A refiner with air inlet and outlet grooves that can be stopped for cleaning

A refiner and air intake trough technology, which is used in cocoa, grain processing, food science, etc., can solve the problems of inconvenient installation and disassembly of the integrated motor sleeve, the refiner is not suitable for shutdown cleaning, and the parts are damaged. Achieve the effect of avoiding personal injury, simple and reasonable structure, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

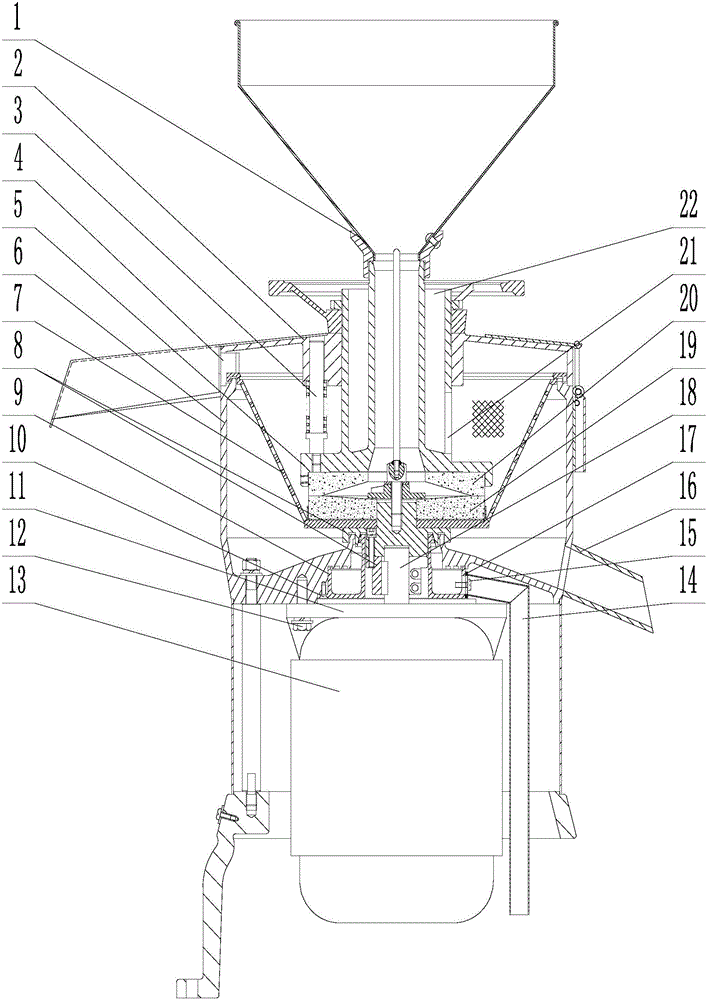

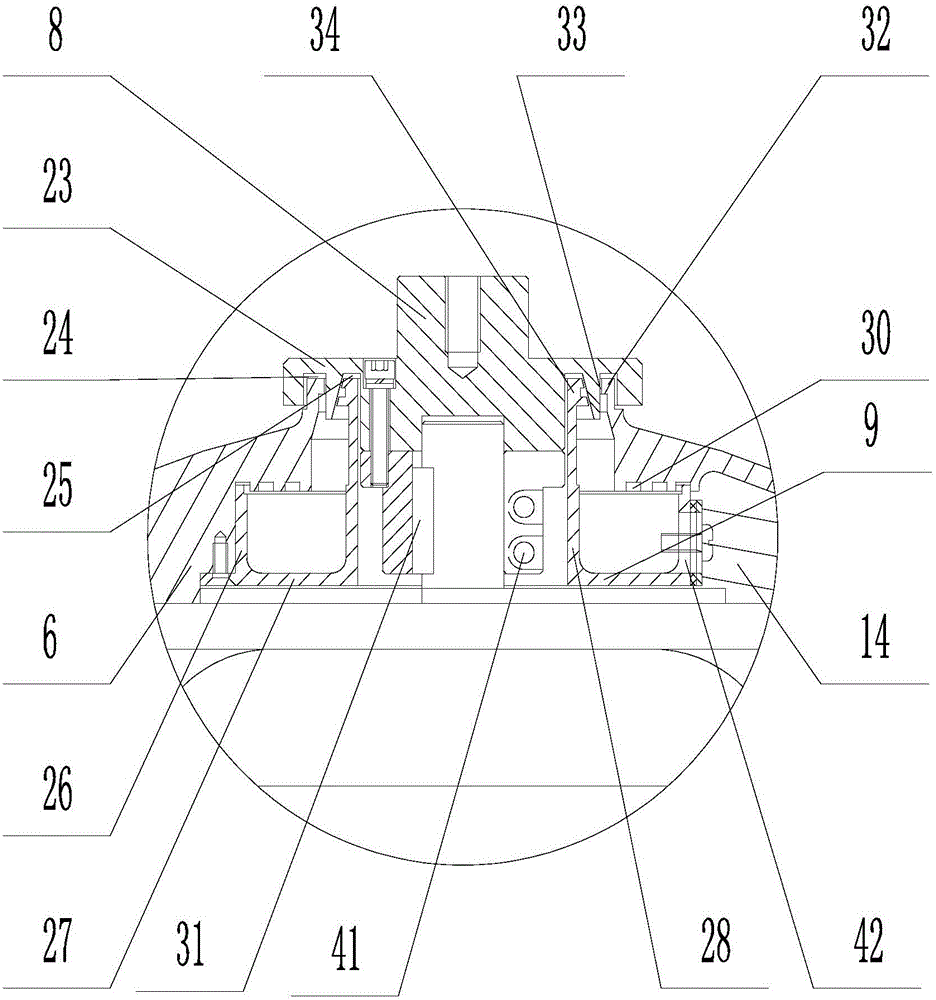

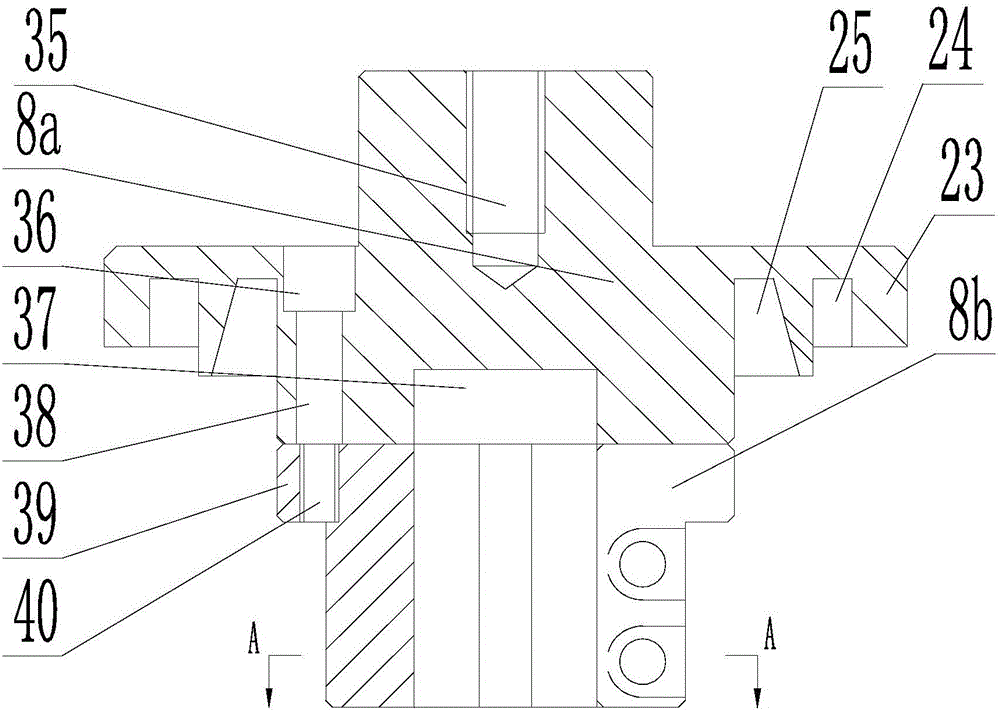

[0031] like figure 1 As shown, a refiner with an air inlet and outlet groove that can be stopped and cleaned includes a hopper 1, a cylinder head 2, a cylinder body 6, a separation basket 7, a static grinding seat 5, a motor sleeve 8 and a motor 13, and the cylinder head 2 is arranged on the top of the cylinder body 6, the hopper 1 is arranged on the top of the cylinder head 2, and the motor 13 is arranged on the bottom of the cylinder body 6; a separation basket 7 with a leakage hole is arranged in the cylinder body 6, and the separation basket 7 and the cylinder body 6 remain There is a gap, the upper grinding wheel sheet 20 and the lower grinding wheel sheet 19 are arranged in the separation basket 7, and the static grinding seat 5 fixedly connected with the cylinder head 2 is arranged under the hopper 1, and the lower part of the static gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com