Coke oven chamber pressure regulation device

A pressure regulation and carbonization chamber technology, which is used in furnace safety devices, coke ovens, petroleum industry, etc., can solve problems such as pressure fluctuations, coal charging and dust removal systems cannot operate normally, and adverse effects of coke ovens, etc. Conducive to coke oven production and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. detailed instructions.

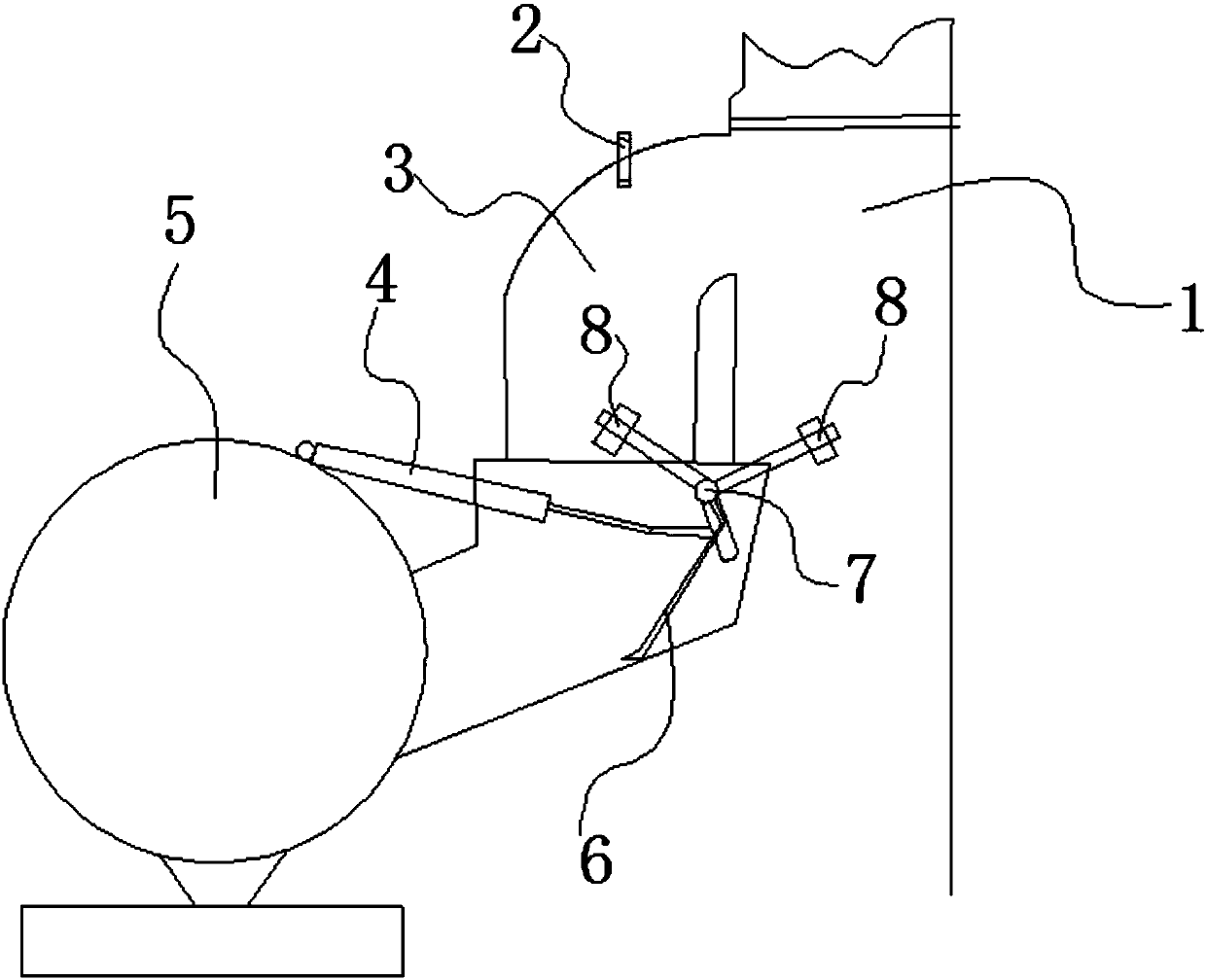

[0014] Such as figure 1 As shown, during the carbonization process of the coke oven carbonization chamber, raw gas is introduced from the carbonization chamber into the gas collecting pipe 5 through the riser pipe 1, the bridge pipe 3, and the bridge pipe water seal valve device, and then exported through the pipeline under the negative pressure generated by the gas blower. In order to realize the automatic adjustment of the pressure of the coke oven carbonization chamber, the lower end of the bridge tube 3 is designed as an inclined surface. By controlling the opening of the flap 6, the gas flow rate can be changed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com