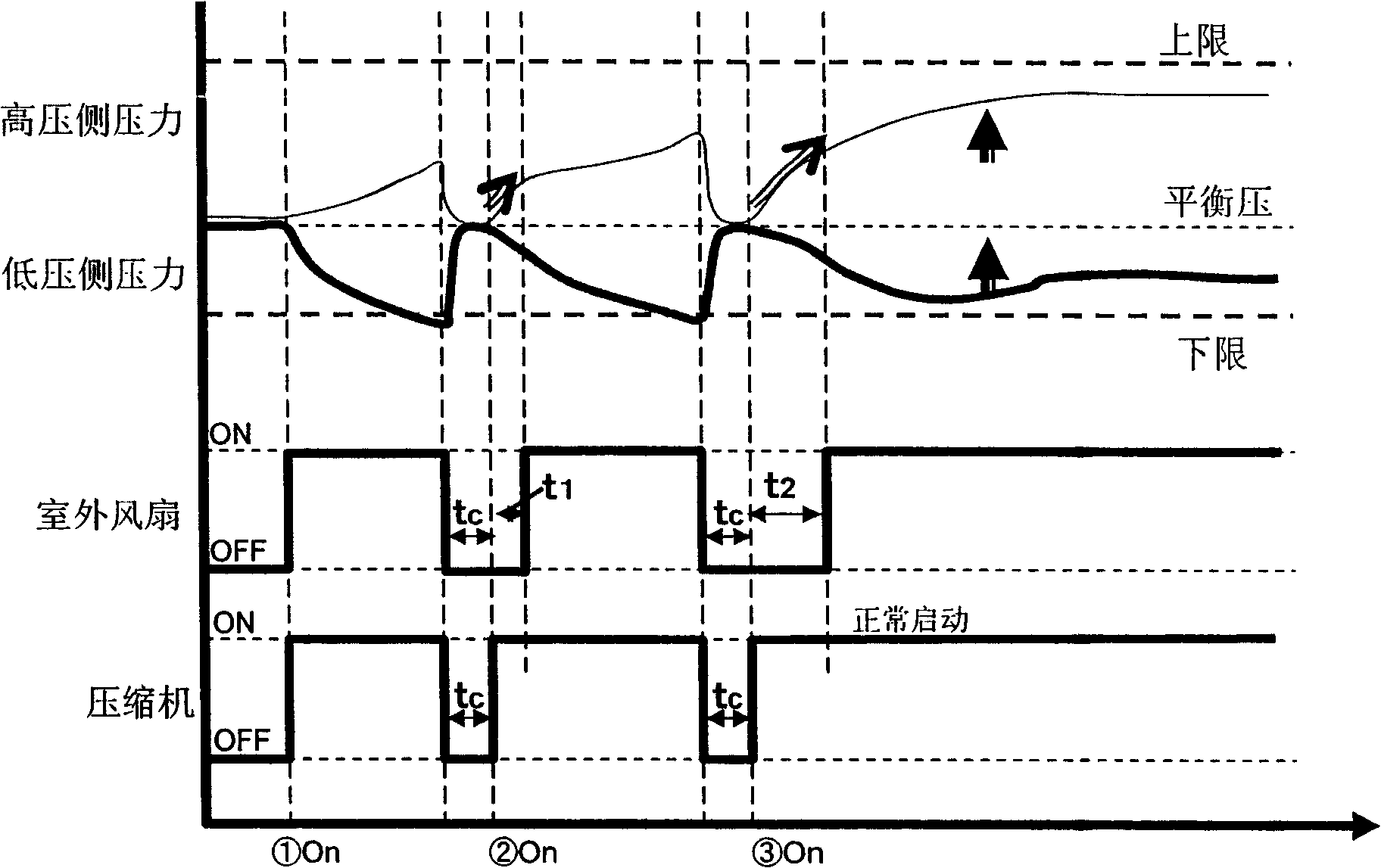

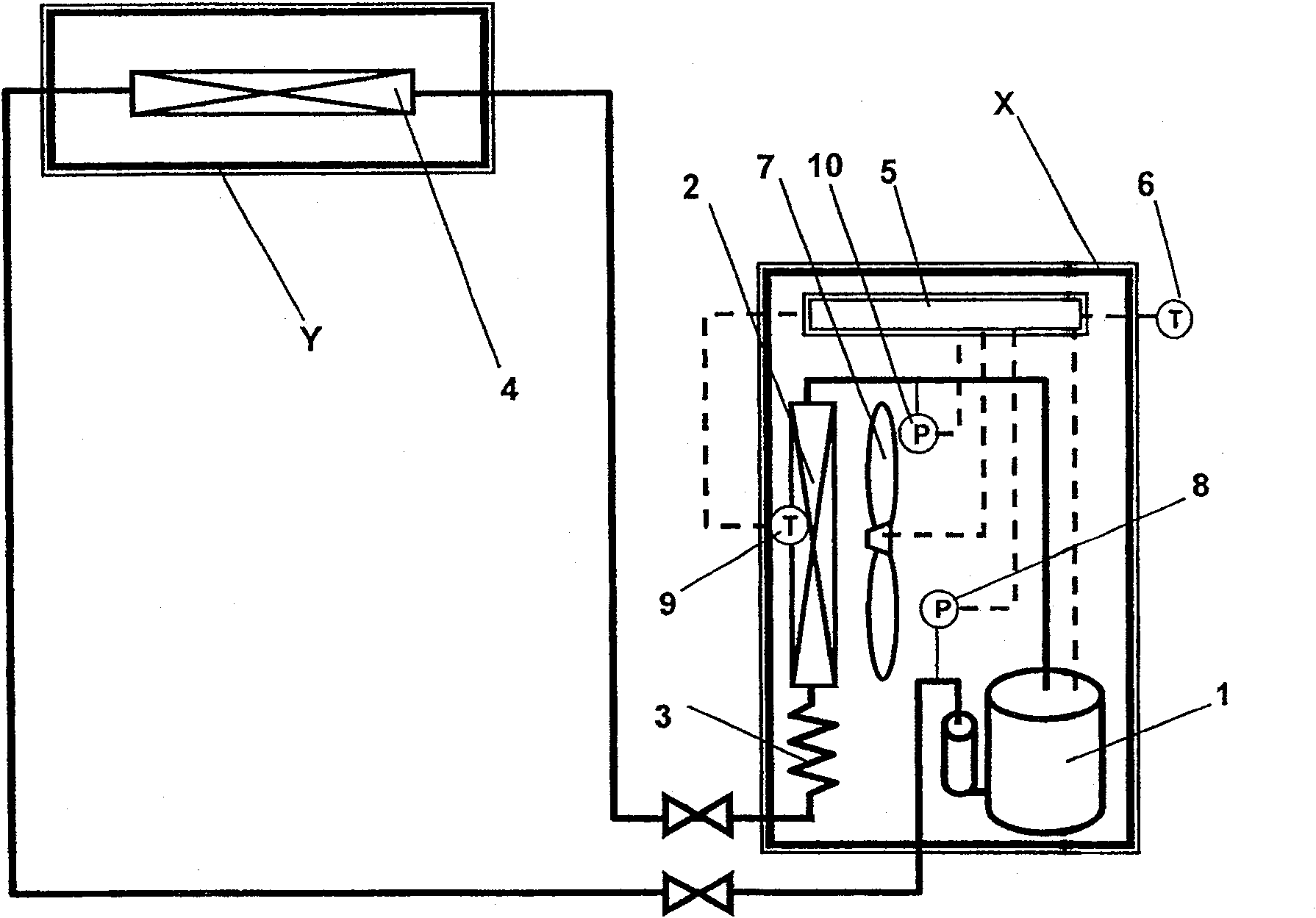

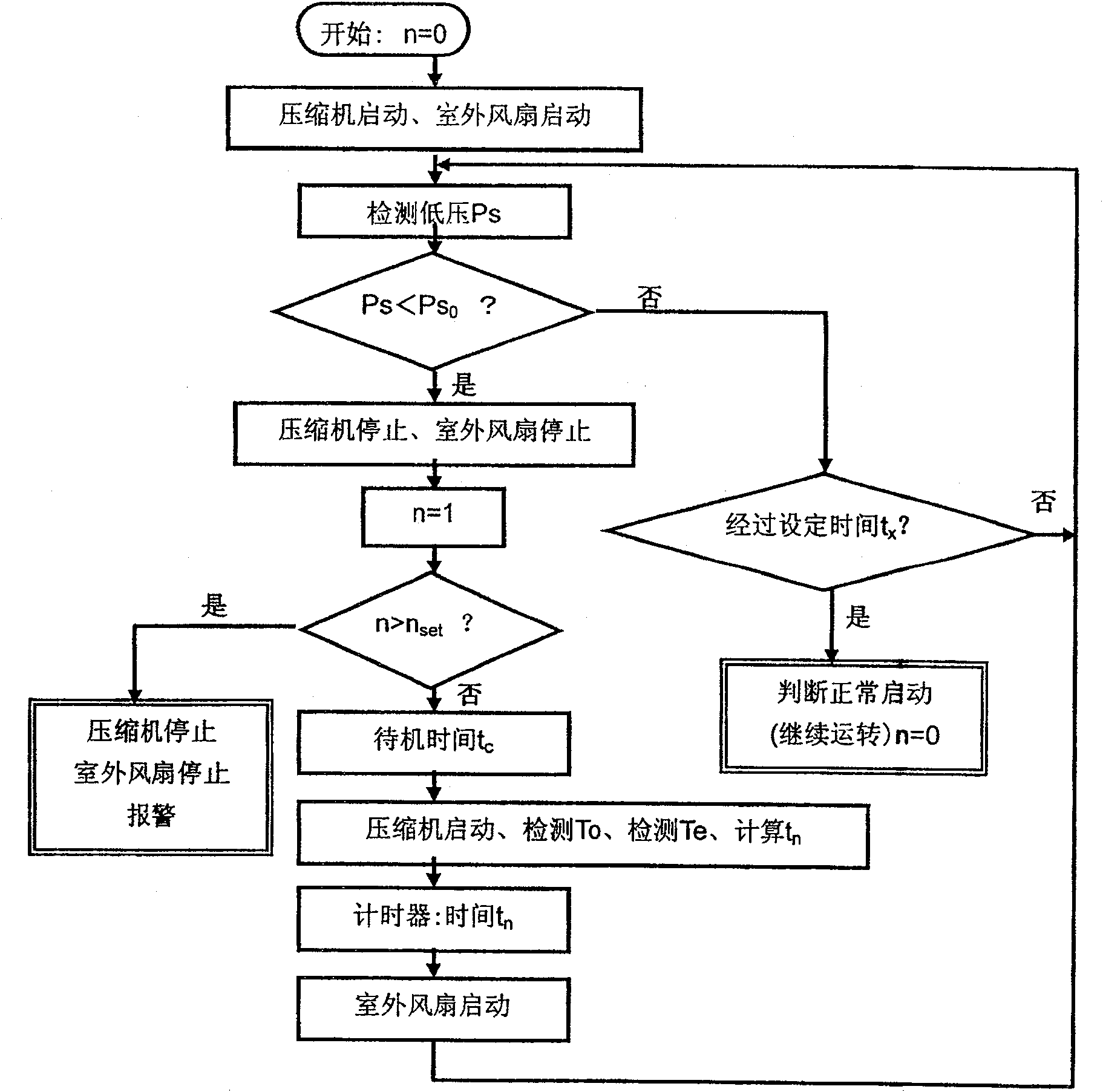

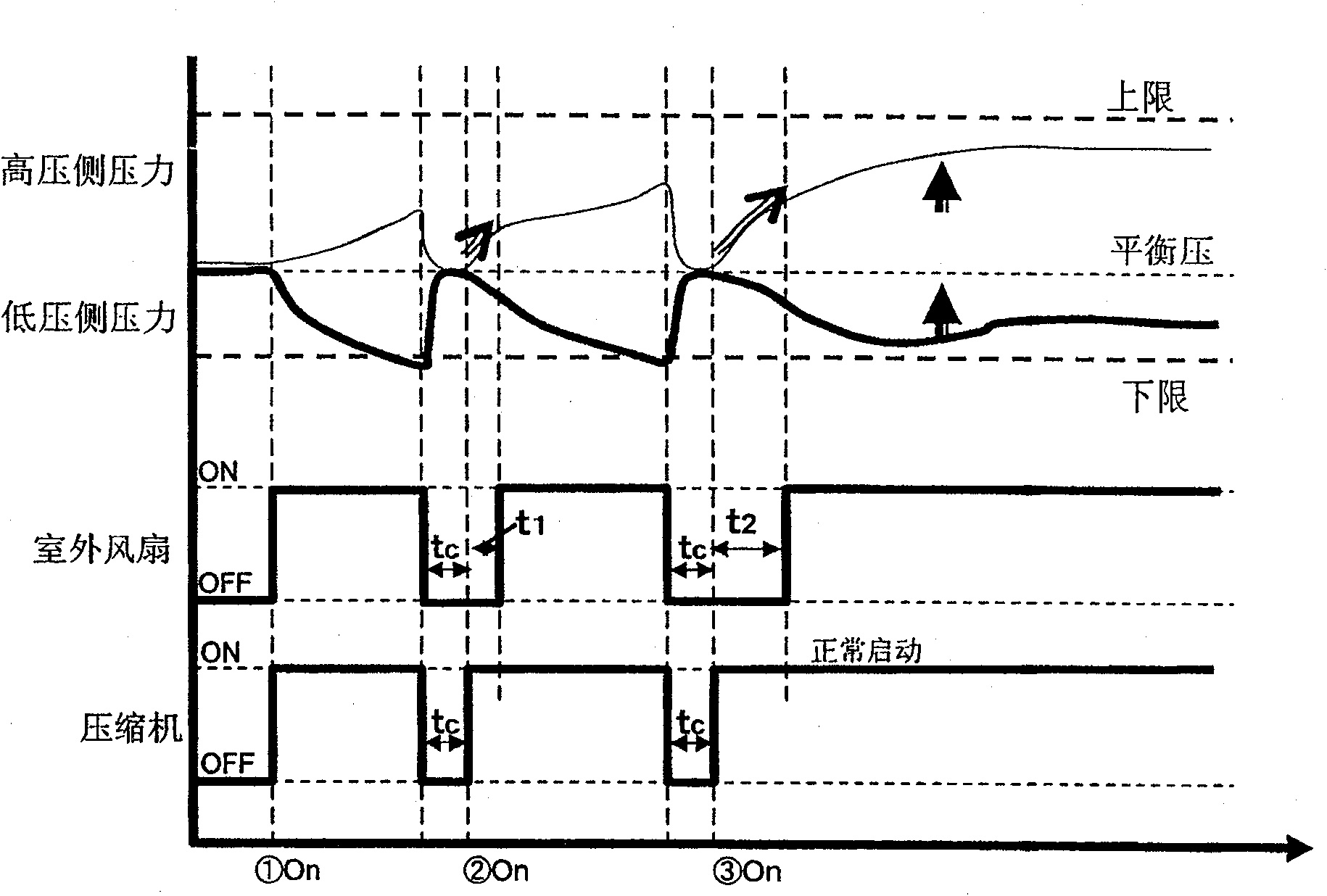

Air conditioner

InactiveCN101256011AReduce the number of starts and stopsSolve the problem of negative pressureSpace heating and ventilation safety systemsLighting and heating apparatusPressure generationEngineering

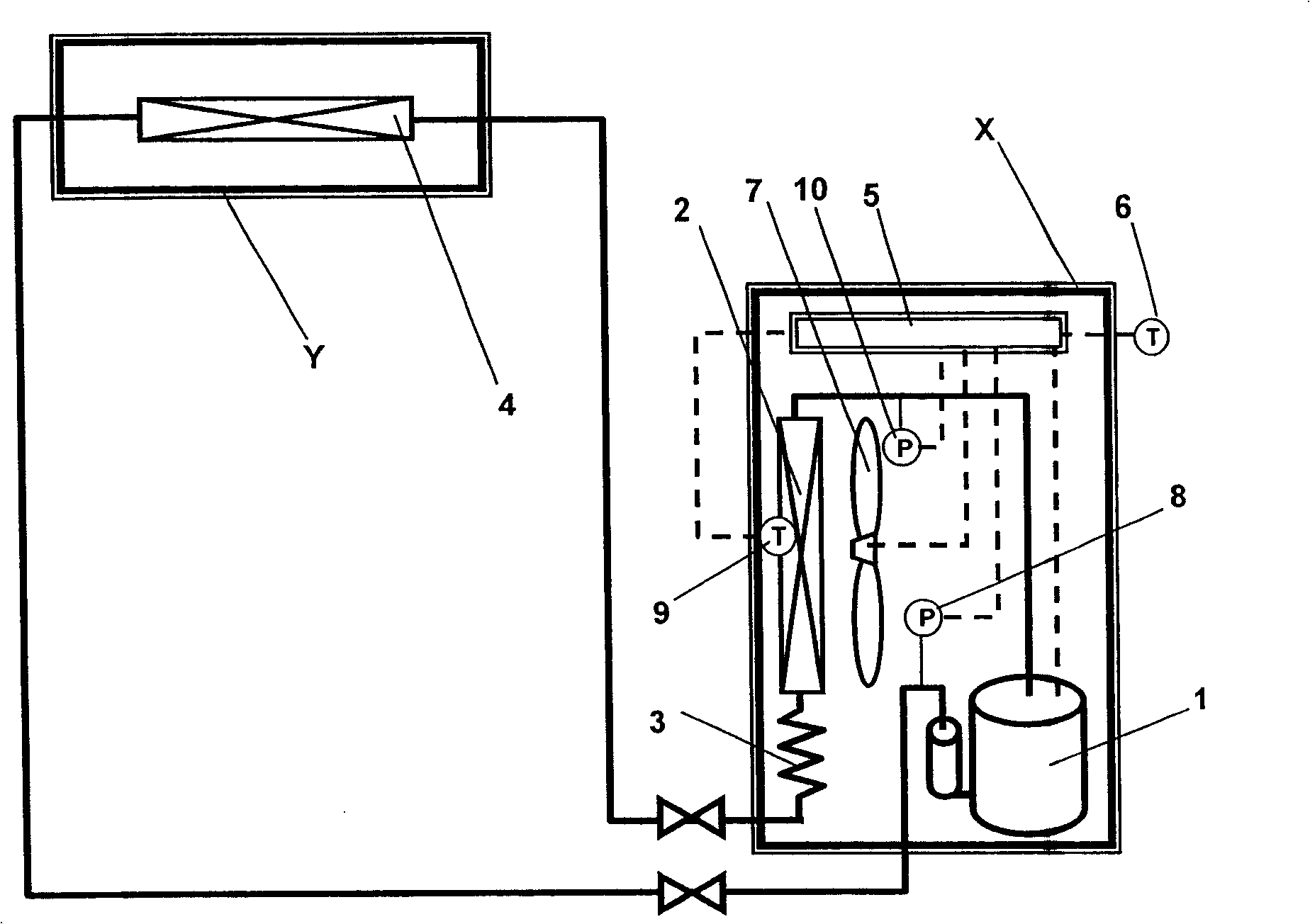

The invention provides an air conditioner comprising an indoor set and an outdoor set. The indoor set at least comprises an indoor heat exchanger, and the outdoor set at least comprises a compressor, an outdoor heat exchanger, a throttling device, an outdoor fan used for the outdoor heat exchanger, and a low pressure detection device at the inhalation side of the compressor, wherein a control device controlling at least the compressor and the outdoor fan is disposed in the outdoor set, stops the compressor when low pressure abnormality is detected by the low pressure detection device during the operation process of the air conditioner, and controls start of the outdoor fan at the same time according to times of low pressure generation of the compressor. The inventive air conditioner facilitates protection of the compressor, elongates life of the compressor and assures normal operation of the air conditioner.

Owner:PANASONIC CORP

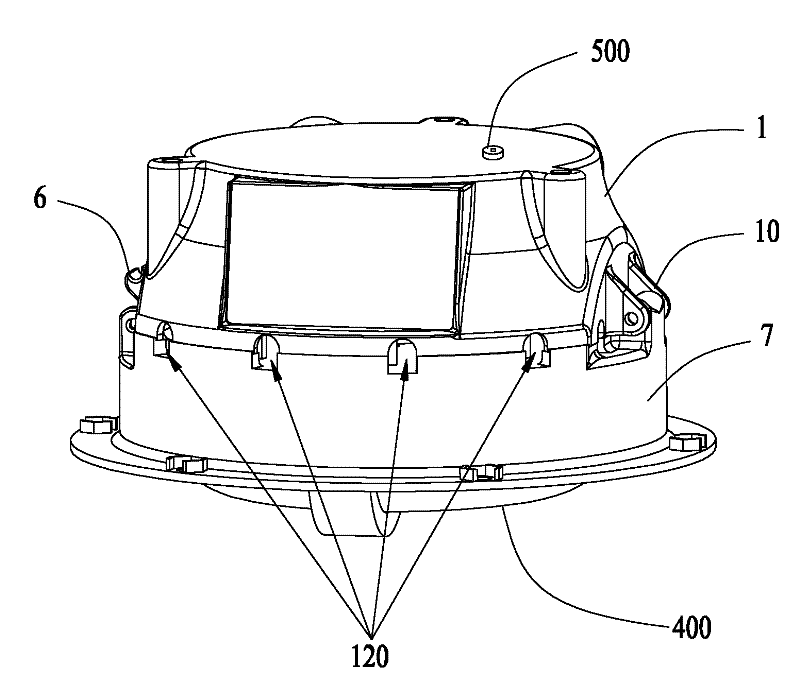

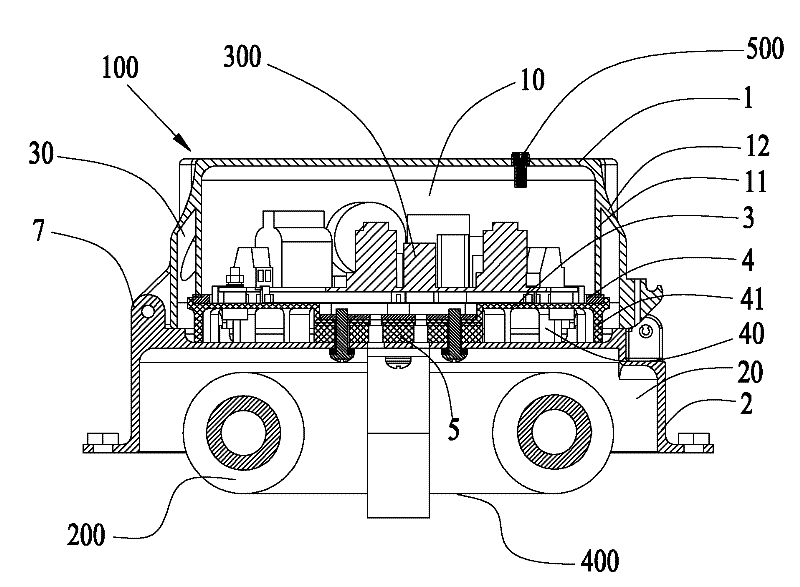

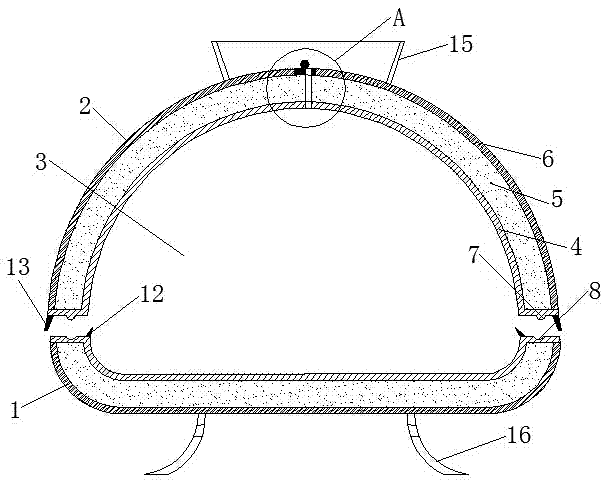

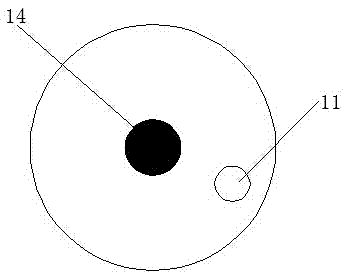

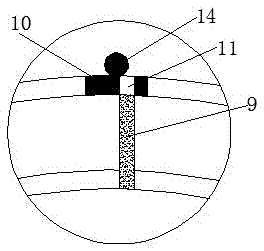

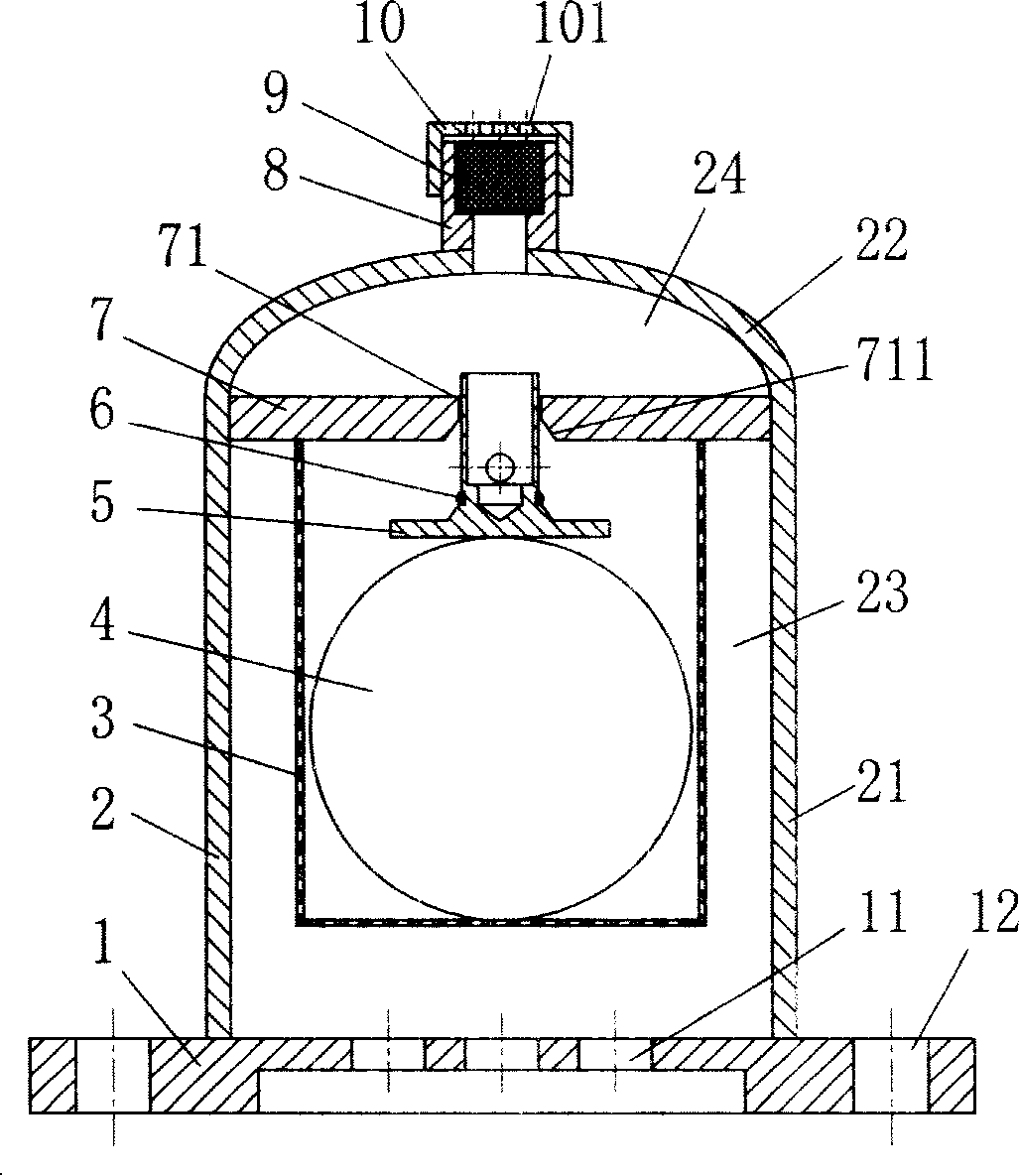

Light fixture

InactiveCN102691993ASolve the problem of negative pressureLighting heating/cooling arrangementsGas-tight/water-tight arrangementsAtmospheric pressureLight fixture

The invention relates to a light fixture. An explosive-proof respiratory device is disposed on a lower housing of the light fixture. A dustproof water-absorbing layer and an explosive-proof layer are disposed in a housing of the explosive-proof respiratory device, and an air pipe is disposed in the explosive-proof layer. On the one hand the dustproof water-absorbing layer can effectively separatedust and absorb water, and on the other hand the explosive-proof respiratory device can realize ventilation through the air pipe and balance the internal and external air pressure of the illuminationlight fixture to prevent water from being sucked into an electrical cavity of the light fixture in the presence of water. Thus the light fixture with the explosive-proof respiratory device can effectively solve the problem that the water is sucked into the light fixture owing to the negative pressure generated therein.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

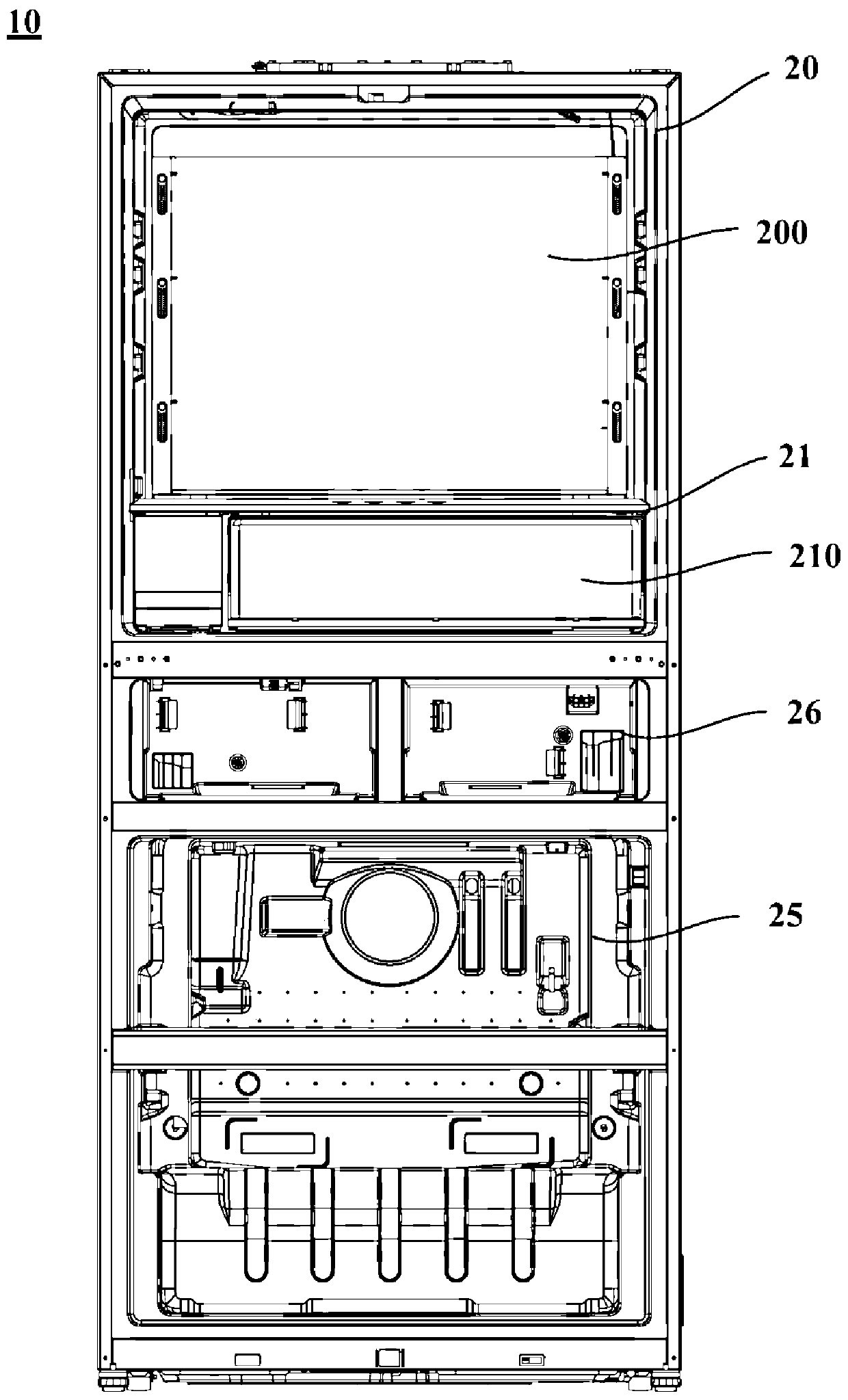

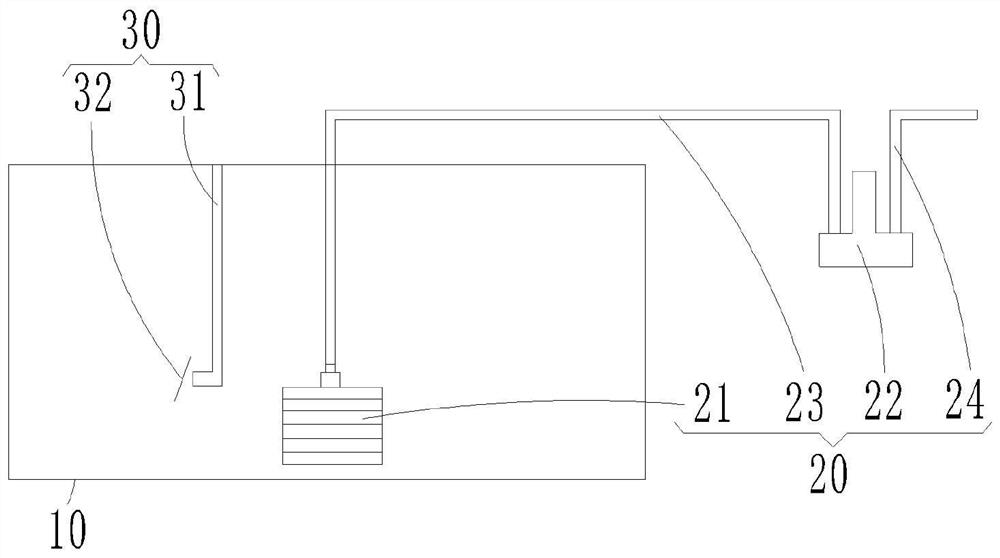

Refrigerating and freezing device

ActiveCN106802047AEasy to keep freshReduce contentLighting and heating apparatusDomestic refrigeratorsNitrogenProcess engineering

The invention provides a refrigerating and freezing device. The refrigerating and freezing device comprises a box body, a gas separator and a sucking pump, wherein storage spaces are defined in the box body, storage containers are arranged in the storage spaces, and gas regulating freshness retaining spaces are arranged in the storage containers; the gas separator is provided with a gas regulating film, a first gas collection cavity and a second gas collection cavity, the gas regulating film is configured into a manner that more oxygen, relative to nitrogen in air, in air in the first gas collection cavity penetrates the gas regulating film to enter the second gas collection cavity, the first gas collection cavity is controlled to communicate with storage chambers so that the air in the storage chambers can enter the first gas collection cavity, the first gas collection cavity is further controlled to communicate with the gas regulating freshness retaining spaces so that other gas, without the gas entering the second gas collection cavity through the gas regulating film, in the air entering the first gas collection cavity can enter the gas regulating freshness retaining spaces; and the sucking pump communicates with the second gas collection cavity through a pipeline so that the gas penetrating the second gas collection cavity can be promoted to be extracted out of the gas separator.

Owner:HAIER SMART HOME CO LTD

Coke oven chamber pressure regulation device

PendingCN107760329APrevent smoke and dust from spillingConducive to coke oven production and stable operationCoke oven safety devicesCoke oven gasProcess engineering

The invention discloses a coke oven chamber pressure regulation device and belongs to the field of coal coking equipment. The coke oven chamber pressure regulation device comprises an ascension pipe,a bridge pipe and a gas collecting tube, wherein the ascension pipe is connected with the bridge pipe; a pneumatic actuating tube is hinged onto the gas collecting tube; one end of the pneumatic actuating tube is hinged onto the gas collecting tube, and the other end of the pneumatic actuating tube is hinged to a turning plate axis; a turning plate is fixedly connected onto the turning plate axis;the pneumatic actuating tube is connected with a control device through a wire. According to the coke oven chamber pressure regulation device disclosed by the invention, with the adoption of a singlecoking chamber pressure regulation system, a stable pressure of a single coking chamber can be realized, lots of raw coke oven gas can be guided into the gas collecting tube during coaling so as to prevent smoke dust from overflowing. The phenomenon that the raw coke oven gas in the gas collecting tube flows backwards into the coke oven chamber in the tail coking period can be avoided, the problem that a negative pressure exists at the bottom of the coke oven chamber in the tail coking period can be solved, and coke oven operation production and steady operation can be facilitated.

Owner:安徽临涣化工有限责任公司

Heat energy circulating system of coating production line

ActiveCN101799204ASediment conveniencePrevent Negative Pressure ProblemsEnergy industryWater heatersPipingThermal energy

The invention relates to a heat energy circulating system of a coating production line, which comprises a heating water tank of a pre-treatment system of the coating production line and a drying box of a drying facility of the coating production line, wherein a stainless steel inner container and a combustor are fixed in a furnace body; the combustor is fixed to the lower part of the stainless steel inner container; an air outlet of a circulating calorifier is communicated with the furnace body; an atmosphere communicating vent opening into atmosphere directly is arranged at the top of the furnace body; a water outlet pipe and a return pipe are arranged on the stainless steel inner container; a hot-water circulating pump is arranged on the water outlet pipe; the water outlet pipe is communicated with hot-water inlets of the heating water tank of the pre-treatment system of the coating production line and the drying box of the drying facility of the coating production line; and hot-water outlets of the heating water tank of the pre-treatment system of the coating production line and the drying box of the drying facility of the coating production line are communicated with the return pipe. The heat energy circulating system has the advantages of completely eradicating the phenomenon of the negative pressure of a loop and a water outlet pipe and solving the problems of the cavitation of the water circulating pump and the water attack of the system along with good anti-explosion performance and convenient overhauling.

Owner:ZHEJIANG MINGQUAN INDAL COATING

Domestic hot dish thermal container

InactiveCN106974527AGood insulation effectImprove insulation performanceTable equipmentsThermal insulationEngineering

The utility model relates to a heat preservation box for household hot dishes, which is used for heat preservation of meals and belongs to the technical field of daily necessities. It includes a thermal insulation chassis, the upper part of the thermal insulation chassis is provided with a thermal insulation cover that can cover the upper part of the thermal insulation cover, and the thermal insulation cover and the thermal insulation chassis are covered to form a storage cavity for placing bowls and plates. It is characterized in that the thermal insulation cover, thermal insulation The chassis is composed of three layers, which are the inner stainless steel liner, the middle foam insulation layer, and the outer plastic shell. The invention has a simple and reasonable structure and is easy to manufacture, not only can be used to reduce the heat loss of meals, but also can be used to prevent dust splashing or mosquito bites, saves time and effort, is economical and practical, and has a broad market space.

Owner:徐长宝

Novel low suction pump

InactiveCN103089654AImprove efficiencyExtended service lifePriming pumpNon-positive displacement fluid enginesImpellerPulp and paper industry

The invention relates to the technical field of water pumps, in particular to a novel low suction pump which is characterized by comprising a pump cover, a pump body, an upper pipe outlet, a cooling lateral pipe, an impeller, a base, a mechanical sealing part, a shaft, a base rubber layer, a vacuum cavity and a vacuum sealing part. The vacuum sealing part is arranged on the periphery of the shaft, the vacuum cavity is arranged on the lower portion of the pump body, and the base rubber layer is arranged on the base and wraps the whole base. When the water pump operates, the novel low suction pump and the water surface form vacuum so that the novel low suction pump can work without water priming and operation efficiency of the water pump is improved.

Owner:SHANGHAI GUANMIN ENVIRONMENTAL TECH

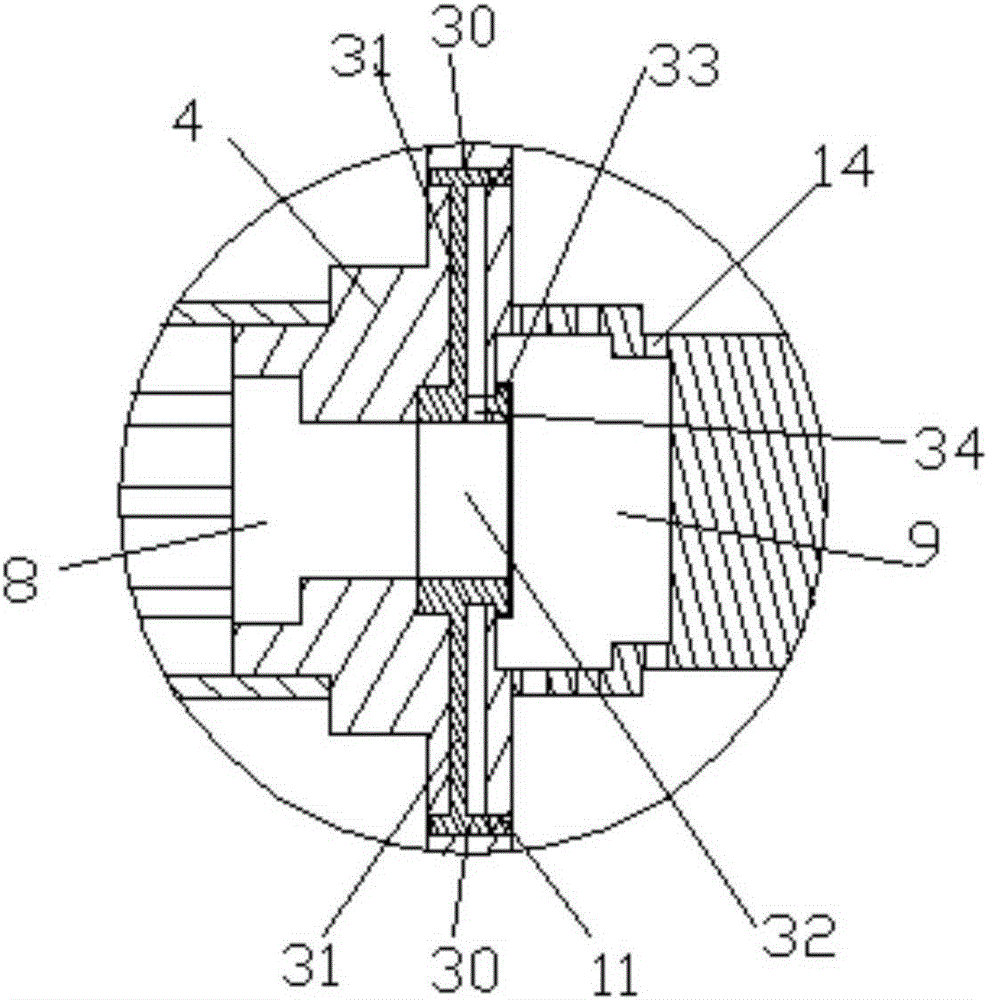

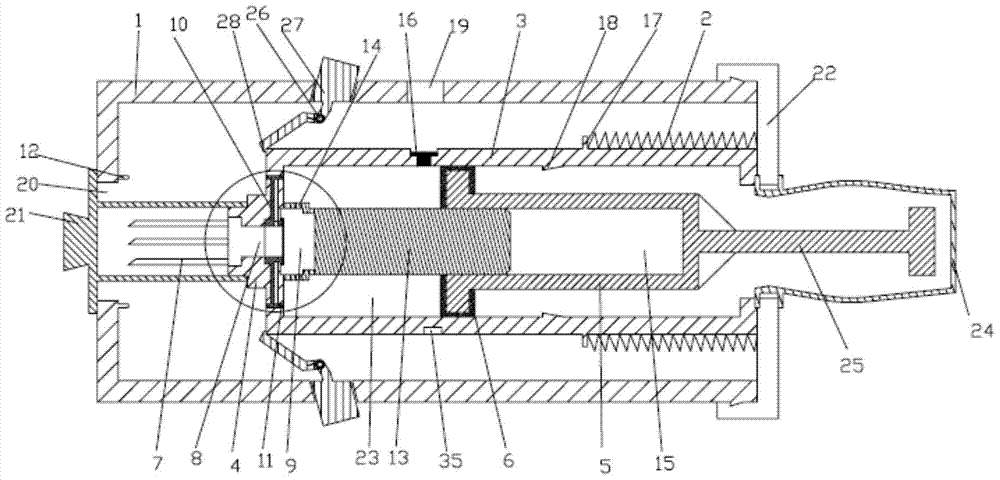

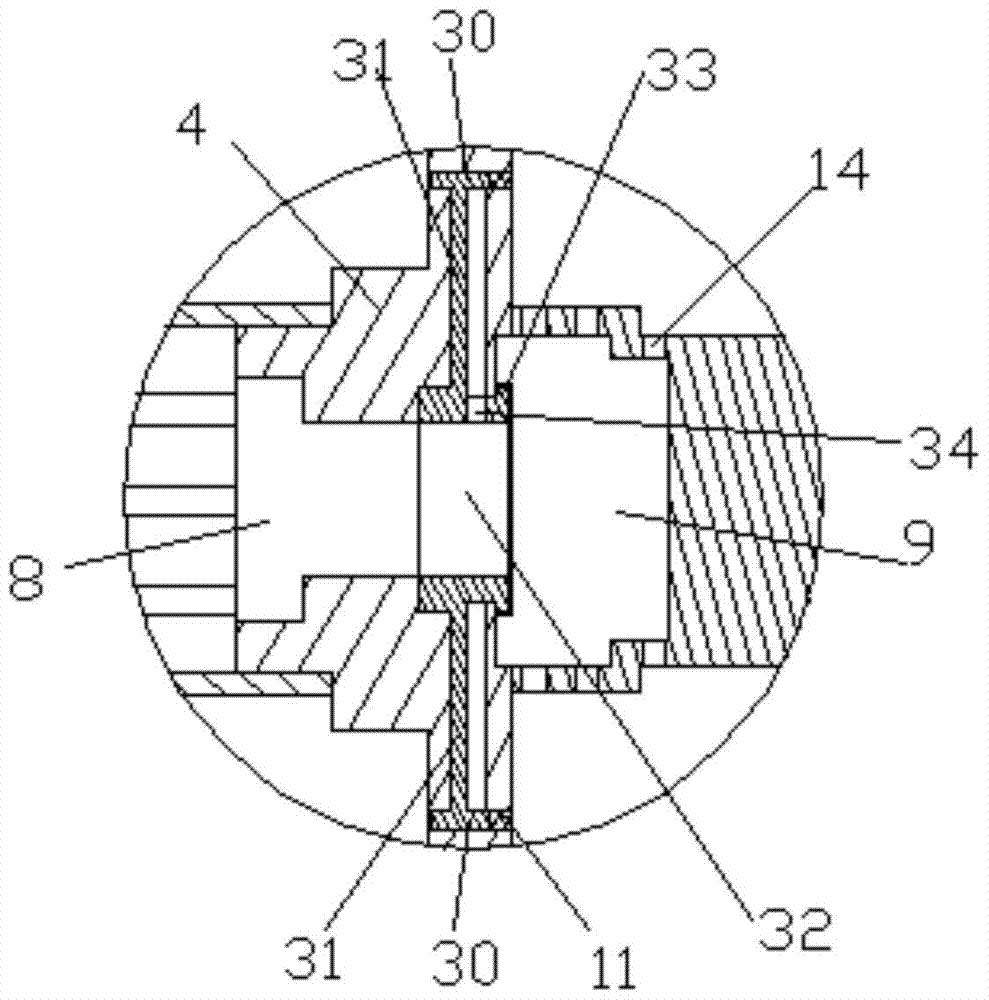

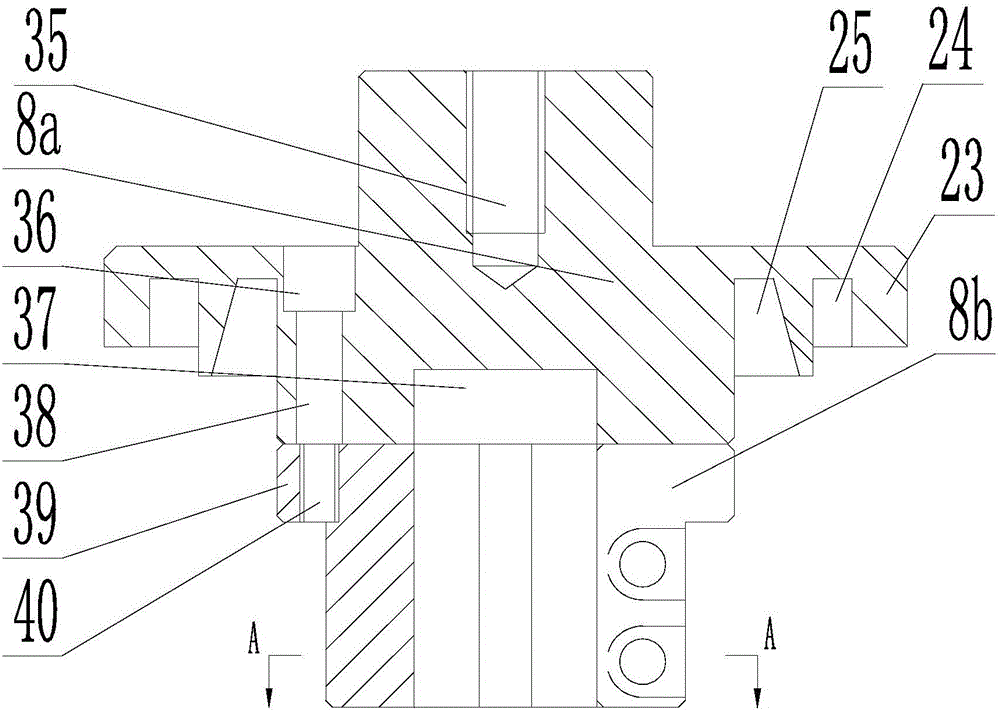

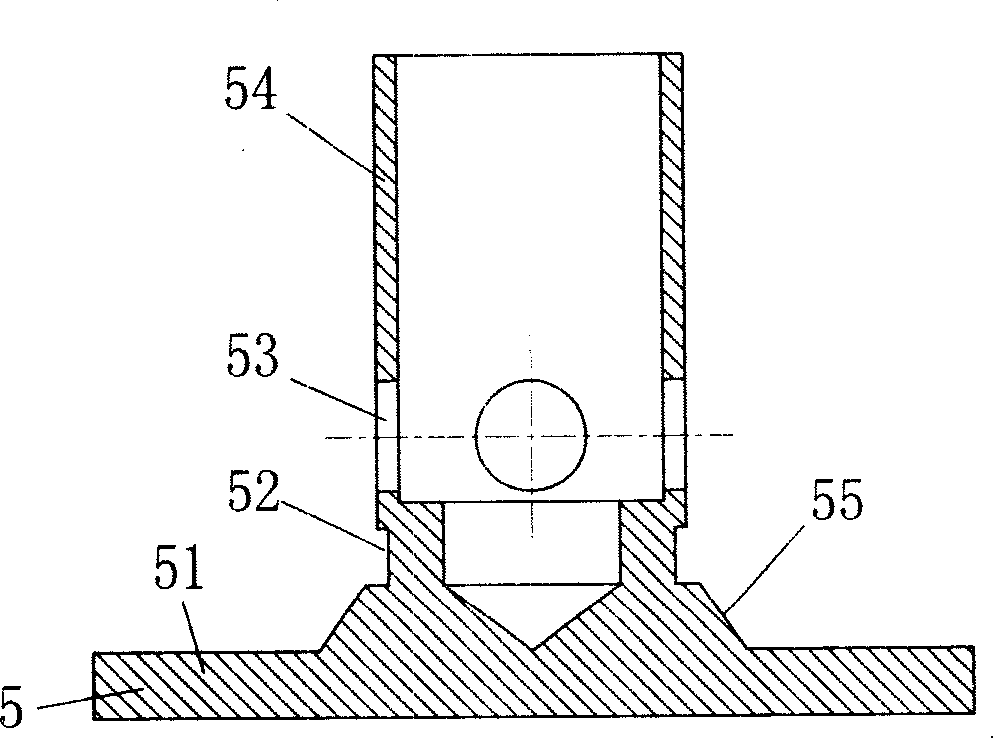

Puncture outfit used in parathyroid hormone or lymph gland operation

ActiveCN105167810AAvoid damageImprove accuracySurgical needlesVaccination/ovulation diagnosticsEngineeringParathyroid hormone

The invention relates to a puncture outfit used in a parathyroid hormone or lymph gland operation. The puncture outfit comprises a shell, an injection device arranged in the shell, an eccentric pressing component and a pressing control structure. The eccentric pressing component is arranged between the injection device and the inner wall of the shell, and the eccentric pressure acts on the injection device so that the injection device can pop out of shell to conduct puncturing. The pressing control structure is arranged between the shell and the injection device and can prevent the injection device from popping out, and blocking to the injection device is released after the pressing control structure is pressed. The puncture outfit used in the parathyroid hormone or lymph gland operation is simple in structure, fast and accurate in punching, convenient to operate, low in cost, small in damage to the human body and short in result obtaining time.

Owner:无锡市江原实业技贸有限公司

Fuel gasifier of diesel engine

InactiveCN1614219ASolve the preheating problemSolve the problem of negative pressureMachines/enginesThermal treatment of fuelEngineeringCarburetor

A fuel oil carburetor for diesel engine is disclosed, which can improve the low-temp start performance and increase the uniformity of air-oil mixture, resulting in low oil consumption and less pollution.

Owner:李兆宇

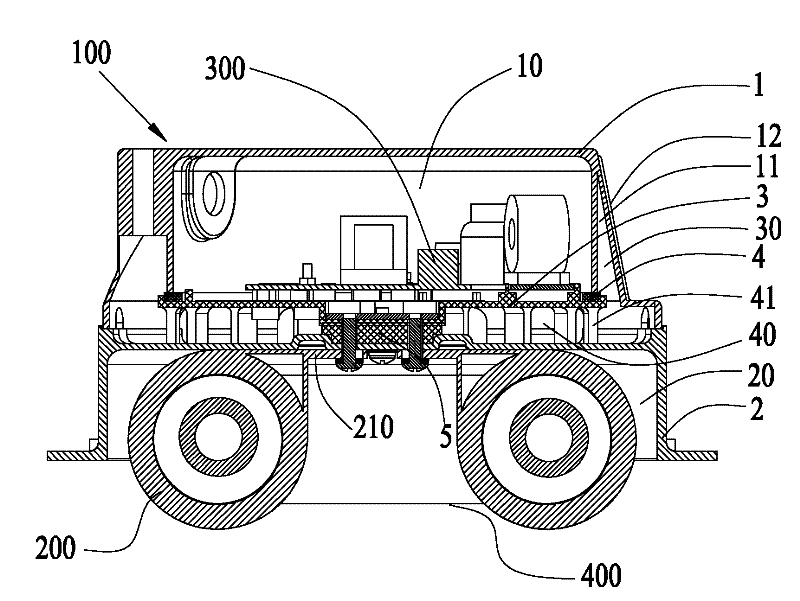

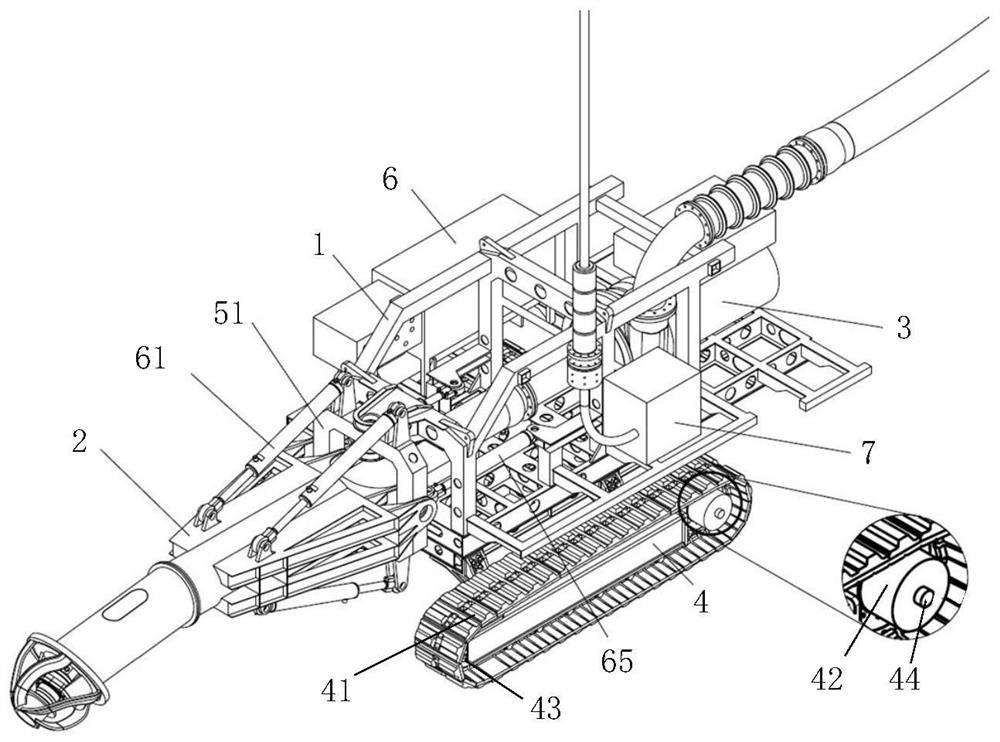

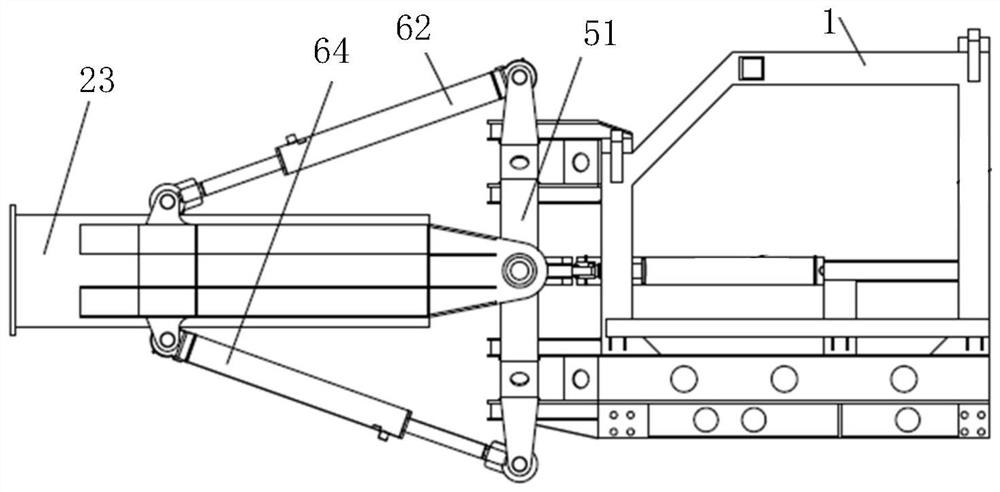

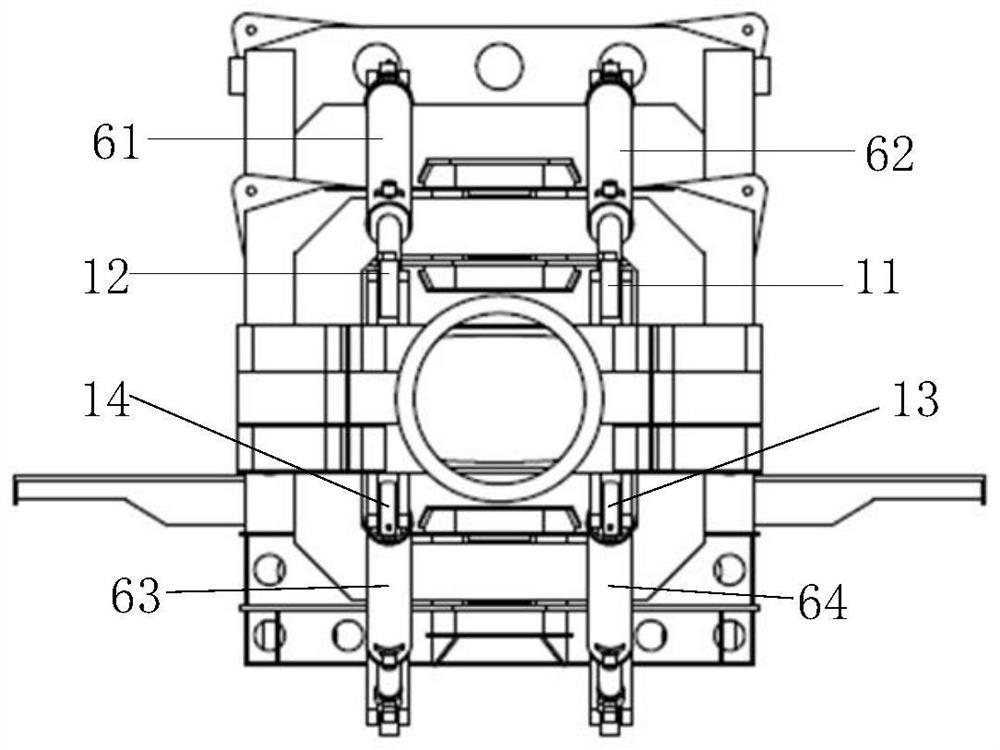

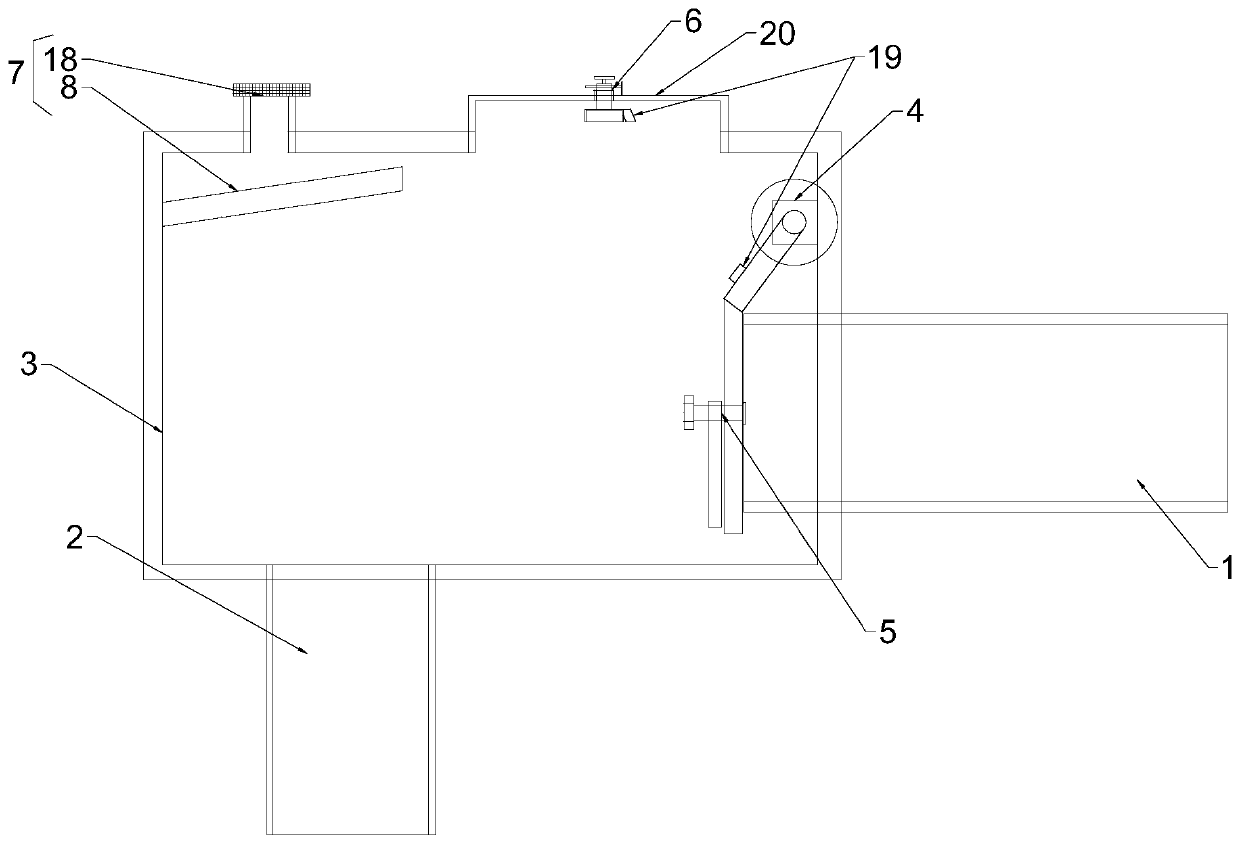

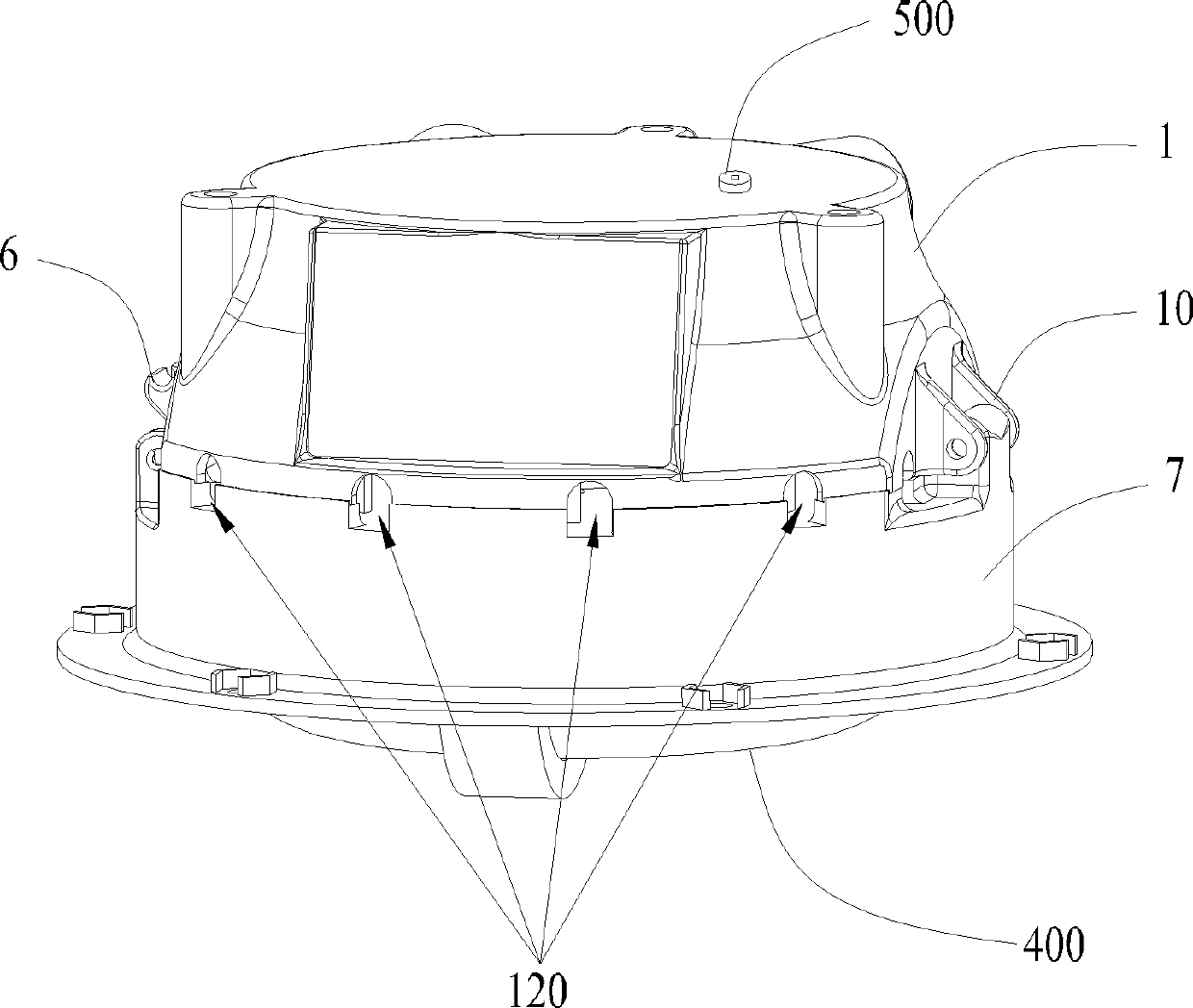

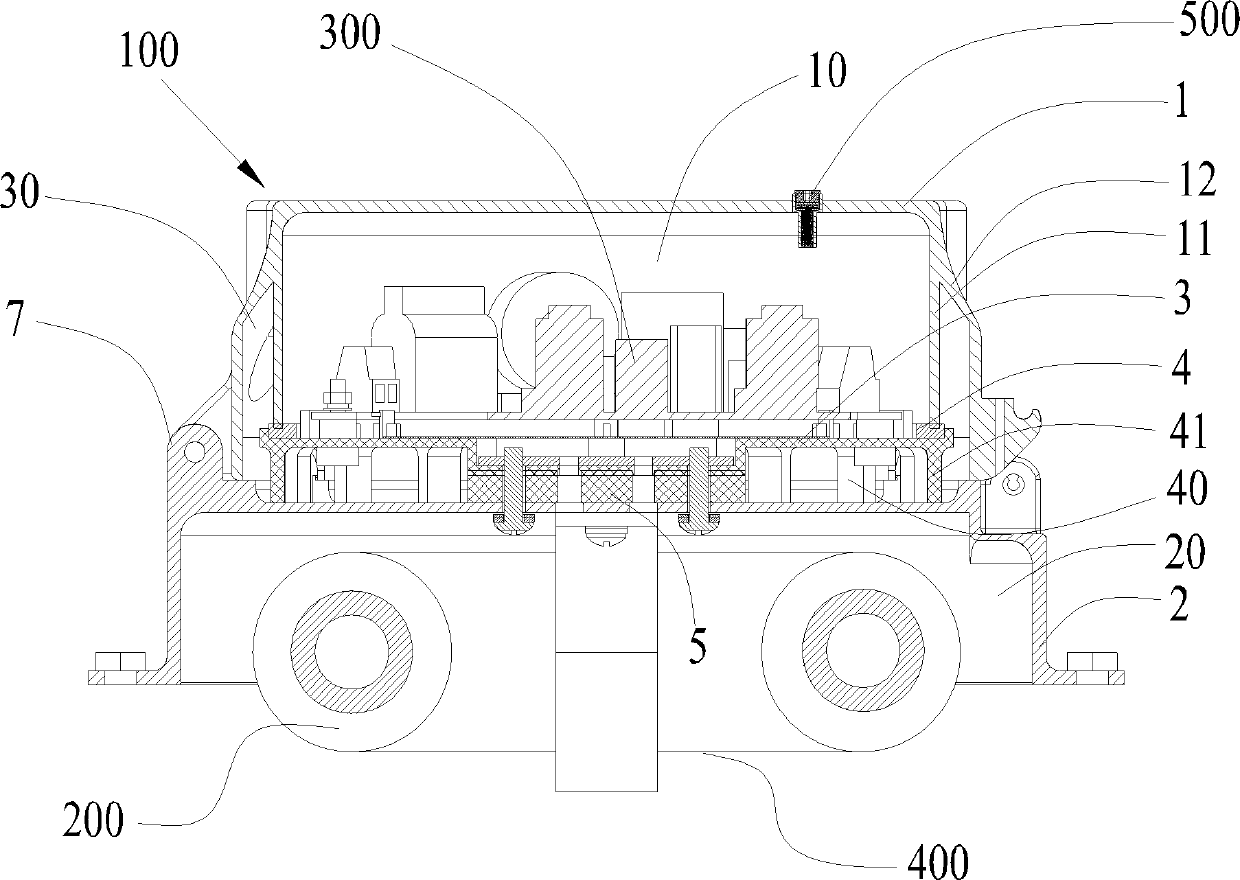

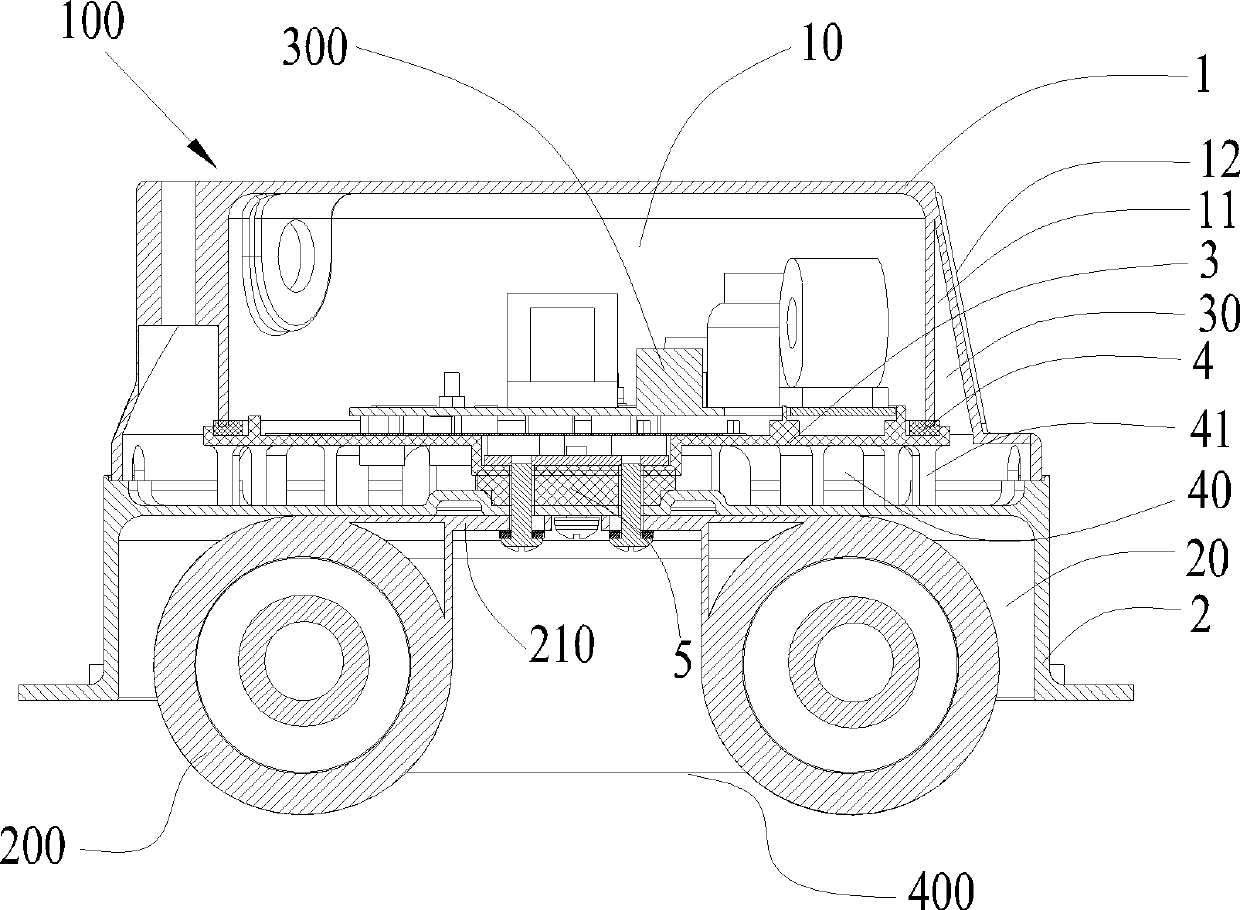

Underwater unmanned self-walking cutter suction device

ActiveCN113374004ARealize flexible operationSolve the problem of negative pressureMechanical machines/dredgersVehicle frameMarine engineering

The invention provides an underwater unmanned self-walking cutter suction device. The device comprises an excavation system, a conveying system and a walking system, wherein the excavation system comprises a frame, a cutter ladder and a transverse swing frame; the cutter ladder is installed on the frame through the transverse swing frame, the excavation end of the cutter ladder can move relative to the frame in a rotating track parallel to a first plane and / or a rotating track parallel to a second plane, and the first plane is perpendicular to the second plane; the conveying system is installed on the frame, one end of the conveying system is connected with the excavation system, and the other end of the conveying system extends to the outside of the frame; and the walking system is installed at the bottom of the frame and used for driving the excavation system to walk. By adopting the cross axle frame structure in which the transverse swing frame, the cutter ladder and a frame body are hinged, the left-right transverse swing and up-down pitching actions of the cutter ladder are realized, so that the cutter suction machine can realize flexible operation in an underwater complex area.

Owner:SHANGHAI JIAO TONG UNIV

Gravity self-adjusting hydraulic pressure stabilizing device

The invention belongs to the technical field of adjusting equipment, and particularly discloses a gravity self-adjusting hydraulic pressure stabilizing device. The device comprises a water inlet pipeline, a water outlet pipeline, an adjusting box, a fixed fulcrum with a rotary mechanism, a flow limiting device, an external water resistance adjusting device and a pressure balancing device. The fixed fulcrum with the rotary mechanism is arranged above a water inlet in the adjusting box, the flow limiting device is arranged on the fixed fulcrum with the rotary mechanism and comprises a connectingpiece, a water flow resistance plate and a gravity resistance adjusting block, the water flow resistance plate is mounted on the fixed fulcrum with the rotary mechanism through the connecting piece,the water flow resistance plate is connected with the connecting piece at an angle, the water flow resistance plate is vertically placed on a water inlet of the water inlet pipeline, and the gravity resistance adjusting block is arranged on the water flow resistance plate.

Owner:江苏多纬智控科技有限公司

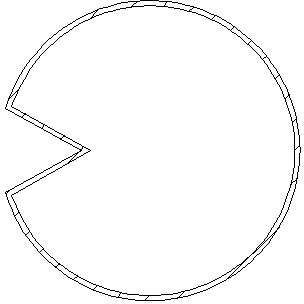

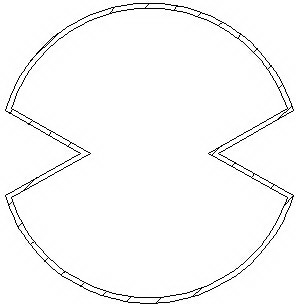

Anti-negative-pressure folding straw

The invention provides an anti-negative-pressure folding straw. The anti-negative-pressure folding straw is characterized by adopting a thin-wall hollow-tube-shaped structure, wherein the section of the straw is provided with at least one lateral inwards-folded section; the section of the straw is of a circular thin-wall structure, and one section of one side is inwards-folded. The anti-negative-pressure folding straw provided by the invention is simple in structure and low in manufacturing cost; the straw can be flatly pressed and folded when not in use, and heaved by pinching when in use; when a plastic film or an aluminium foil to package a drink, a negative-pressure problem is solved by ventilation due to the existence of a notch.

Owner:崔春枝

Intraoperative trocar for parathyroid or lymph nodes

ActiveCN105167810BImprove accuracyImprove stabilitySurgical needlesVaccination/ovulation diagnosticsBiomedical engineeringInjection device

The invention relates to a puncture device for parathyroid gland or lymph node surgery, which includes a casing; an injection device, arranged in the casing; a biasing member, arranged between the injection device and the inner wall of the casing, and its biasing force Acting on the injection device, causing the injection device to pop out of the casing for puncturing; the pressing control structure, arranged between the casing and the injection device, can prevent the injection device from ejecting, and release the injection device after pressing. With respect to the blocking of the injection device, the parathyroid or lymph node intraoperative puncture device of the present invention has the advantages of simple structure, fast and accurate puncture, convenient operation, low cost, little damage to the human body, and short time for obtaining results.

Owner:无锡市江原实业技贸有限公司

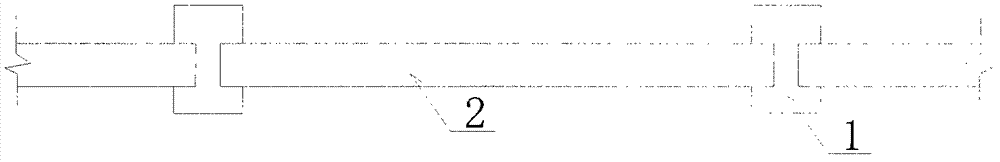

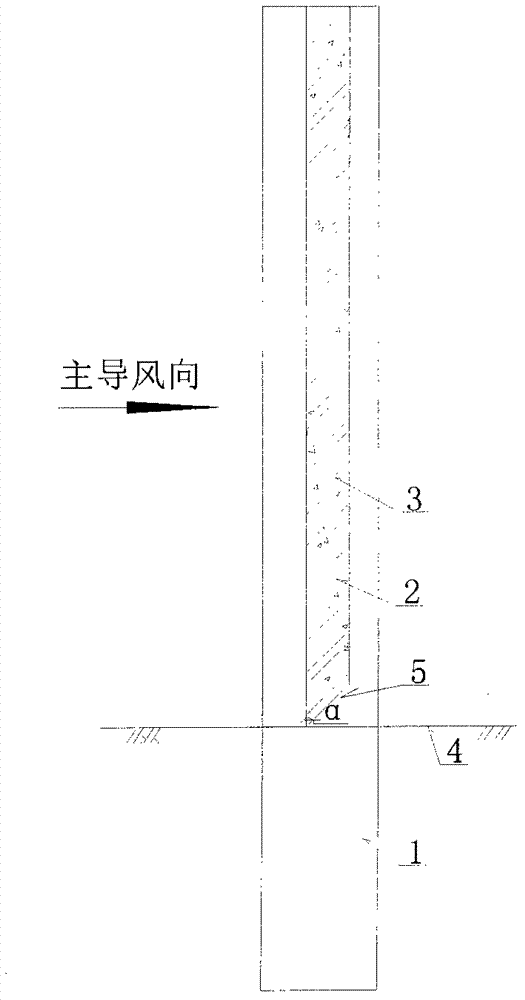

Inclined inserting plate type sand blocking wall

InactiveCN102505643BImprove structural strengthIncreased durabilityProtective constructionSoil preservationStructural engineeringNarrow angle

The invention discloses a high vertical type sand barrier device, namely an inclined inserting plate type sand blocking wall, which comprises upright posts and a plate type blocking body fixed among upright posts, wherein one ends of the upright posts are buried in ground and the other ends of the upright posts extend out of the ground; the plate type blocking body fixed among the upright posts is composed of separated inserting plates by lamination; and an air channel with an included angle of 30-60 degrees with the horizontal plane is reserved between each lamination layers of each inserting plate. The inserting plates used by the embodiment of the invention have the shape, of which the cross section is a diamond with narrow angle alpha of 30-60 degrees and the longitudinal section is a concave shape with an opening; under the arrangement conditions of the sand blocking wall, the diamond narrow angle alpha of each inserting plate points to wind direction; and under an assembling state, the concave inserting plates are inserted into fixing grooves of the upright posts so as to be fixed, and an air channel with an included angle with the horizontal plane is formed between the straight of the opening of one inserting plate and the top plane of another inserting plate contacting the inserting plate.

Owner:NORTHWEST RES INST CO LTD OF C R E C

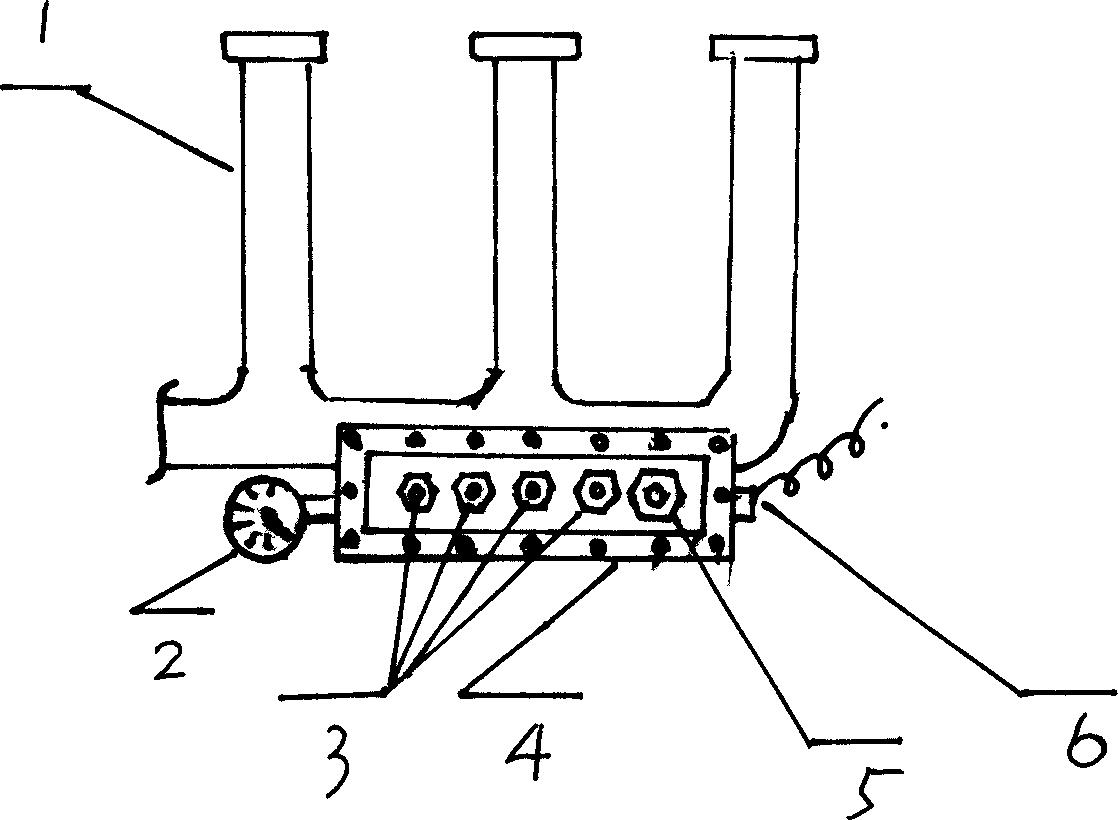

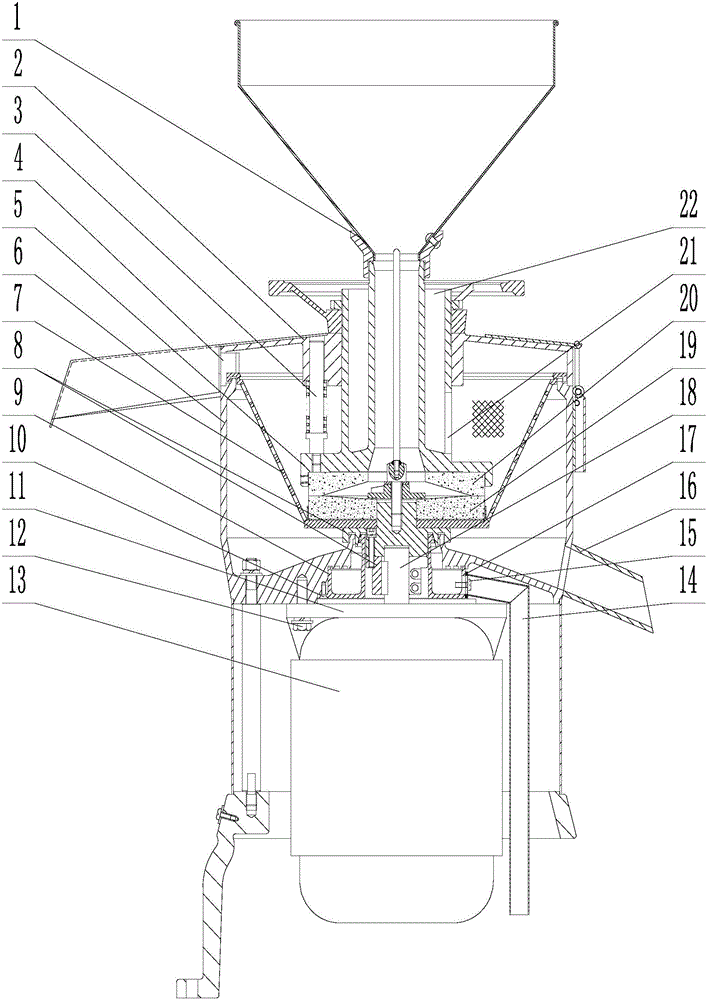

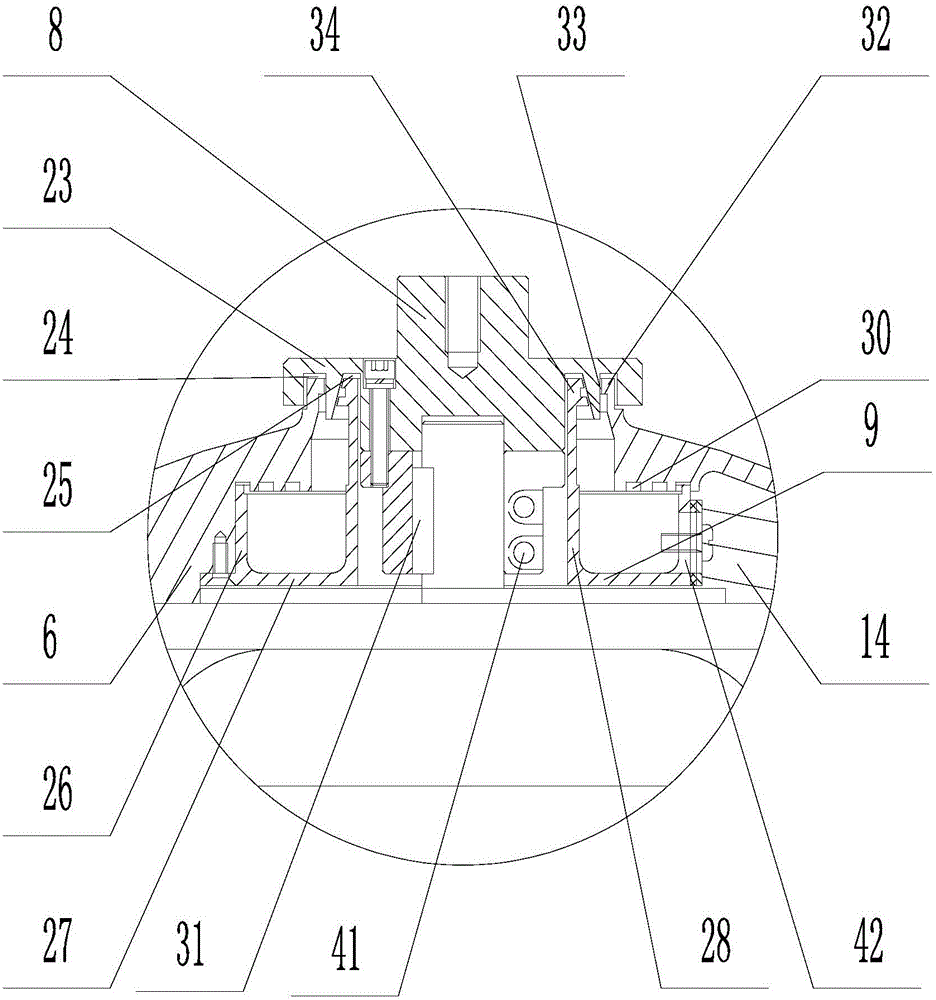

A refiner with air inlet and outlet grooves that can be stopped for cleaning

ActiveCN103816960BSimple and reasonable structureLow costCocoaGrain treatmentsSlagElectric machinery

The invention relates to a pulping machine, in particular to a pulping machine provided with an air inlet groove and an air outlet groove and capable of being cleaned in machine halt. The pulping machine has the advantages of high working efficiency, low cost, and capability of saving energy. The pulping machine comprises a hopper, a cylinder cover, a cylinder body, a separation basket, a fixed grinding seat, a motor casing and a motor, wherein the cylinder cover is arranged at the top of the cylinder body; the hopper is arranged at the top of the cylinder cover; the motor is arranged at the bottom of the cylinder body; the separation basket with leak holes is arranged in the cylinder body; the fixed grinding seat is arranged below the hopper; the lower part of the fixed grinding seat is arranged in the cylinder body; an upper grinding wheel is fixed at the bottom of the fixed grinding seat, and corresponds to a lower grinding wheel; a motor shaft of the motor is fixedly connected with the separation basket and the lower grinding wheel through the motor casing; a pulp outlet is formed in the bottom of the cylinder body; a slag hole is formed in the cylinder cover. The pulping machine is characterized in that at least one air inlet groove and at least one air outlet groove are formed in the fixed grinding seat, a water pan is arranged below a through hole in the bottom of the cylinder body, a water leak hole is formed in the water pan, and the area of the water leak hole is larger than that of a gap formed by the motor casing and the bottom of the cylinder body.

Owner:沈阳市食品机械制造有限公司

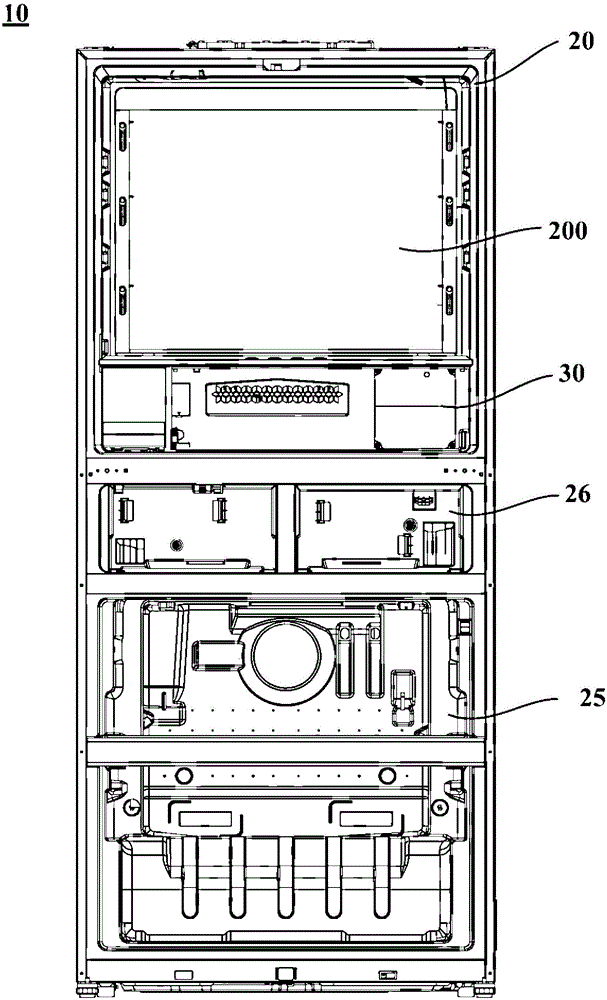

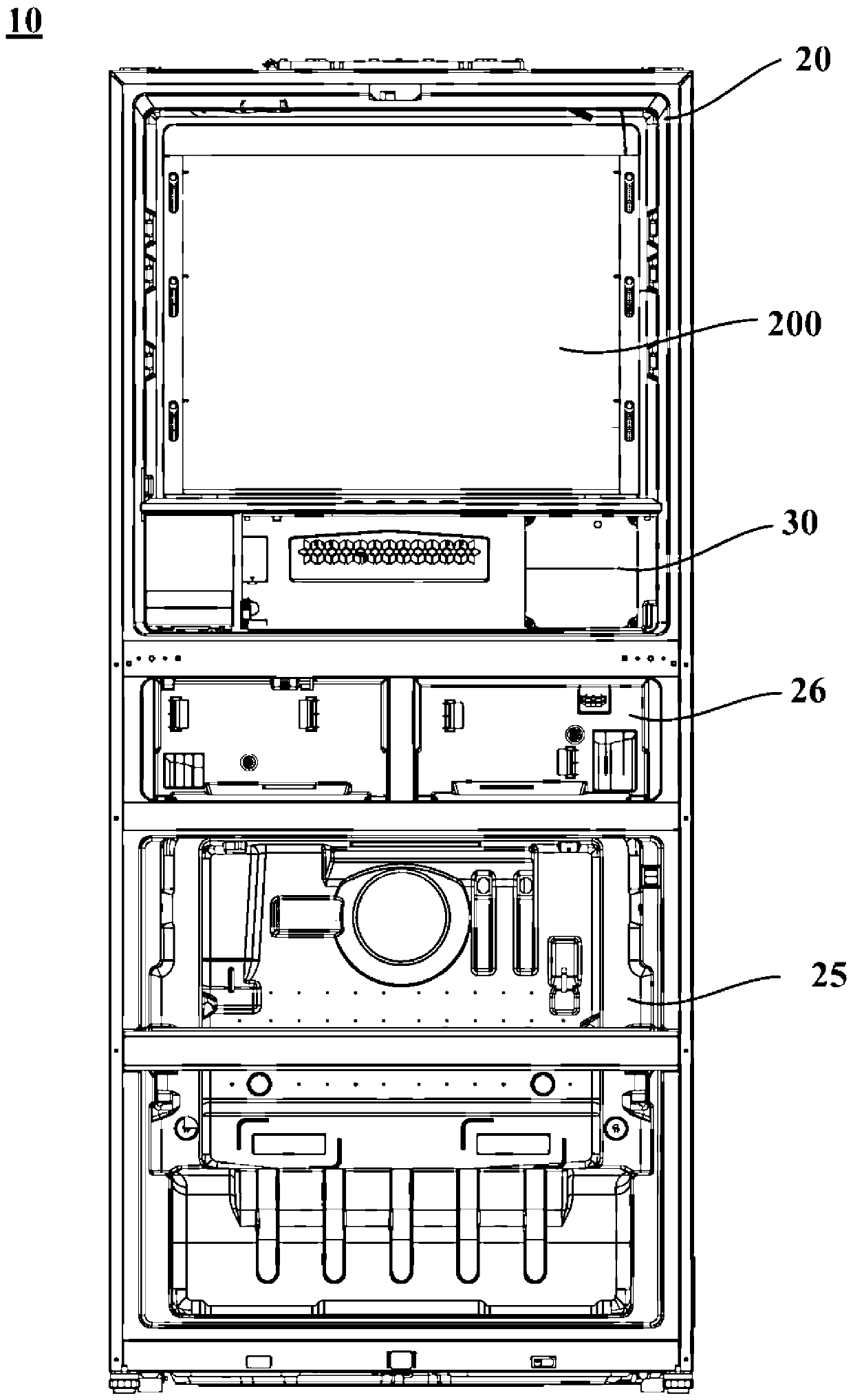

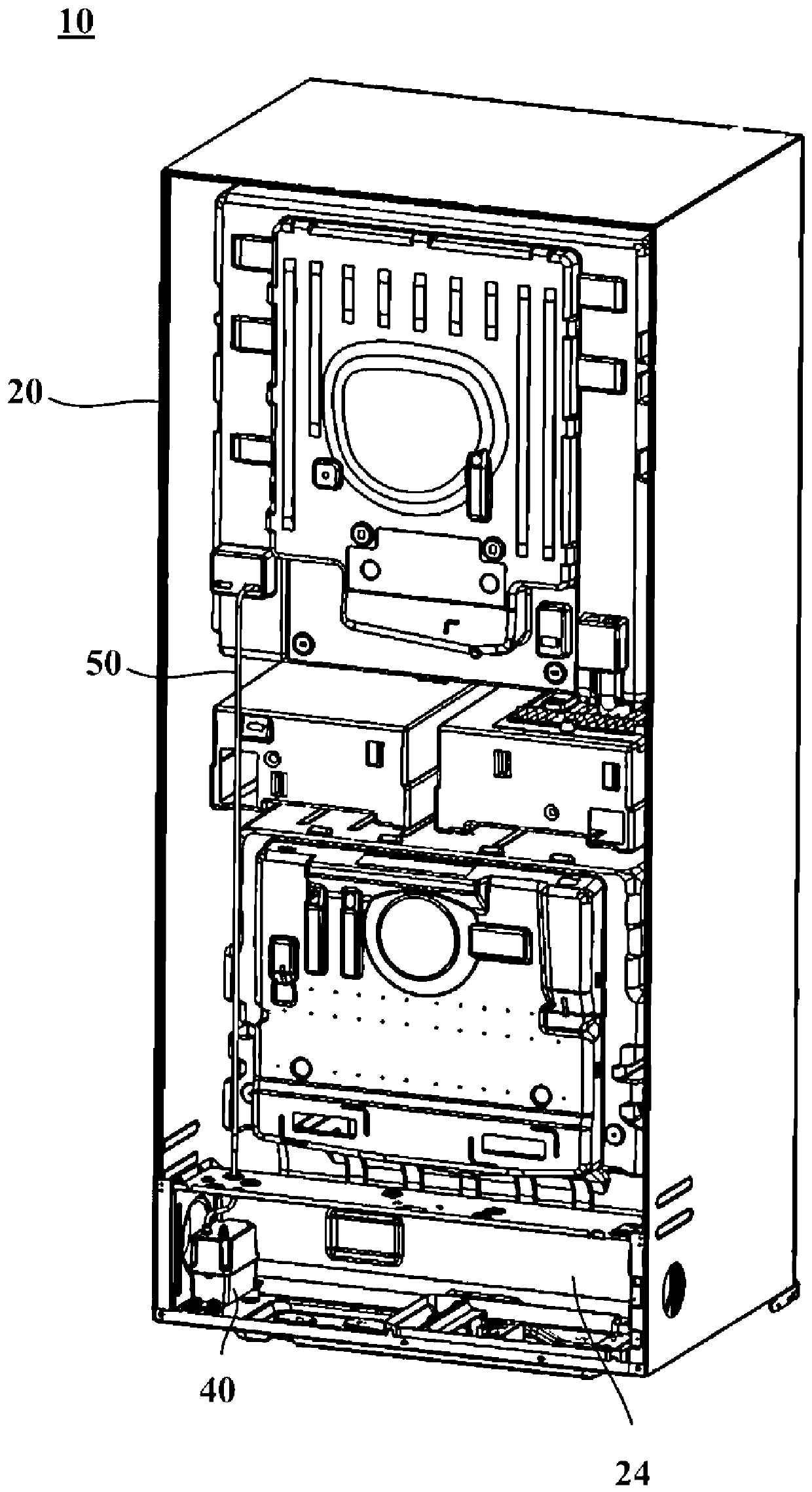

Freezer

ActiveCN106802047BEasy to keep freshReduce contentLighting and heating apparatusDomestic refrigeratorsNitrogenModified atmosphere

Provided is a refrigerating and freezing device (10). The refrigerating and freezing device comprises a box body (20), a gas separator (30) and a suction pump (41). A storage space (200) is defined in the box body (20), a storage container (21) is provided in the storage space (200), and the storage container (21) is provided with a modified atmosphere fresh-keeping space (210). The gas separator (30) is provided with a modified atmosphere film (300), a first gas collection cavity (310) and a second gas collection cavity (320). The modified atmosphere film (300) is configured in such a way that more oxygen, relative to nitrogen, of the air in the first gas collection cavity (310) penetrates the modified atmosphere film (300) and enters the second gas collection cavity (320), the first gas collection cavity (310) is controlled to communicate with storage chambers so that the air in the storage chambers can enter the first gas collection cavity (310), the first gas collection cavity (310) is further controlled to communicate with the modified atmosphere fresh-keeping space (210) so that other gas, except the gas which has entered the second gas collection cavity (320) by penetrating the modified atmosphere film (300), of the air which has entered the first gas collection cavity (310) can enter the modified atmosphere fresh-keeping space (210). The suction pump (41) communicates with the second gas collection cavity (320) through a pipeline, so as to facilitate pumping and discharging the gas which has penetrated into the second gas collection cavity (320), out of the gas separator (30).

Owner:HAIER SMART HOME CO LTD

Light fixture

InactiveCN102691993BSolve the problem of negative pressureLighting heating/cooling arrangementsGas-tight/water-tight arrangementsPhysicsLight fixture

The invention relates to a light fixture. An explosive-proof respiratory device is disposed on a lower housing of the light fixture. A dustproof water-absorbing layer and an explosive-proof layer are disposed in a housing of the explosive-proof respiratory device, and an air pipe is disposed in the explosive-proof layer. On the one hand the dustproof water-absorbing layer can effectively separate dust and absorb water, and on the other hand the explosive-proof respiratory device can realize ventilation through the air pipe and balance the internal and external air pressure of the illumination light fixture to prevent water from being sucked into an electrical cavity of the light fixture in the presence of water. Thus the light fixture with the explosive-proof respiratory device can effectively solve the problem that the water is sucked into the light fixture owing to the negative pressure generated therein.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

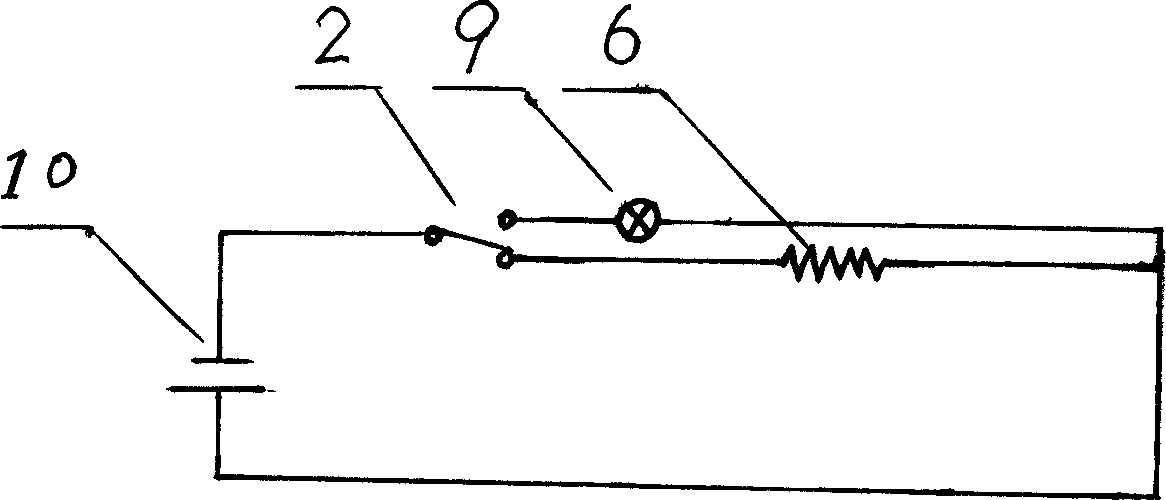

Non negative pressure controller

InactiveCN101210423ASimple structureLow production costService pipe systemsWater mainsPistonPressure controller

The invention provides a controller with no negative pressure, which consists of a housing, a flange, a float, a guide cover, a piston and a piston plate, wherein the float is arranged in the guide cover in the housing; the guide cover is fixed on the piston plate; the piston plate is fixed on the housing; the piston is disposed above the piston and is positioned in a center hole of the piston plate to make free up and down movement; and a guide rod is sealed with the piston plate through an O-shaped gasket provided on the bottom of the guide rod. The invention has simple structure, low fabrication cost and reliable use, and can be installed above a sealed water storage container in font of a water suction pipe of a water pump of pressurization equipment directly serially connected with water supply pipes in city, thus solving the negative pressure problem due to the absorbing height of the water pump when the water inflow volume of the pressurization equipment is less than the water supply volume and not influencing water usage of other users.

Owner:张明亮

High-frequency electromagnetic water storage type steam boiler

PendingCN113475928AImprove efficiencyEfficiency, energy saving and environmental protectionSteam cooking vesselsPressure-cookersTube furnaceElectric heating

The invention relates to a high-frequency electromagnetic water storage type steam boiler, which comprises a high-frequency electromagnetic generating device and a pressure cooker body, a high-frequency wire coil is arranged at the bottom of the pressure cooker body, a water inlet channel communicated with the interior of the pressure cooker body is formed in the side wall of the pressure cooker body, and a steam channel communicated with the interior of the pressure cooker body is formed in the top of the pressure cooker body; the high-frequency electromagnetic generating device and the high-frequency wire coil resonate to generate an alternating magnetic field acting on the pressure cooker body, and according to a vortex principle, the pressure cooker body converts electric energy into heat energy, so that water in the cooker is boiled, and steam is generated. The novel steam boiler is manufactured by combining the high-frequency electromagnetic technology and the steam boiler, and compared with a traditional electric heating tube furnace, a heat conduction oil furnace and the like, the novel steam boiler has the beneficial effects of being high in heat efficiency, environmentally friendly, capable of saving energy, free of open fire and waste heat and high in safety performance; and the steam boiler has the functions of removing scale, automatically adjusting the steam quantity and the like, and parts and sensors can be conveniently maintained.

Owner:GUANGDONG GAJUM IND CO LTD

Air conditioner

InactiveCN100545523CReduce the number of starts and stopsSolve the problem of negative pressureSpace heating and ventilation safety systemsLighting and heating apparatusPressure generationEngineering

The invention provides an air conditioner comprising an indoor set and an outdoor set. The indoor set at least comprises an indoor heat exchanger, and the outdoor set at least comprises a compressor, an outdoor heat exchanger, a throttling device, an outdoor fan used for the outdoor heat exchanger, and a low pressure detection device at the inhalation side of the compressor, wherein a control device controlling at least the compressor and the outdoor fan is disposed in the outdoor set, stops the compressor when low pressure abnormality is detected by the low pressure detection device during the operation process of the air conditioner, and controls start of the outdoor fan at the same time according to times of low pressure generation of the compressor. The inventive air conditioner facilitates protection of the compressor, elongates life of the compressor and assures normal operation of the air conditioner.

Owner:PANASONIC CORP

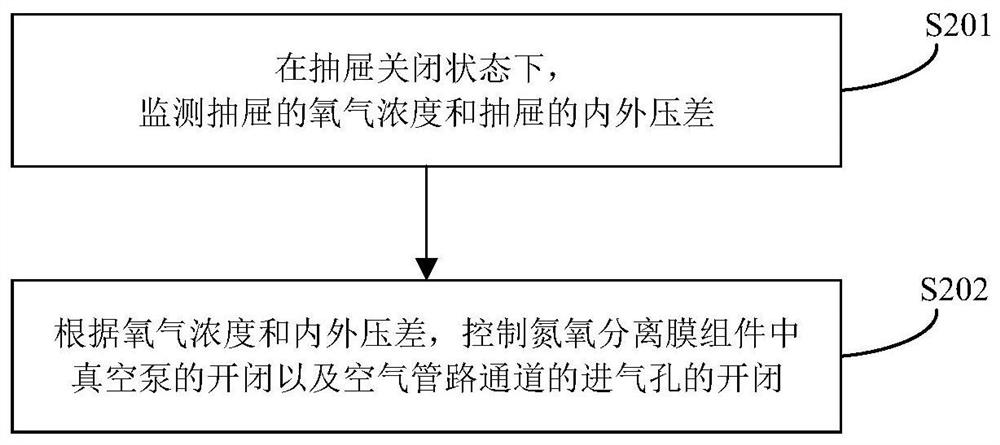

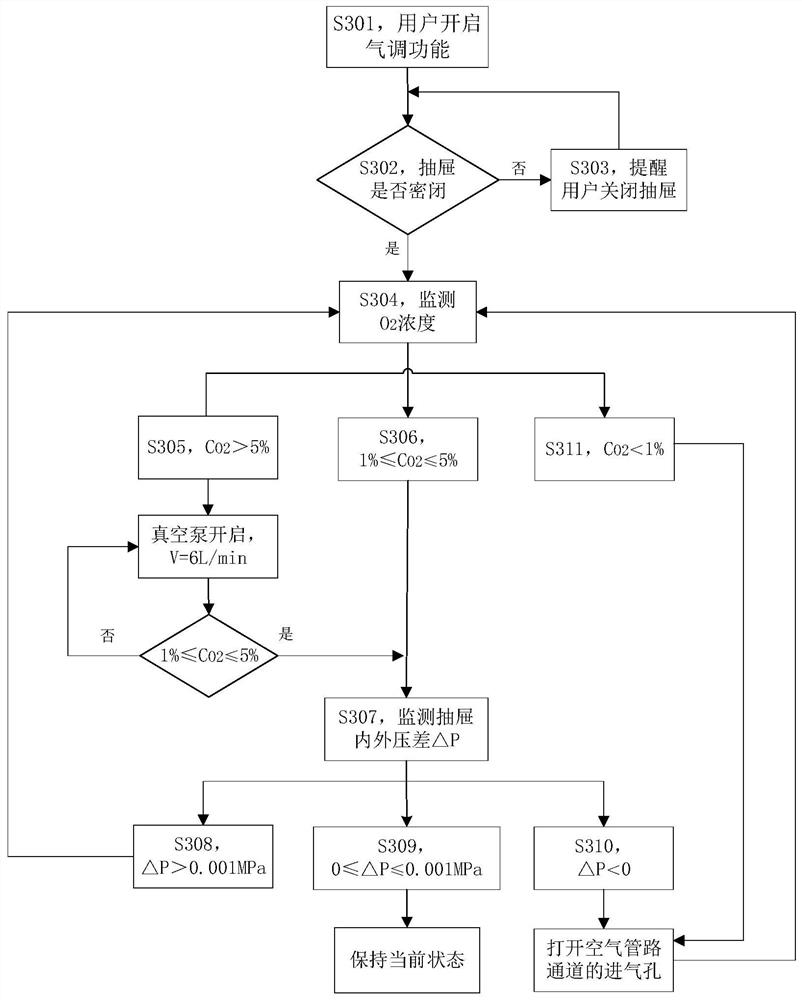

Air regulation control method of refrigerator, air regulation drawer and fresh-keeping refrigerator

ActiveCN113124611AReduce air pressureReduce internal and external pressure differenceLighting and heating apparatusDomestic refrigeratorsPressure generationIcebox

The invention discloses an air regulation control method of a refrigerator, an air regulation drawer and the fresh-keeping refrigerator. The method comprises the following steps that when the drawer is in a closed state, the oxygen concentration of the drawer and the internal and external pressure difference of the drawer are monitored ; and according to the oxygen concentration and the internal and external pressure difference, opening and closing of a vacuum pump in a nitrogen-oxygen separation membrane assembly and opening and closing of an air inlet hole of an air pipeline channel are controlled. According to the air regulation control method of the refrigerator, the air regulation drawer and the fresh-keeping refrigerator, linkage control over the nitrogen-oxygen separation membrane assembly and opening and closing of the air inlet of the air pipeline channel is achieved, the gas concentration of the drawer can be adjusted to effectively preserve refrigerated food, the problems of drawer deformation and negative pressure generation can be solved, and the drawer is easy to push and pull and safe.

Owner:GREE ELECTRIC APPLIANCES INC

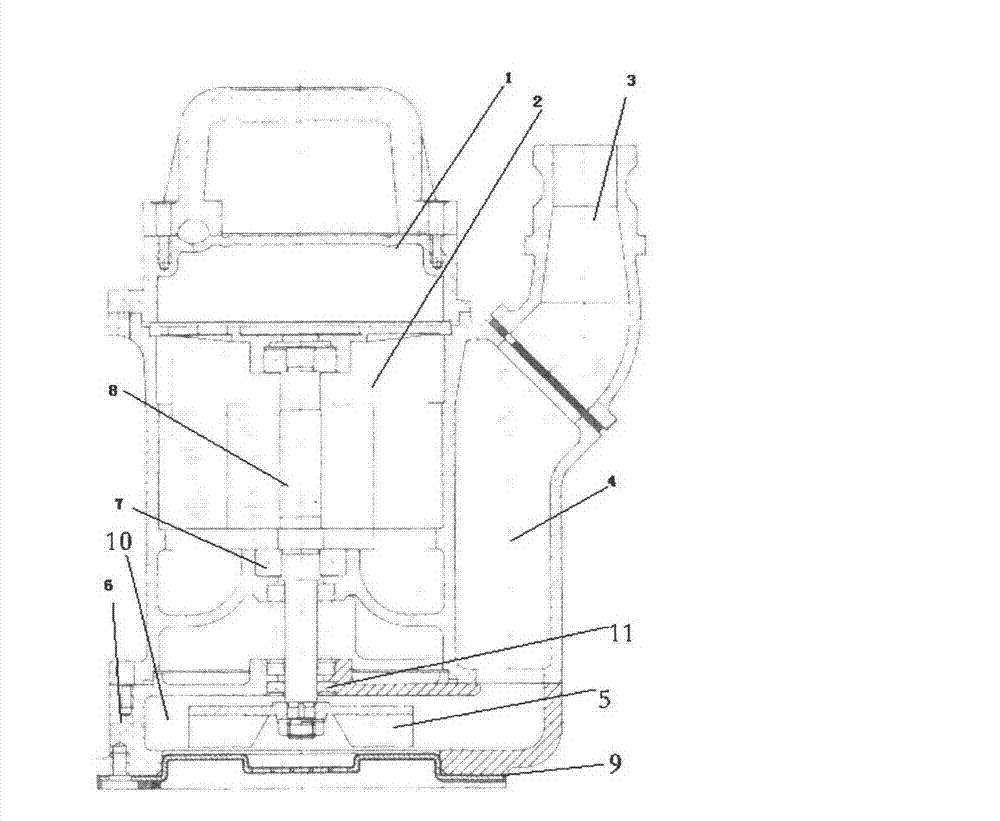

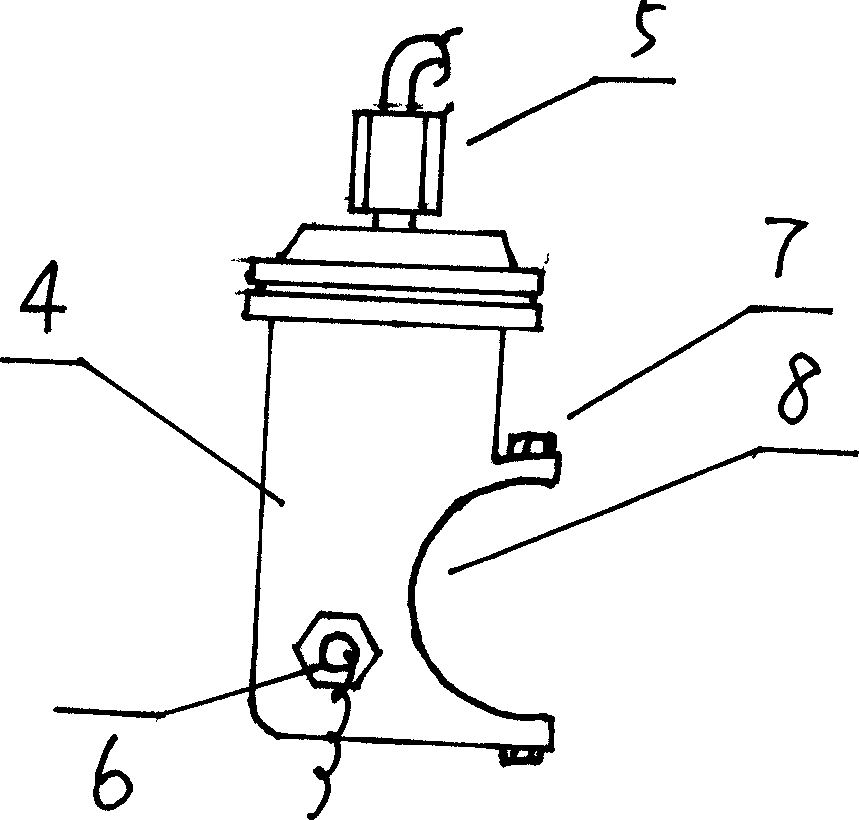

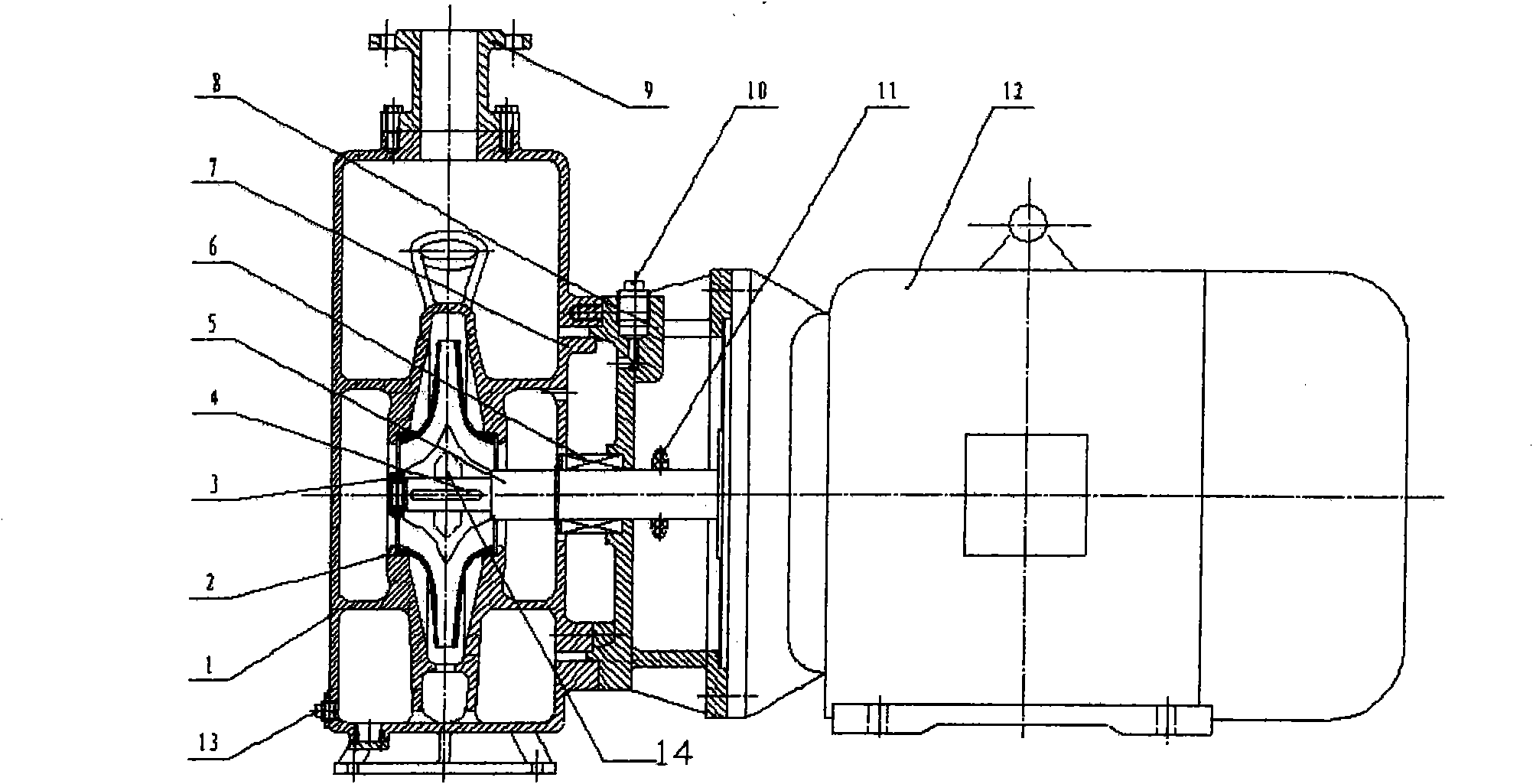

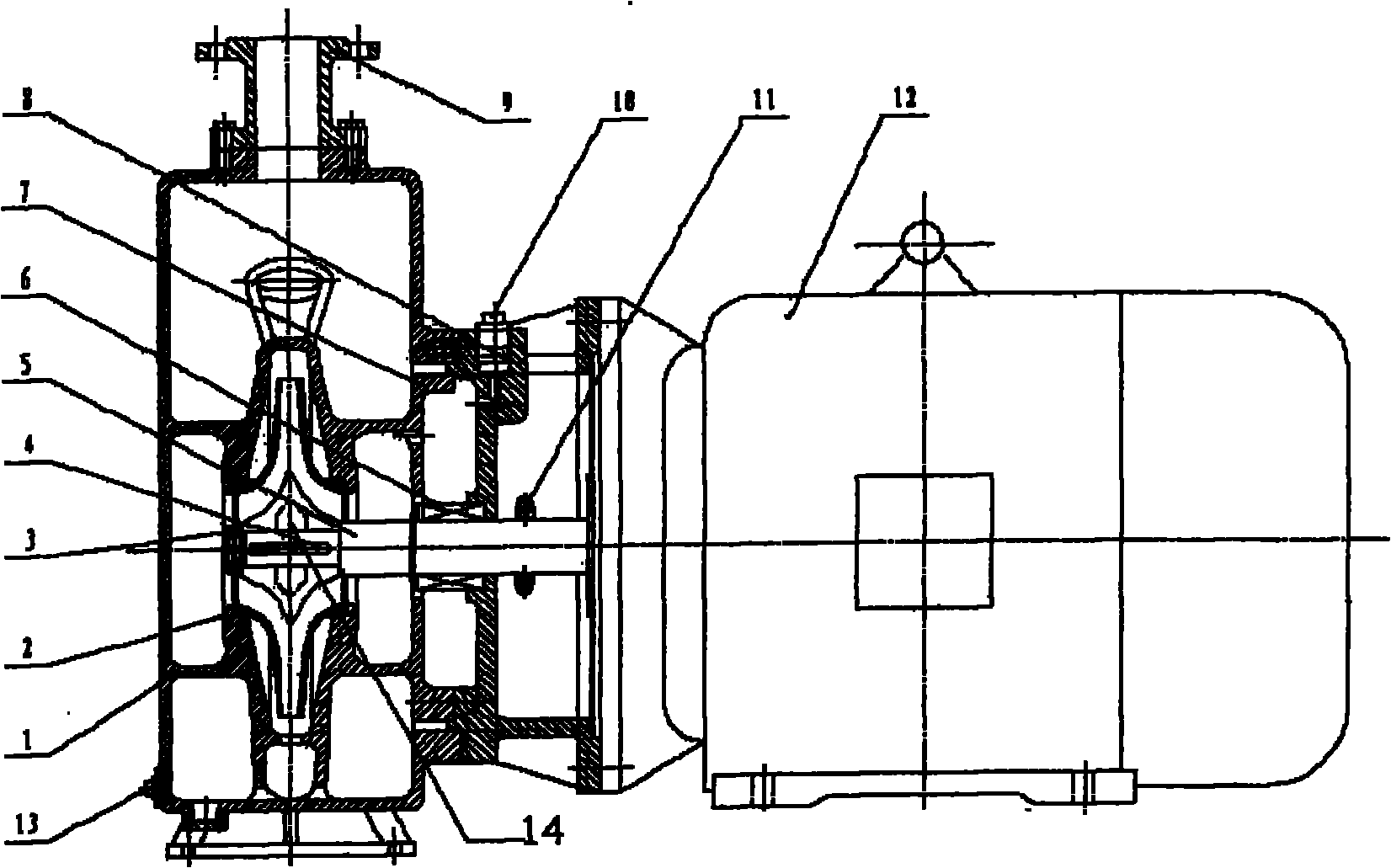

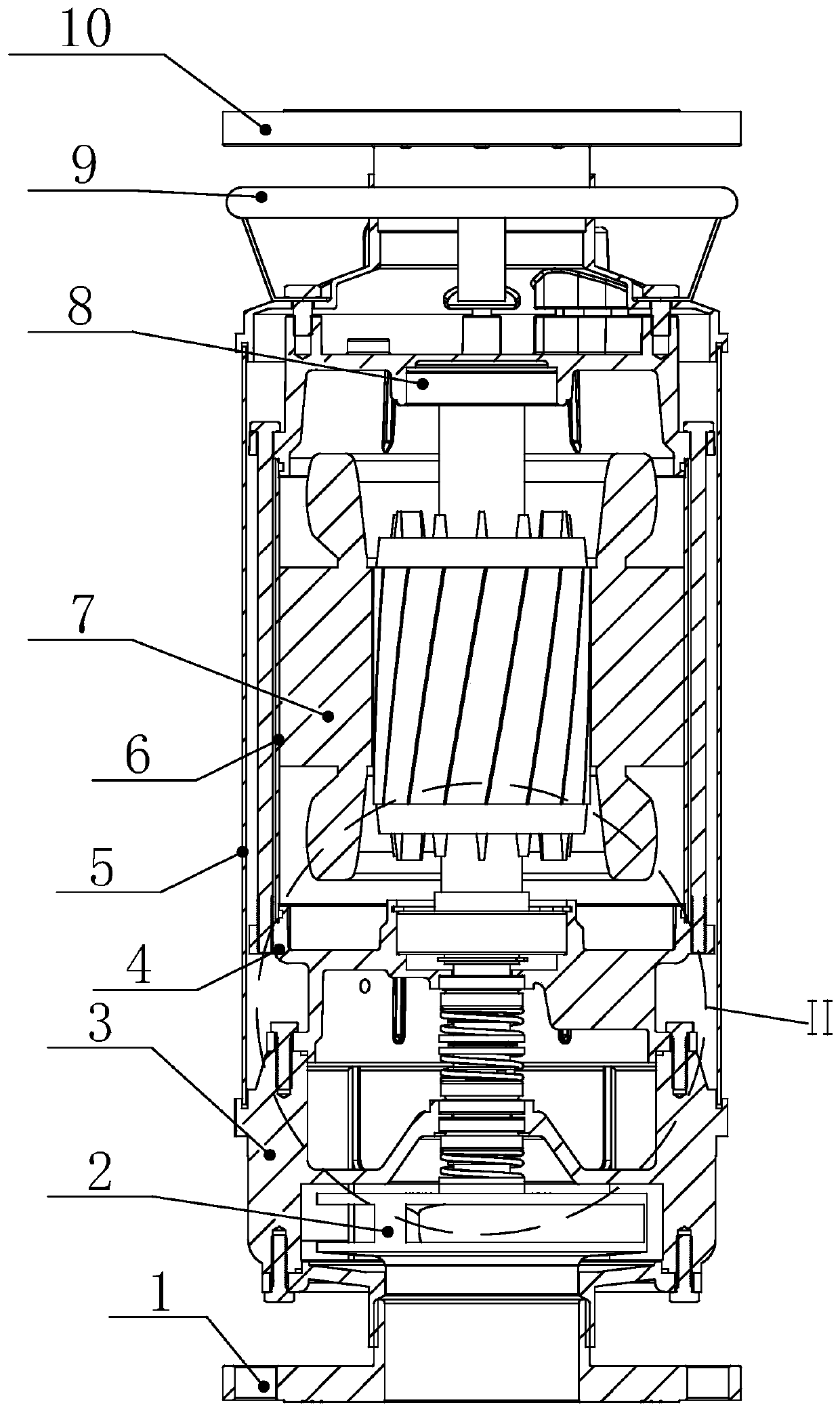

Novel energy-saving self-sucking pump

InactiveCN102032196AImprove efficiencyExtended service lifePriming pumpNon-positive displacement fluid enginesImpellerWater leakage

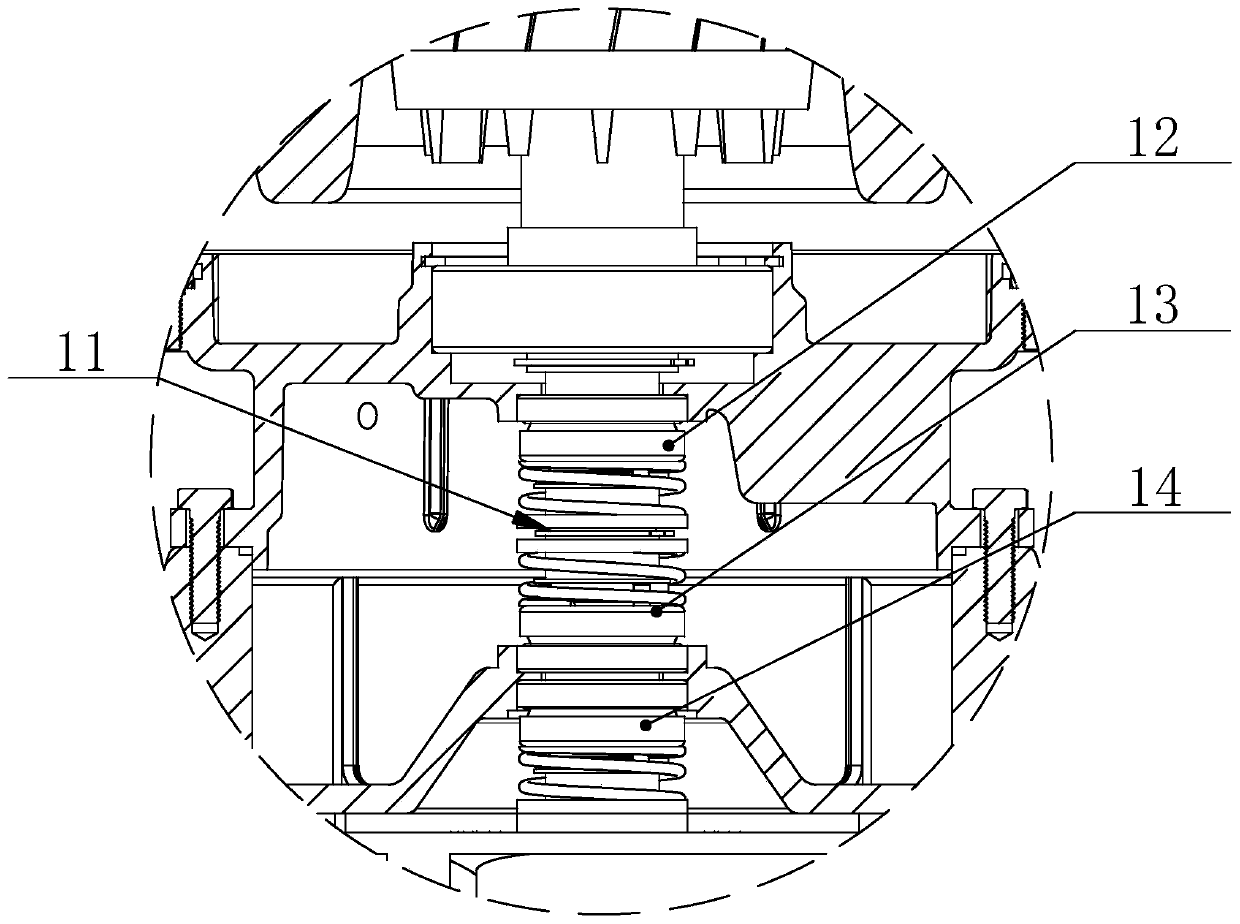

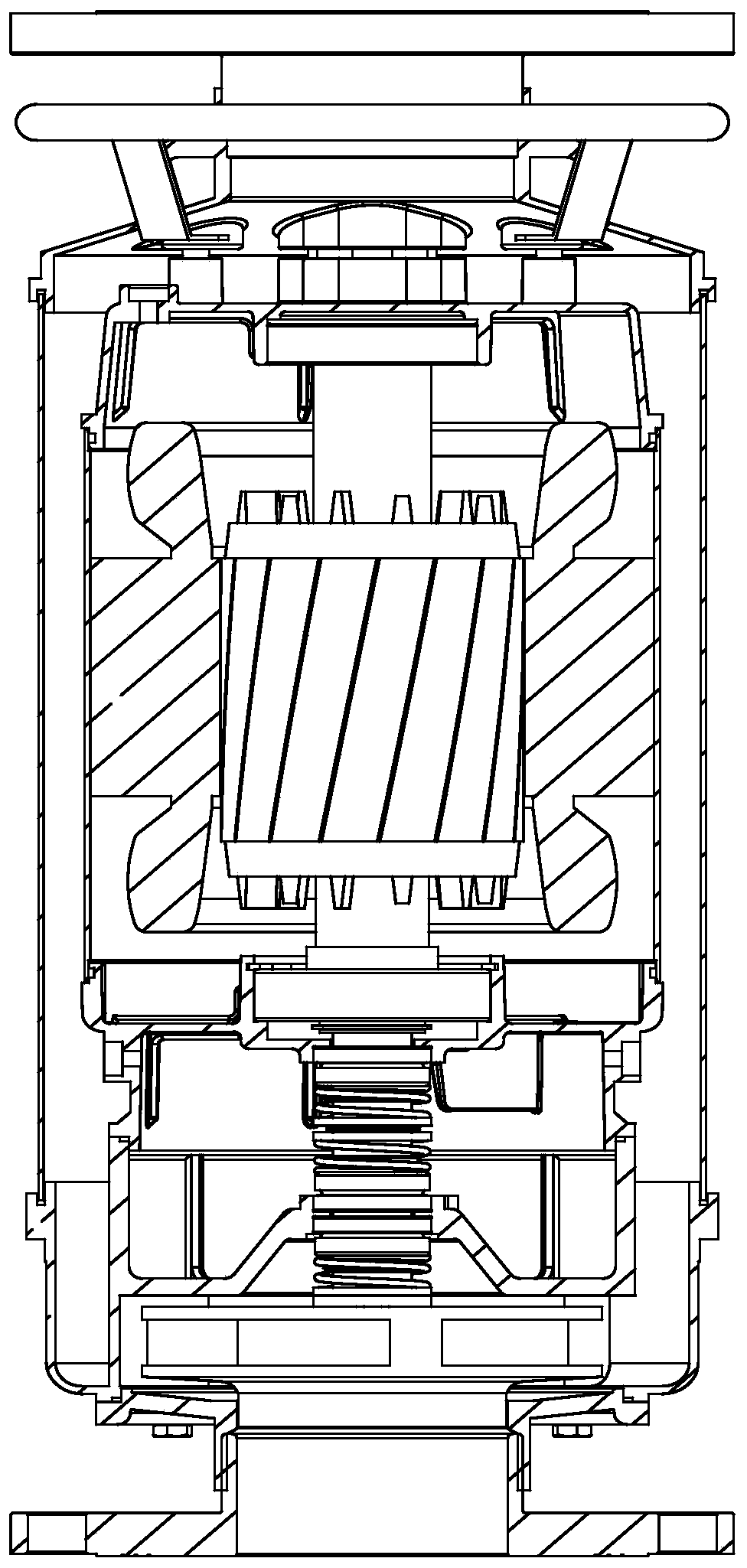

The invention relates to the technical field of water pumps, in particular to a novel energy-saving self-sucking pump which is characterized by comprising a pump body 1, an impeller 2, an impeller nut 3, a key 4, a shaft 5, a mechanical seal 6, a volute chamber cover 7, a pump cover 8, an outlet flange 9, an air discharging valve 10, a water blocking ring 11, a motor 12, a water discharging valve 13 and a water inlet 14. Because water is sucked from the single side of the impeller 2 of a traditional self-sucking pump, and the generated axial centrifugal tension is larger and is markedly larger if the traditional self-sucking pump is in the model with larger caliber, larger flow and higher lift, the pump shaft of the motor 12 is rapidly damaged, and the service life is shorter. Because the self-sucking pump belongs to a single-sucking structure, the pump is always in a pressurized state in the operation of the water pump, and the high the lift is, the higher the pressure is, the water is quite easily leaked to cause the water seepage and the damage of the motor. Differing from the design that the inlet of a traditional pump is positioned on the lateral surface, the water inlet 14 of the novel energy-saving self-sucking pump is drilled on the front surface of the pump, thereby the problems of water leakage and negative pressure are well solved, the work efficiency is improved, and the service life is prolonged. The novel energy-saving self-sucking pump can run at a low water level and has low water-sucking water level, high lift and high efficiency and saves energy; a front-surface water-sucking structure is adopted, the motor 12 has no axial tension, the radial force is lightened and balanced, the pump efficiency is improved, and the problems of water leakage and negative pressure are well solved; the service life of the pump is greatly prolonged; and the pump has more reasonable and compact structure and attractive appearance, and safer and more reliable in running.

Owner:叶宗旨

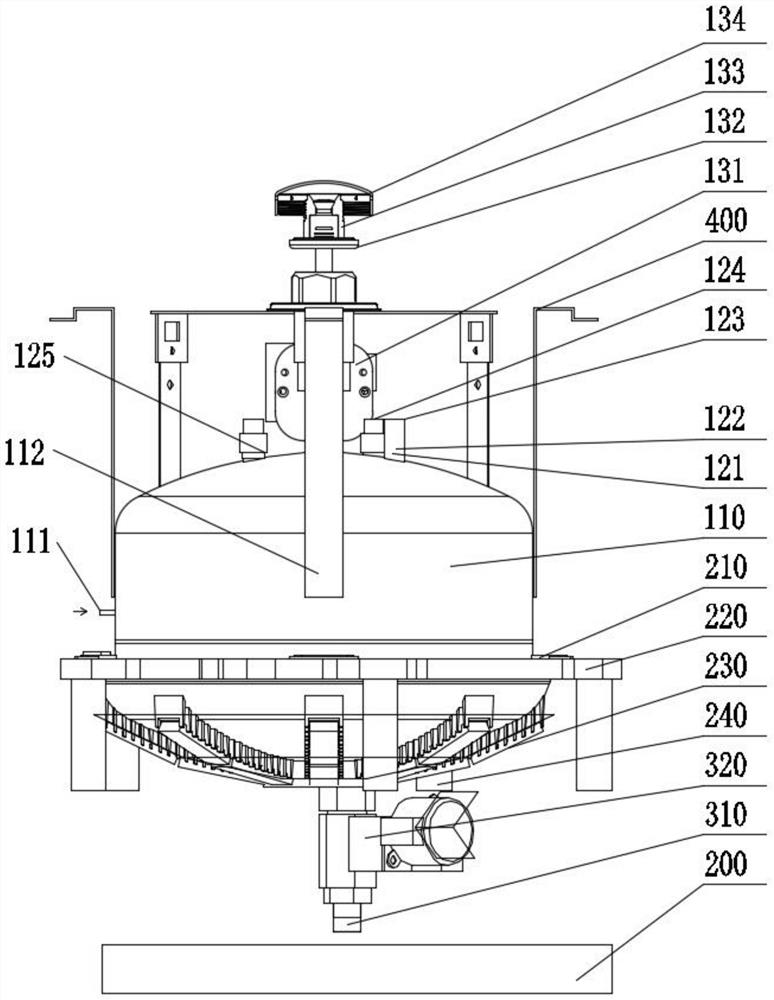

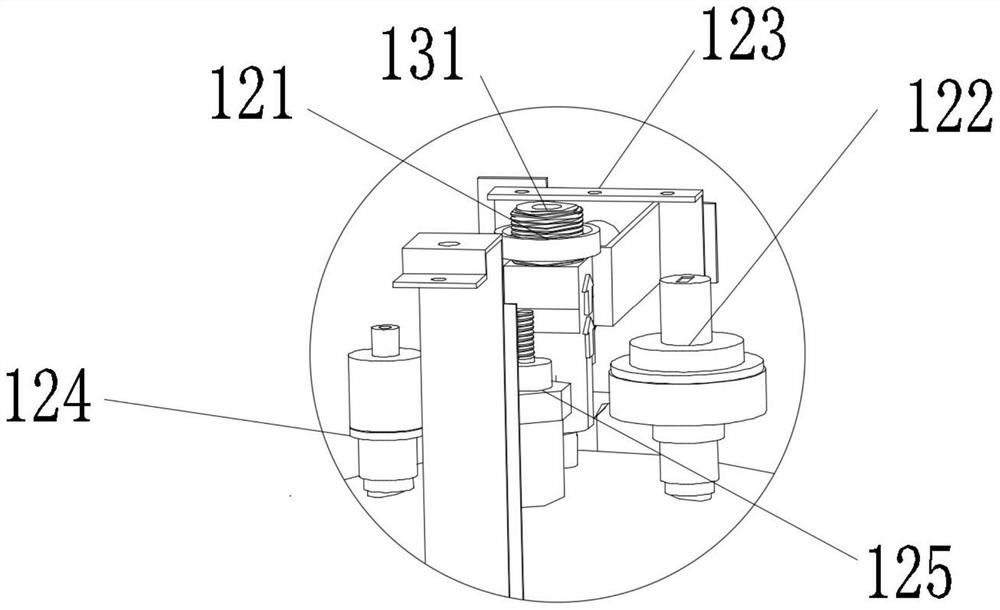

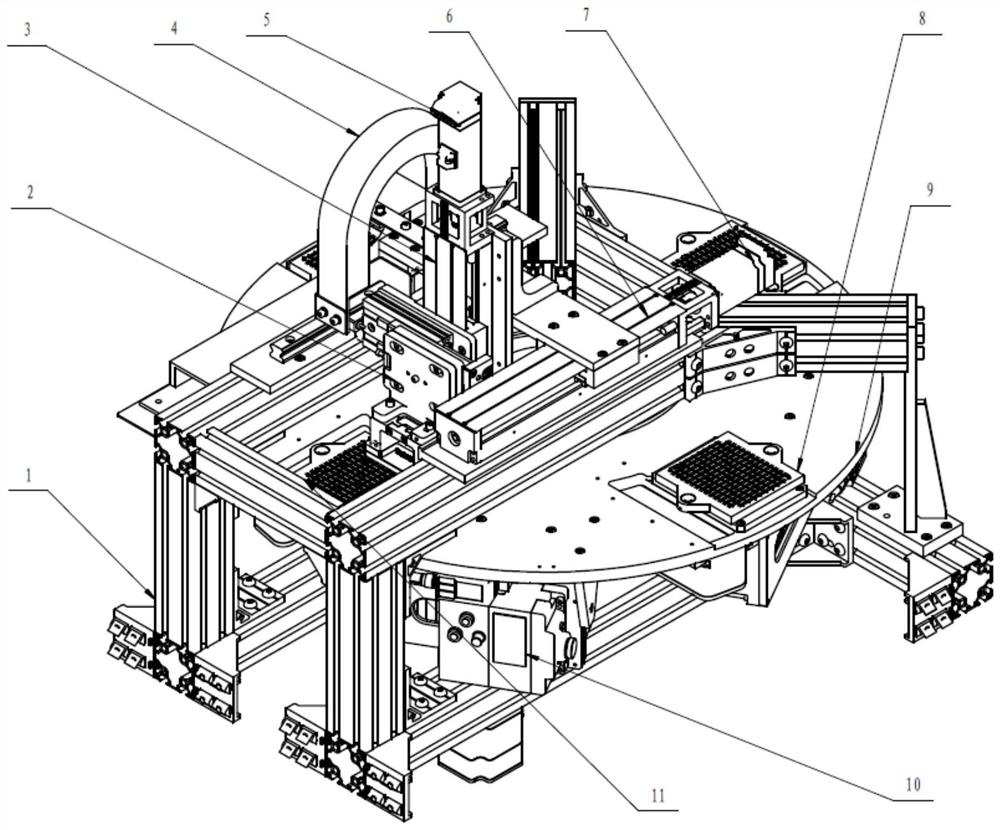

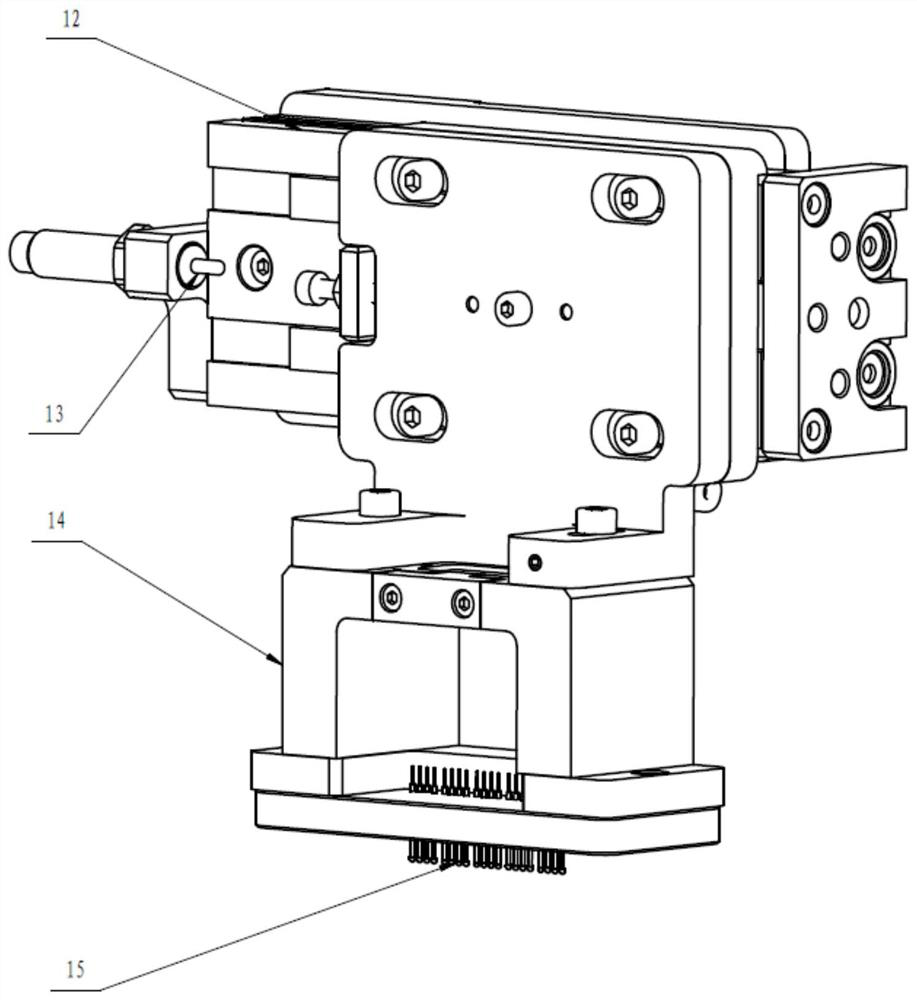

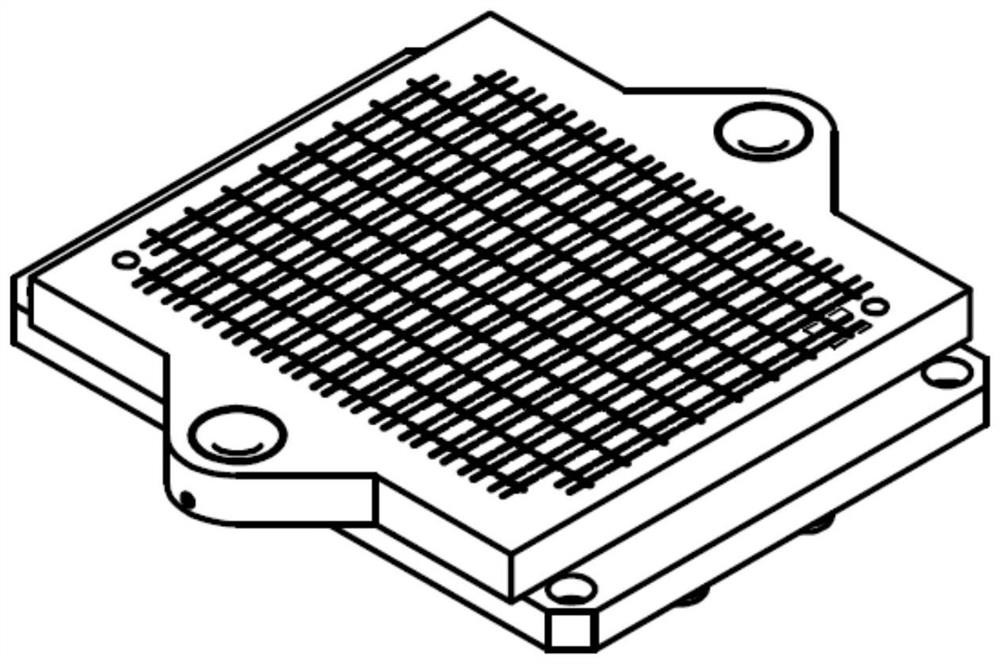

Automatic resistance measuring device of strain gauge and operation method

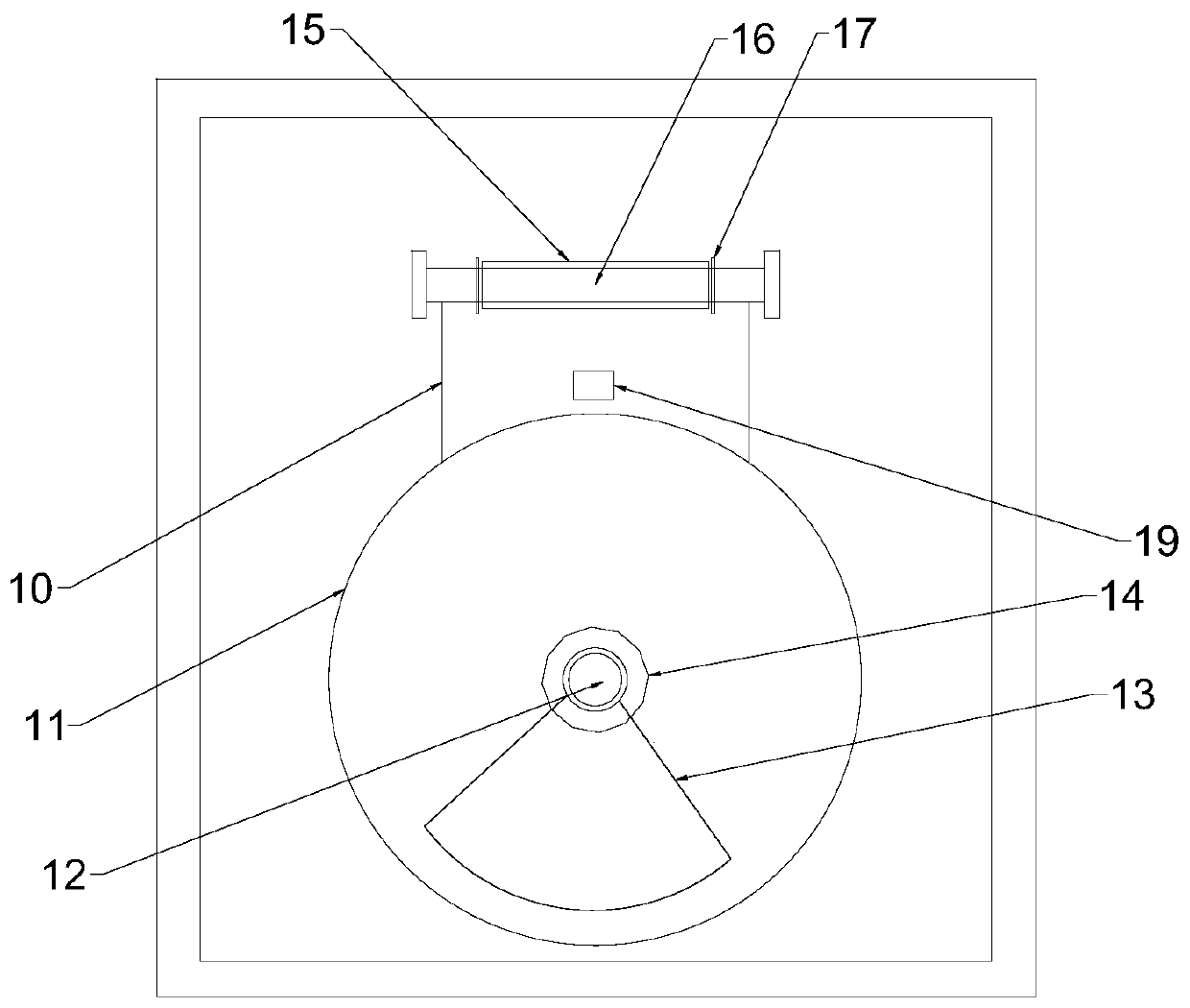

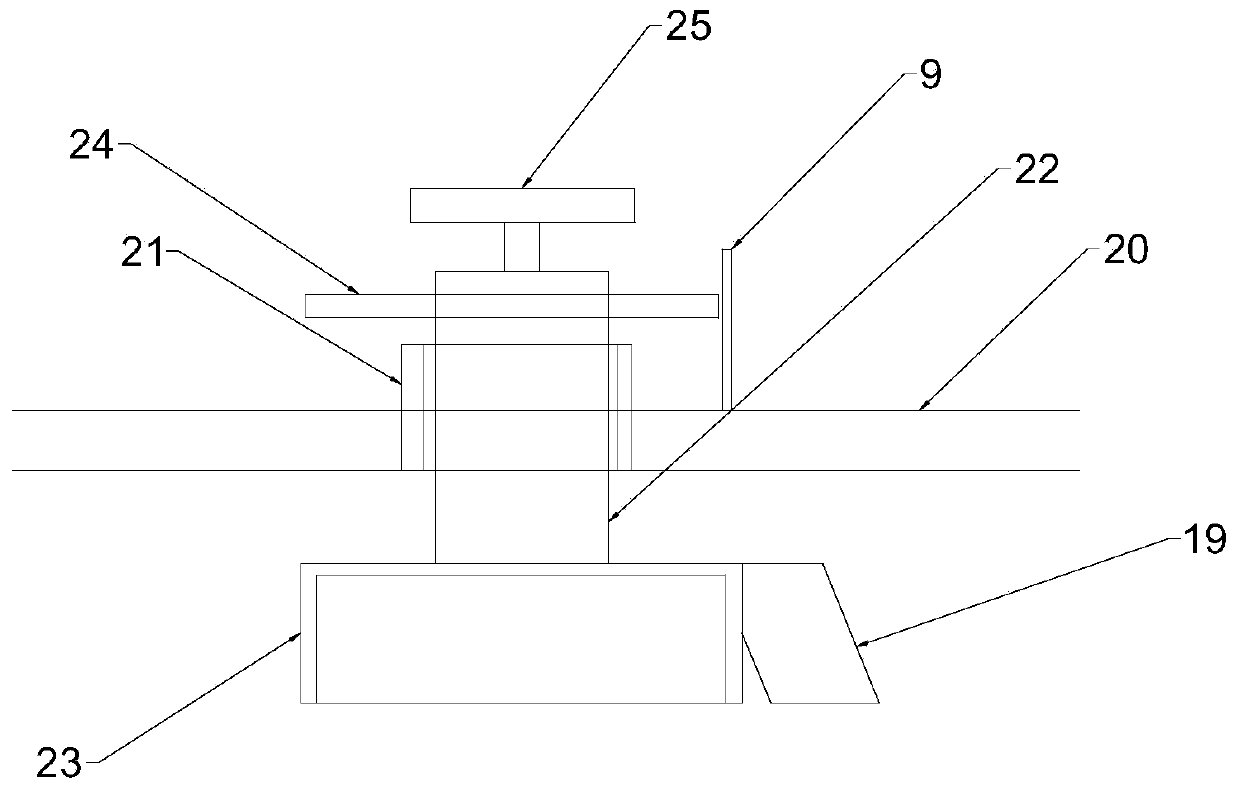

PendingCN112815822AReduced stabilityRealize automatic resistance measurement functionResistance/reactance/impedenceElectrical/magnetic solid deformation measurementEngineeringMachine

The invention discloses an automatic resistance measuring device for a strain gauge and an operation method. The automatic resistance measuring device comprises a rack, a rotary disc, material discs, a Y-axis movement unit, a Z-axis movement unit and a resistance measuring head, wherein the rotary disc is arranged on the rack, and a plurality of material discs are arranged on the rotary disc; and the Y-axis movement unit is arranged on the machine frame, the Z-axis movement unit is arranged on the Y-axis movement unit, the resistance measuring head is arranged on the Z-axis movement unit, and after the rotary disc rotates, the material discs are located below the resistance measuring head. The stability of the resistance measuring process is controlled by controlling the pressing depth of the probe, the rotating angle of the rotating disc, the negative pressure adsorption force and other parameters, the automatic resistance measuring function is achieved, and the automatic resistance measuring device has great advantages in the aspect of achieving batch and automatic operation. Meanwhile, a high-precision calibration plate greatly improves the measurement accuracy.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

Wind-proofing sand-blocking device

InactiveCN101871199BStable structureRealize industrial productionProtective constructionEngineeringMonomer

Owner:NORTHWEST RES INST CO LTD OF C R E C

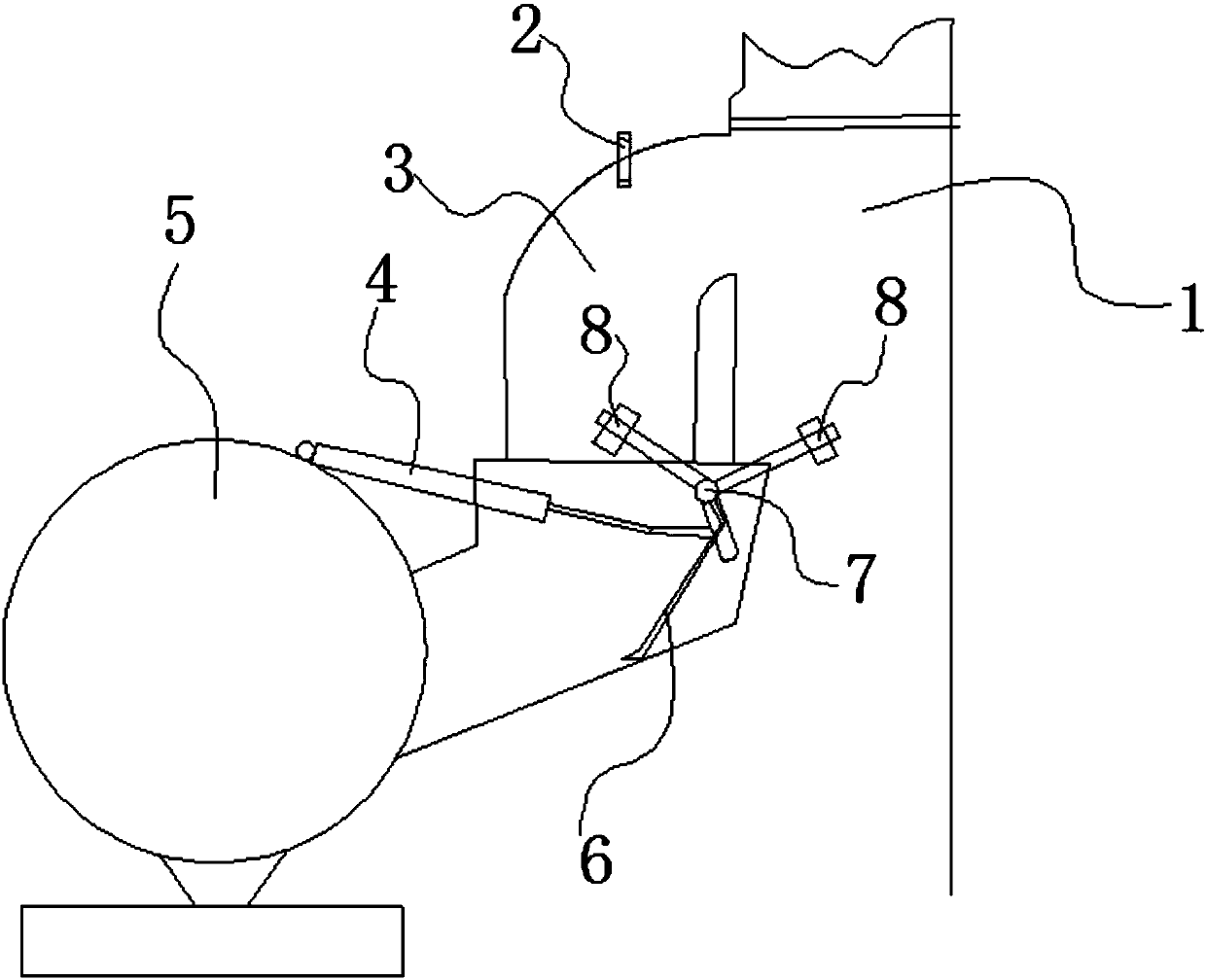

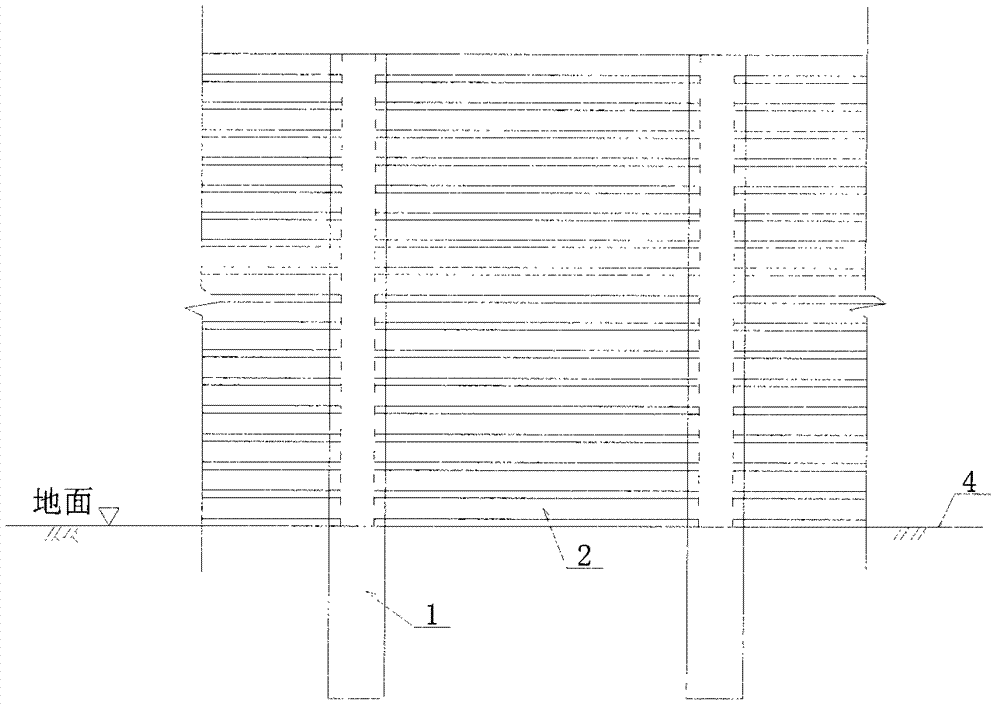

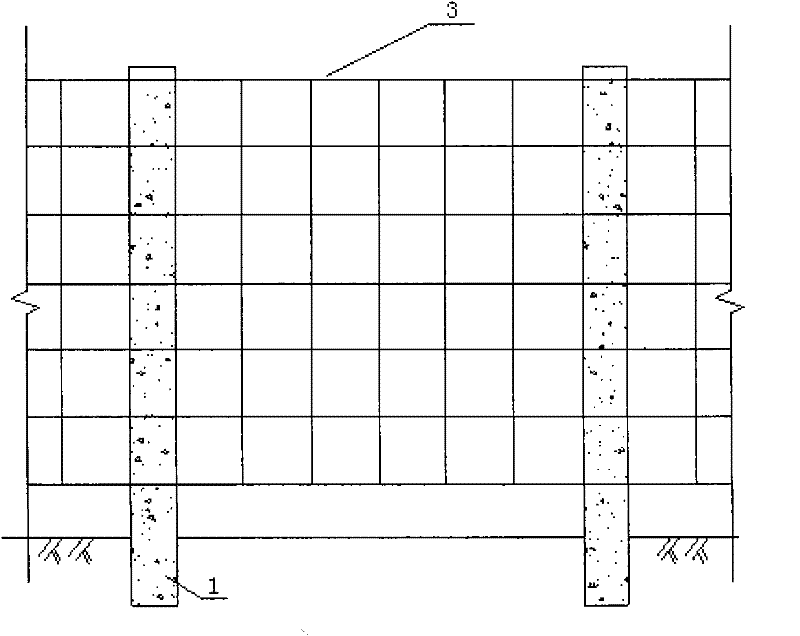

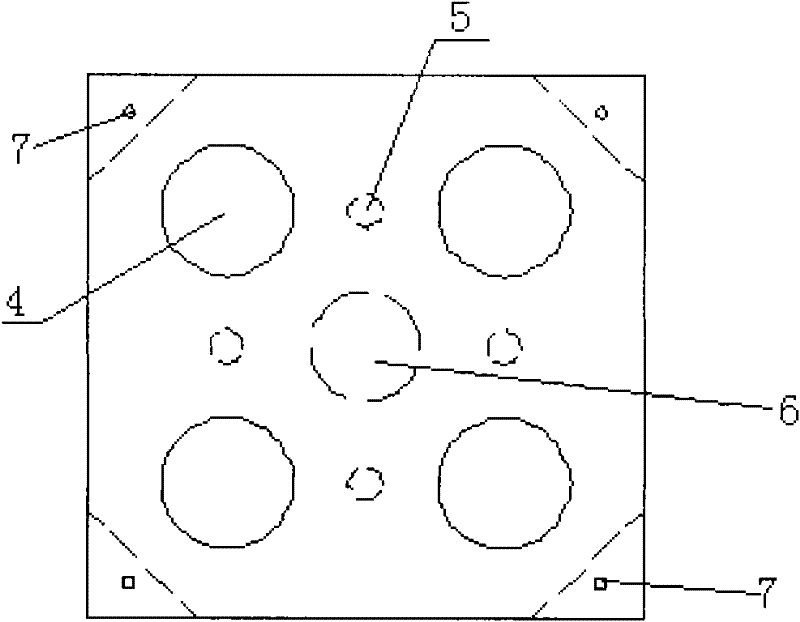

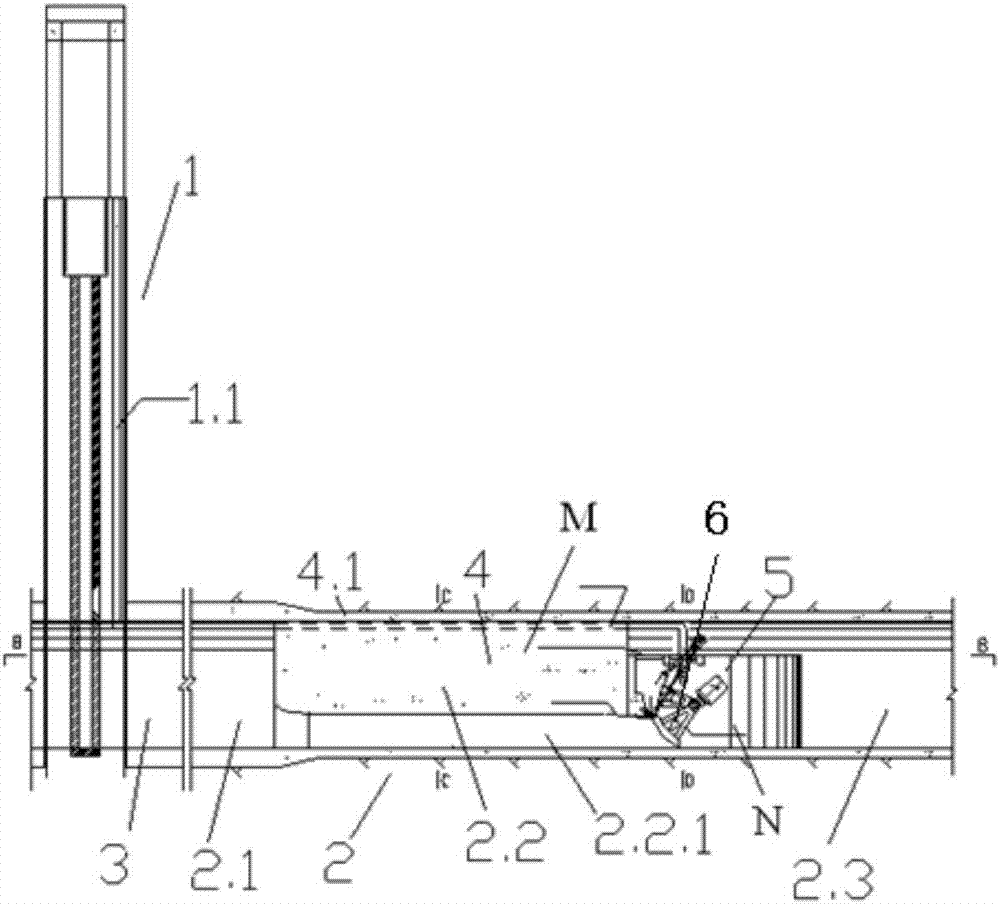

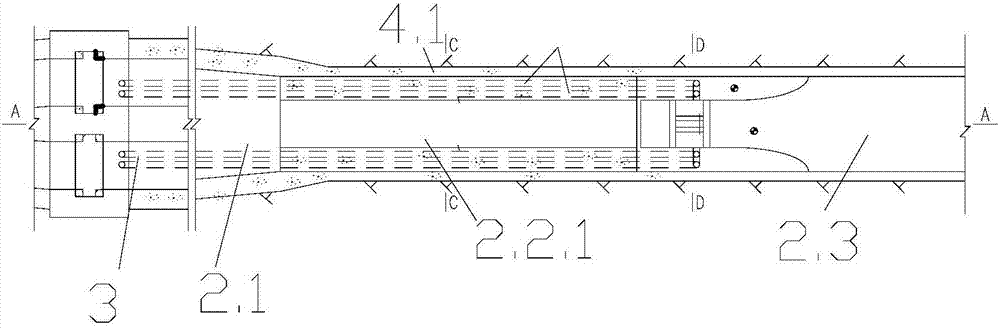

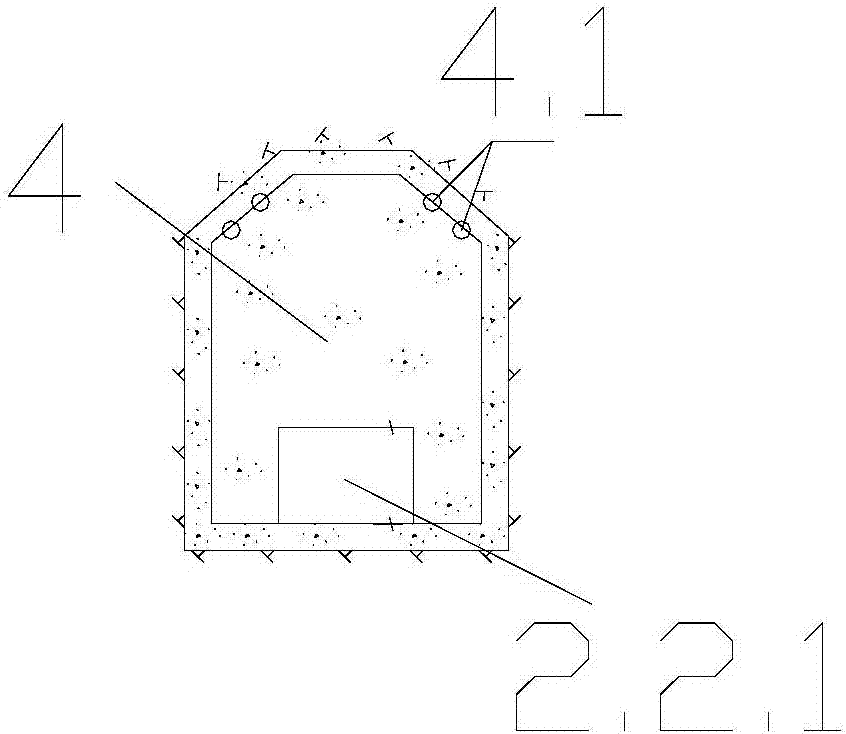

Ventilation hole and layout method after the diversion tunnel is rebuilt into arc gate control

ActiveCN105421312BSolve the problem of negative pressureReduce adverse effectsWater-power plantsHydro energy generationEngineeringTower

The invention discloses a ventilation hole and an arrangement method after diversion tunnels are rebuilt into arc gates and controlled, which includes setting a water inlet tower (1) upstream of the diversion tunnel (2) to be transformed, and Ventilation holes (1.1) are pre-set in the water inlet tower (1), and an inlet gradient section (3) is arranged between the water inlet tower (1) and the diversion tunnel (2) to be transformed. The ecological water discharge tunnel section (2.2) is divided into M and N two sections successively, and the M section is a concrete reconstruction body A (4) made by concrete pouring for the described ecological drainage tunnel section (2.2), and the concrete reconstruction body A(4) The bottom of A(4) is reserved to form a drainage channel (2.2.1); it overcomes the disadvantage that the lower gate will take away the air when the full flow is discharged, resulting in the formation of a negative pressure area behind the gate, which will damage the gate and other discharge facilities. , has the advantage of eliminating the adverse effect of negative pressure on the safety of arc doors and discharge facilities.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

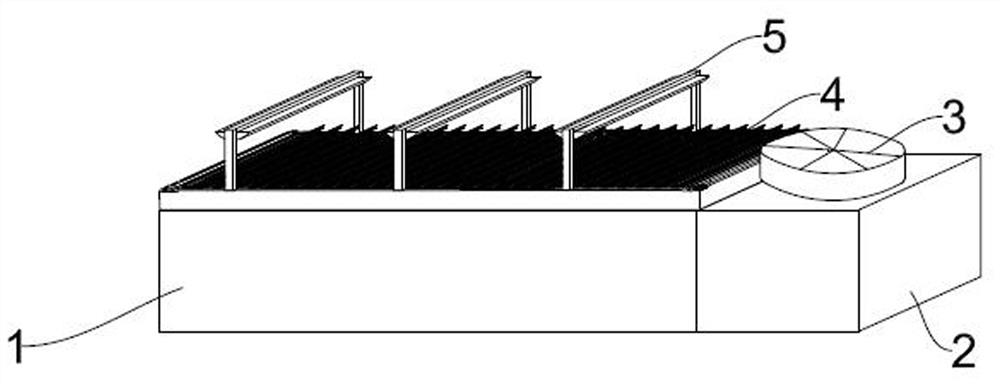

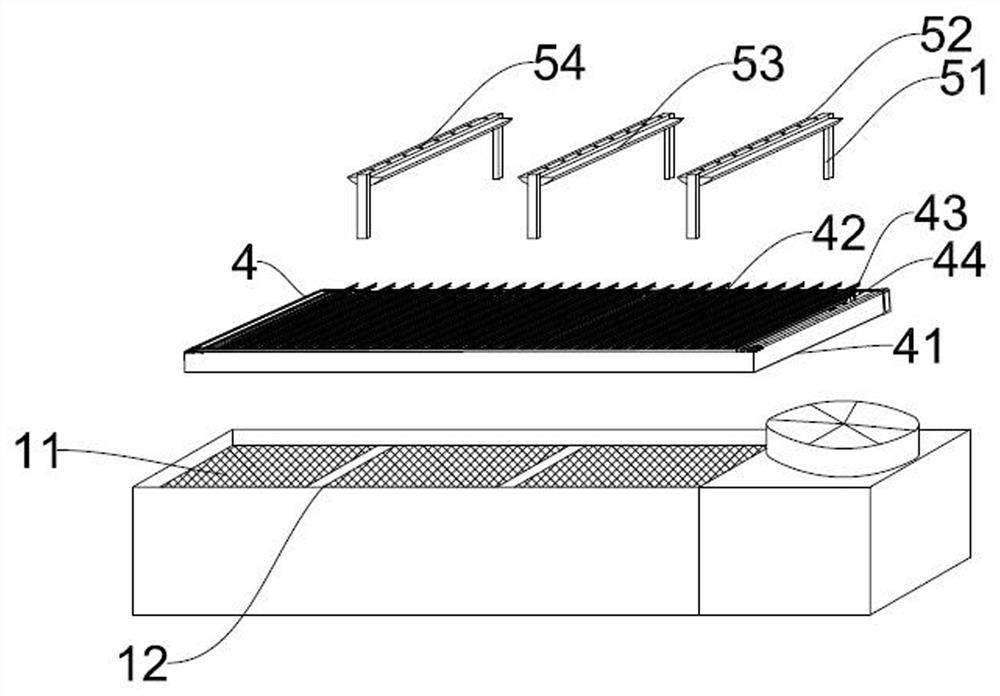

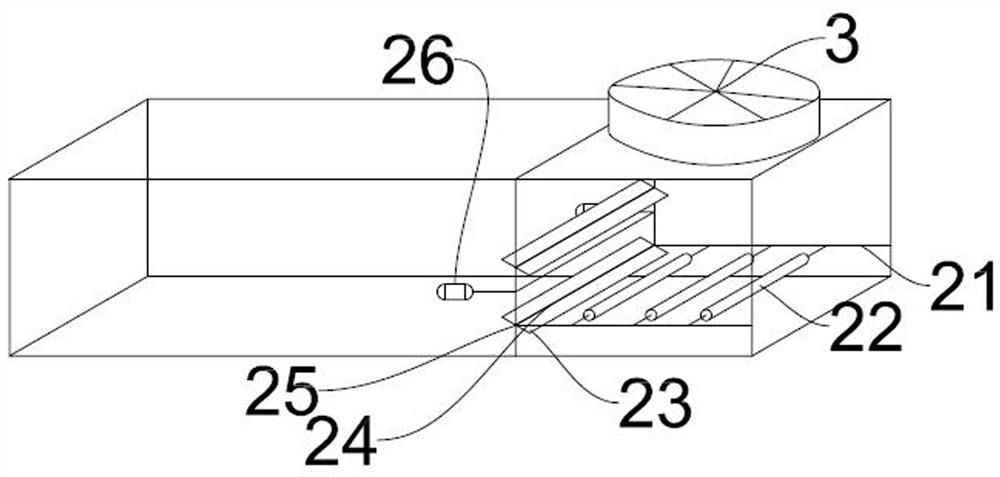

Fresh tea leaf treatment device and treatment method thereof

PendingCN112616951ASolve the problem of negative pressureUniform withering effectDrying solid materials with heatPre-extraction tea treatmentInfraredCarbon fibers

The invention relates to a fresh tea leaf treatment device and a treatment method thereof. The fresh tea leaf treatment device comprises a withering bed and a heating device; a fan is fixedly arranged above the heating device; the fresh tea leaf treatment device is characterized in that a PTC heating body is arranged in the heating device; an air guide plate is arranged at the front end of the heating device; the fan blows air from top to bottom, airflow is heated through the PTC heating body, and hot gas moves towards the withering bed; a sunlight withering simulation device is fixedly arranged above the withering bed; a luminous body adopts a carbon fiber thermal inductance tube and only radiates 4.5-13.4 mu m far infrared rays, so that the fresh tea leaves can be uniformly heated from inside to outside, the heat conversion efficiency is high, and the energy is saved by 30 percent or above compared with that of a common metal heating body; and the sunlight withering simulation device comprises a louver board and a far infrared emission device fixed on the louver board. The air flow flows transversely after being heated by the PTC heating body and flows to the withering bed, and the flow speed of the transverse air flow is not high, so that the problems that the traditional withering bed cannot be heated at the position close to the fan and has negative pressure can be effectively solved, and the tea withering effect is uniform and good.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

Heat energy circulating system of coating production line

ActiveCN101799204BEasy to removeSediment conveniencePretreated surfacesEnergy industryThermal energyCavitation

The invention relates to a heat energy circulating system of a coating production line, which comprises a heating water tank of a pre-treatment system of the coating production line and a drying box of a drying facility of the coating production line, wherein a stainless steel inner container and a combustor are fixed in a furnace body; the combustor is fixed to the lower part of the stainless steel inner container; an air outlet of a circulating calorifier is communicated with the furnace body; an atmosphere communicating vent opening into atmosphere directly is arranged at the top of the furnace body; a water outlet pipe and a return pipe are arranged on the stainless steel inner container; a hot-water circulating pump is arranged on the water outlet pipe; the water outlet pipe is communicated with hot-water inlets of the heating water tank of the pre-treatment system of the coating production line and the drying box of the drying facility of the coating production line; and hot-water outlets of the heating water tank of the pre-treatment system of the coating production line and the drying box of the drying facility of the coating production line are communicated with the return pipe. The heat energy circulating system has the advantages of completely eradicating the phenomenon of the negative pressure of a loop and a water outlet pipe and solving the problems of the cavitation of the water circulating pump and the water attack of the system along with good anti-explosion performance and convenient overhauling.

Owner:ZHEJIANG MINGQUAN INDAL COATING

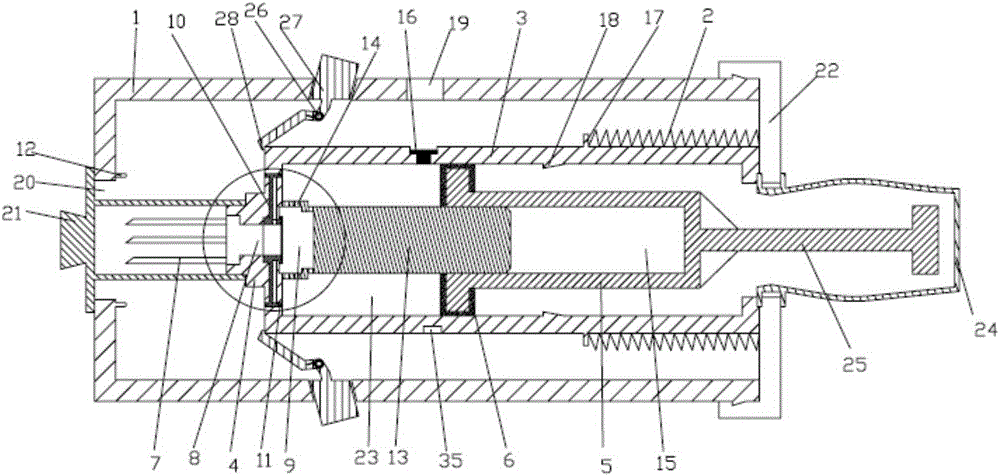

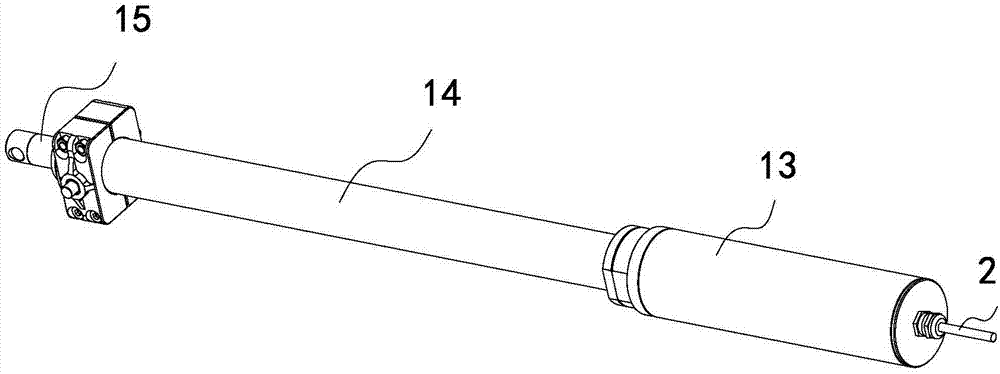

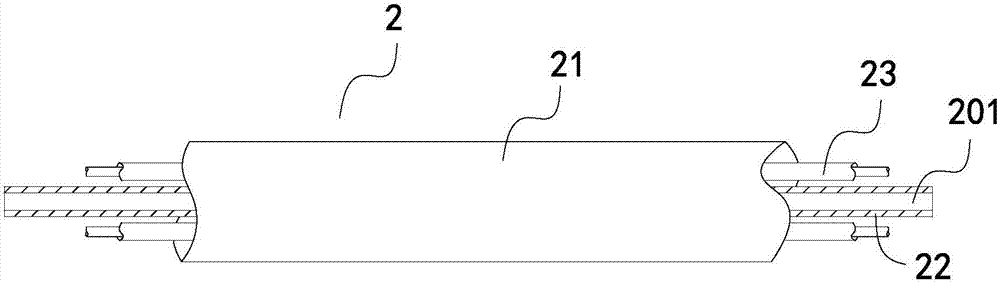

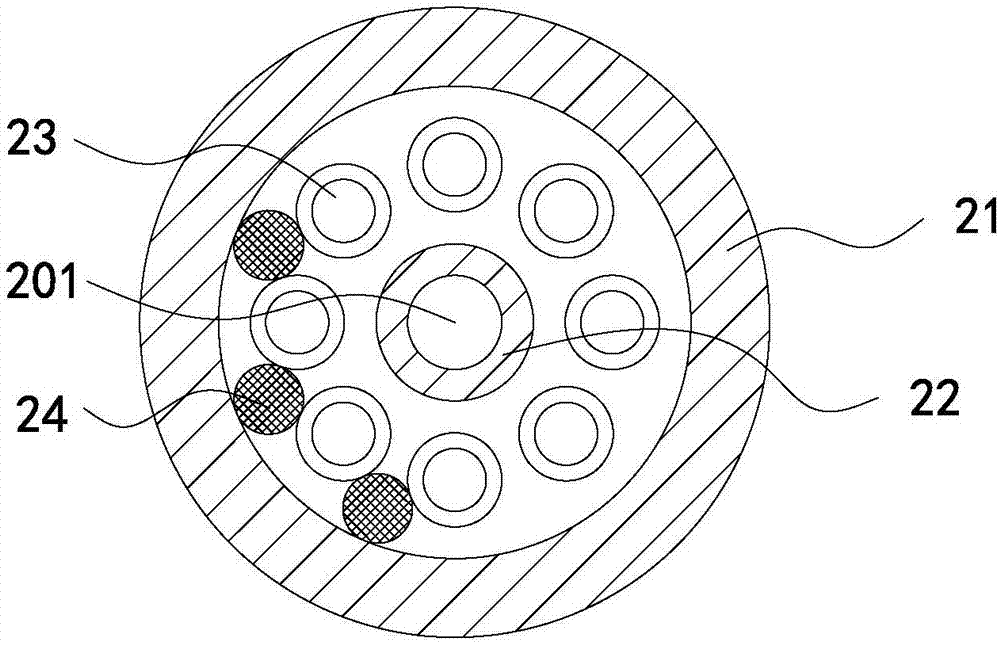

Electric push rod used for solar photo-thermal power generation

PendingCN107453534AReduce gapImprove sealingInsulated cablesFlexible pipesElectric machineEngineering

The invention discloses an electric push rod used for solar photo-thermal power generation, and belongs to the linear driving technical field. A motor is arranged in the electric push rod; the motor is in transmission connection with a transmission threaded rod; the rotation of the transmission threaded rod drives a nut to axially move relative to the transmission threaded rod; the electric push rod is characterized in that the motor is connected with a cable; the cable extends out of the electric push rod; the cable comprises a sheath; and a ventilation channel for connecting the interior and the exterior of the electric push rod is formed in the sheath. The electric push rod has the advantages of ensuring the waterproof and dustproof effects of the electric push rod while solving the problem of easily generated negative pressure in the electric push rod.

Owner:ZHEJIANG JIECHANG LINEAR MOTION TECH

Amphibious pump

PendingCN110805562AWill not affect normal useSolve the sealing problemPump componentsPump installationsMarine engineeringMechanical engineering

The invention discloses an amphibious pump. The pump comprises a pump body, a water inlet flange arranged at the lower end of the pump body, a water pumping structure arranged inside the pump body, ahollow side wall arranged around the outer side of the water pumping structure, and a water outlet arranged at the upper end of the pump body. According to the amphibious pump, the pump can be suitable for land operation and underwater operation at the same time, the application range of the product is greatly expanded, the adaptability of the product is improved, the type of pumps to be preparedwhen a user needs to perform the land operation and underwater operation at the same time is reduced, the production cost of the user is well reduced, and the progress of enterprises and an industry is well promoted.

Owner:广州市洋茂泵业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com