Ore conveying belt device of plate-type ore feeder

A plate-type ore feeding and ore transporting technology, which is applied in transportation, packaging, conveyors, etc., can solve the problem that the imported crusher center cannot be crowded with ore feeding and insufficient ore feeding, a large amount of cleaning by post workers, and many ore transport belt failures. and other problems, to achieve the effect of facilitating the installation of cleaners, preventing bolt breakage, and improving intrinsic safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

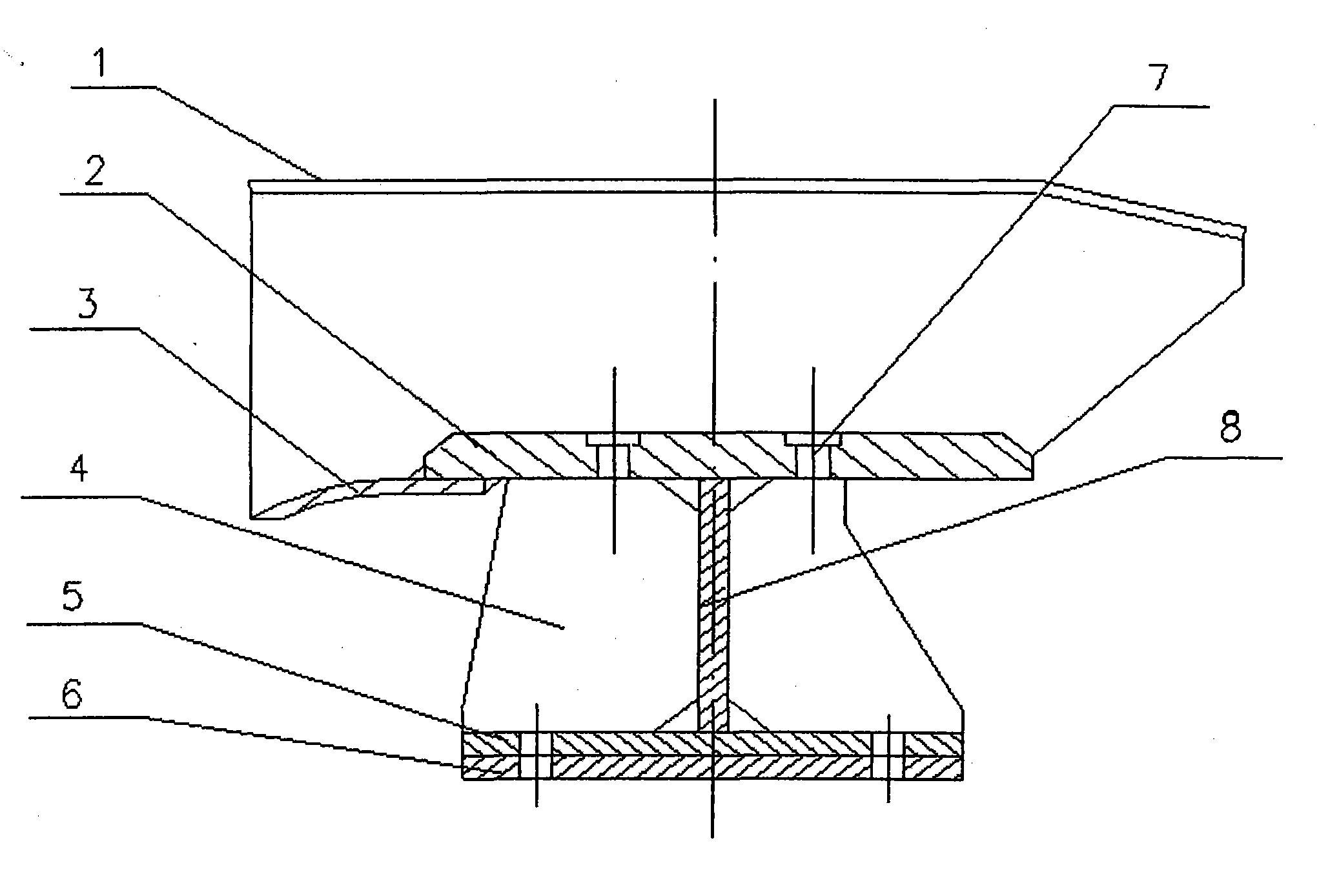

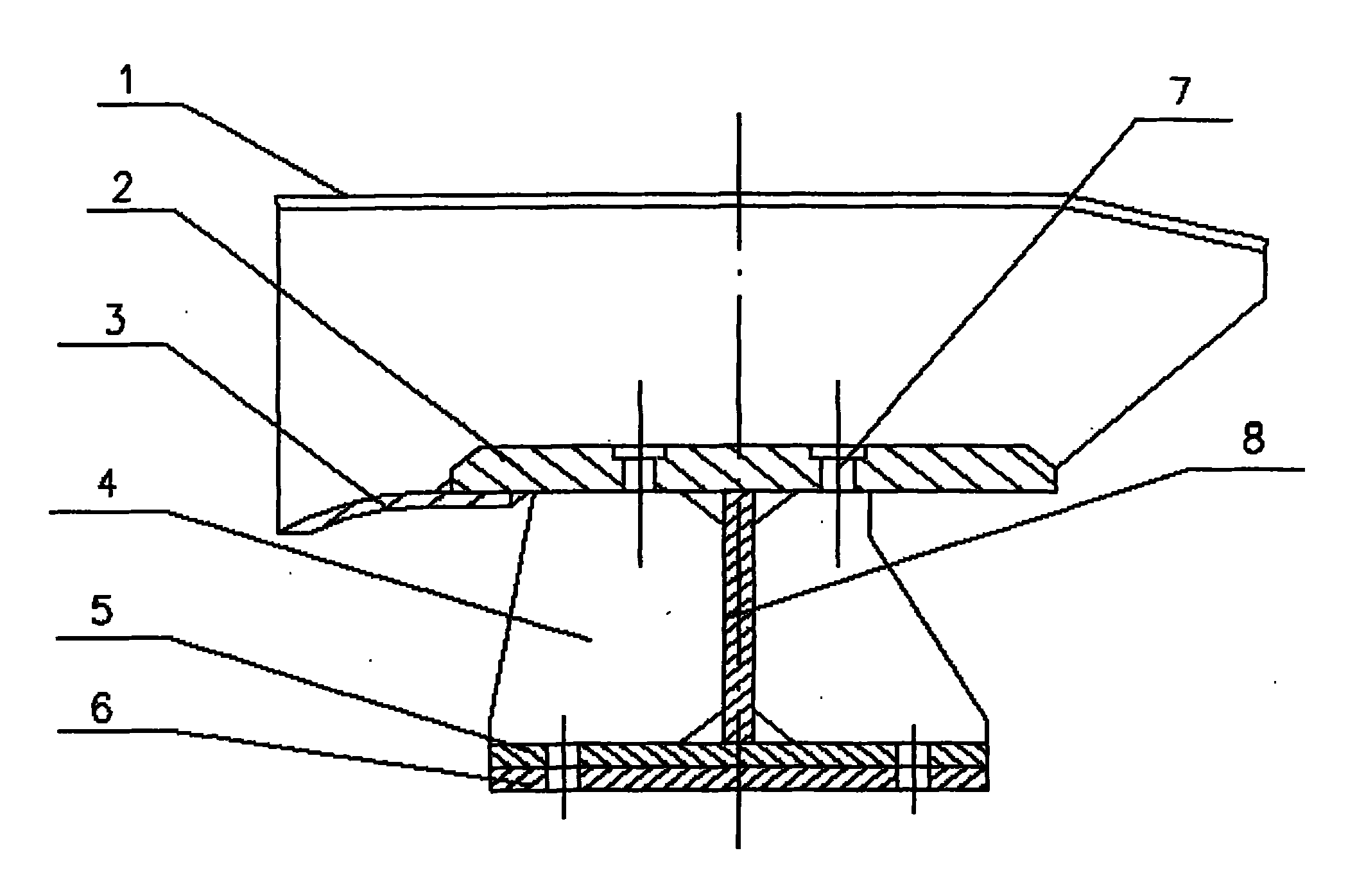

[0009] The support plate 6 is made of 45# high-quality steel, and is fixed on the connecting plate 5 by countersunk head bolts M20×90 (840 sets, the depth of the countersunk head is improved to 8mm). Iron ore weight and resistance.

[0010] The slot plate 2 is fixed on the tank chain through the countersunk head bolt M20×90 in the screw hole 7, and the chain link length of the tank chain is 228mm. On the front side of the trough plate 2, an arc-shaped sealing plate 3 is arranged according to the diameters of the head drive sprocket and the rear reversing drum, and its function is to seal the dynamic gap between the trough plates 2 during the ore transportation process of the combined trough plate , Effectively prevent ore leakage during ore transportation. Slot plate 2 is welded with ore retaining plate 1 along two sides of length direction, promptly is welded with ore retaining plate 1 along width direction two sides in whole ore conveying belt. In order to ensure the stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com