Regeneration and recycling technology for acid copper chloride etching waste liquid

A technology of etching waste liquid and copper chloride, which is applied in the regeneration and recovery process of acidic copper chloride etching waste liquid, and can solve the problems of high management difficulty, environmental pollution, and large amount of chemical waste liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

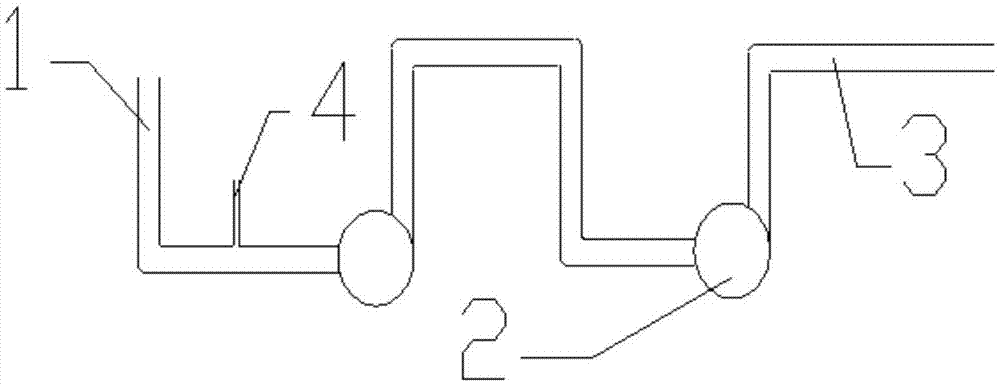

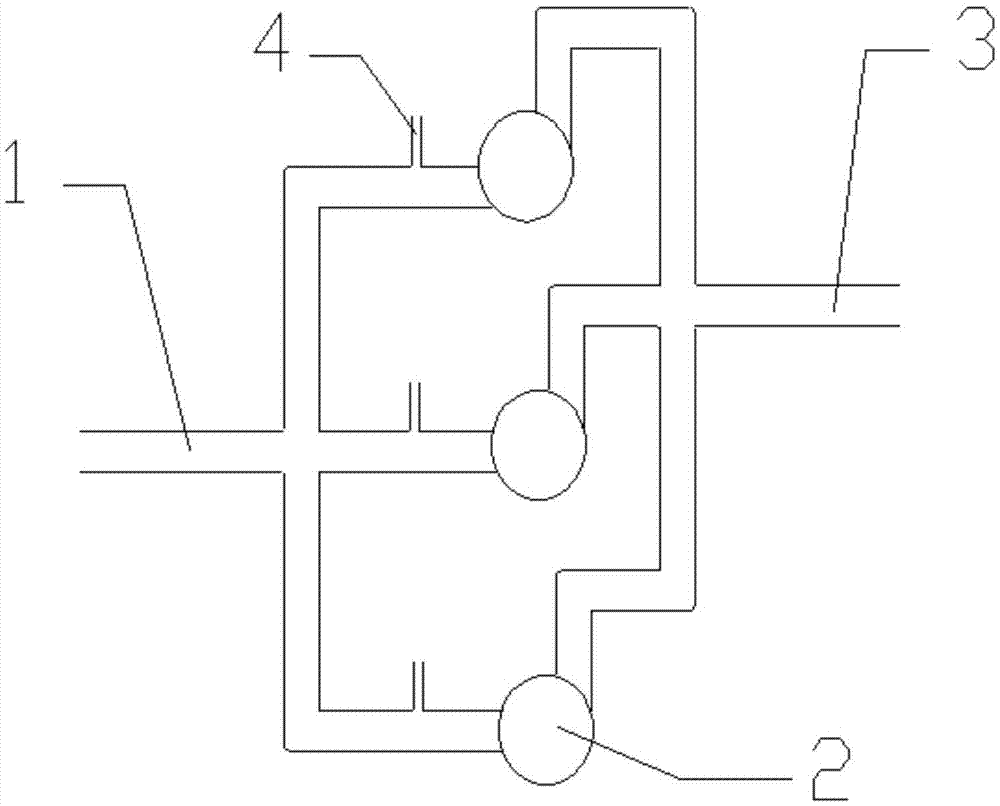

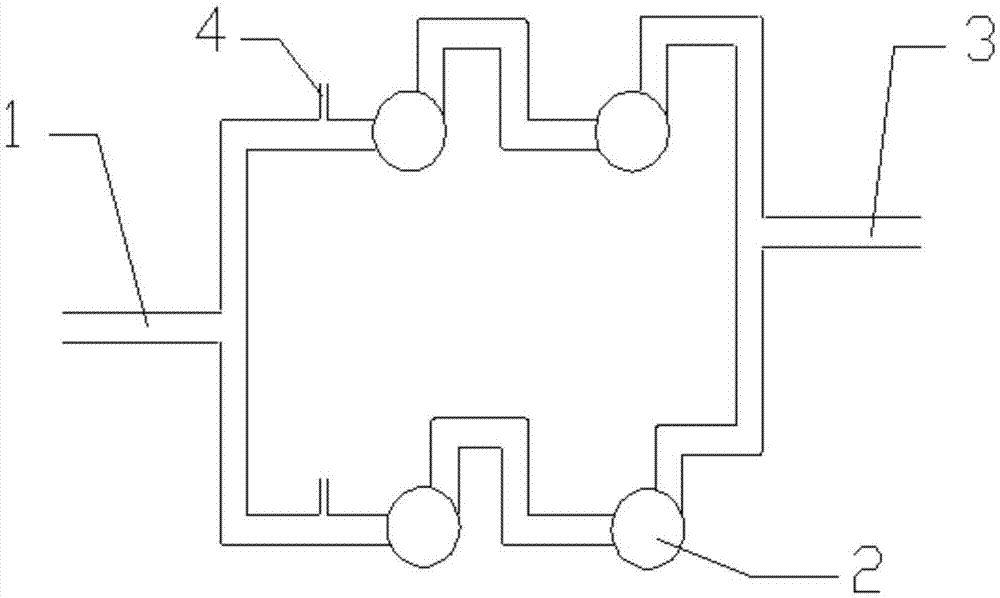

Image

Examples

Embodiment 1

[0111] A kind of regeneration process of acid copper chloride etching solution, comprises the following steps:

[0112] 1. Replacement: Take 500mL of etching waste liquid, and use the titration method to detect that the concentration of copper ions in the etching waste liquid is 1.9mol / L, and the concentration of ferric ion is 0.14mol / L; put 55g of iron powder into the etching waste liquid , and stir until no more bubbles are produced;

[0113] 2. Filtration: After the mixture obtained in step 1 is cooled to room temperature, it is filtered to obtain filtrate A and filter residue B;

[0114] 3. Clean the filter residue: place the filter residue B obtained in step 2 in excess 5M hydrochloric acid and react until no bubbles are produced; after the resulting mixture is cooled to room temperature, filter it quickly to obtain filtrate C and filter residue D; the composition of filter residue D is copper , analyzed by X-ray spectrometer, its purity is 92.8%; the quality of the copp...

Embodiment 2

[0118] A kind of regeneration process of acid copper chloride etching solution, comprises the following steps:

[0119] 1. Replacement: Take 500mL of etching waste liquid, and use the titration method to detect that the concentration of copper ions in the etching waste liquid is 0.01mol / L, and the concentration of ferric ion is 0.001mol / L; put 0.3g of iron into the etching waste liquid powder, and stir until no more bubbles are produced;

[0120] 2. Filtration: After the mixture obtained in step 1 is cooled to room temperature, it is filtered to obtain filtrate A and filter residue B;

[0121] 3. Clean the filter residue: put the filter residue B in an excess of 5M hydrochloric acid to react until no gas is produced; after the resulting mixture is cooled to room temperature, filter it quickly to obtain filtrate C and filter residue D; the composition of filter residue D is copper, and the X-ray Spectrometer analysis shows that its purity is 94.7%, which can be directly reused...

Embodiment 3

[0125] A kind of regeneration process of acid copper chloride etching solution, comprises the following steps:

[0126] 1. Replacement: Take 500mL of etching waste liquid and use the titration method to detect that the concentration of copper ions in the etching waste liquid is 0.2mol / L, and the concentration of ferric ion is 0.7mol / L; put 15.7g of iron into the etching waste liquid powder, and stir until no more bubbles are produced;

[0127] 2. Filtration: After the mixture obtained in step 1 is cooled to room temperature, it is filtered to obtain filtrate A and filter residue B;

[0128] 3. Clean the filter residue: place the filter residue B obtained in step 2 in excess 5M hydrochloric acid to react until no gas is produced; after the resulting mixture is cooled to room temperature, filter it quickly to obtain filtrate C and filter residue D; the composition of filter residue D is copper , analyzed by X-ray spectrometer, its purity is 95.1%, which can be directly reused; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com