Online resistance temperature and pressure monitoring early-warning instrument

A technology of temperature, pressure and resistance temperature, applied in the direction of measuring resistance/reactance/impedance, instruments, measuring electrical variables, etc., can solve problems such as increased maintenance time and cost, production safety accidents, corrosion of metal tanks, etc., and achieve equipment loss And the effect of low maintenance cost, avoiding leakage, and reducing response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Now in conjunction with the anticorrosion storage tank and accompanying drawings, the present invention will be described in further detail. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

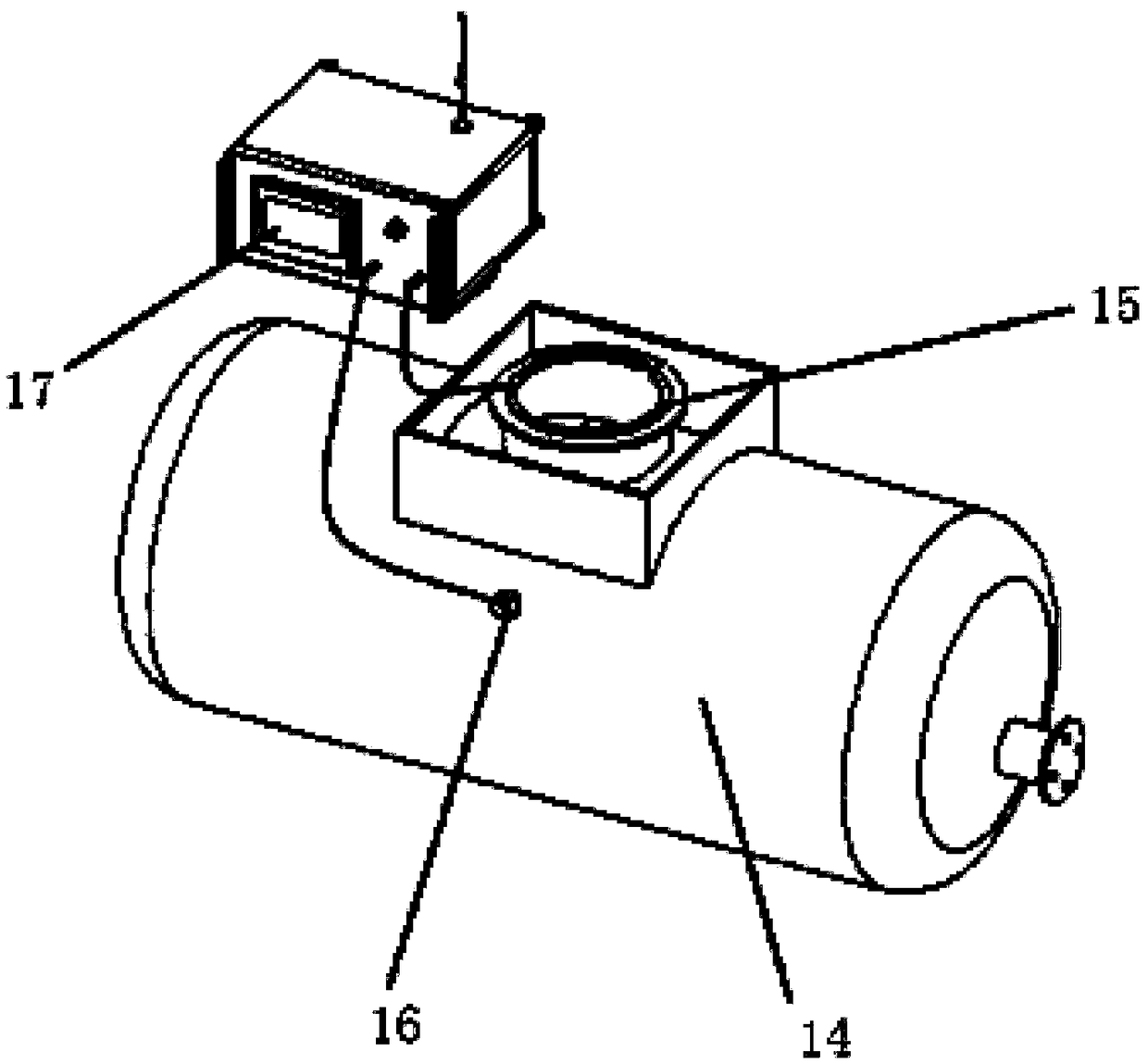

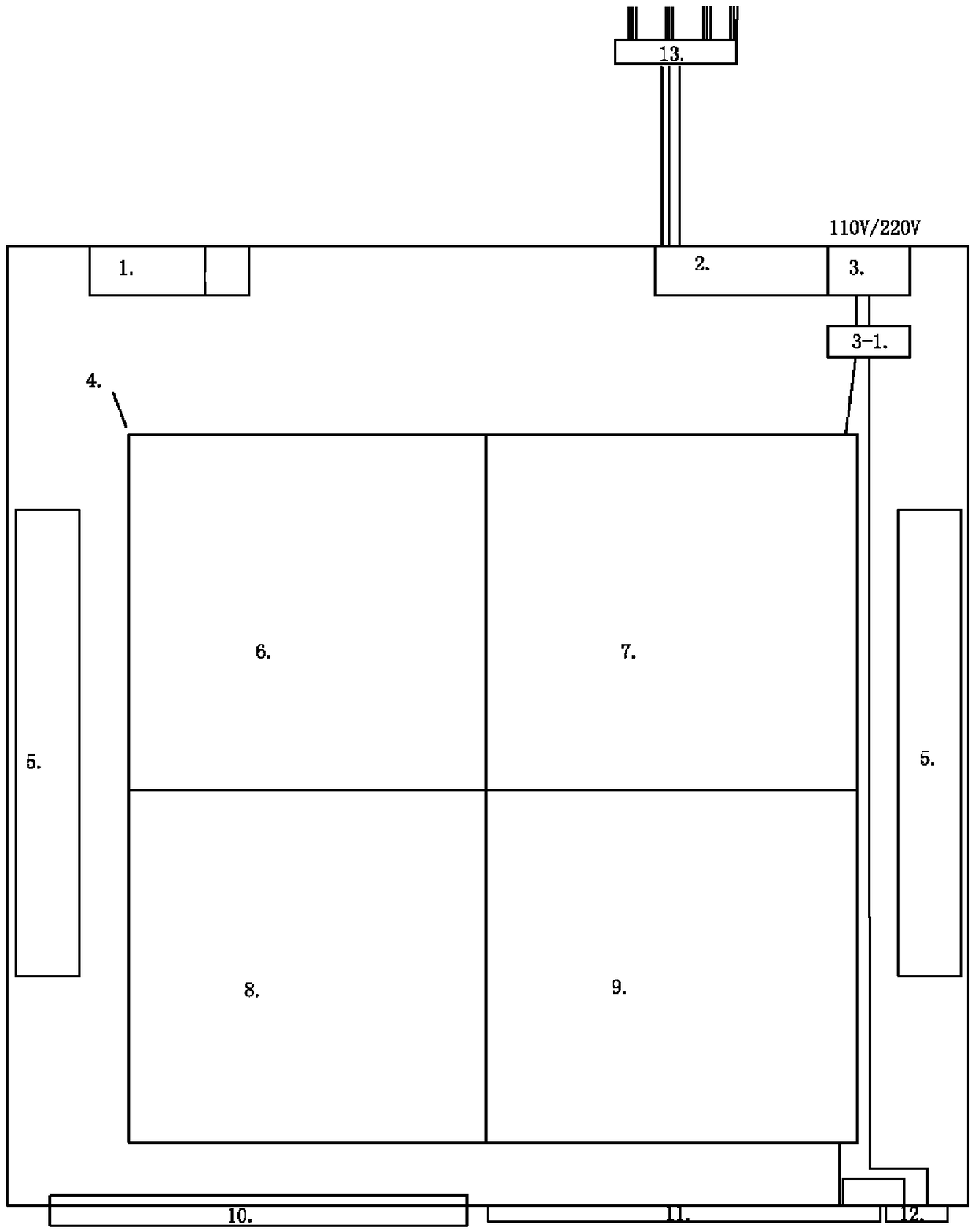

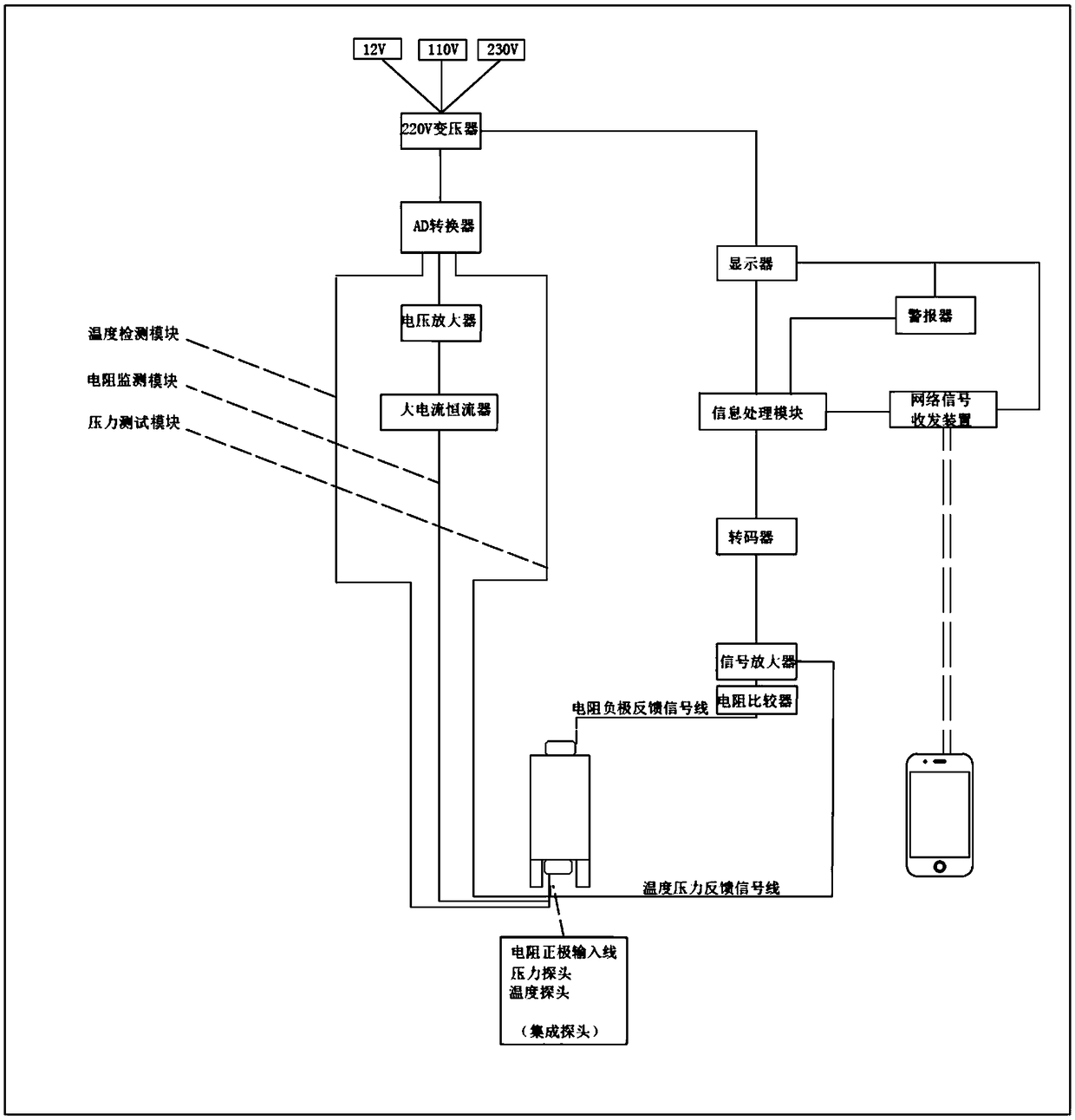

[0023] Such as Figure 1-Figure 3 As shown, an anti-corrosion storage tank includes a tank body 14, an anti-corrosion inner liner 15 is provided inside the tank body 14, and integrated probes 16 are respectively provided on both sides of the inner liner 15; the integrated probes 16 include resistance probes , a pressure probe and a temperature probe; the tank body 14 is an iron tank or a stainless steel tank, and a GPS positioning device is provided outside the tank body 14. The resistance probe, the pressure probe and the temperature probe are set as an integrated probe of an integrated structure; the integrated prob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com