Gravity self-adjusting hydraulic pressure stabilizing device

A voltage stabilizer and self-regulating technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of increased water outlet resistance of pipelines, increased energy consumption of circulation systems, and high installation requirements , to ensure the balance of internal and external pressure, solve the problem of negative pressure at the outlet, and maintain the balance of pipeline resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

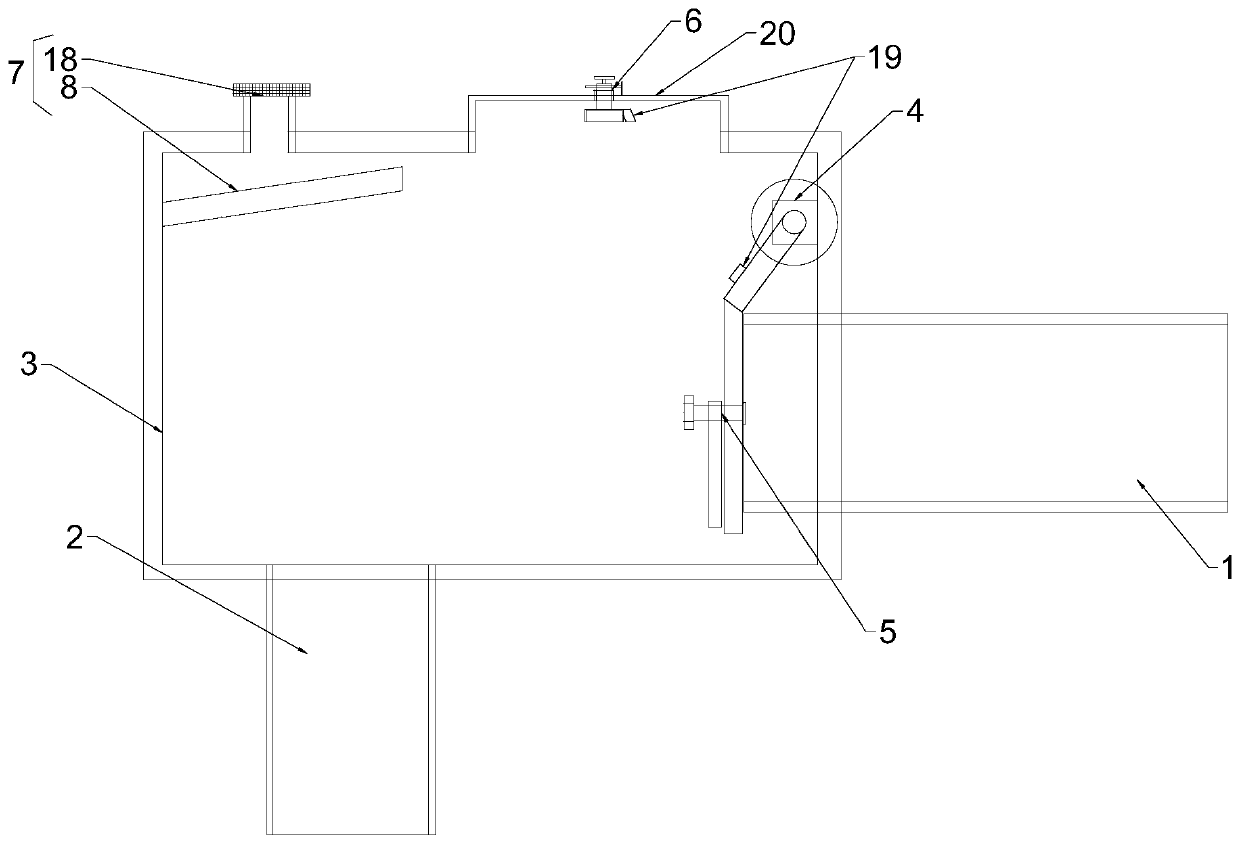

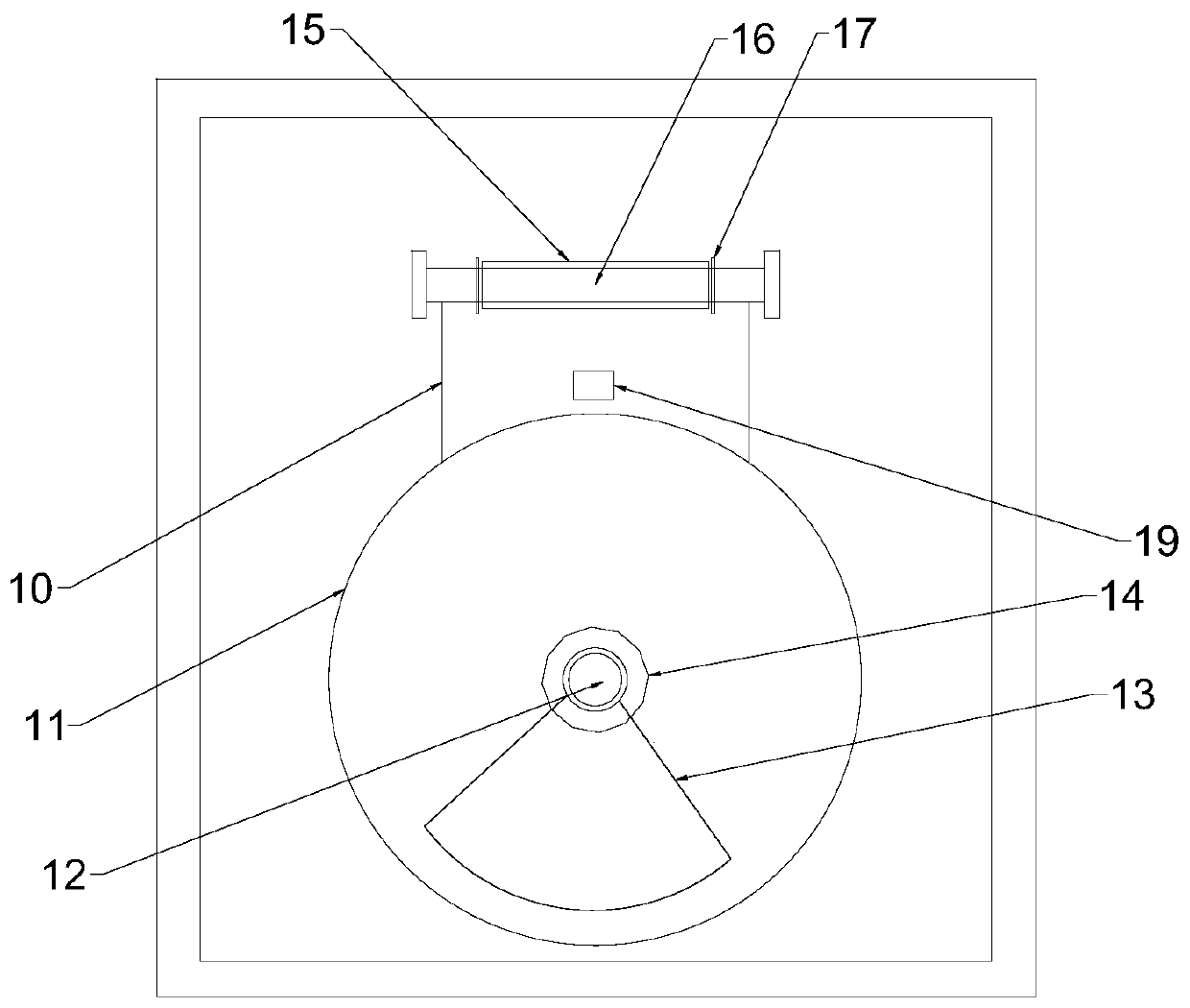

[0028] Example 1: See Figure 1-3 , the present invention provides a technical solution: a gravity self-adjusting hydraulic pressure stabilizing device, including a water inlet pipe 1, an outlet pipe 2, an adjustment box 3, a fixed fulcrum 4 with a rotating mechanism, a flow limiting device 5, an external water resistance Adjusting device 6, pressure balance device 7, above the water inlet inside the regulating box 3 is provided with a fixed fulcrum 4 with a rotating mechanism, a flow limiting device 5 is arranged on the fixed fulcrum 4 with a rotating mechanism, the limiting The flow device 5 includes a connecting piece 10, a water flow resistance plate 11, and a gravity resistance adjustment block 13. The water flow resistance plate 11 is installed on the fixed fulcrum 4 with a rotating mechanism through the connecting piece 10, and the water flow resistance plate 11 and the connecting piece 10 are connected at a certain angle, the water flow resistance plate 11 is placed on...

Embodiment 2

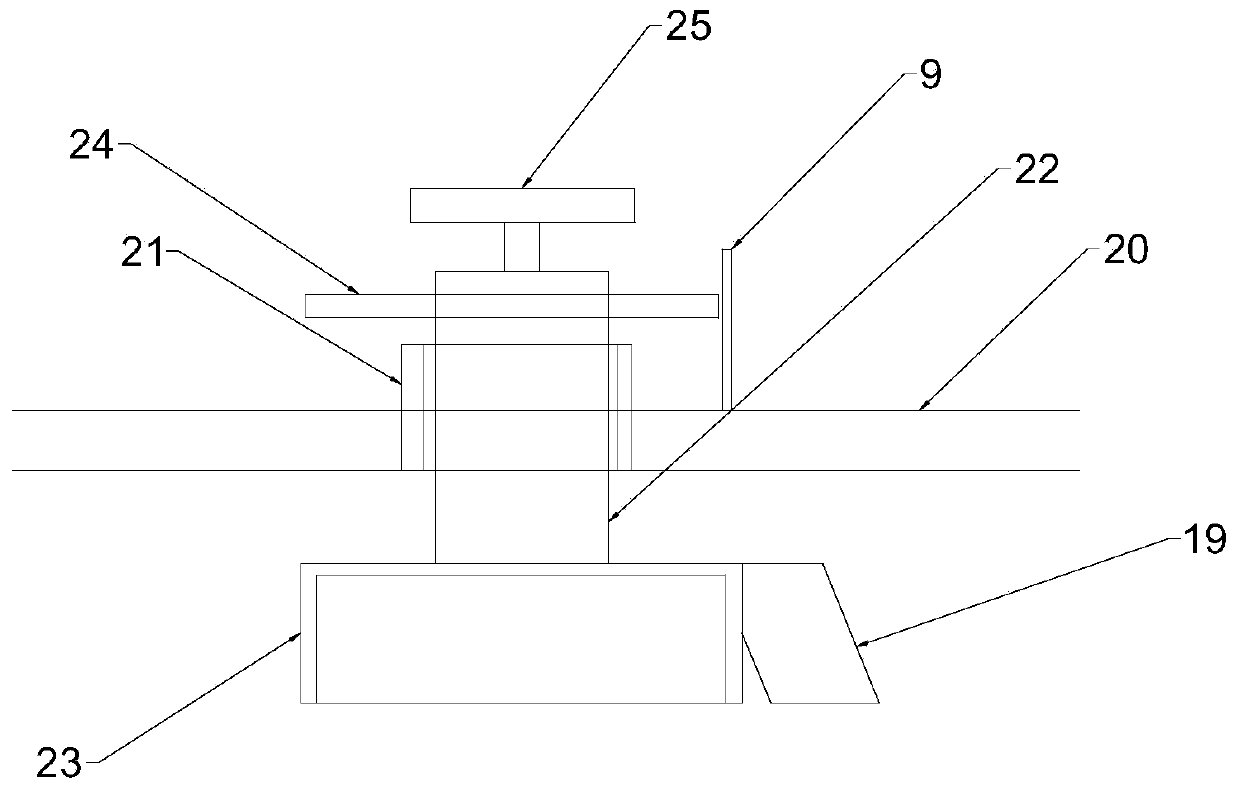

[0034] Example 2: see Figure 4, the present invention provides a technical solution: a gravity self-adjusting hydraulic pressure stabilizing device, including a water inlet pipe 1, an outlet pipe 2, an adjustment box 3, a fixed fulcrum 4 with a rotating mechanism, a flow limiting device 5, an external water resistance Adjusting device 6, pressure balance device 7, above the water inlet inside the regulating box 3 is provided with a fixed fulcrum 4 with a rotating mechanism, a flow limiting device 5 is arranged on the fixed fulcrum 4 with a rotating mechanism, the limiting The flow device 5 includes a connecting piece 10, a water flow resistance plate 11, and a gravity resistance adjustment block 13. The water flow resistance plate 11 is installed on the fixed fulcrum 4 with a rotating mechanism through the connecting piece 10, and the water flow resistance plate 11 and the connecting piece 10 is connected at a certain angle, and the water flow resistance plate 11 is placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com