Automatic resistance measuring device of strain gauge and operation method

A strain gage, automatic technology, applied in the field of strain gage automatic resistance measuring devices, can solve the problems of high labor intensity, unfavorable production line automation, low efficiency of manual resistance measuring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described below in conjunction with accompanying drawing:

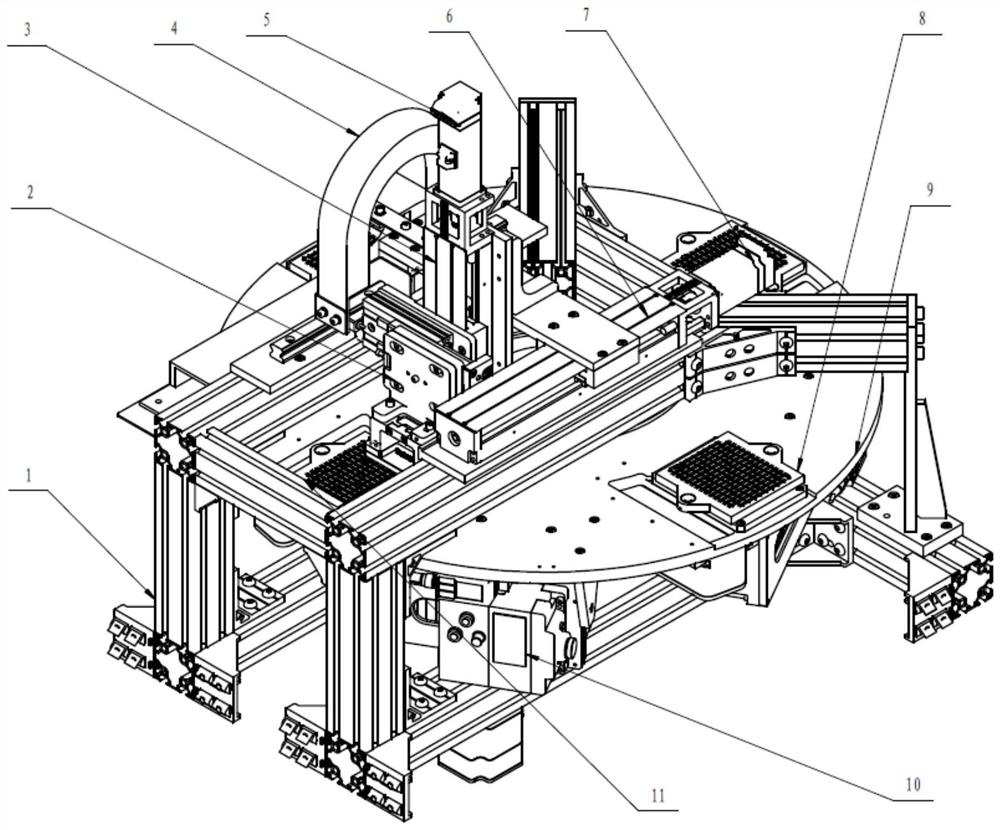

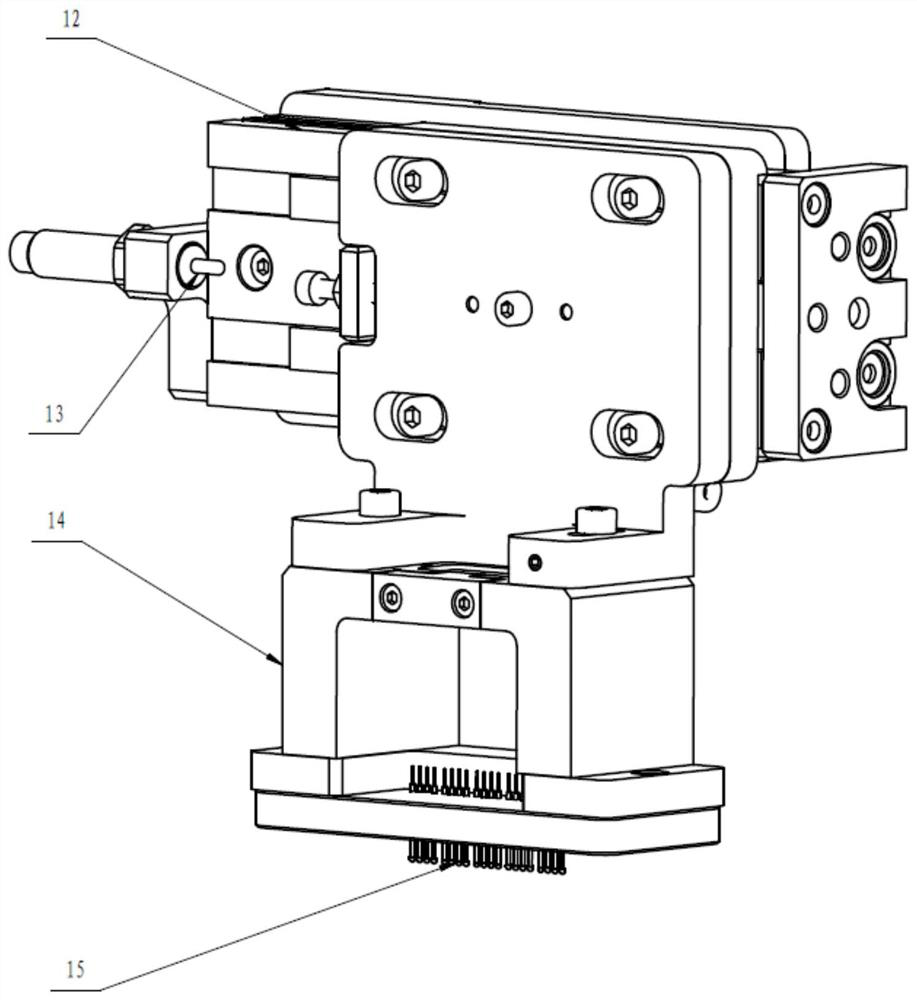

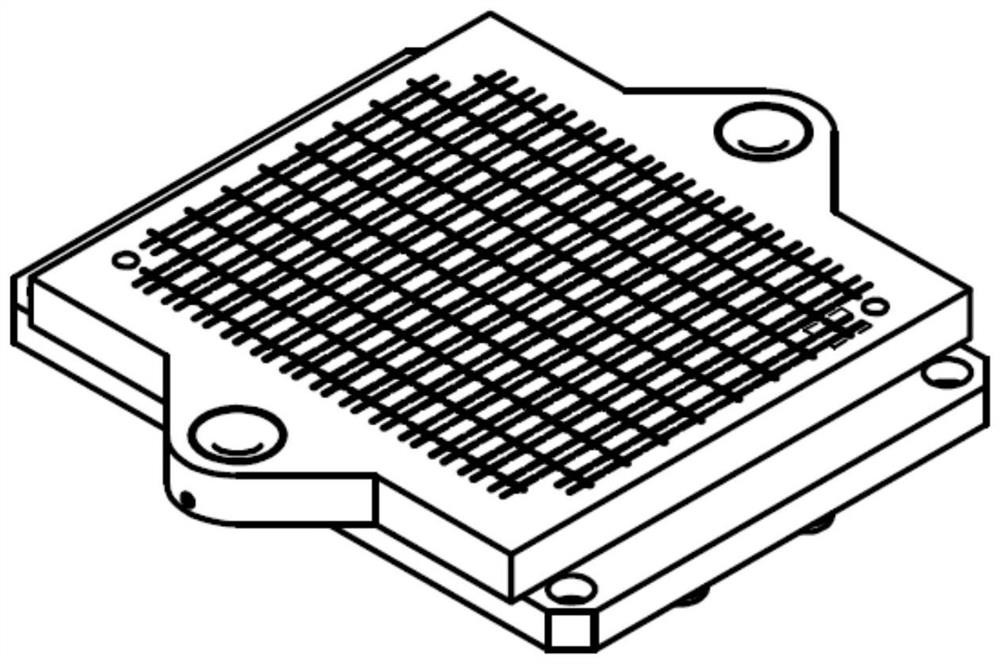

[0031] see Figure 1 to Figure 3 , the present invention is a resistance strain gauge automatic resistance measuring machine, such as figure 1 with figure 2 As shown, the automatic resistance measuring machine frame 1 is included, the base part of the rotary disk 9 is connected with the automatic resistance measuring machine frame 1 through screws, and the rotary disk 9 can be driven by a servo motor to realize free rotation. Four resistance-measuring stations are evenly distributed on the rotary table 9, and there is a material tray 8 above each station, and a communication valve island 10 is distributed below the station. By controlling the communication valve island 10, the negative pressure of the corresponding tray 8 can be controlled on and off to absorb or release the strain gauge. The electric slip ring is located at the center of the rotary disc 9, so that when the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com