Fresh tea leaf treatment device and treatment method thereof

A processing device and technology for fresh tea leaves, which are applied in the directions of tea processing before extraction, tea drying, food heat treatment, etc., can solve the problems of poor withering effect, unfavorable airflow passing, and inability to cover with hot air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with the accompanying drawings, the specific embodiments of the present invention will be further described in detail, so as to make the technical solution of the present invention easier to understand and grasp.

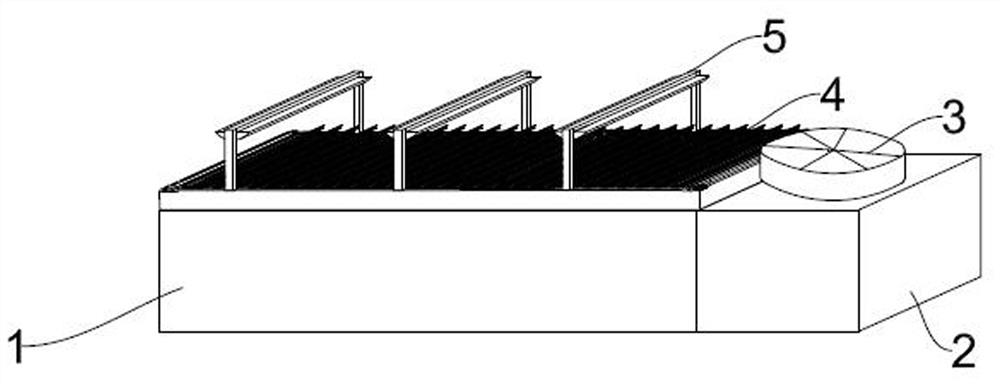

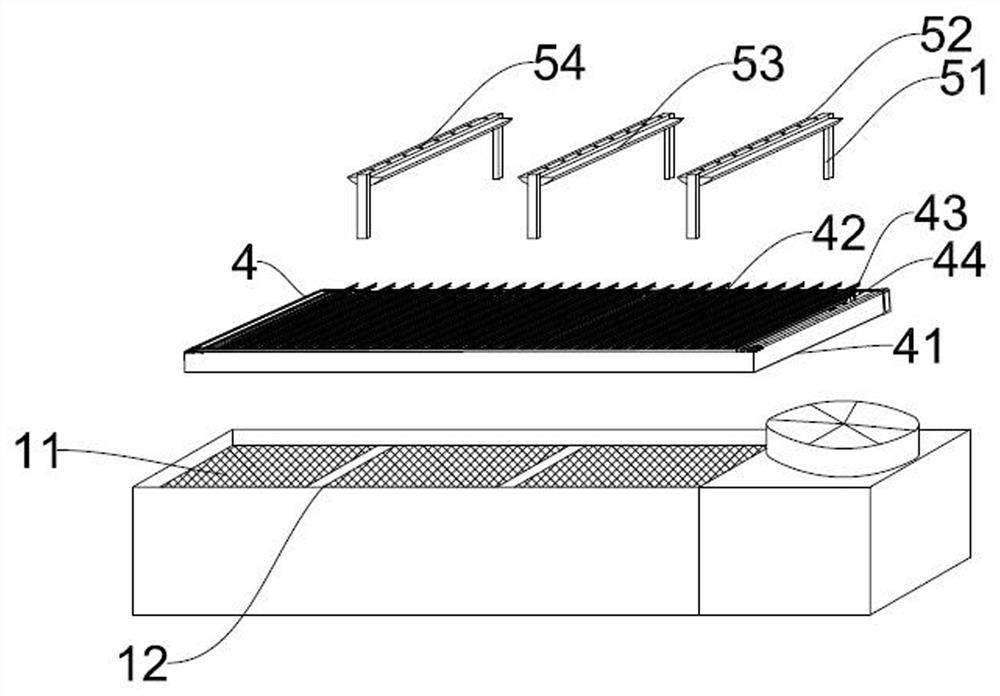

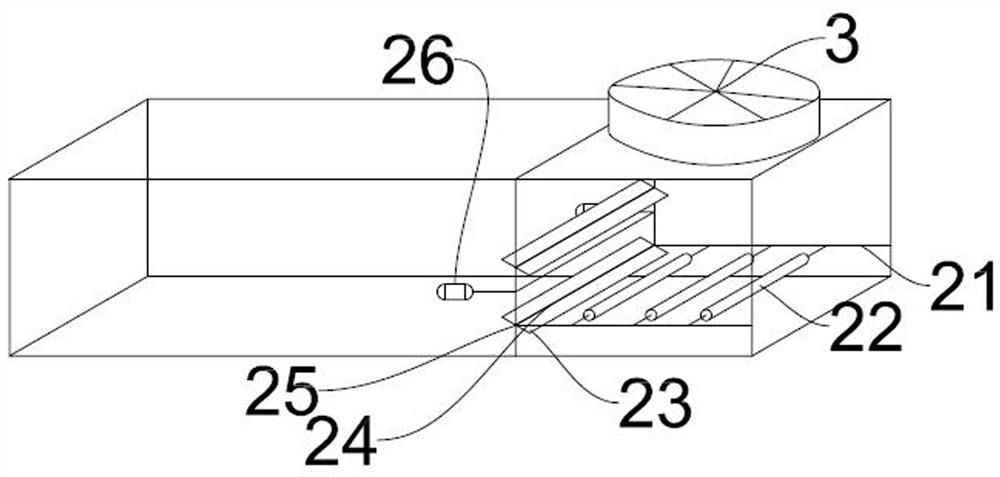

[0030] combine Figure 1 to Figure 5 , a processing device for fresh tea leaves, comprising a withering bed 1, a heating device 2 is arranged on the side of the withering bed 1, and a fan 3 is fixedly installed on the top of the heating device 2. The blower fan 3 starts blowing to the heating device 2 from top to bottom, and the cold wind blows hot air to the withering bed 1 after being heated, so that the tea leaves laid on the withering bed 1 have a suitable withering temperature.

[0031] The top of the withering bed 1 is provided with an opening, and a support bar 12 is longitudinally arranged in the opening, and a net plate 11 is fixedly arranged on the support bar 12, and the tea leaves that need to wither are laid on the net plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com