A method for protecting the steel water jacket at the anode furnace mouth and the flue mouth, and the steel water jacket

A technology of molten steel jacket and flue mouth, applied in furnace, furnace cooling, furnace components, etc., can solve the problems of influence, easy deformation of heat-resistant alloys, and expensive production of heat-resistant alloy plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Such as figure 1 shown, follow the steps below,

[0021] A. Replacement and installation: Replace the corroded old steel water jacket at the anode furnace mouth and flue mouth, and install a new steel water jacket;

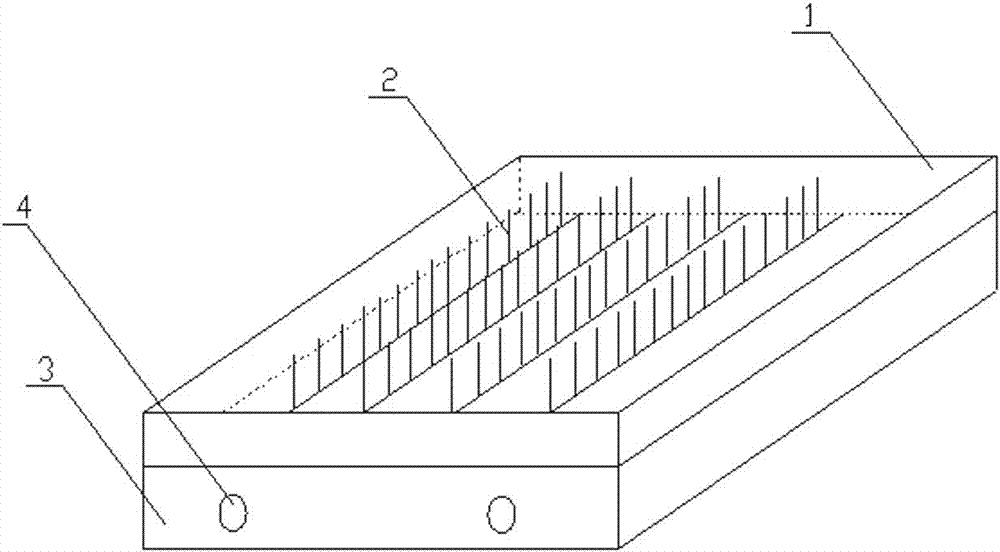

[0022] B. Mold making: After the molten steel jacket at the anode furnace mouth and the flue mouth is installed normally, the surface of the exposed molten steel jacket is flat and staggered to weld the catch 2, and the iron mold 1 with the same length and size as the molten steel jacket is welded on the edge of the molten steel jacket;

[0023] C. Casting: Cast the configured aluminum-carbon casting material in the welded iron mold, and at the same time, vibrate and fill the aluminum-carbon casting material firmly;

[0024] D. Ignition and heating: After the aluminum-carbon refractory is cast, the anode furnace can be ignited and heated up normally after 8 hours of maintenance.

[0025] Such as figure 1 As shown, a molten steel jacket includes a molten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com