Control method and device suitable for foamed slag furnace condition in iron bath smelting reduction

A control method, iron bath melting technology, applied in the field of ironmaking, can solve problems such as inapplicable iron bath melting reduction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0137] The quantitative recovery method of the iron bath smelting reduction of the present application comprises wind mode (OW mode), simmering furnace mode (Idle mode), maintenance mode (Hold mode), climbing mode (OR-1 mode), production mode (OR-1 mode). 2 mode)

[0138] The characteristics of the five productions are as follows:

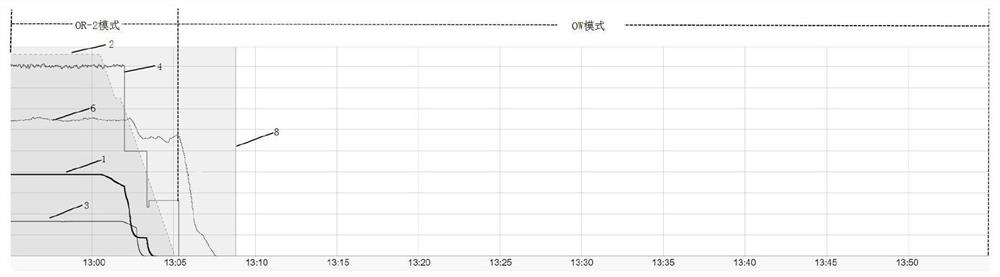

[0139] 1) OW mode: refers to temporarily stopping the air supply to the SRV furnace for some reason, and the SRV furnace is quickly switched from the production status to the maintenance and safety standby stage in a short period of time, and HAF=0Nm at this stage 3 / h, Ore-I=0, Coal-I=0, Lime-I=0, the gas release valve of the smelting reduction furnace is opened, and the SP is gradually reduced to 0, as figure 1 shown.

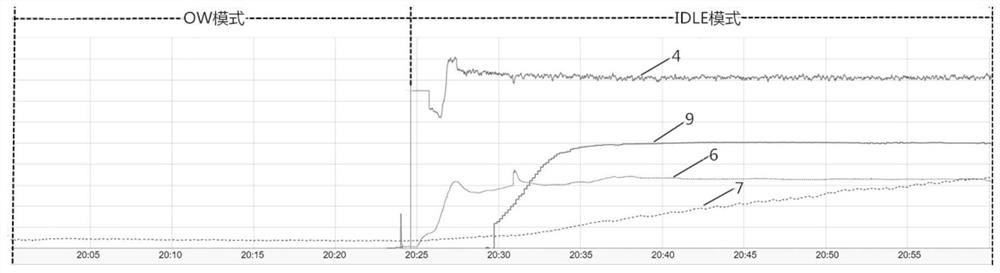

[0140] 2) Idle mode: refers to the injection of oxygen-enriched hot air and natural gas into the smelting reduction furnace after re-airing to establish heat balance and provide the heat required for the start-up of the smelting...

Embodiment 2

[0145] The foamy slag is produced in the iron bath smelting reduction process. C in the pulverized coal injected into the molten pool is dissolved in the iron bath and enters the molten iron. Bubbles formed by mixing. The foamy slag presents a fine film-like structure. During normal production, the semi-coke in the molten pool is not wetted by the liquid slag, which can effectively destroy the bubbles and achieve a dynamic balance, so that the bubbles in the slag are of different sizes. When the foaming speed Speed up, semi-coke is not enough to suppress the formation of foam, and foamy slag will occur. After the foamy slag is formed, a large number of small bubbles appear in the slag, and the average density of the slag is less than 0.3t / m 3 .

[0146] Based on many years of production practice and summed up experience, the inventor of the present application divided the foam slag into three grades: slight foam slag, medium foam slag and severe foam slag, and clarified the...

Embodiment 3

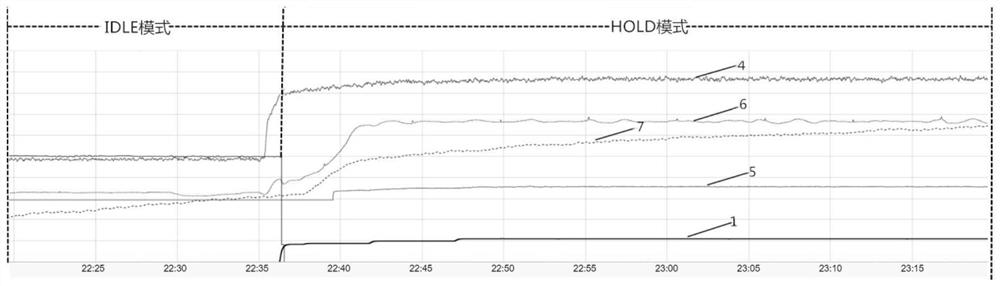

[0182] Due to peripheral equipment failure and other reasons, after the SRV furnace enters the shutdown state, it is necessary to quickly find the cause and enter the re-air flow process. The SRV furnace startup logic control module follows the order of OW mode, Idle mode, Hold mode, OR-I mode, and OR-2 mode. Enter in sequence and return to normal production status.

[0183] Process technicians click the IDLE button of the DCS control system to enter the Idle mode, and send the signal to the hot blast stove control system. After entering the Idle state, ignite the natural gas spray gun, and the NG-Flow is increased to 6000Nm at most 3 / h, the SP parameter is set to 10-40kpa, the natural gas pressure adjustment range is 100-500kpa, the flue drum pressure is 1-4Mpa, the steam drum is sent to the power plant with a steam flow rate of 0-30t / h, and a stable steam drum cycle is established.

[0184] One of the judgment bases for switching from "Idle mode" to "Hold mode" is that HTT=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com