Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Avoid bond failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

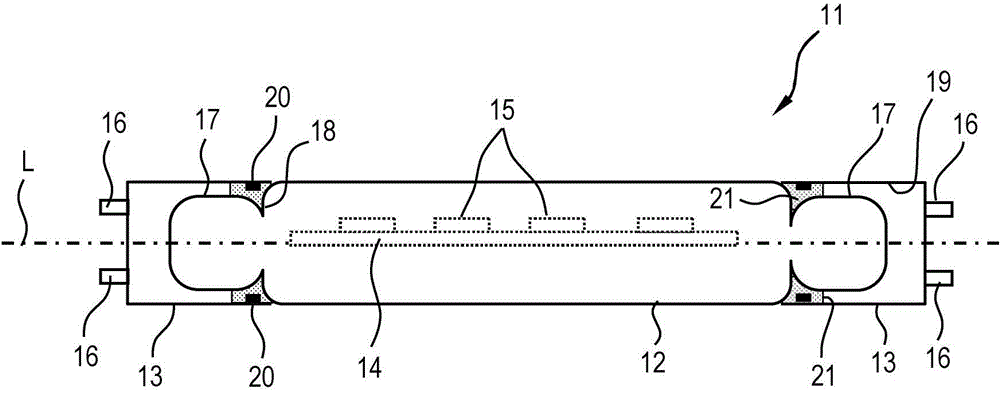

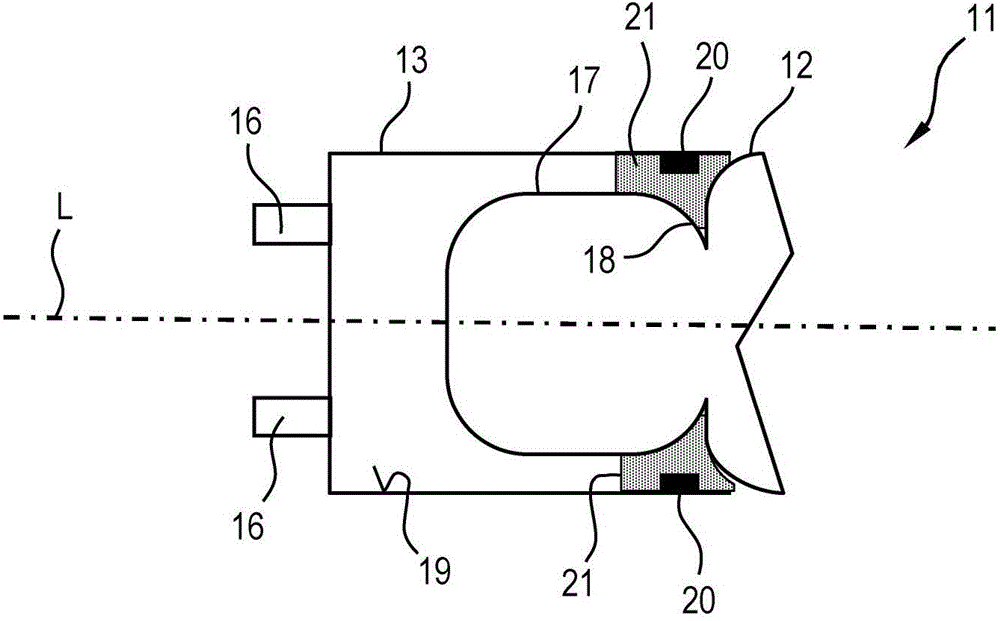

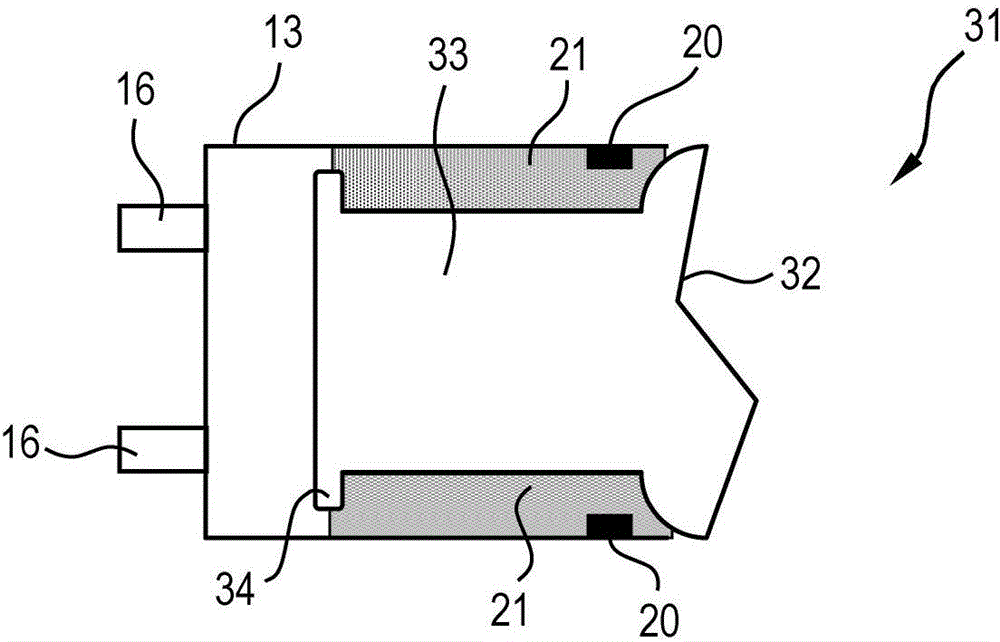

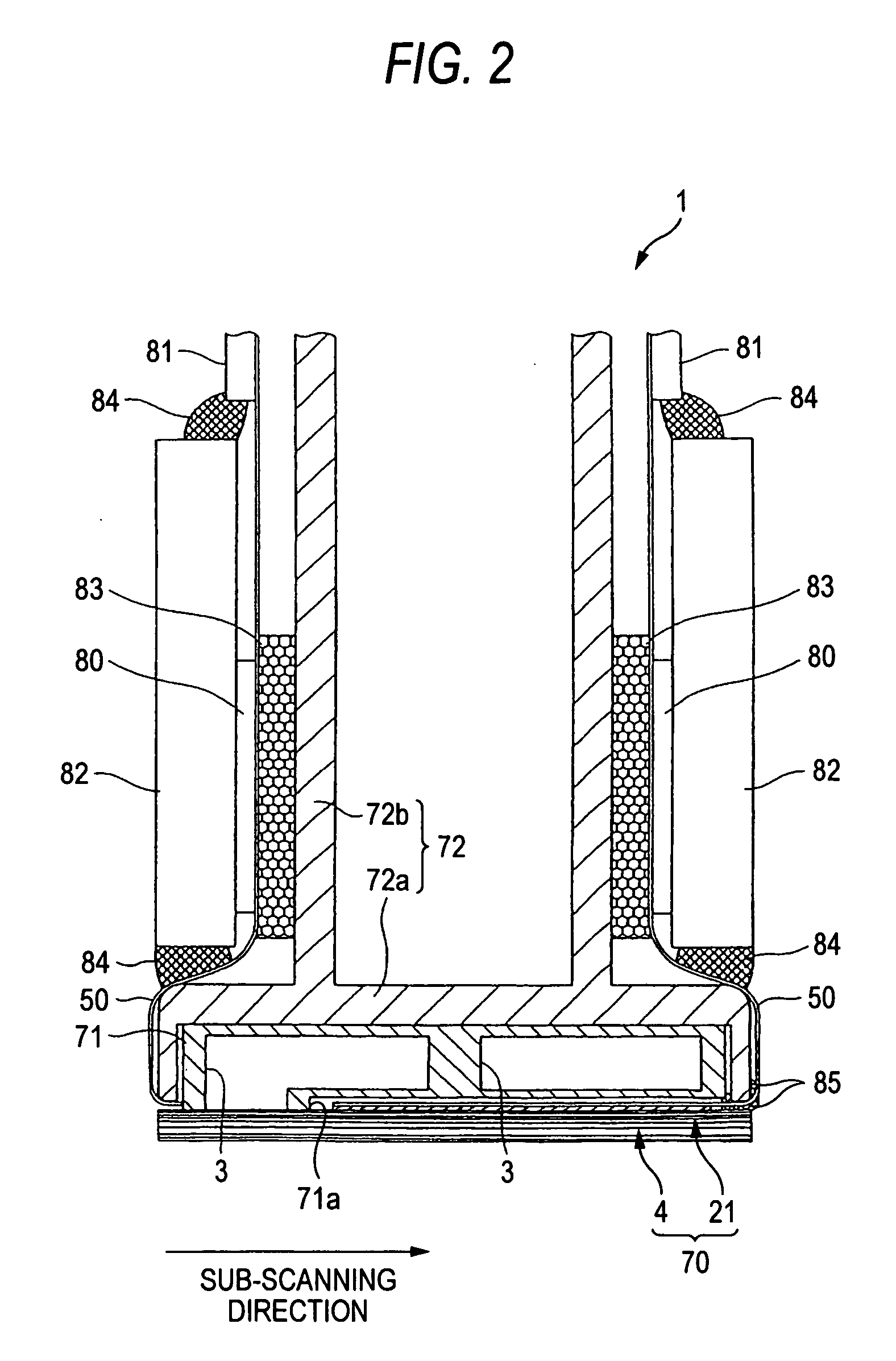

Lighting device including interconnected parts

InactiveCN103851547ASimple fit fixEasy to fixPoint-like light sourceProtective devices for lightingAdhesiveLight emitting device

A lighting device (11) especially a semiconductor lighting device is provided. The lighting device may include at least one first part (12) and at least one second part (13), fastened to the first part (12), wherein the first and second parts are interconnected by a potting compound (21) especially a cured adhesive, the parts being positively interconnected by the potting compound (21).

Owner:LEDVANCE GMBH

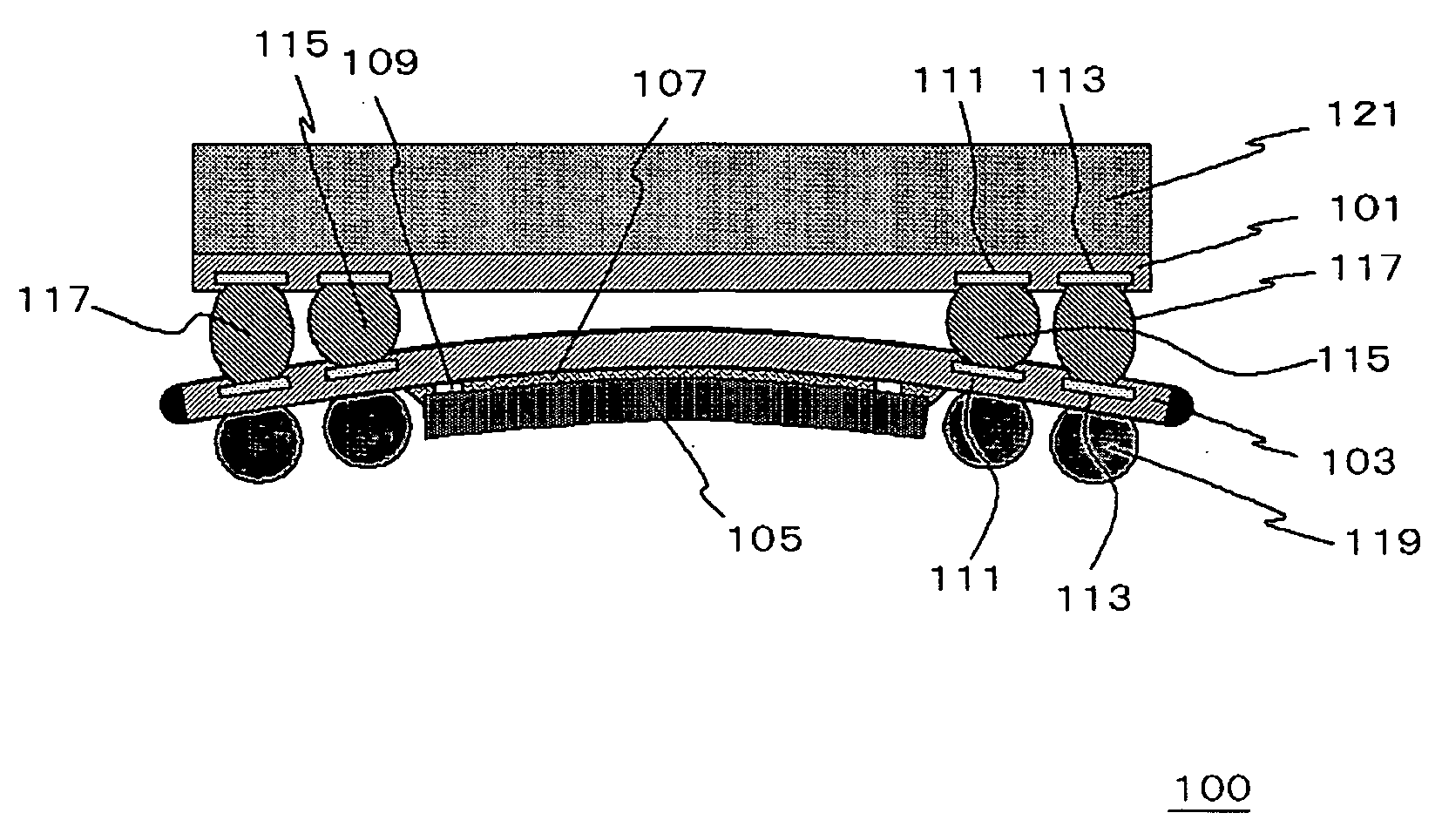

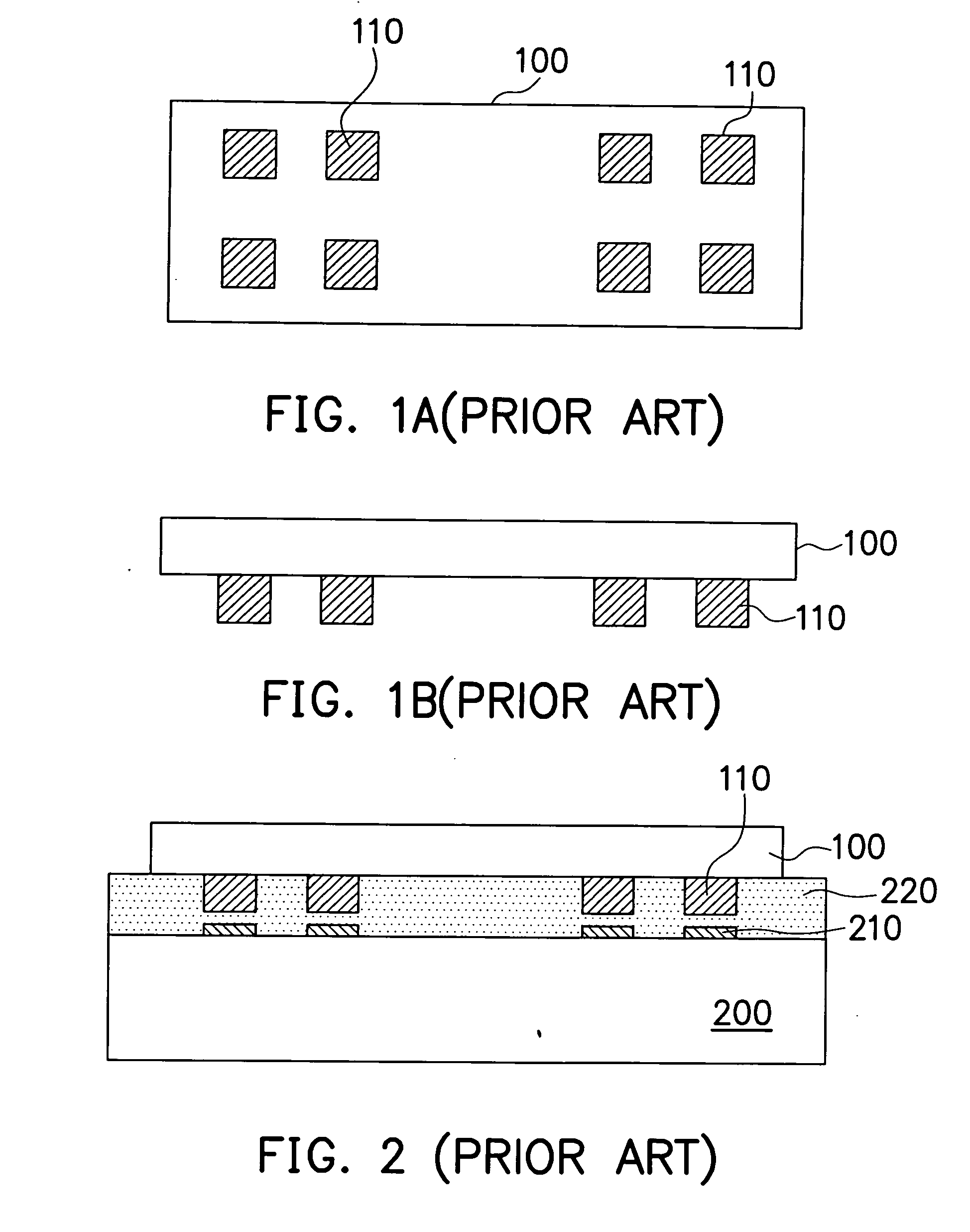

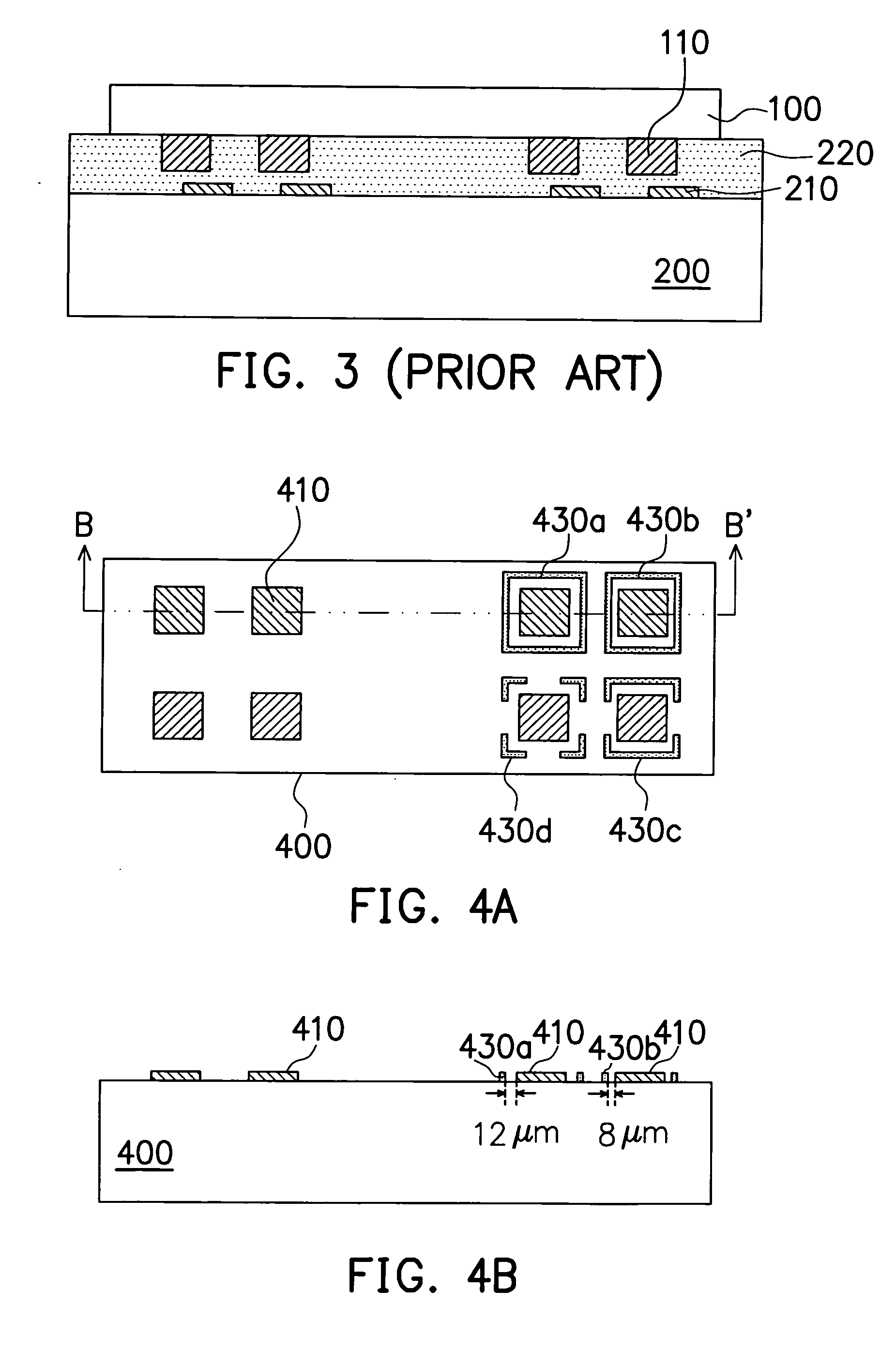

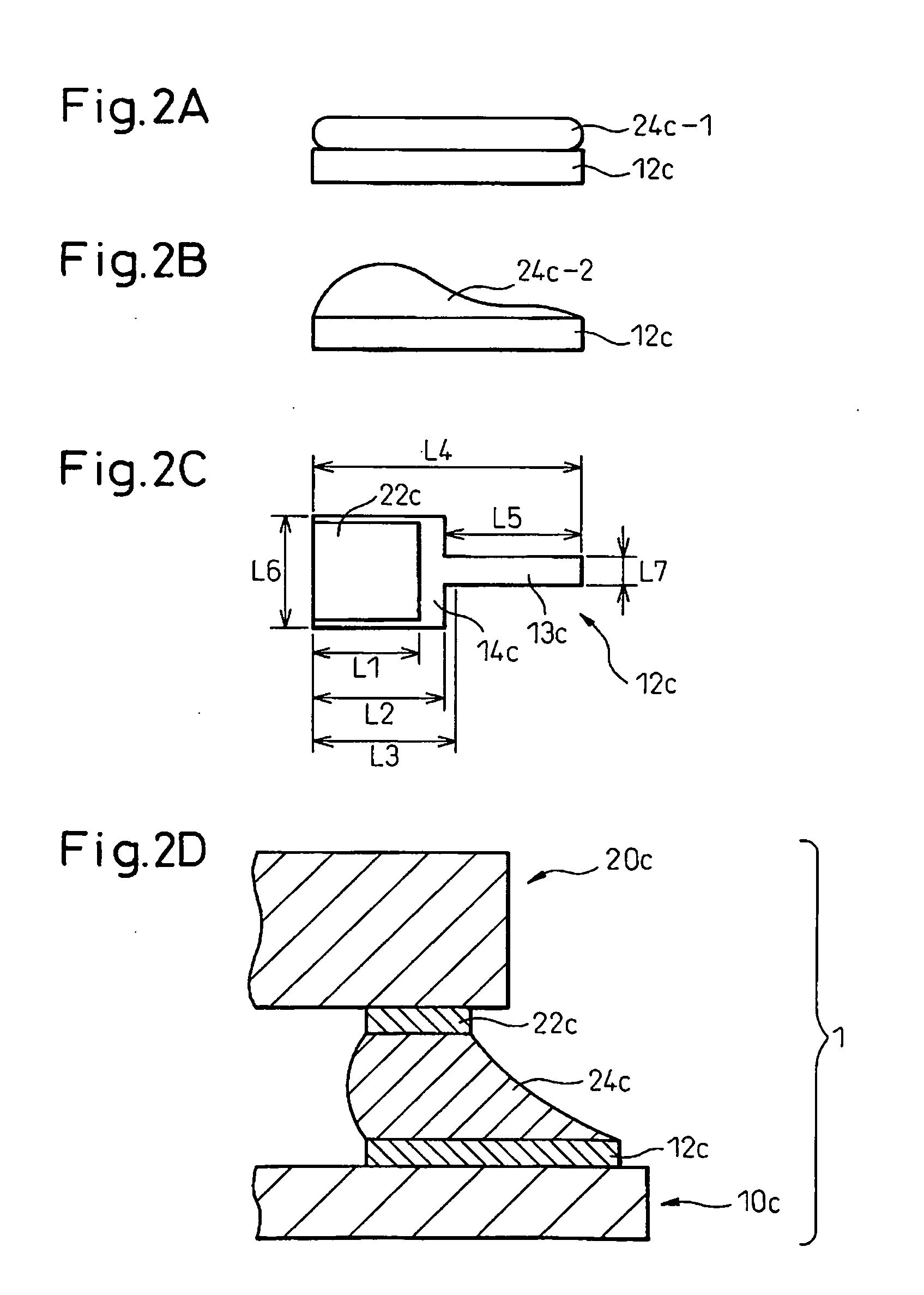

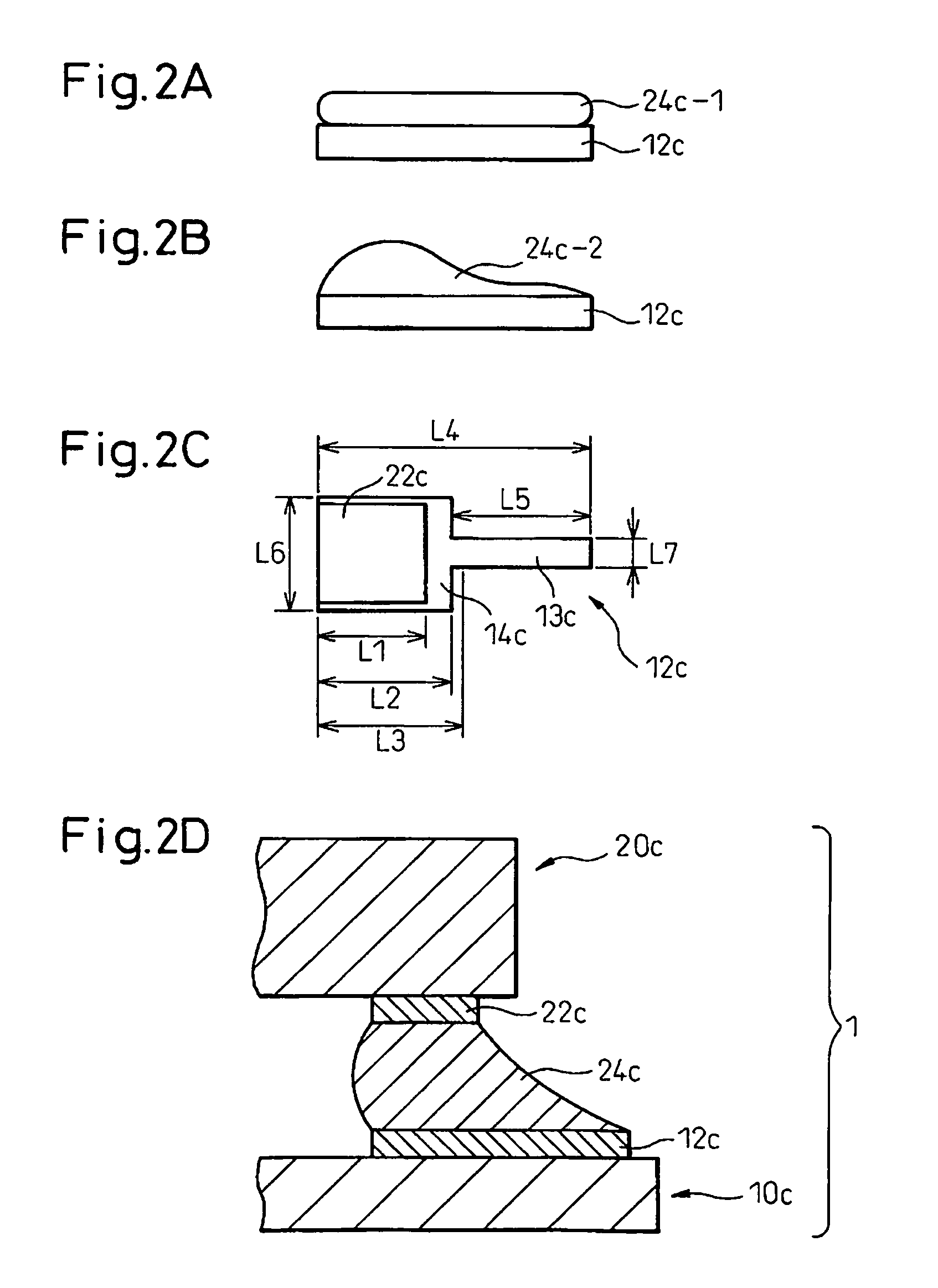

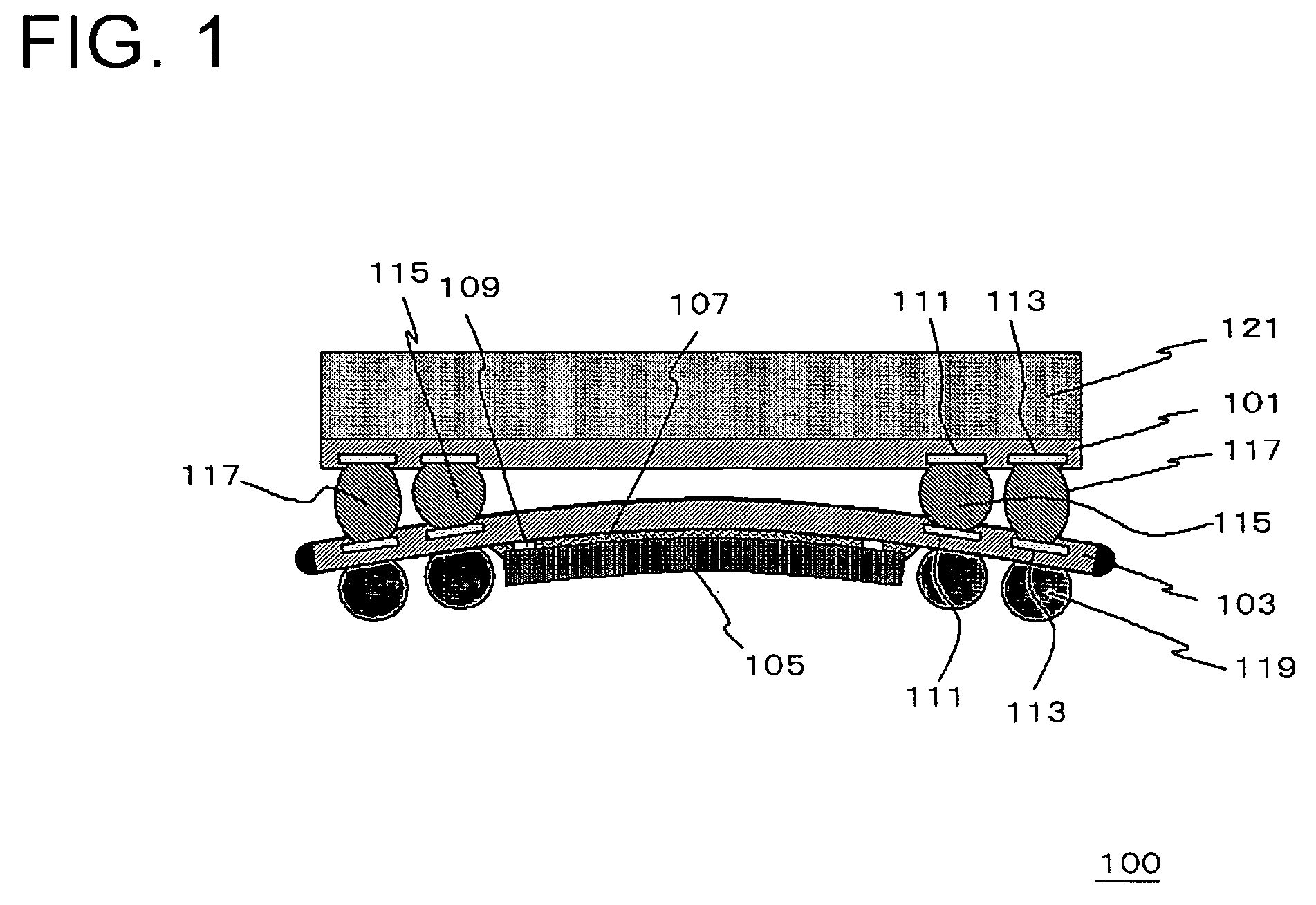

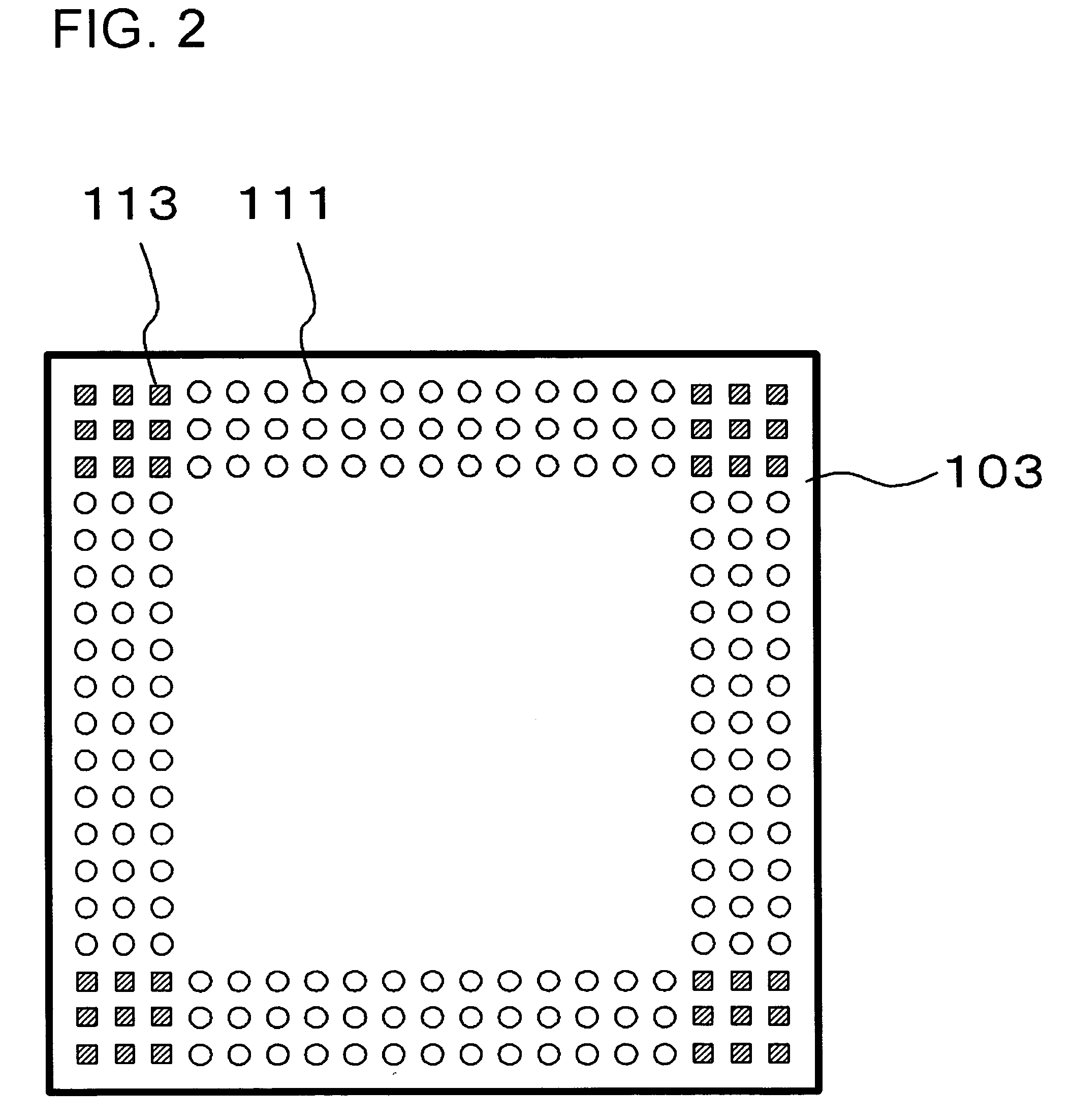

Substrate and semiconductor device

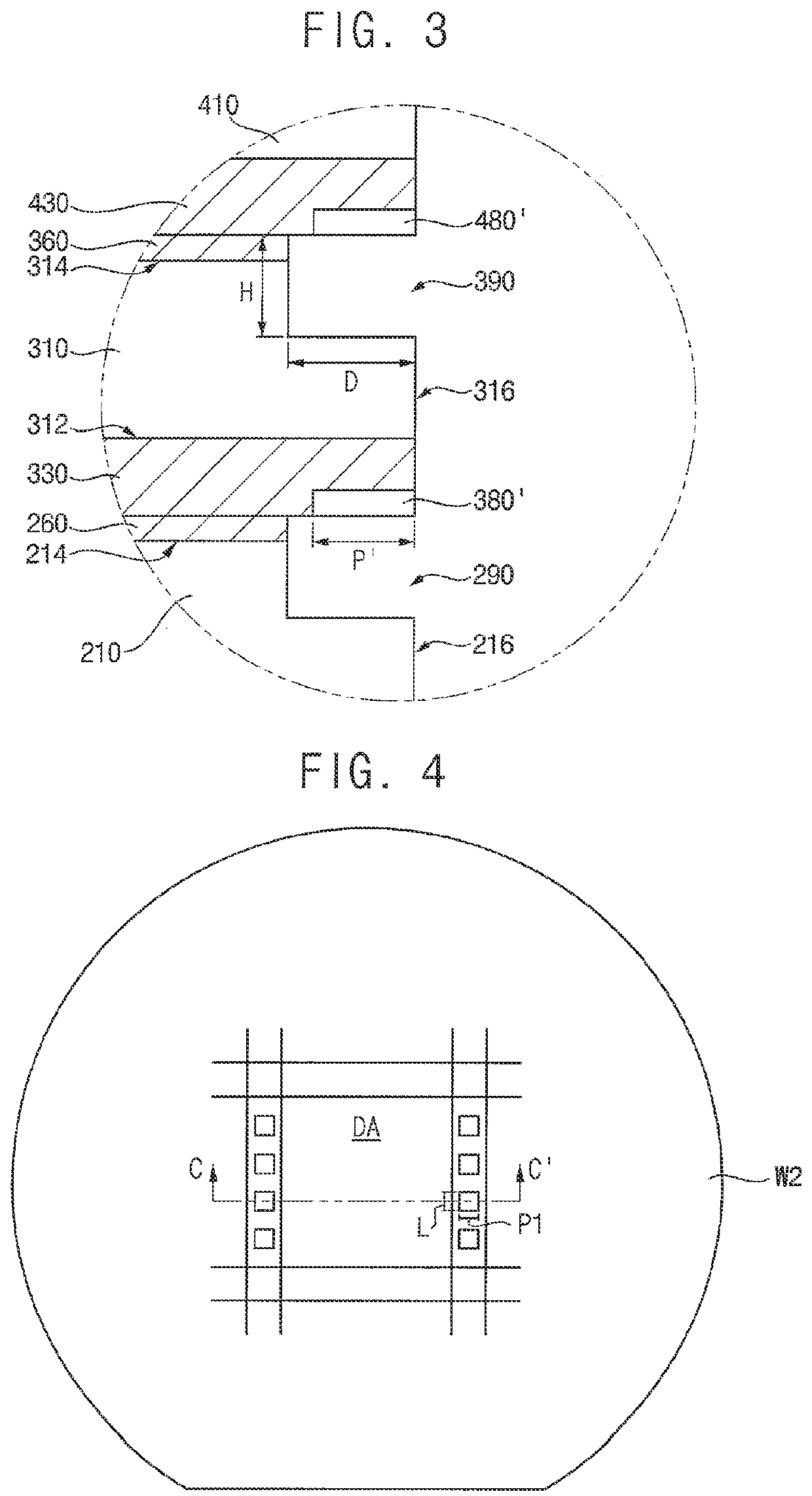

InactiveUS20070164445A1Easy to adjustSuppress bonding failureFinal product manufactureSemiconductor/solid-state device detailsSemiconductorSemiconductor device

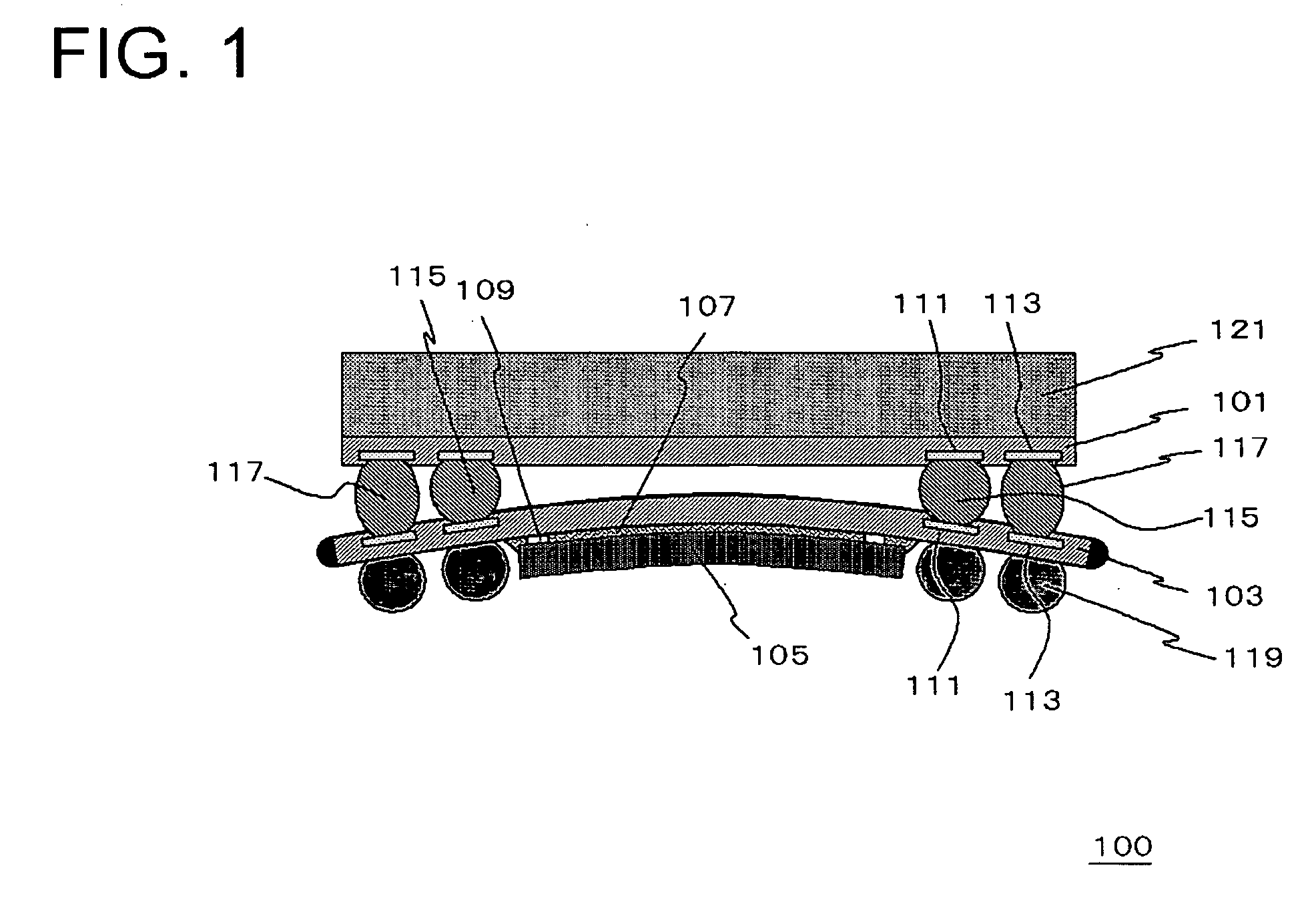

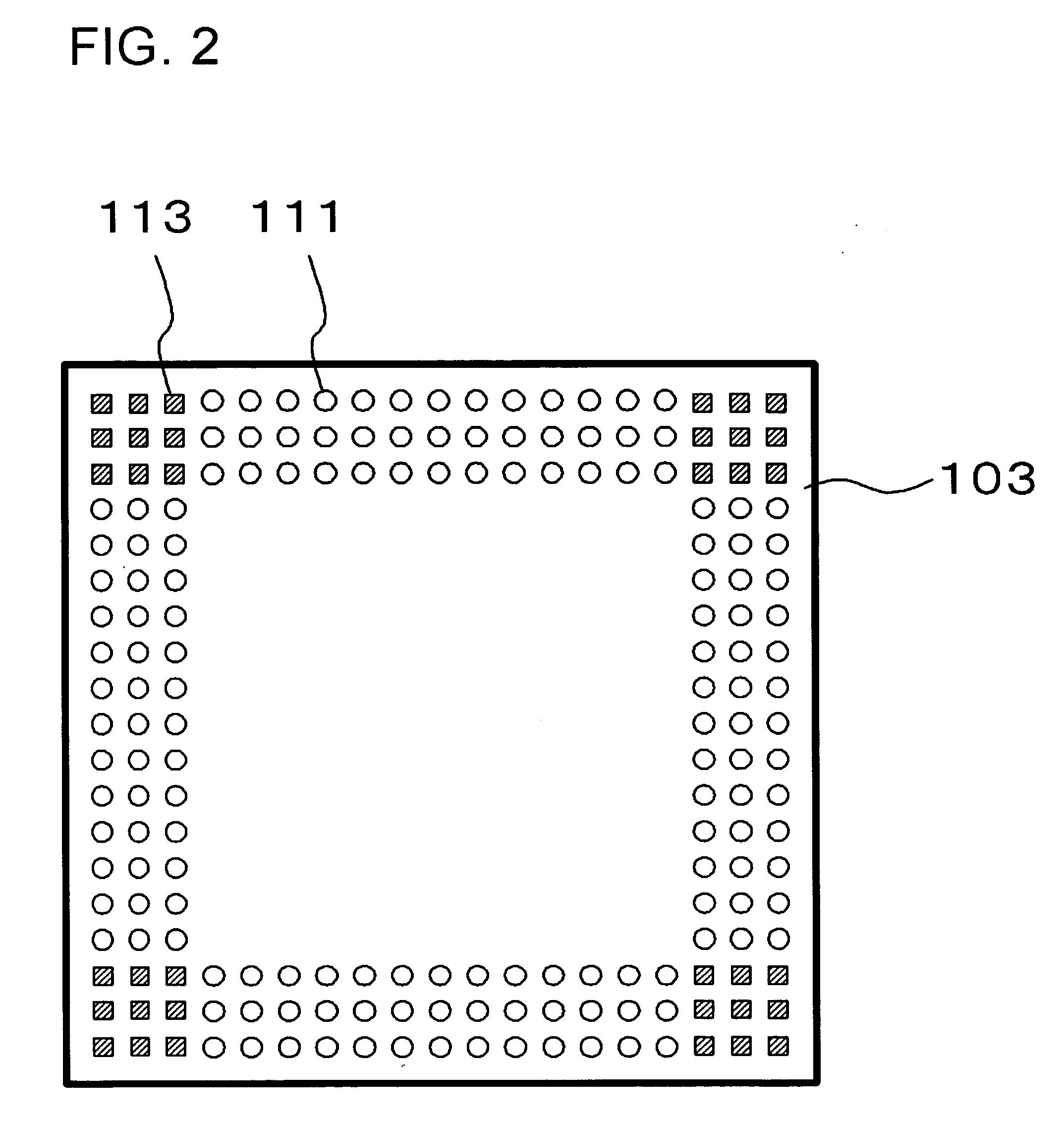

Aiming at adjusting the height of bump electrodes connected to lands on a substrate, a semiconductor device 100 has a first interconnect substrate 103 and a second interconnect substrate 101. On one surface of these substrates, first lands 111 and second lands 113 are provided. The plane geometry of the second lands 113 is a polygon characterized by the inscribed circle thereof having an area smaller than the area of the inscribed circle of the first land.

Owner:RENESAS ELECTRONICS CORP

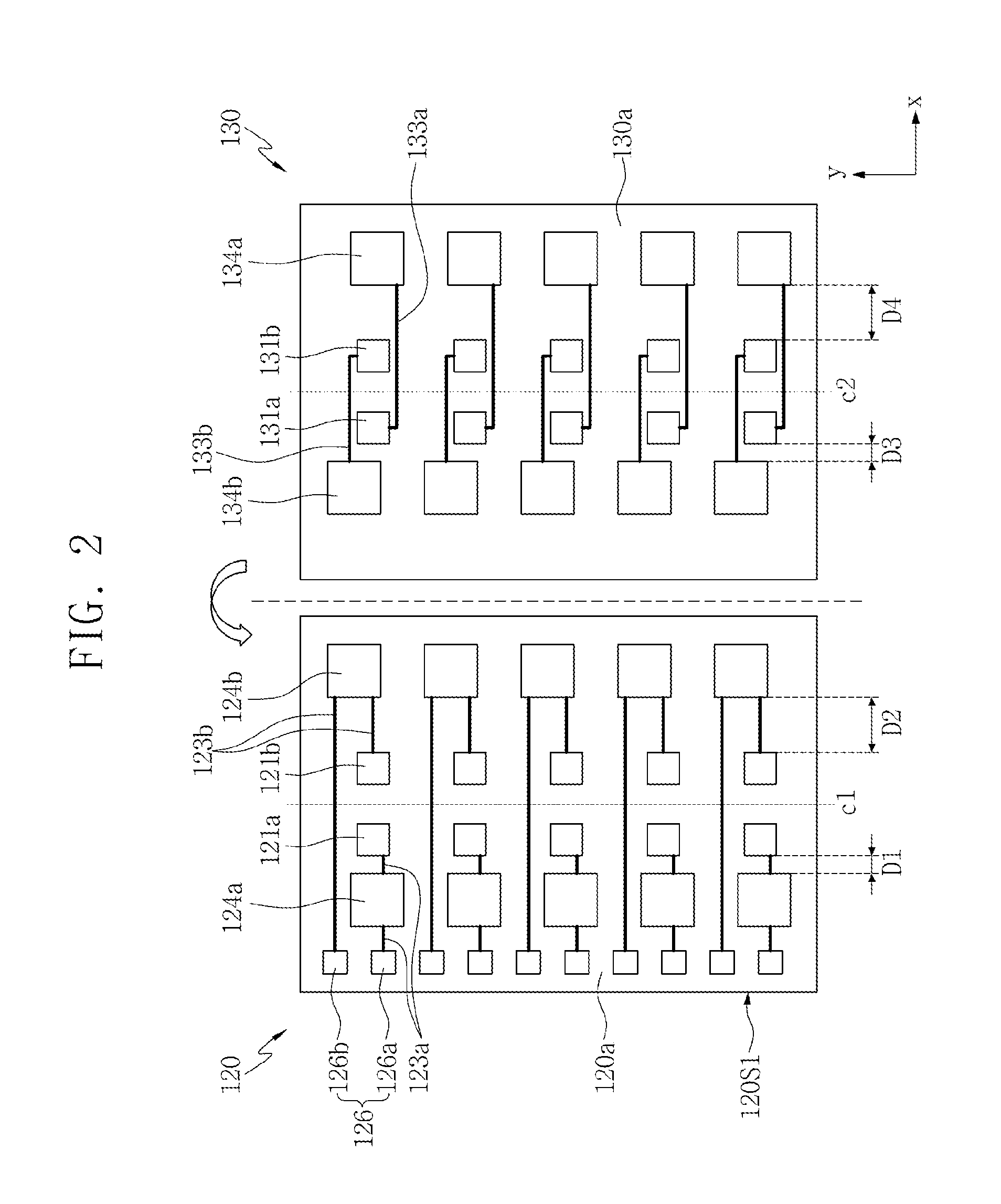

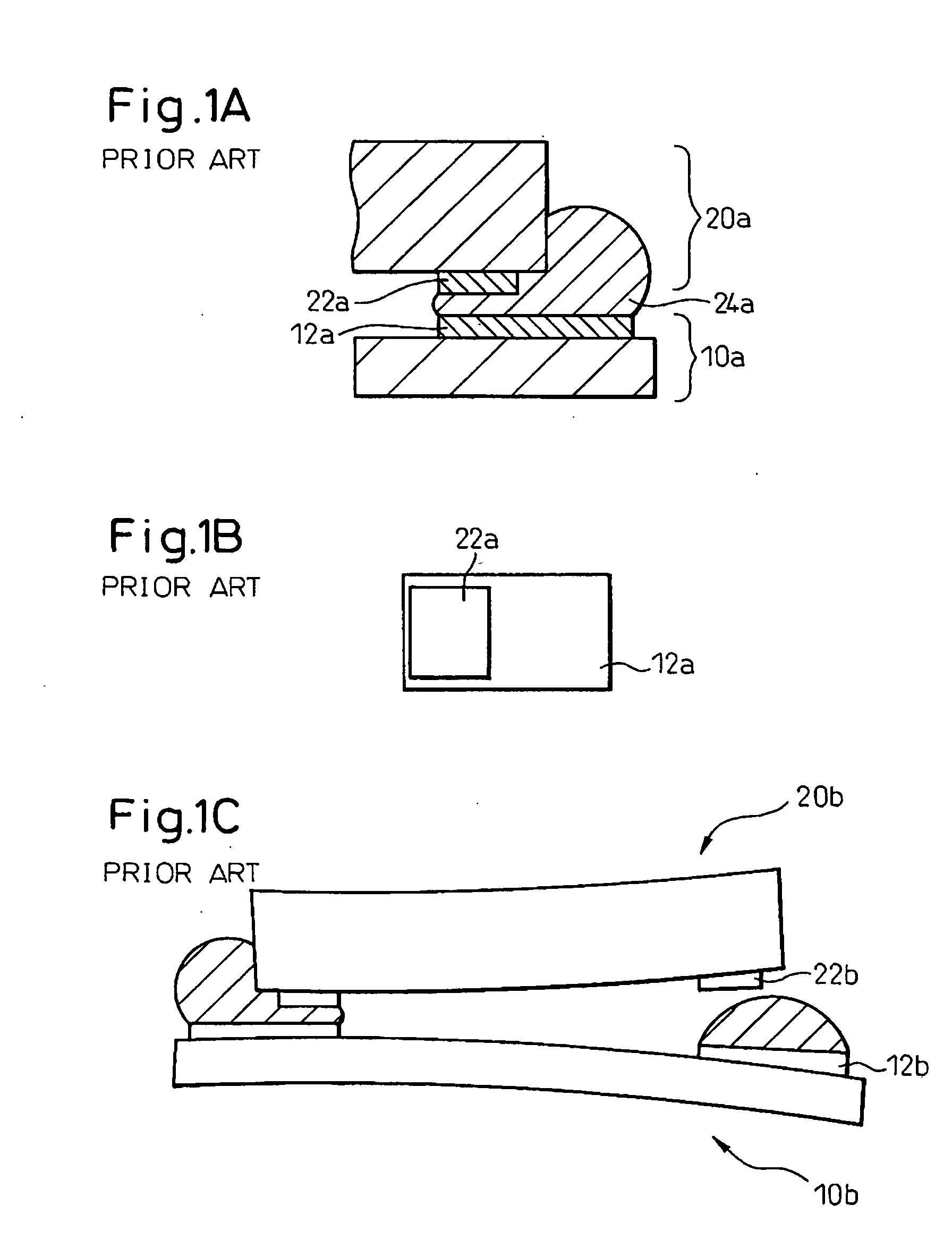

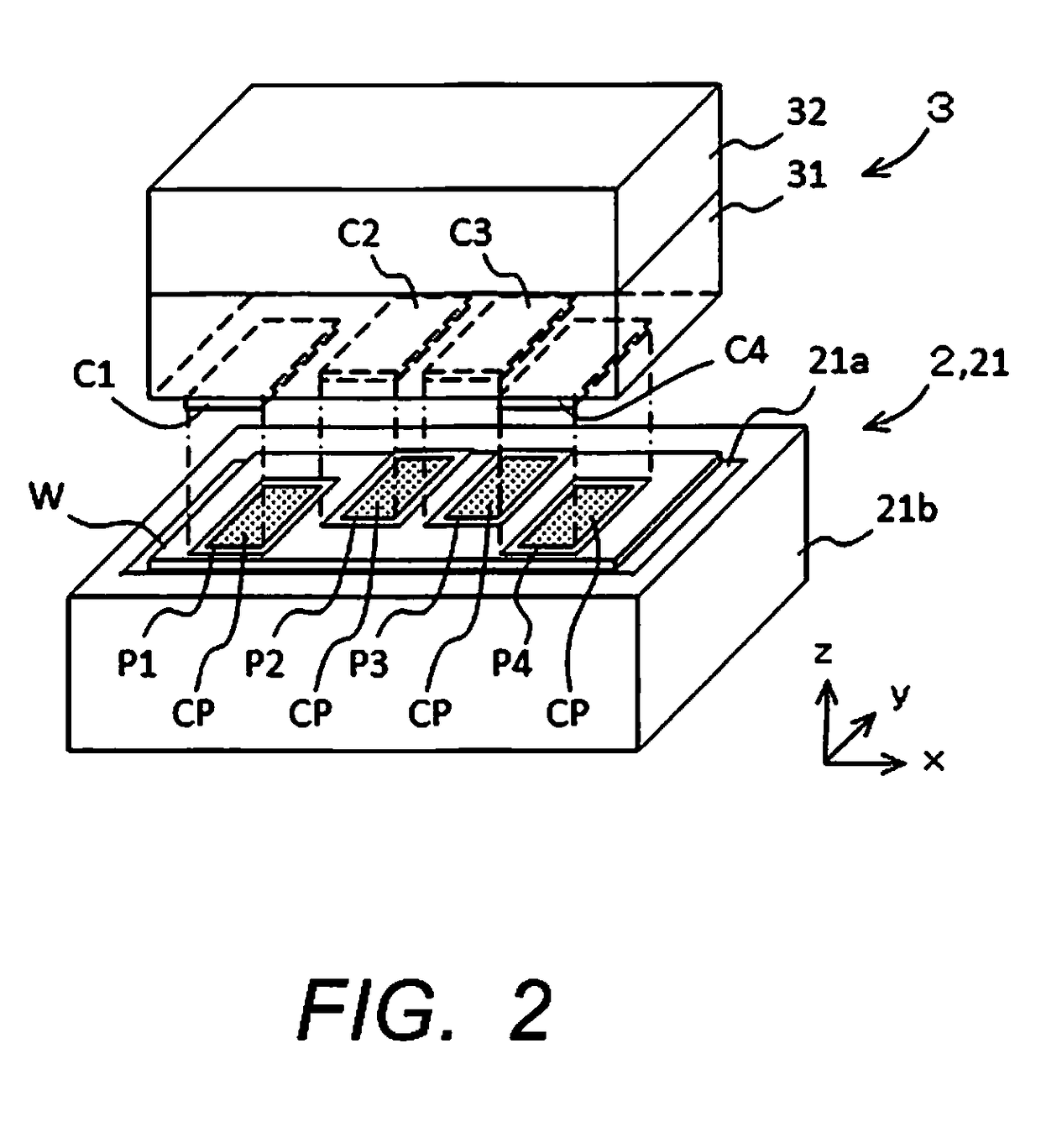

Semiconductor package having cascaded chip stack

ActiveUS20160086921A1Avoid bond failureSmall thicknessSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

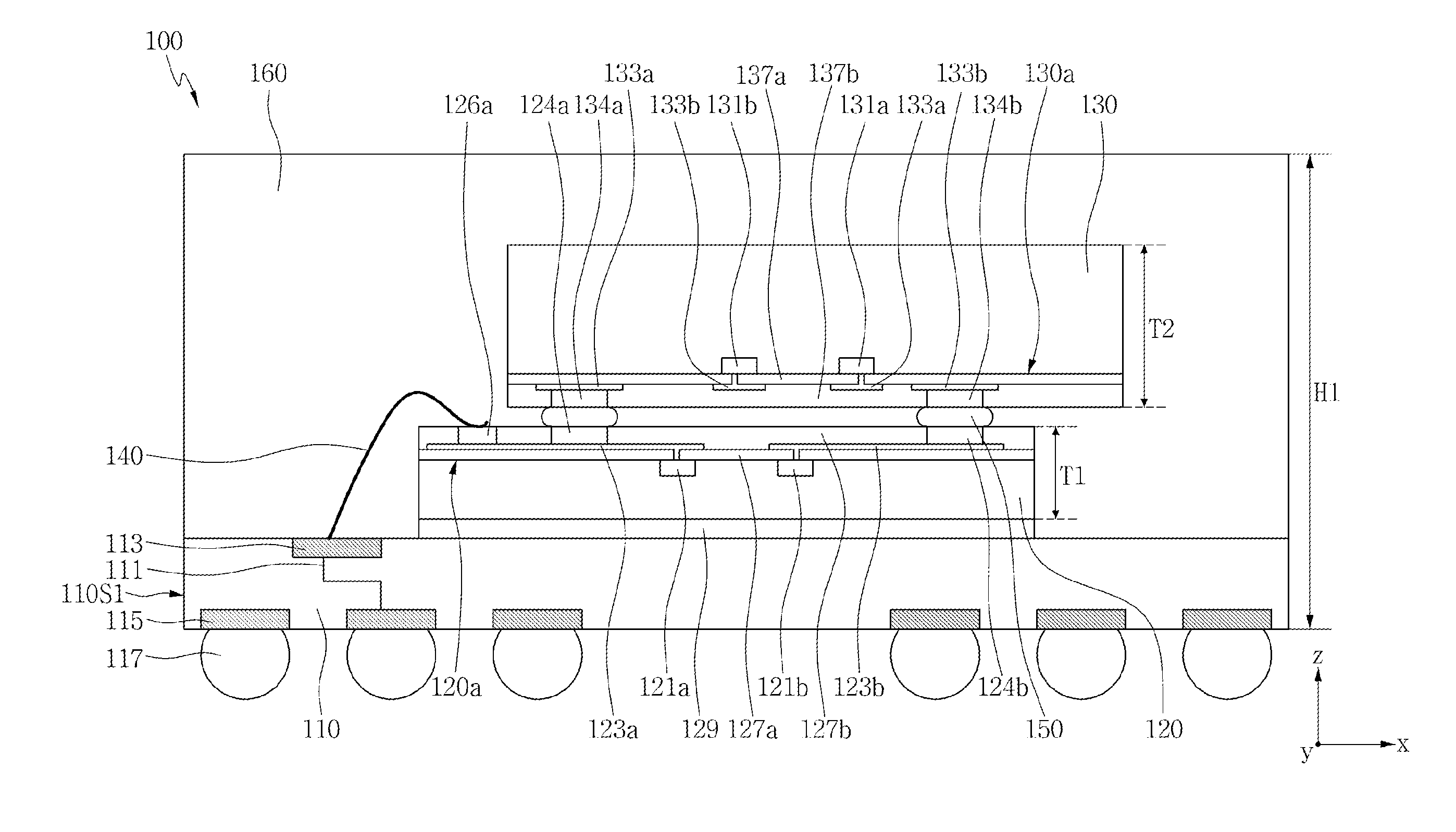

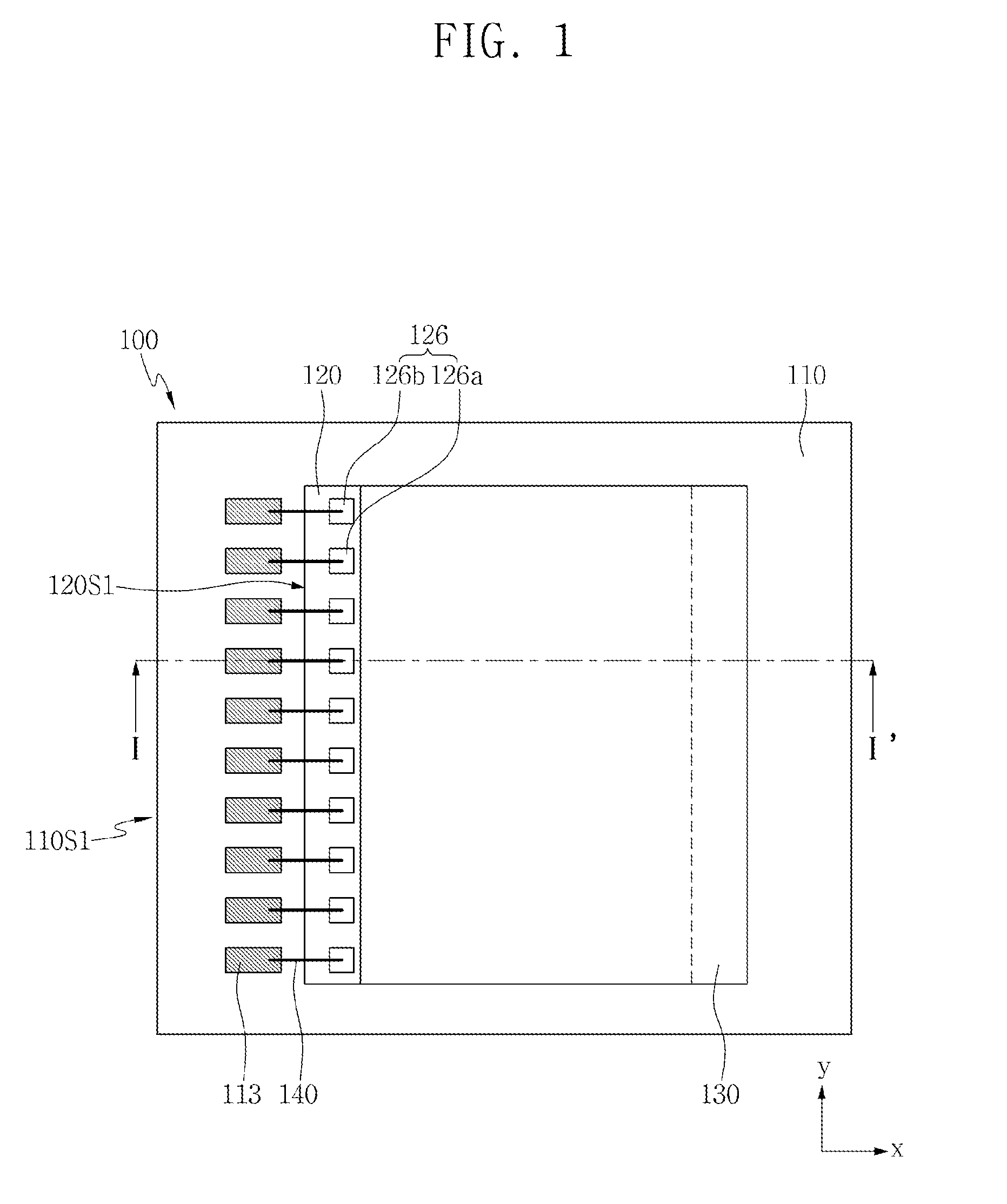

A semiconductor package that includes a package substrate, a lower semiconductor chip mounted on the package substrate, and an upper semiconductor chip stacked on the lower semiconductor chip in a cascade shape is provided. An active surface of the lower semiconductor chip is facing an active surface of the upper semiconductor chip.

Owner:SAMSUNG ELECTRONICS CO LTD

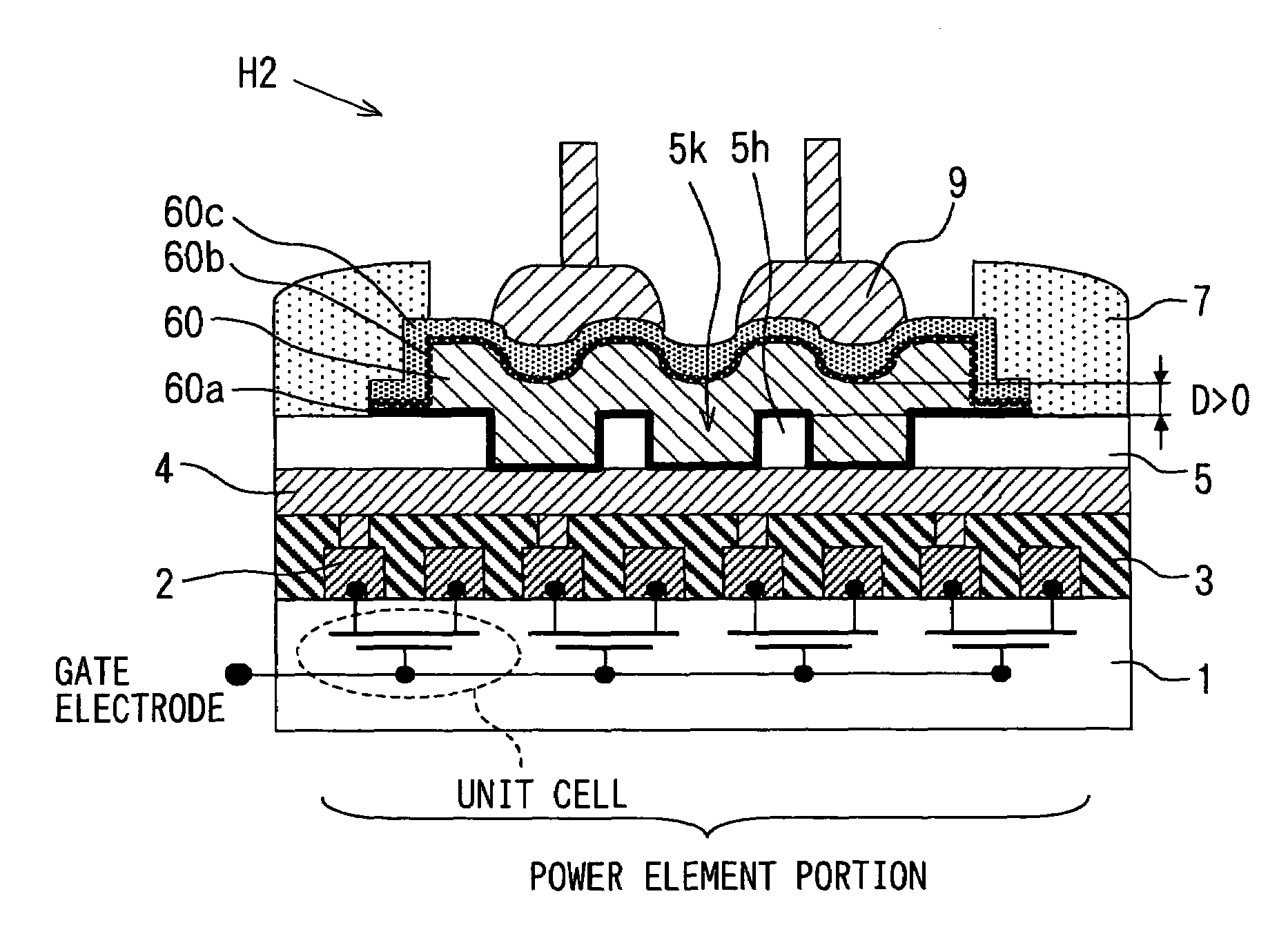

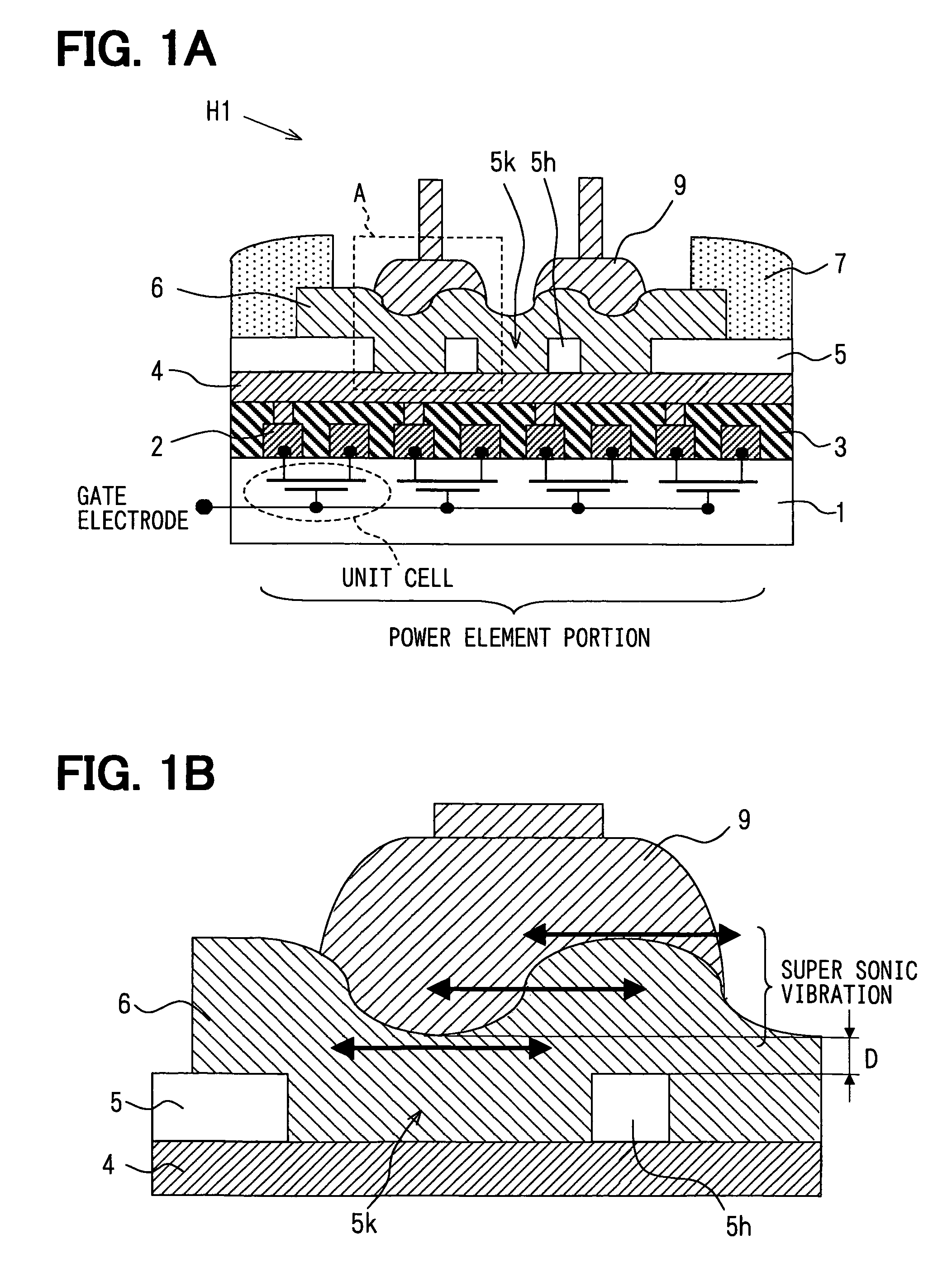

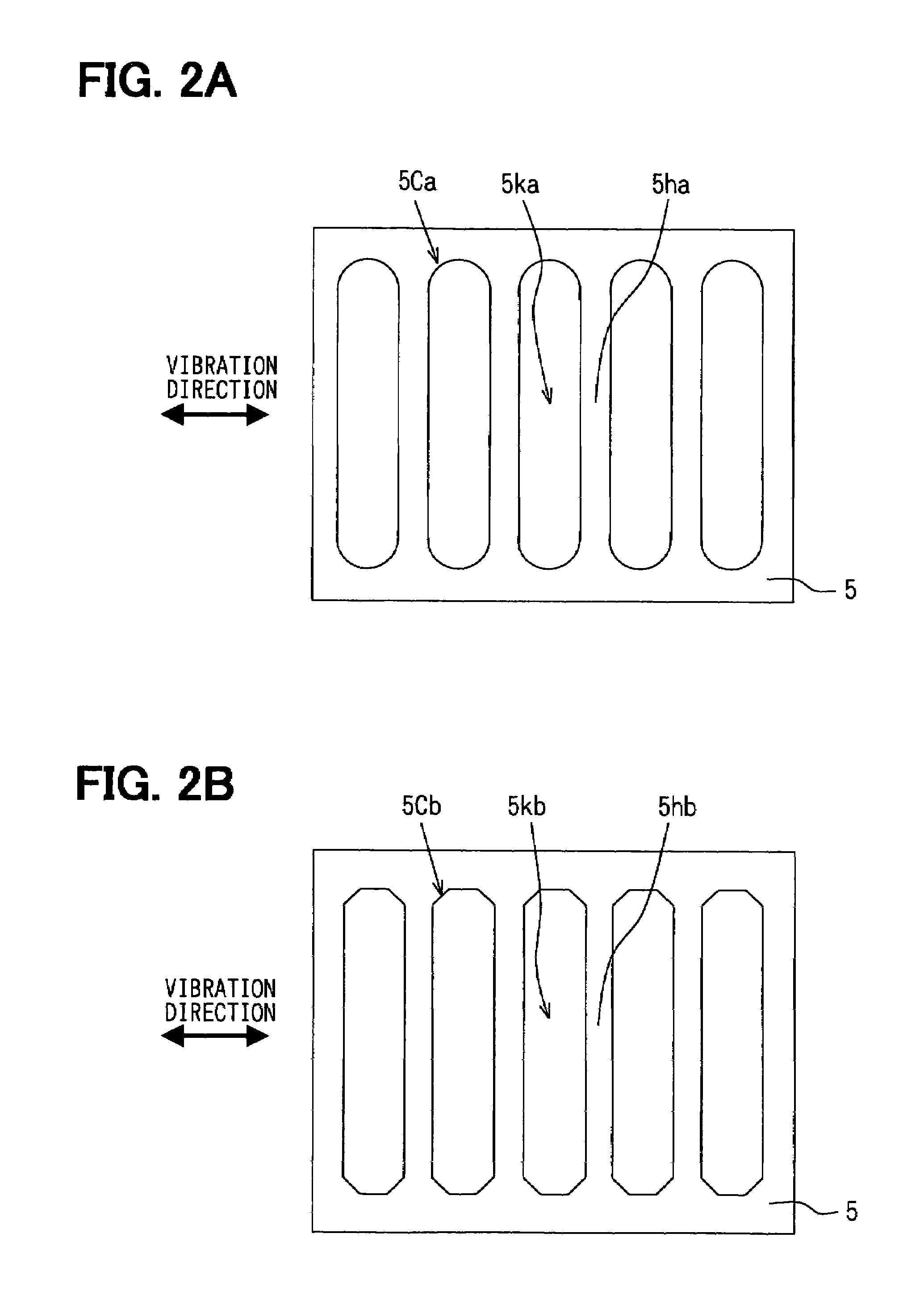

Integration type semiconductor device and method for manufacturing the same

InactiveUS7420283B2AdhesivenessHigh mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesTectorial membraneSemiconductor

A semiconductor device includes: a plurality of power MOS cells on a semiconductor substrate; a plurality of lead wires connecting to a source and a drain of each power MOS cell through a contact hole; a plurality of collecting electrodes connecting in parallel with the lead wires through a via hole; an interlayer protection film on the collecting electrode; a thick film electrode connecting to the collecting electrode through the opening; and a terminal protection film having an opening for bonding connection. The openings are formed in the interlayer protection film such that a portion between the openings becomes a beam shape

Owner:DENSO CORP

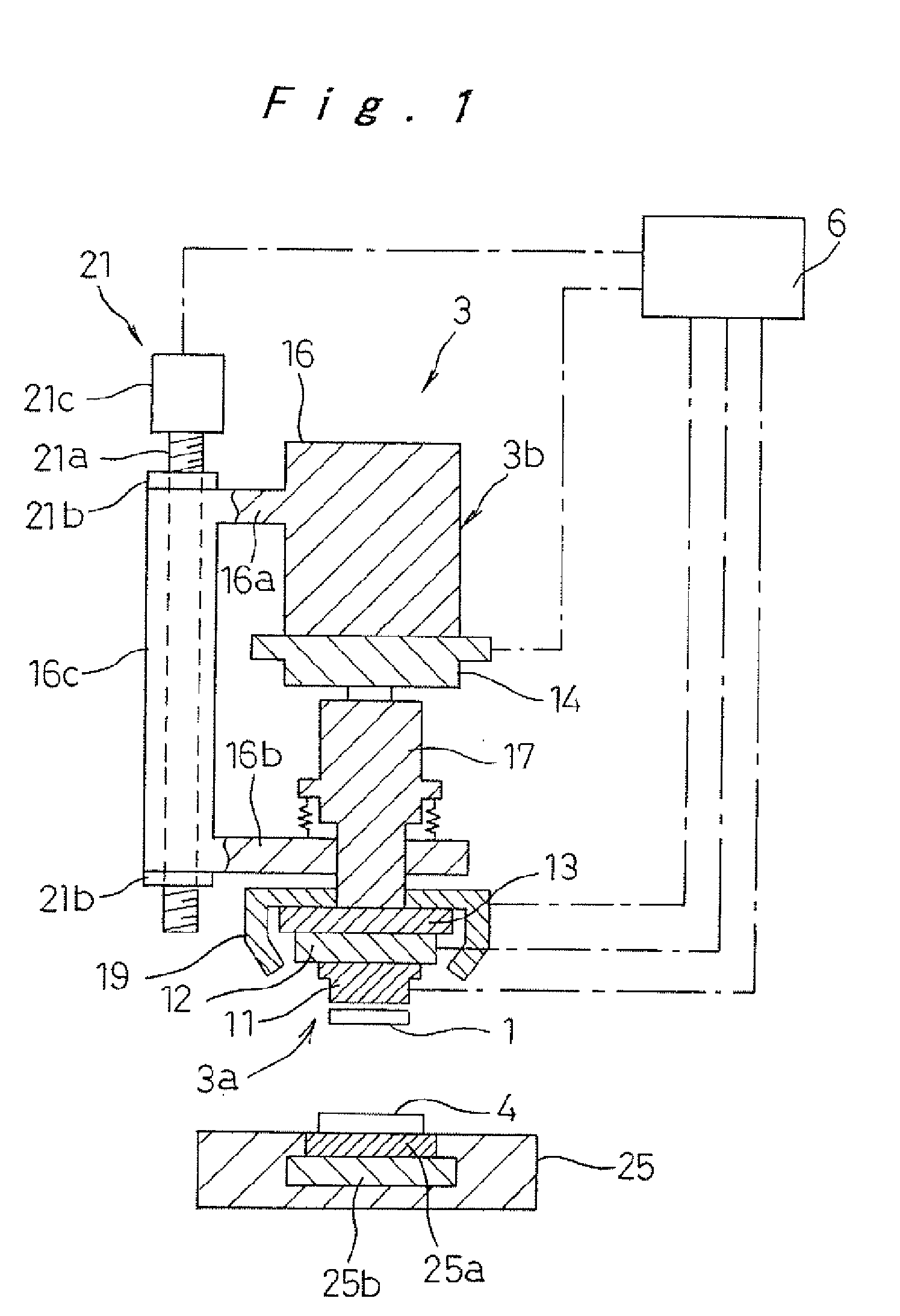

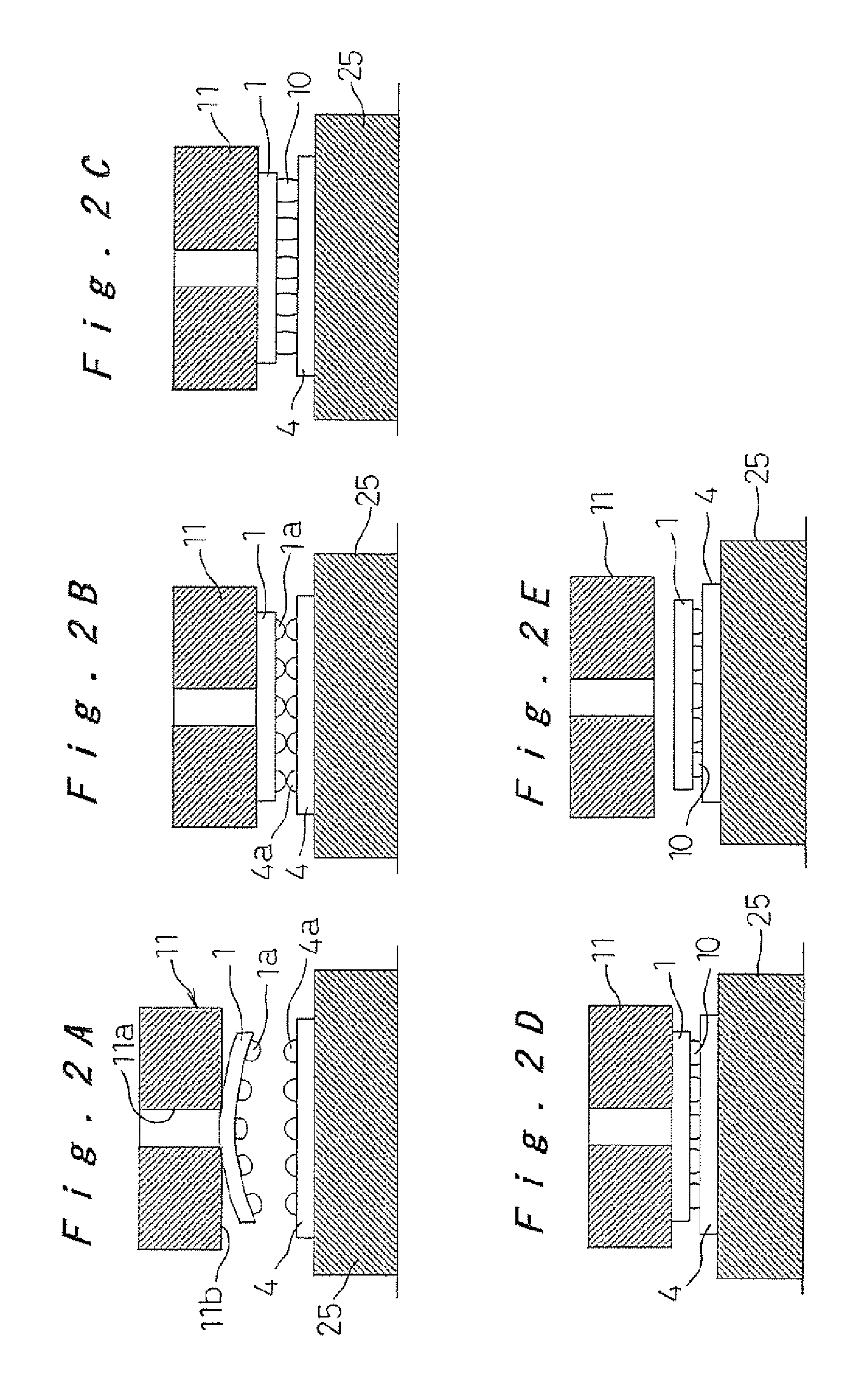

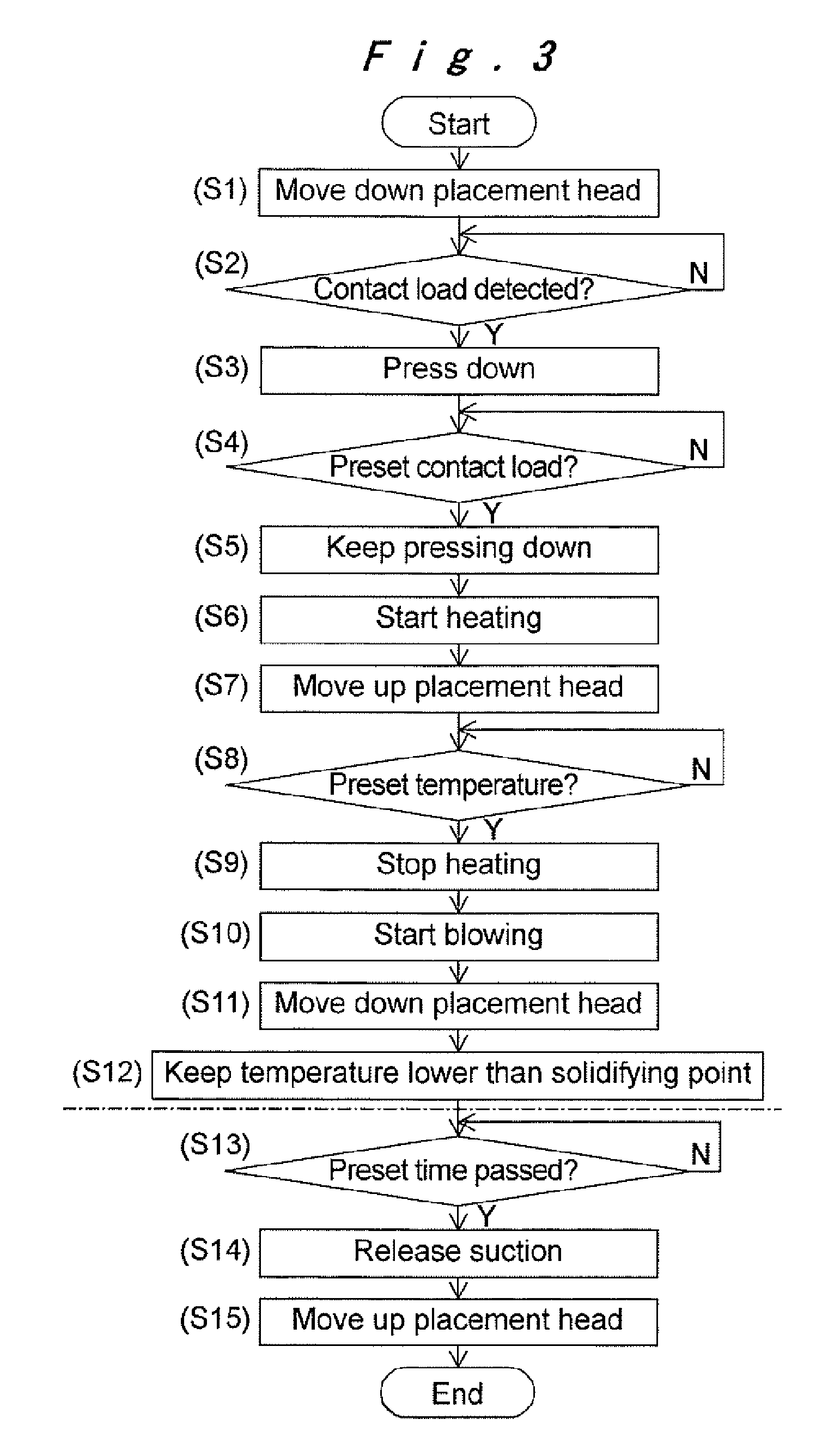

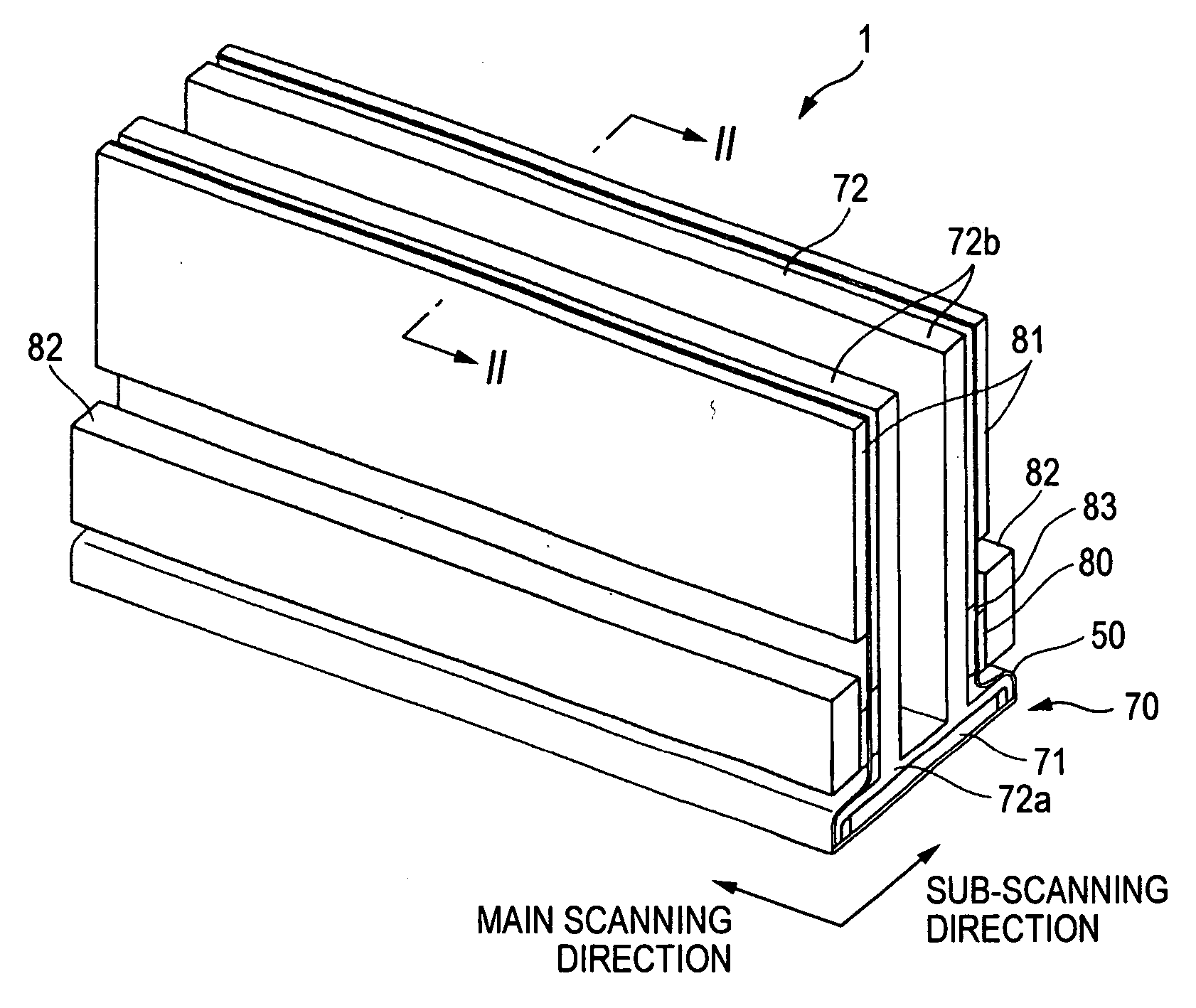

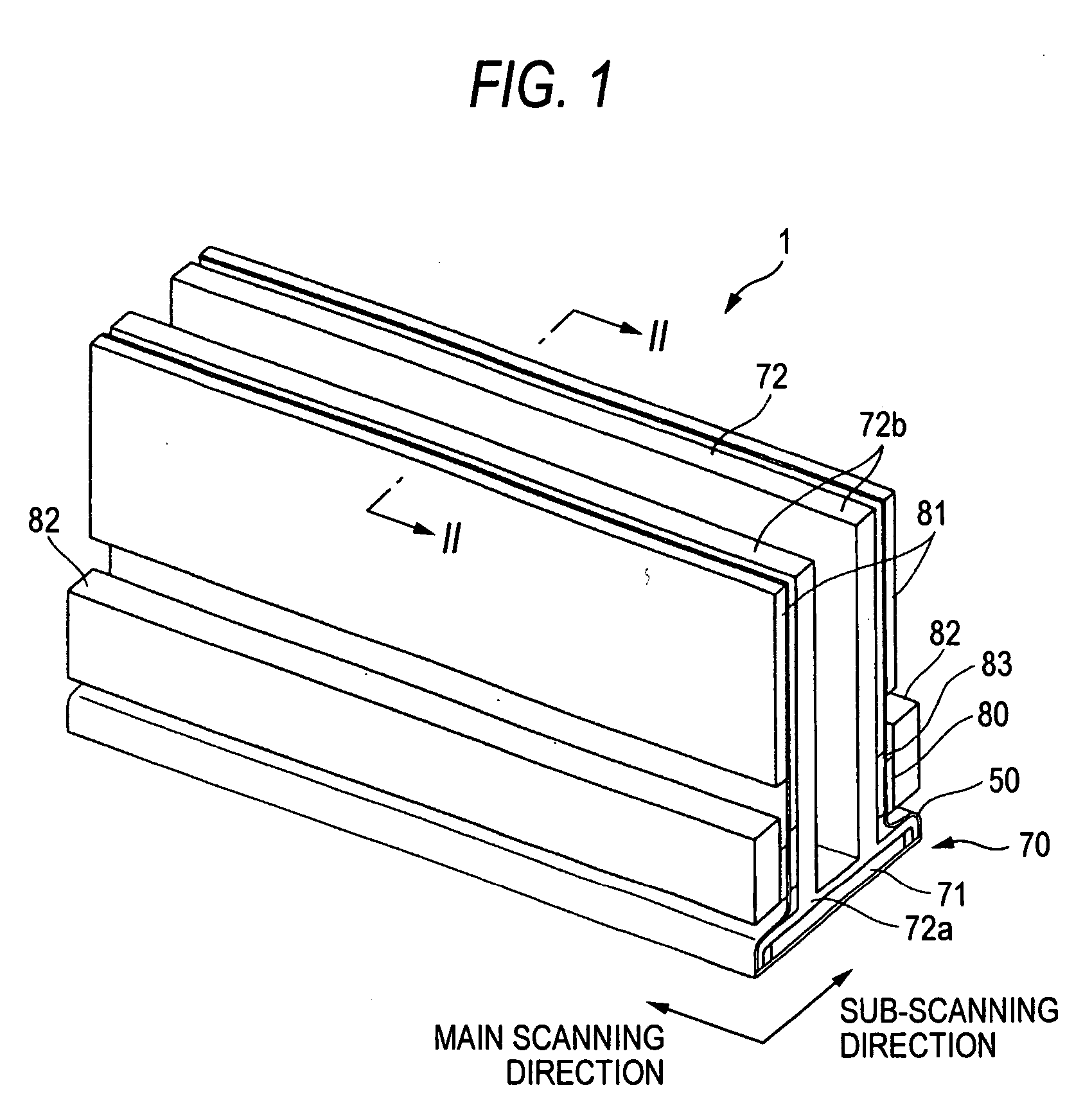

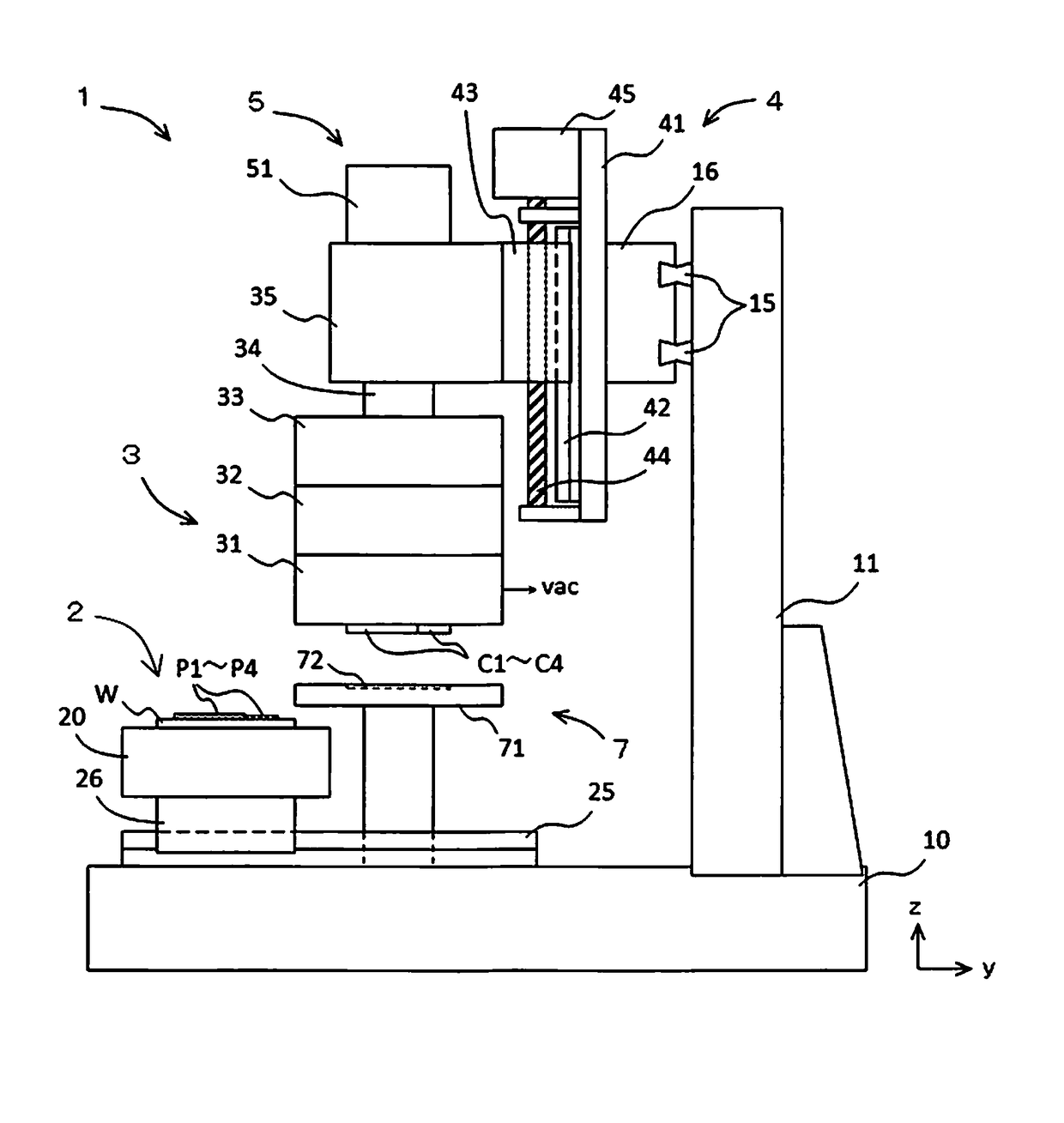

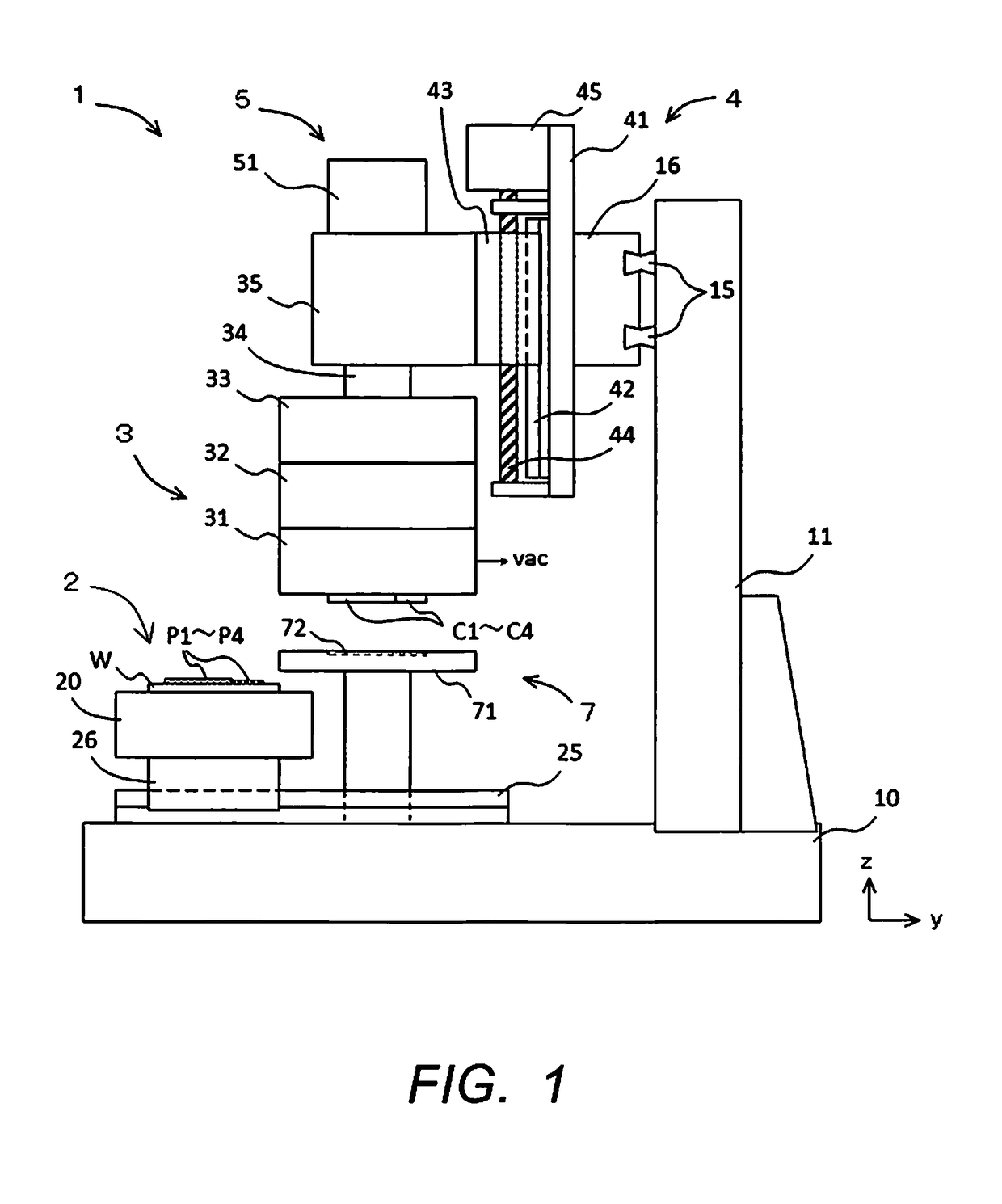

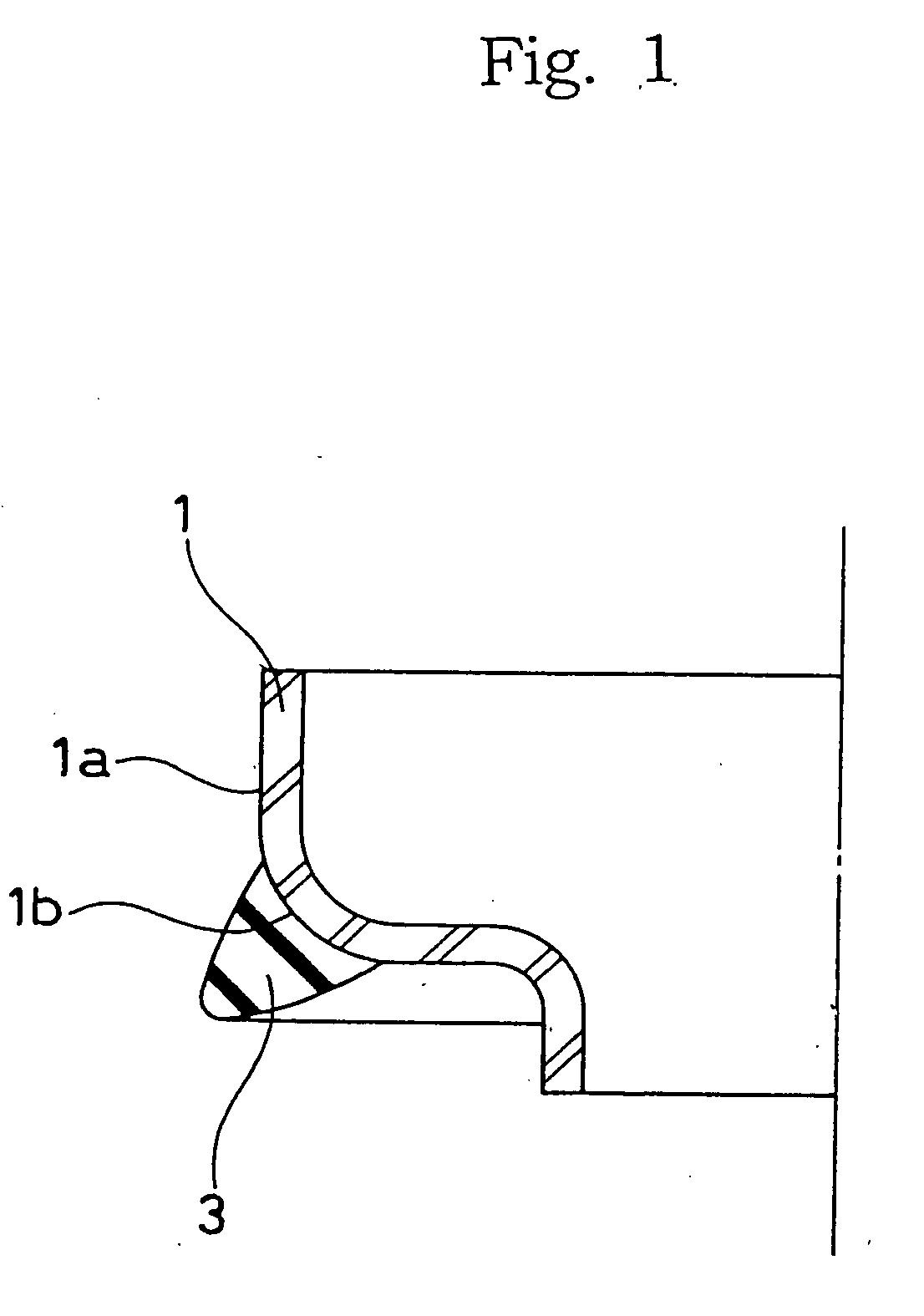

Component mounting method and component mounting apparatus

InactiveUS20070181644A1Avoid bond failureFlatness is easy to guaranteeCooking-vessel materialsPrinted circuit assemblingSuction stressEngineering

A method and an apparatus for mounting electronic components that enables precise mounting of electronic components, such as deformation-prone thin IC chips or fine-pitch and high-pin-count IC chips, on a substrate. Thin IC chips, which conventionally tend to lose flatness because of warping that occurs during production or deformation that occurs when picked up with a suction nozzle, are pressed against a substrate (4) with a preset load using a suction nozzle with a flat suction surface (11b) so as to correct deformation; the suction nozzle (11) is controlled to move up to make up for a decrease in the distance between the oppositely spaced IC chip and the substrate (4) that is caused by thermal expansion due to the heating for melting solder bumps (1a) on the electrodes; and the suction nozzle (11) is controlled to move down to mitigate the effect of a pulling-apart force applied to the molten parts as the thermally expanded parts cool down and contract.

Owner:PANASONIC CORP

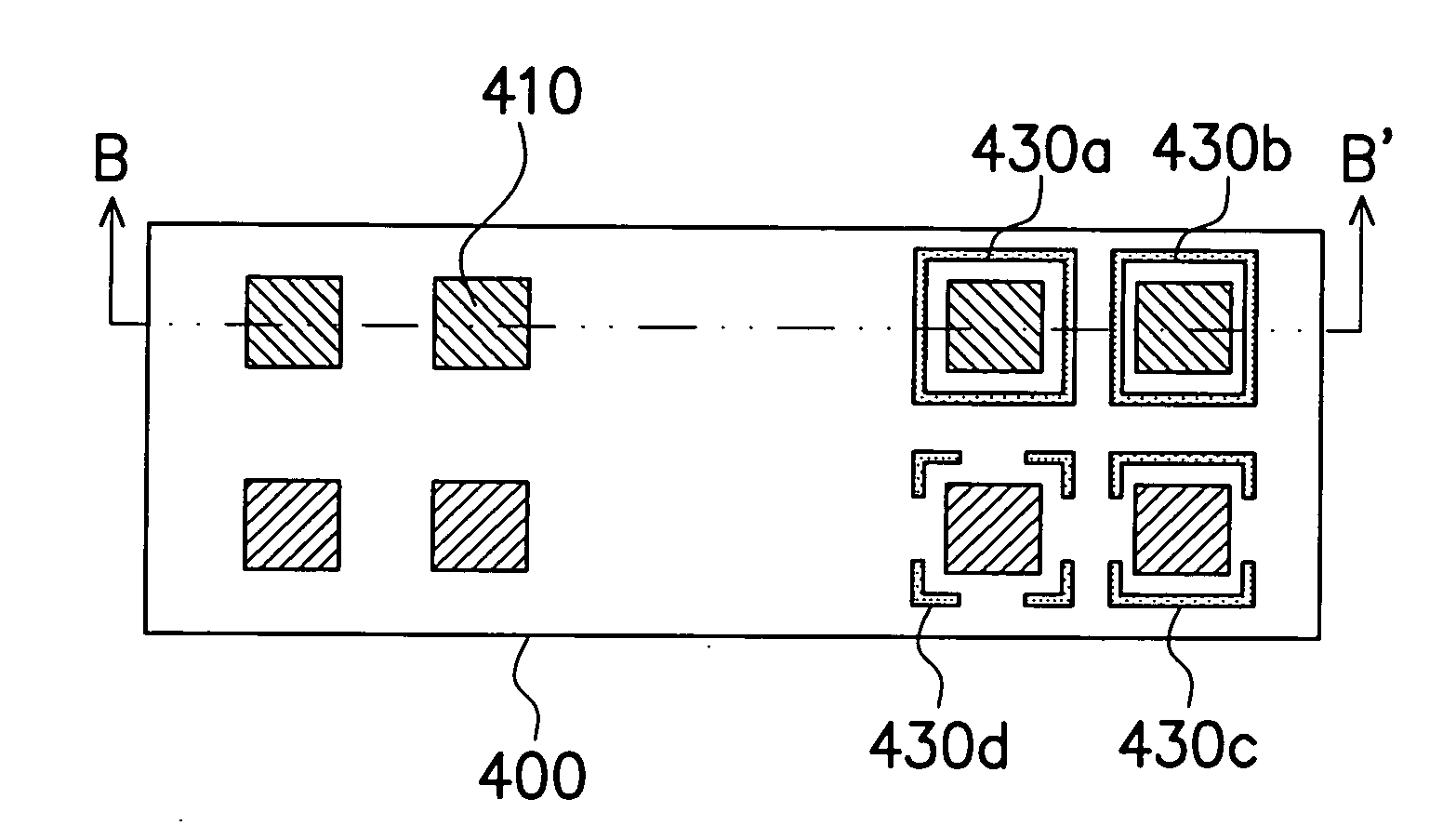

Flat panel display device and method of correcting bonding misalignment of driver IC and flat panel display

InactiveUS20070052344A1Increase productionImprove display qualityDischarge tube luminescnet screensLamp detailsContact padDisplay device

A method of correcting bonding misalignment between flat display panel and driver IC is provided. First, the contact pads of the bonding flat display panel and the bumps of the driver IC are bonded, wherein the flat display panel further includes a plurality of alignment marks around each contact pad. A bonding misalignment variation between the flat display panel and the driver IC may be identified by matching the position of the alignment mark and the position of the corresponding bump. Thereafter, a correction may be performed according to the bonding misalignment variation.

Owner:CHUNGHWA PICTURE TUBES LTD

Manufacturing method for semiconductor light emitting device

InactiveUS20060094140A1Prevent stress distributionReduce contact areaSemiconductor/solid-state device manufacturingSemiconductor devicesFailure preventionLength wave

A manufacturing method for a semiconductor light emitting device is provided. The method includes preparing a first wafer in which at least one semiconductor layer including the emitter layer is formed; disposing a second wafer transparent to an emission wavelength of the emitter layer on the surface of the first wafer; providing a bonding failure prevention structure to at least either the first wafer or the second wafer for preventing bonding failures of the first wafer and the second wafer; and applying compressive force to a contact face between the first wafer and the second wafer while at the same time, heating the contact face. The first and second wafers can be bonded across their entire surfaces without causing bonding failure.

Owner:SHARP KK

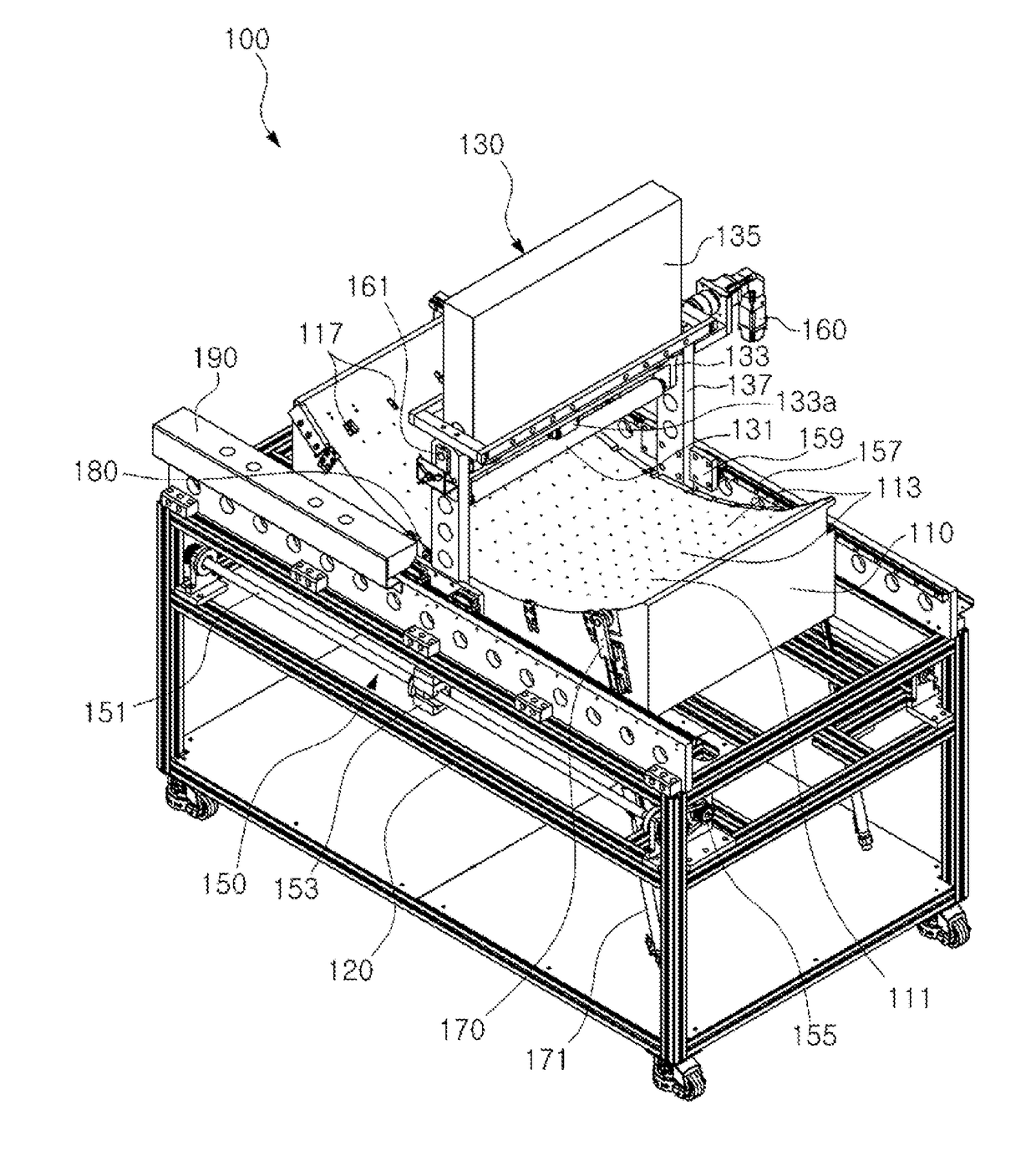

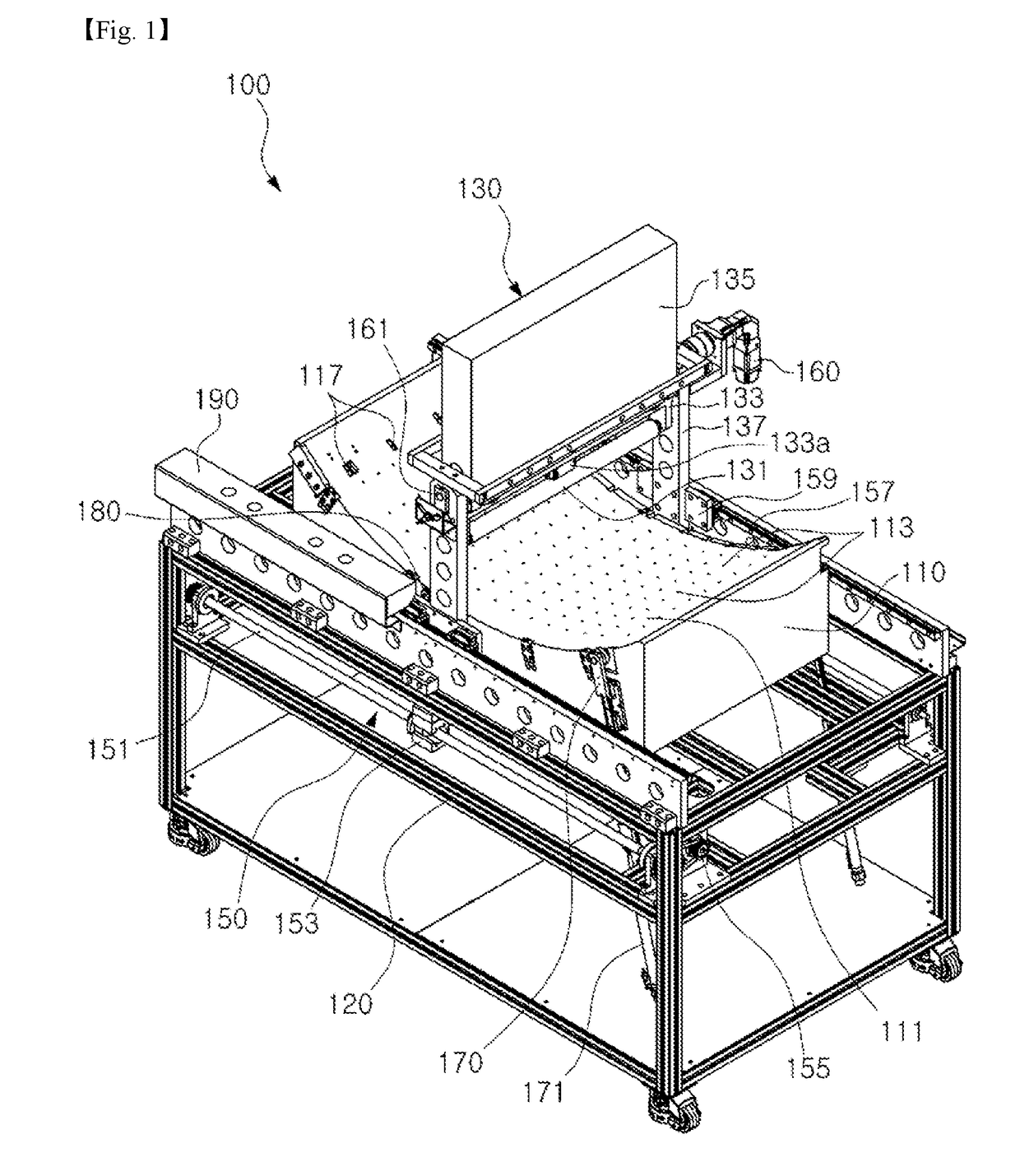

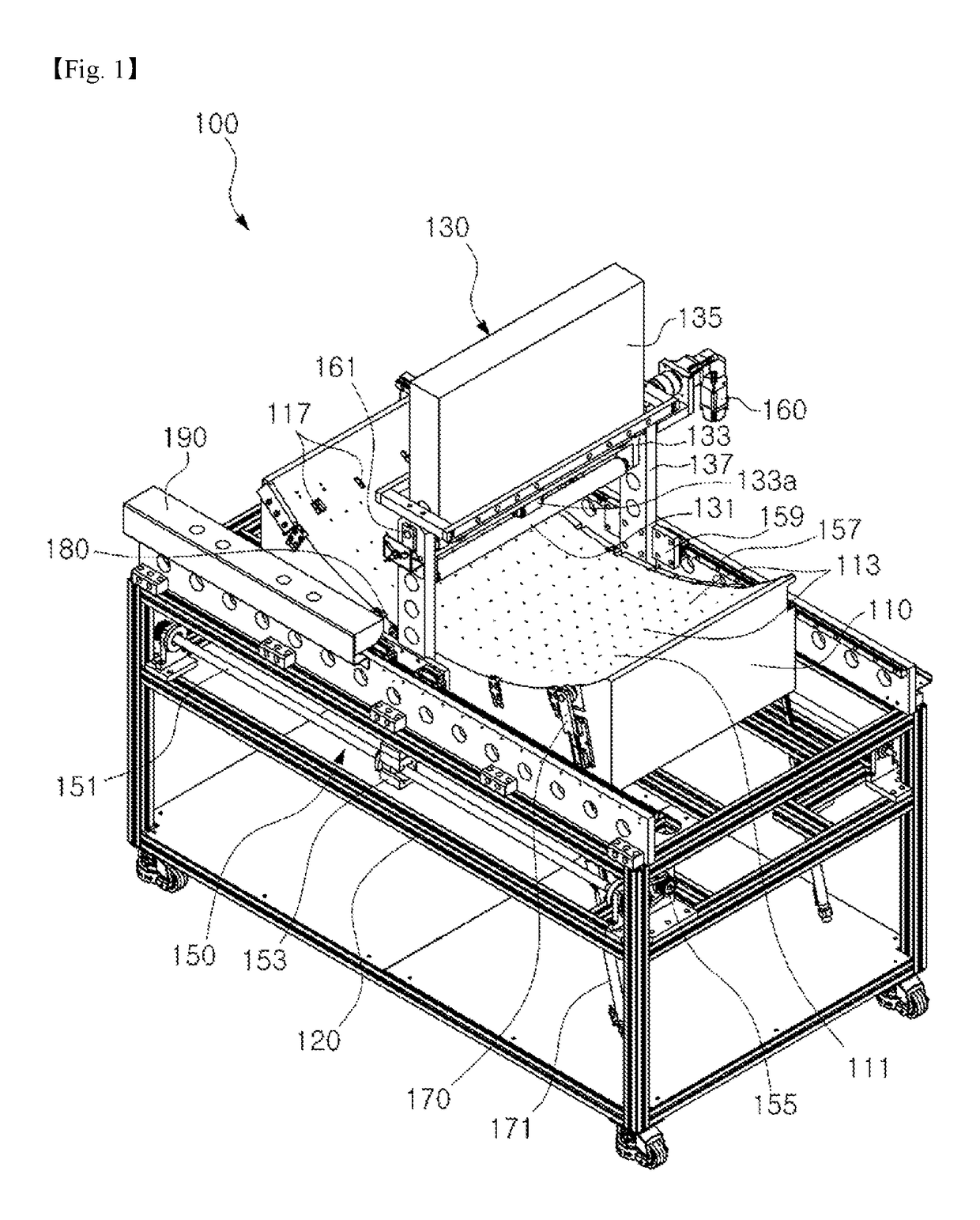

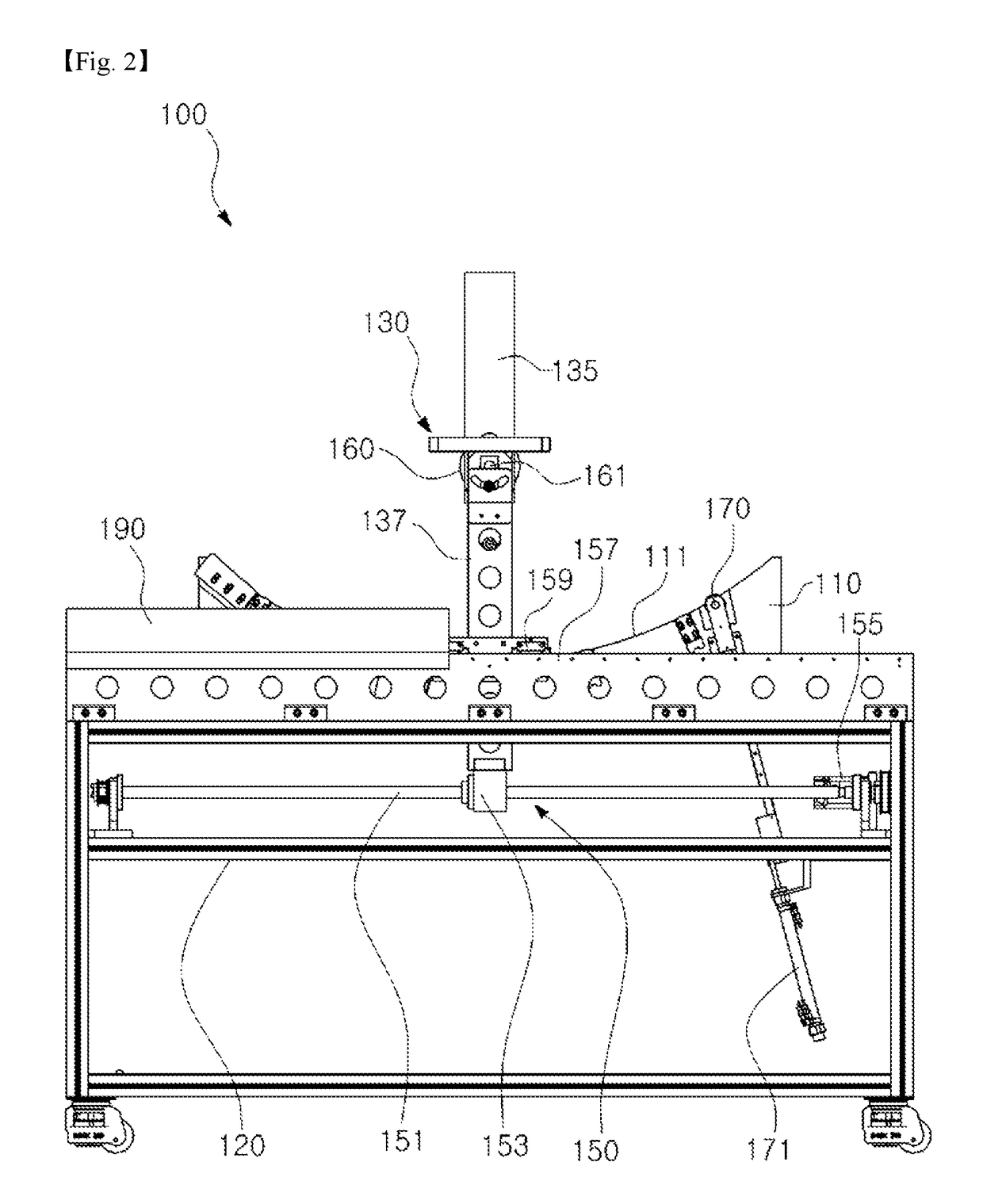

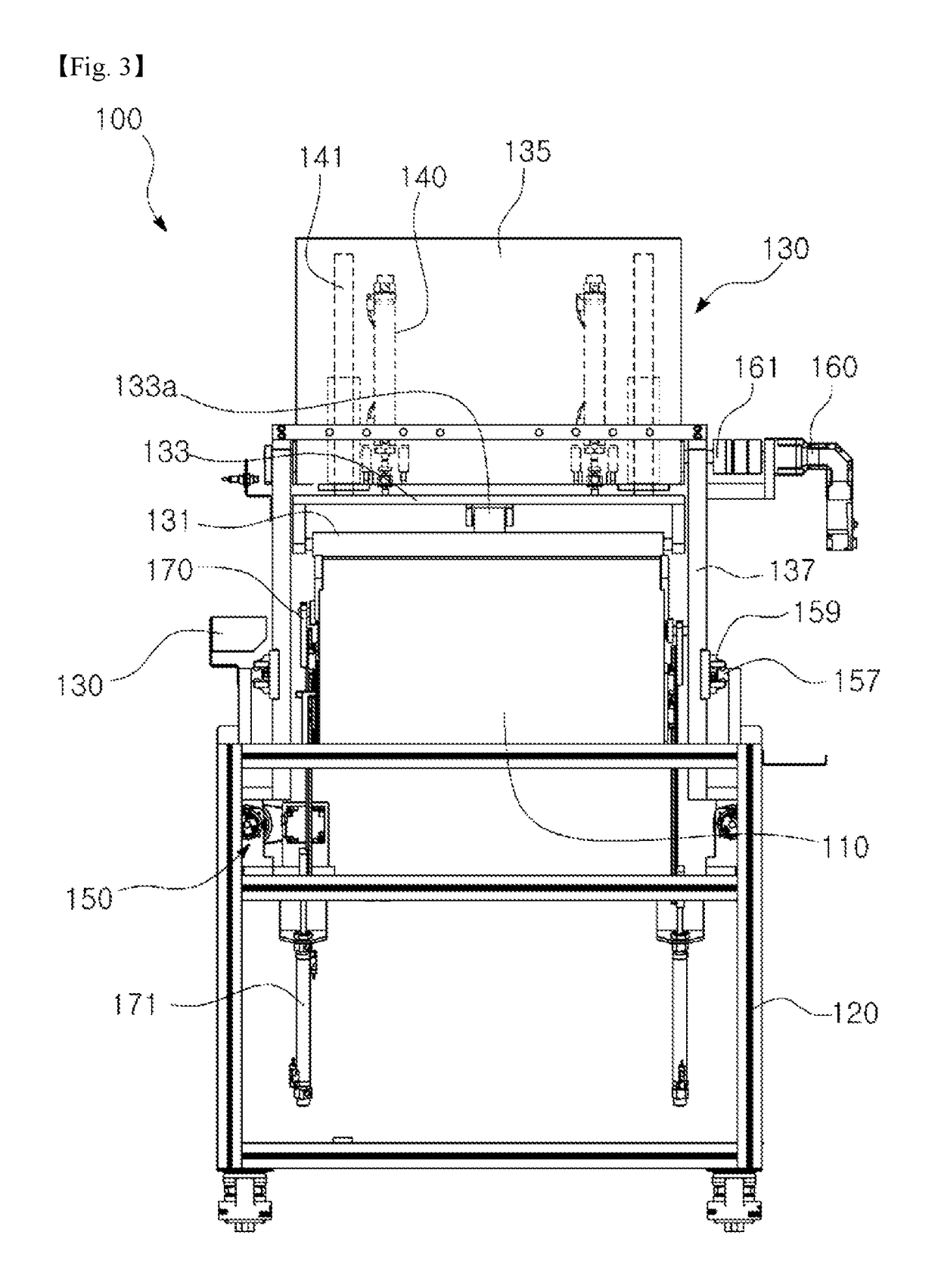

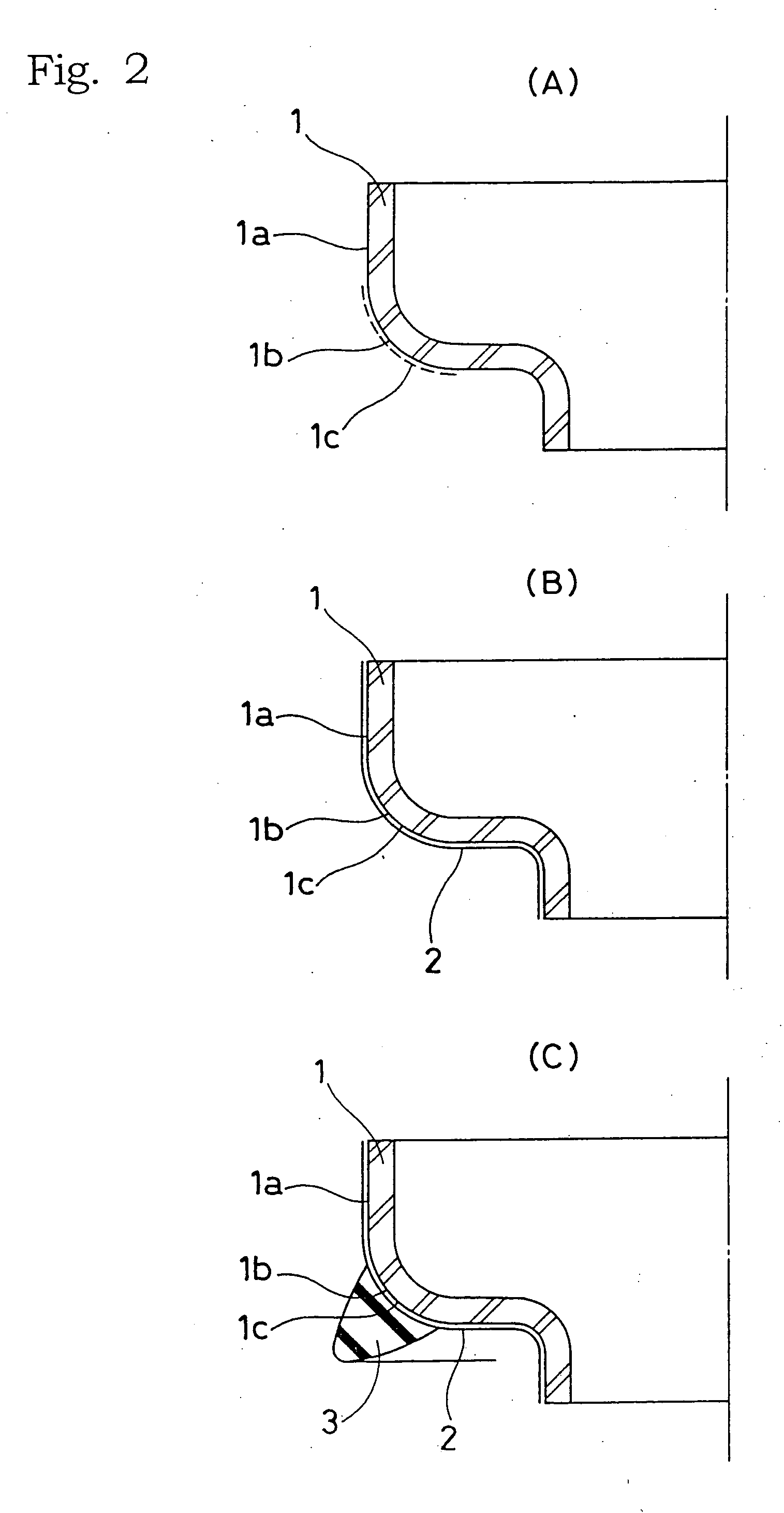

Curved display manufacturing device and curved display manufacturing method

ActiveUS20170255033A1Damage preventionPrevent failure of bondingNon-linear opticsIdentification meansCurve shapeEngineering

Owner:TOVIS

Curved display manufacturing device and curved display manufacturing method

ActiveUS10222638B2Avoid normal displayAvoid bond failureNon-linear opticsElectrical componentsCurve shapeManufactured apparatus

Owner:TOVIS

Printed circuit board and method of production of an electronic apparatus

ActiveUS20090056985A1Avoid bond failureAvoid yield lossPrinted circuit assemblingFinal product manufactureEngineeringMethods of production

A printed circuit board provided with board electrodes, wherein each board electrode is provided with a board electrode base, for carrying by soldering a bottom electrode arranged at a bottom of an electronic device inside from outer edges of the electronic device, arranged inside from the outer edges of the electronic device and a projection projecting out from the board electrode base, narrower in width than the board electrode base, and connected to an interconnect of the printed circuit board.

Owner:FUJITSU LTD

Method for bonding metallic plates and jig for the bonding of the metallic plates

ActiveUS20060180638A1Prevent failure of bondingSimple manufacturing processWelding/cutting auxillary devicesAuxillary welding devicesMaterials scienceAtmosphere

A method for bonding metallic plates includes: sandwiching a laminated body, which includes a plurality of metallic plates and is formed with an inner cavity opening on a surface thereof, between a pair of jigs each having a flat abutment surface abutting against respective surfaces of the laminated body, wherein at least one of the jigs is formed with an atmosphere communication path, which communicates with the inner cavity and atmosphere; and heating the laminated body while applying pressure to the laminated body with the pair of jigs in a lamination direction of the laminated body.

Owner:BROTHER KOGYO KK

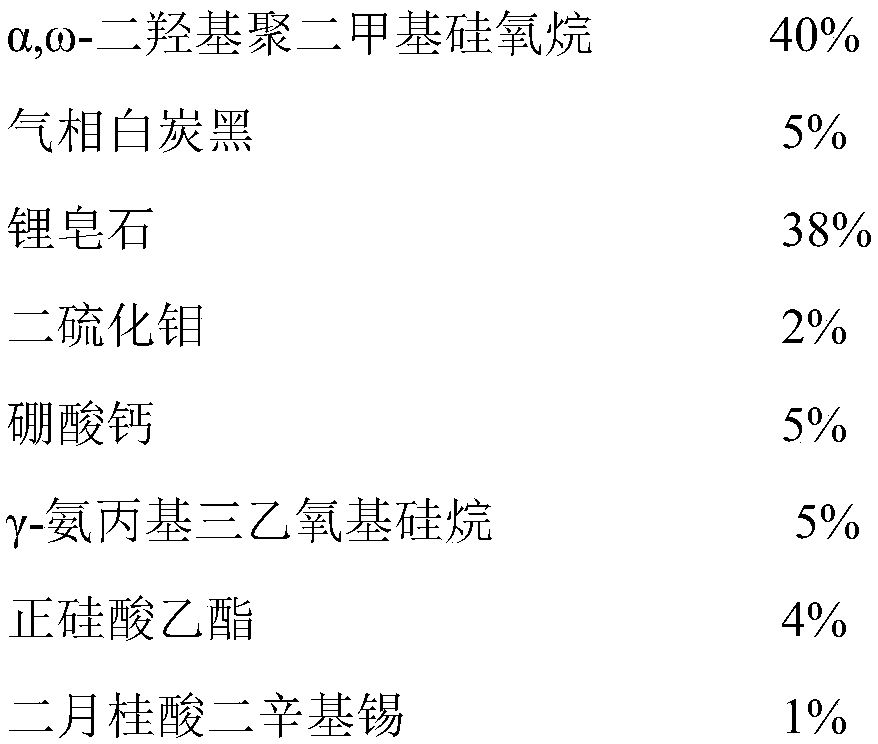

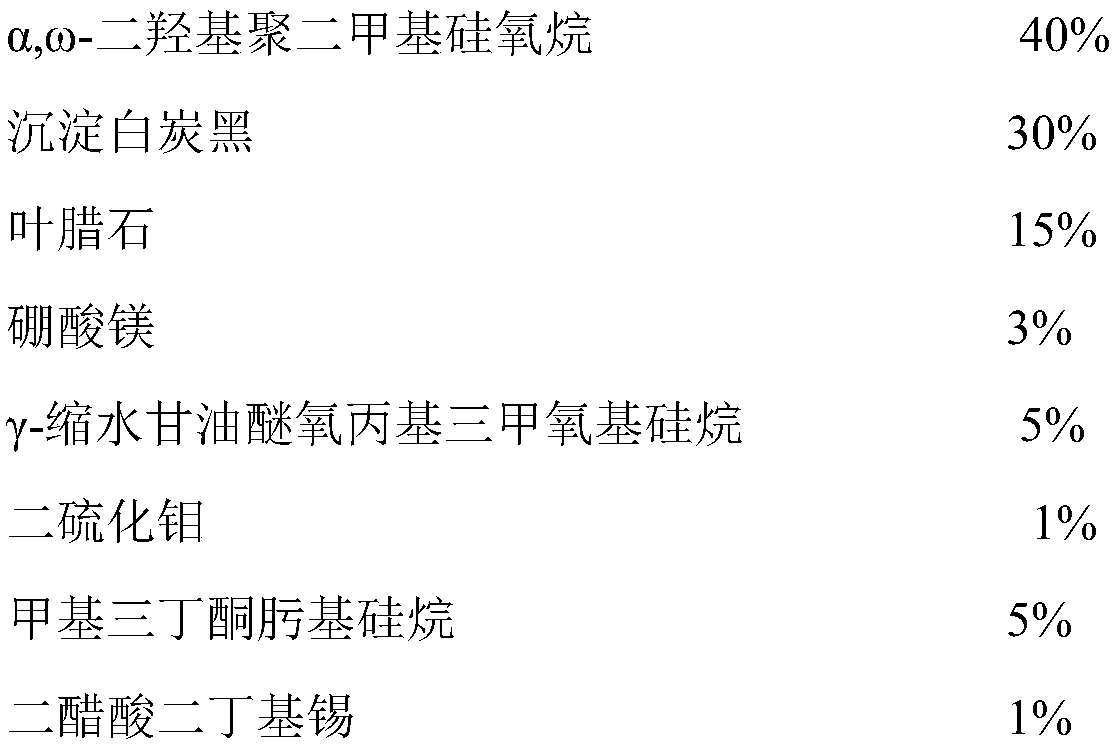

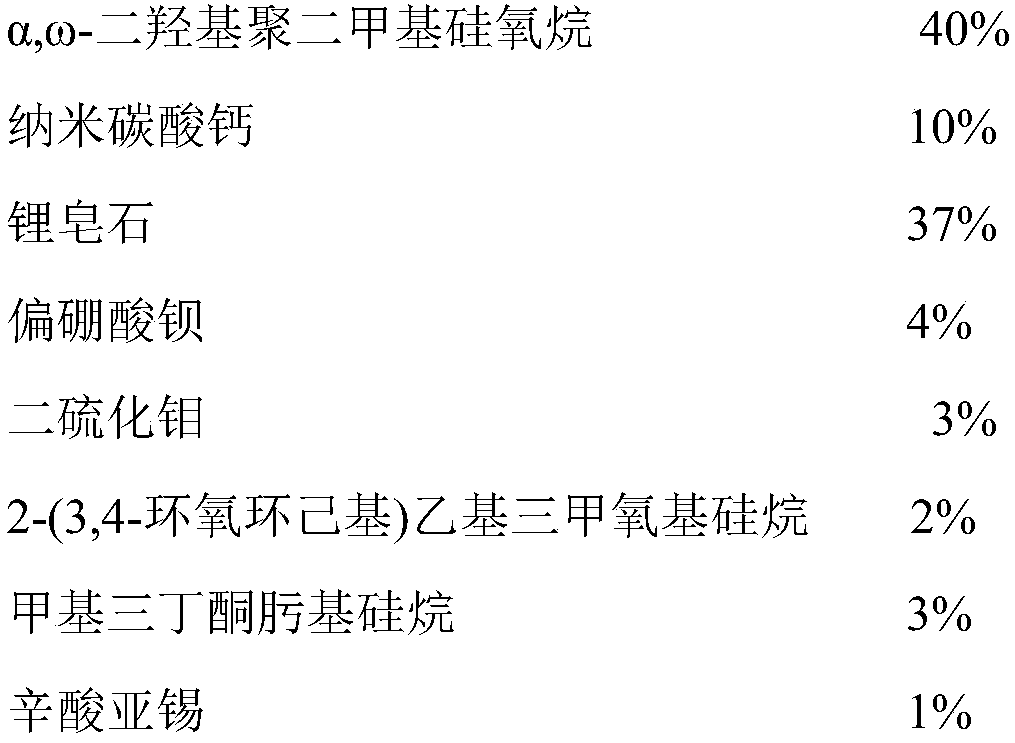

Ceramic-able room-temperature vulcanized organic silicone sealant capable of retarding flame and inhibiting smoke and preparation method thereof

ActiveCN109401634AImprove mechanical propertiesGood adhesionNon-macromolecular adhesive additivesInorganic adhesivesPolymer scienceRoom temperature

The invention discloses ceramic-able room-temperature vulcanized organic silicone sealant capable of retarding flame and inhibiting smoke and a preparation method thereof. The organic silicone sealantis composed of, by mass, 40-70% of silicone rubber, 5-30% of a reinforcing agent, 10-40% of porcelainized filler, 3-10% of a fluxing agent, 1-5% of a flame-retarding and smoke-inhibiting agent, 1-10%of a coupling agent, 1-5% of a catalyst, and 1-10% of a crosslinking agent. The preparation method includes: stirring the fluxing agent and the porcelainized filler at 500-900 DEG C until the surfacelayer of the fluxing agent is melted and a part of the porcelainized filler is adhered; then dehydrating a mixture of the silicone rubber substrate, the reinforcing agent, a ceramic-forming precursor, and the flame-retarding and smoke-inhibiting agent to prepare a base material; mixing and stirring the base material with the crosslinking agent, the catalyst and the coupling agent. If ablation temperature is higher than 800 DEG C, a reaction product containing a Si-B-Al bond can be generated at the binding interface between the ceramic material and a glass curtain wall, so that stripping of the glass curtain wall at high temperature can be effectively prevented.

Owner:SOUTH CHINA UNIV OF TECH

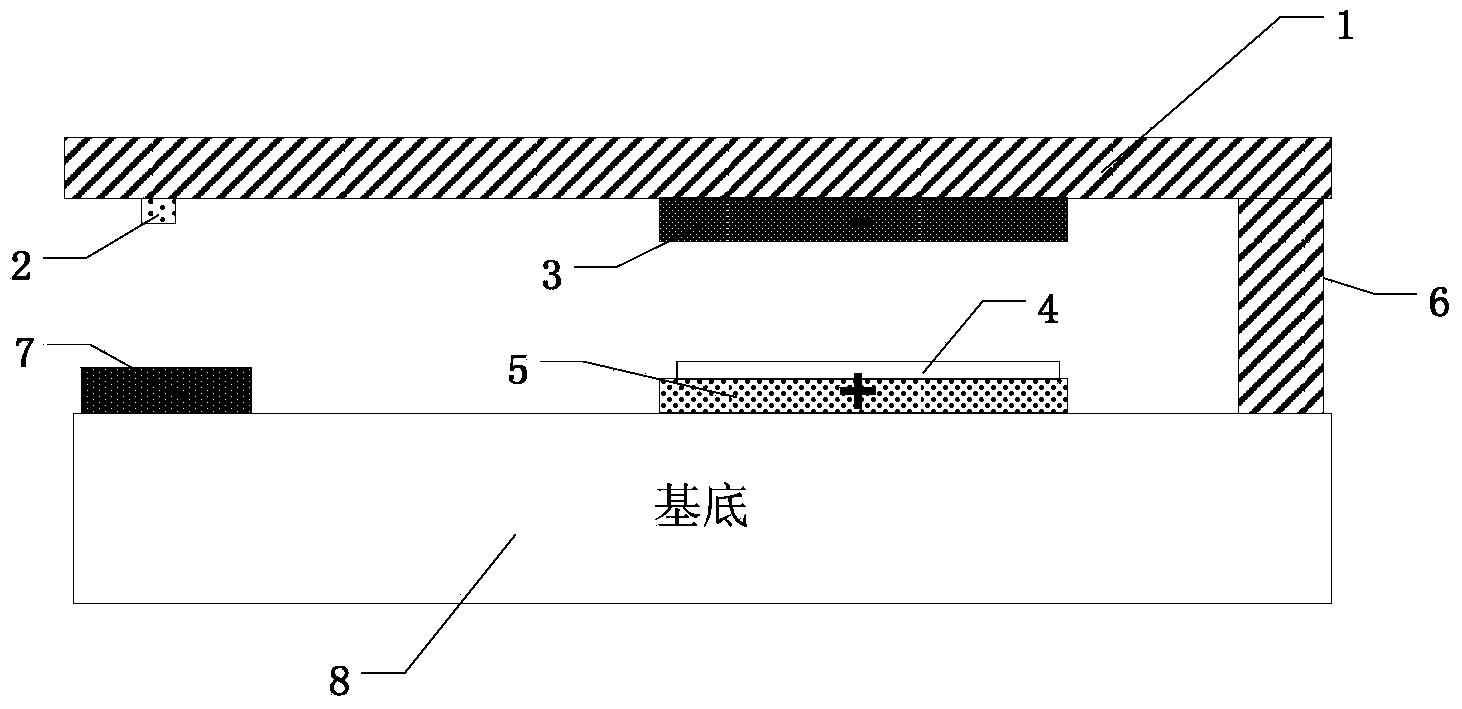

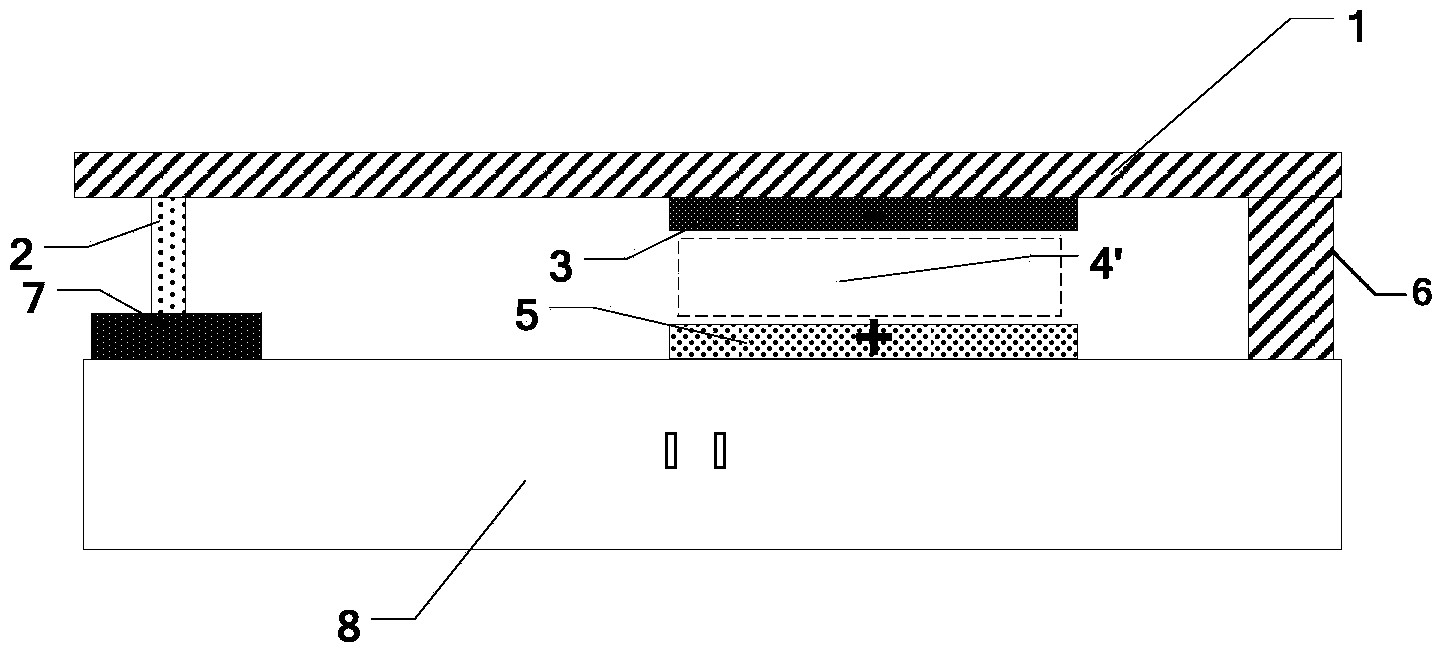

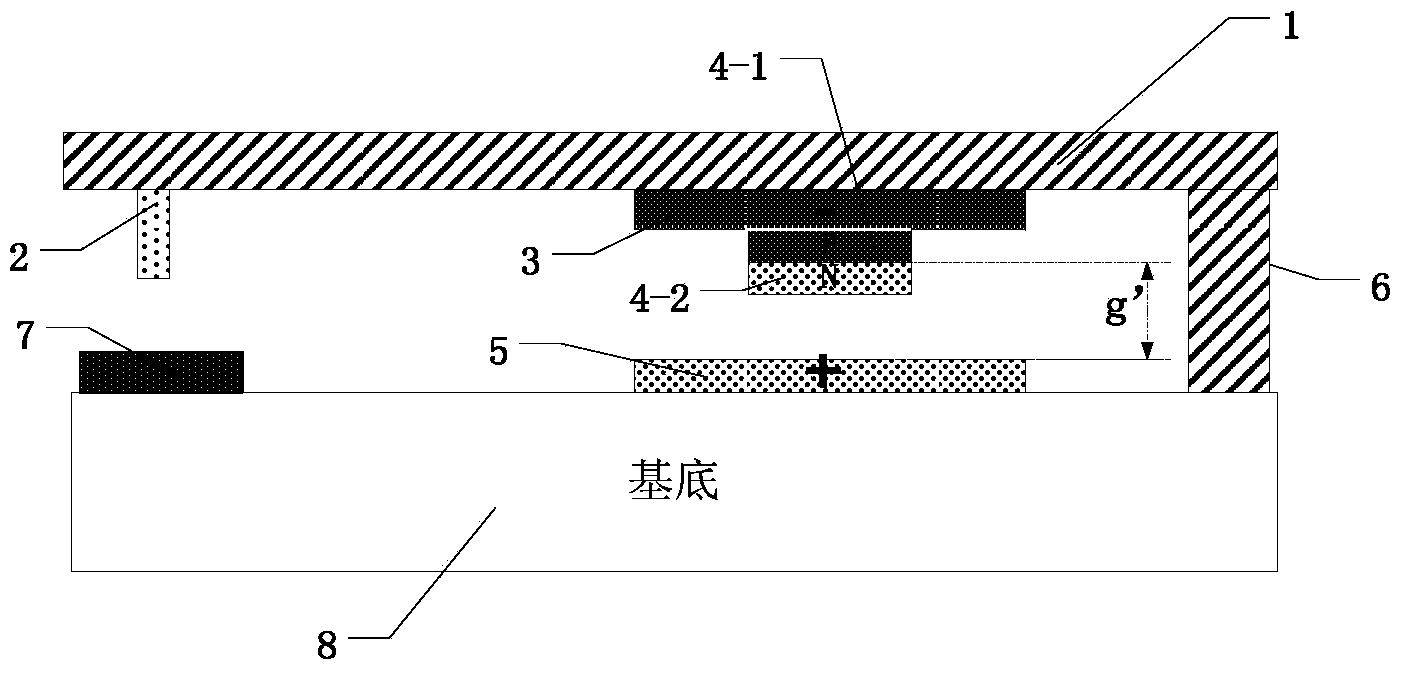

MEMS capacitor switch with PN junction

InactiveCN103985608AAvoid bond failureImprove reliabilityElectrostatic/electro-adhesion relaysSemiconductor devicesCapacitanceMems capacitors

The invention discloses an MEMS capacitor switch with a PN junction, and belongs to the technical field of electronics. The MEMS capacitor switch is characterized in that a longitudinal PN junction structure is additionally arranged between an upper drive electrode and a lower drive electrode of the MEMS capacitor switch; when the switch is in the Up state, drive voltage is not applied between the upper drive electrode and the lower drive electrode, and an electric contact point does not make contact with a signal line; when the switch is in the Down state, the upper drive electrode is pulled downwards under the action of the drive voltage, the electric contact point makes contact with the signal line, and meanwhile the longitudinal semiconductor PN junction is in the reversal of biasing state. When the MEMS capacitor switch with the PN junction works in the Down state, charge injection and accumulation cannot be generated, the bonding failure problem of the upper drive electrode and the lower drive electrode is solved, the MEMS capacitor switch is made to work under the sufficient drive voltage, it can be guaranteed that the electric contact point tightly makes contact with the signal line, and eventually reliability and stability of the MEMS capacitor switch can be improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

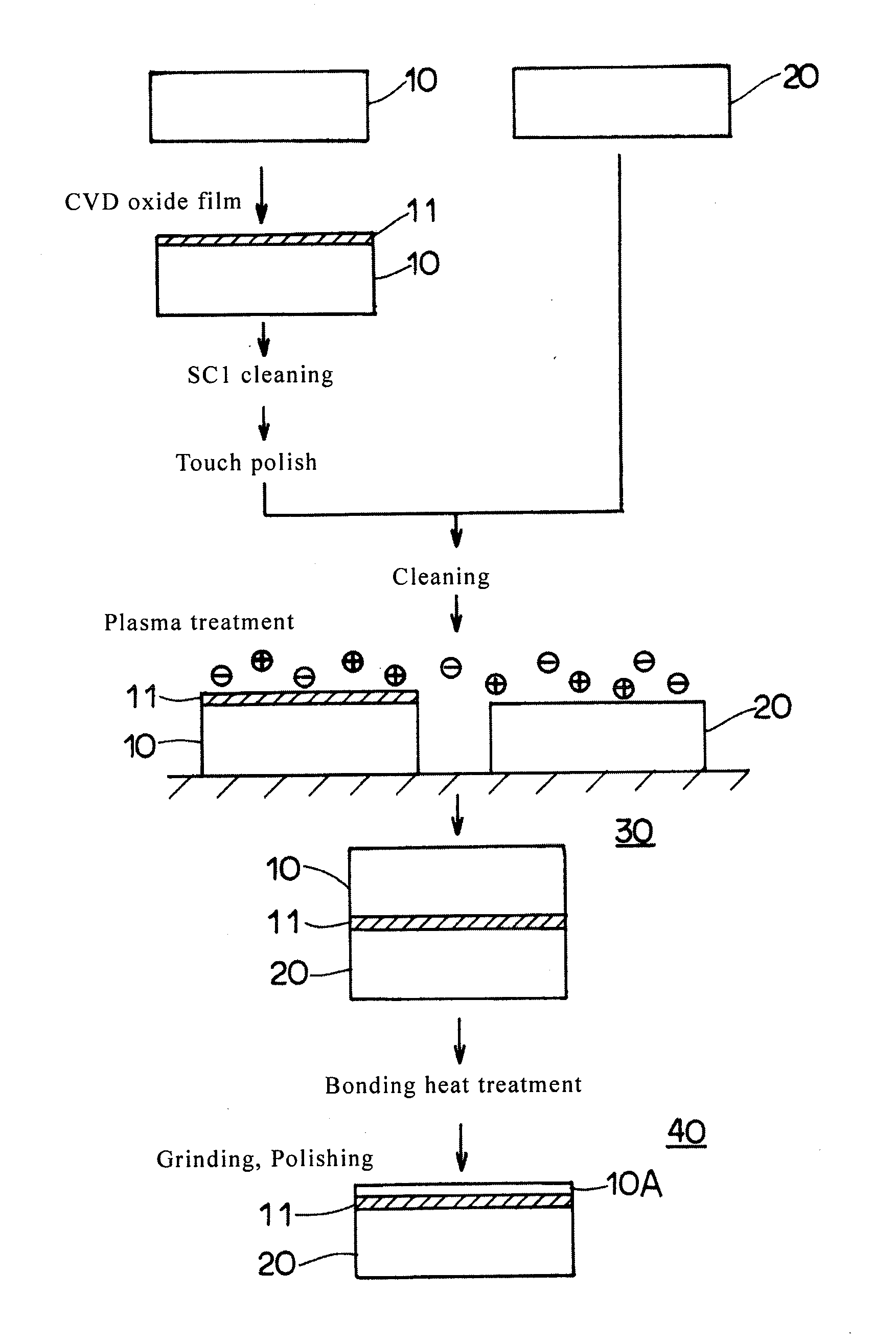

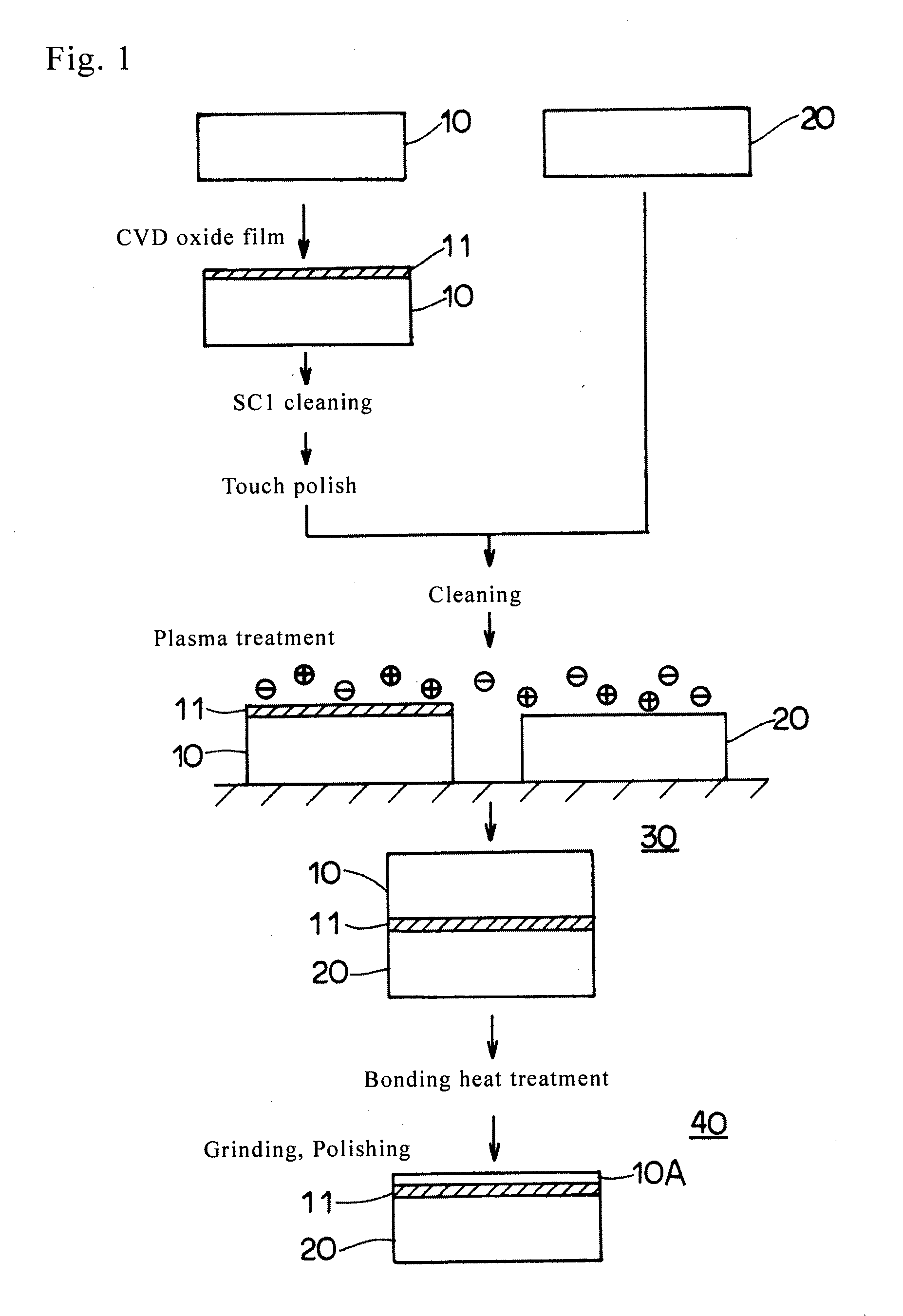

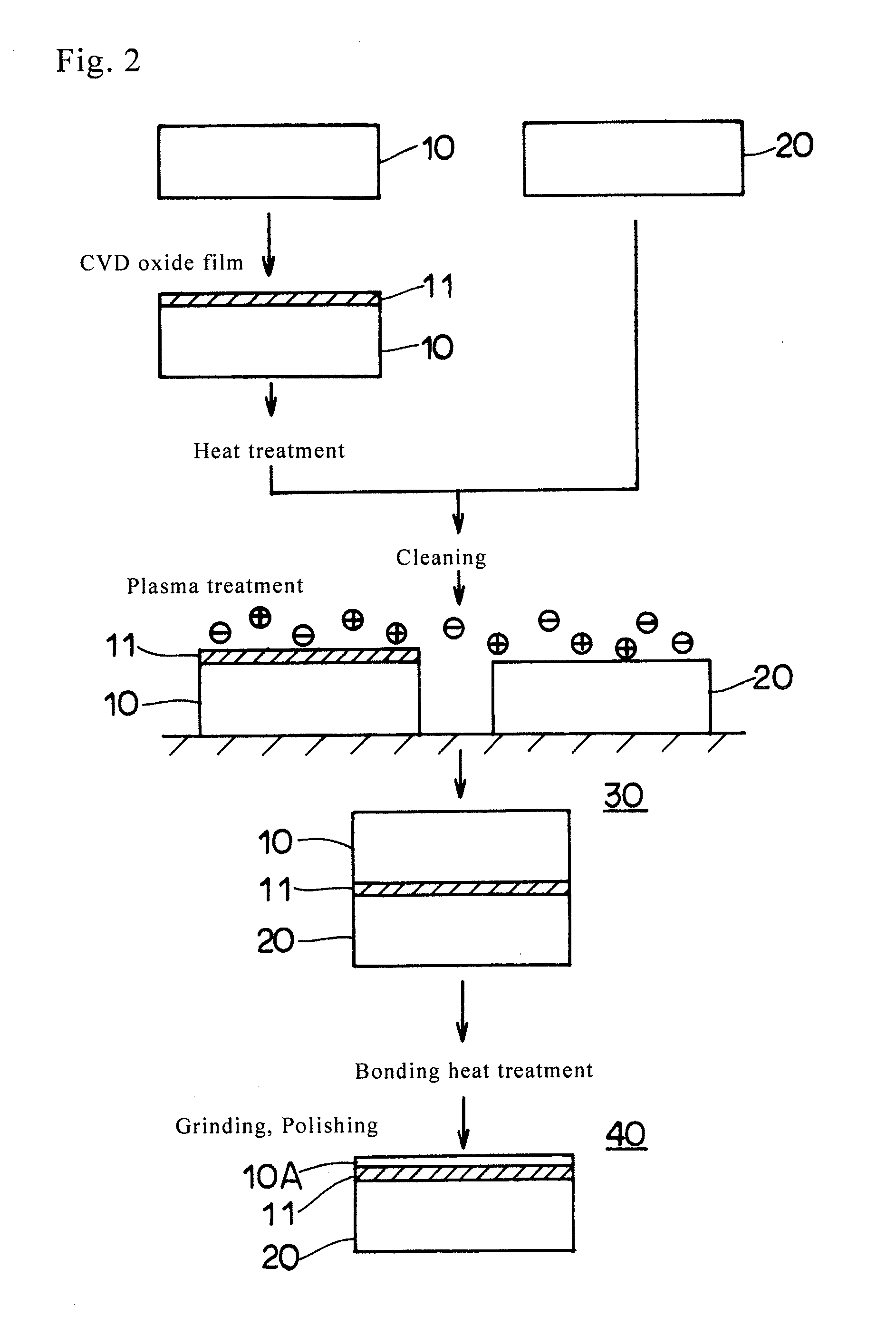

Wafer bonding method

InactiveUS20110111594A1Avoid bond failureAvoid it happening againSemiconductor/solid-state device manufacturingBond interfaceSurface roughness

Even for the case where a CVD oxide film is interposed at a bonding interface, as a pre-processing of bonding a first wafer and a second wafer, at least the surface roughness of the CVD oxide film of the first wafer is made small after removing organic substances. Therefore, it is possible to prevent void occurrence which is caused by the organic substances existing at and the roughness of the bonding interface of the two wafers.

Owner:SUMCO CORP

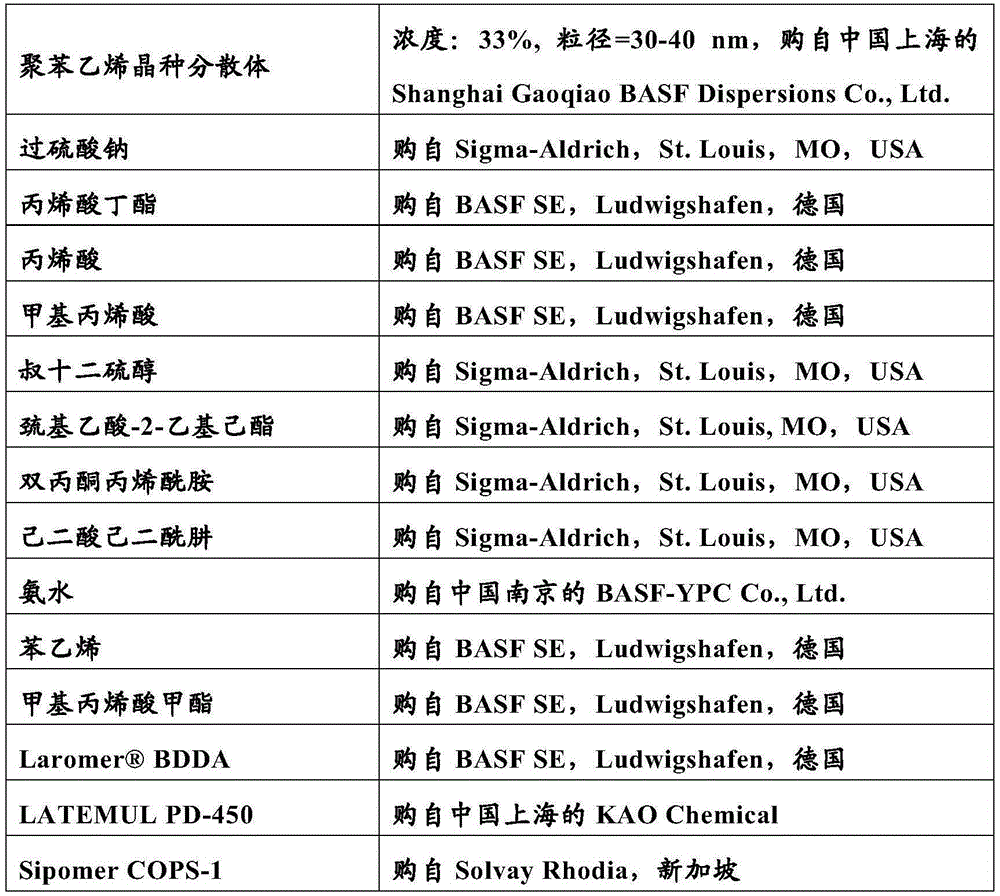

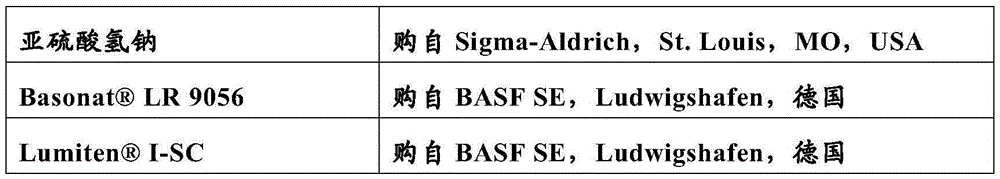

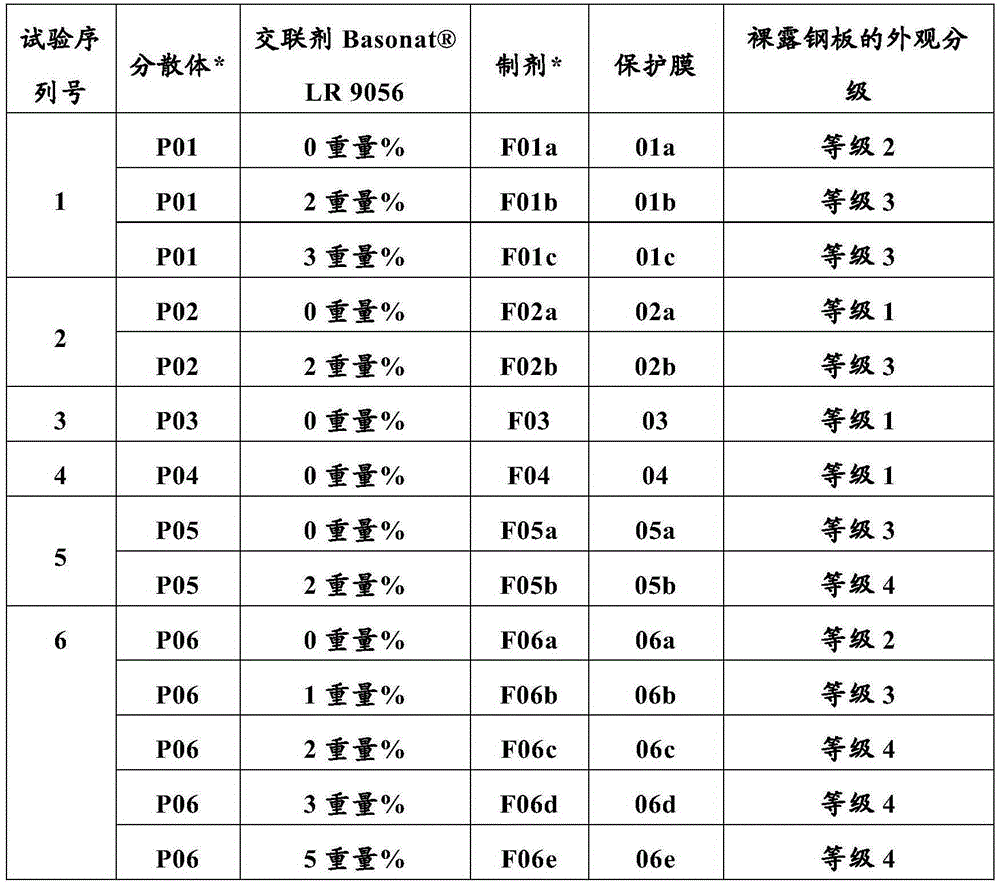

Preparation of pressure sensitive adhesive dispersions from multi-stage emulsion polymerization for applications of protective films

ActiveCN105408437AAvoid bond failureAvoid diversionEster polymer adhesivesOrganic non-macromolecular adhesiveCross-linkTectorial membrane

The invention describes a preparation process of pressure sensitive adhesives,wherein a multi-stage emulsifier-free emulsion polymerization and applications of the obtained dispersions for pressure sensitive protective films are included. At least one carboxylic acid group containing monomer is used in the first stage of emulsion polymerization. The theoretical glass transition temperatures are lower than 0 DEG C (for the first stage polymer), -20 DEG C (for the second stage polymer) and -15 DEG C (for the overall dispersion), respectively. The dispersion is preferably cross-linked with polyfunctional crosslinking agents, such as aziridine, isocyanate, carbodiimide and oxazoline. The adhesives obtained from the process thereof can be used for the application of protective films to reduce or eliminate ghost shadow on the protected surfaces.

Owner:BASF AG

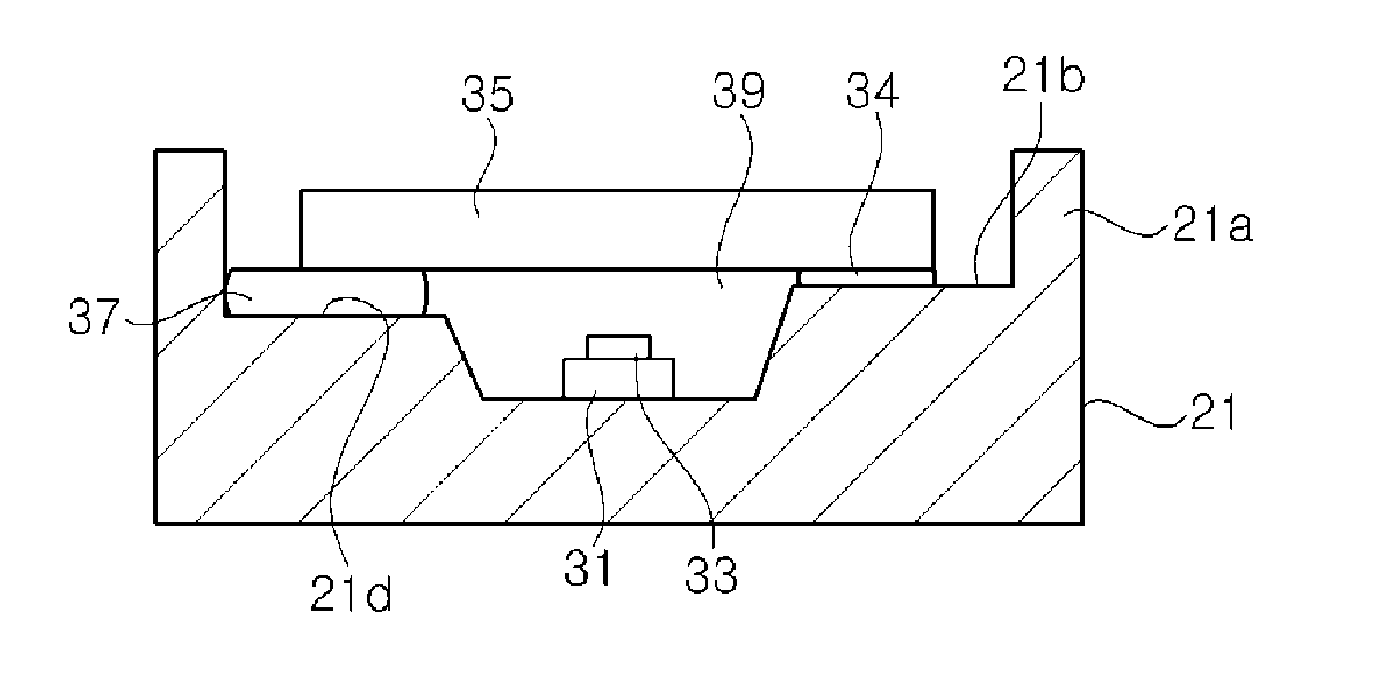

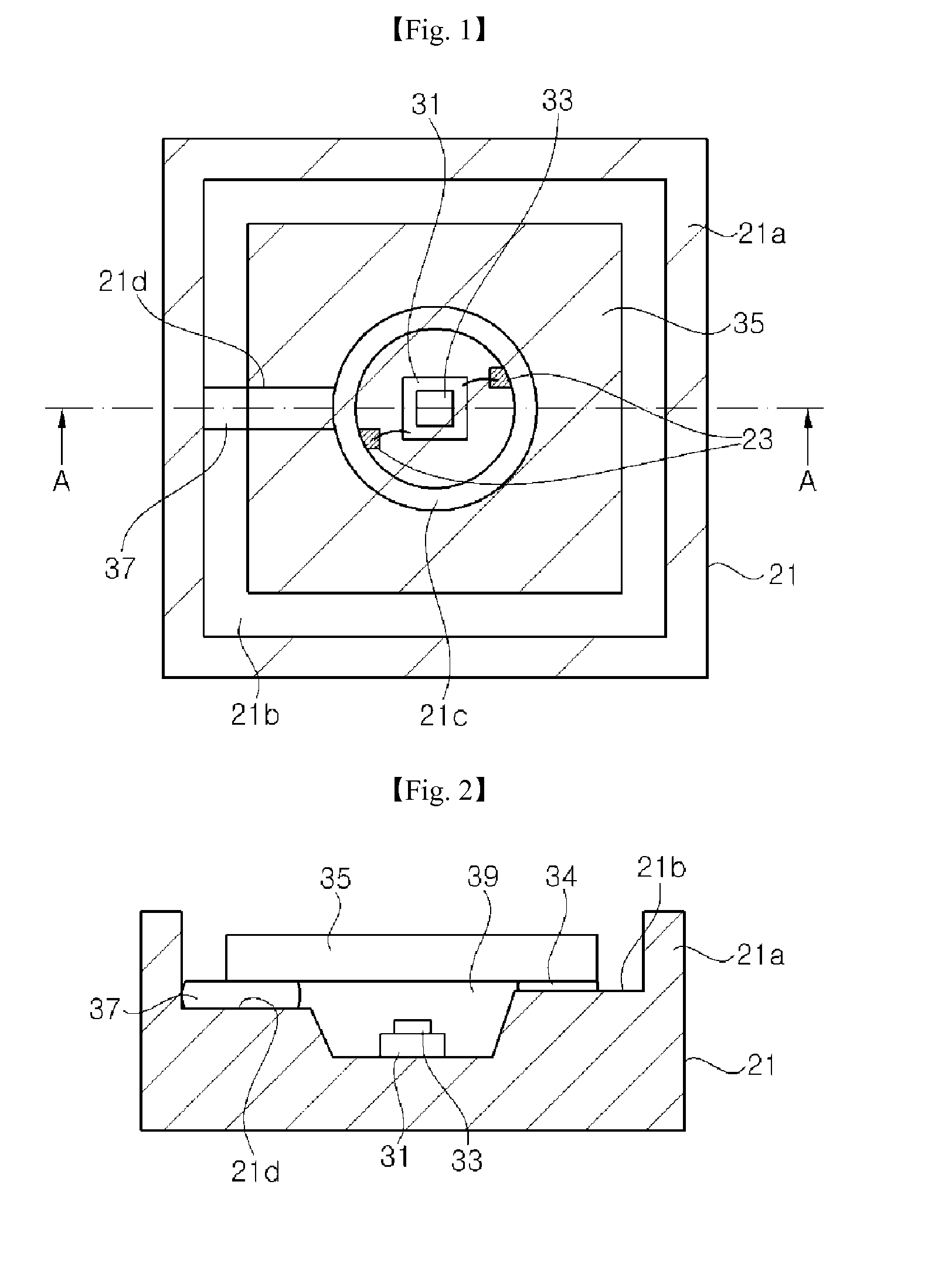

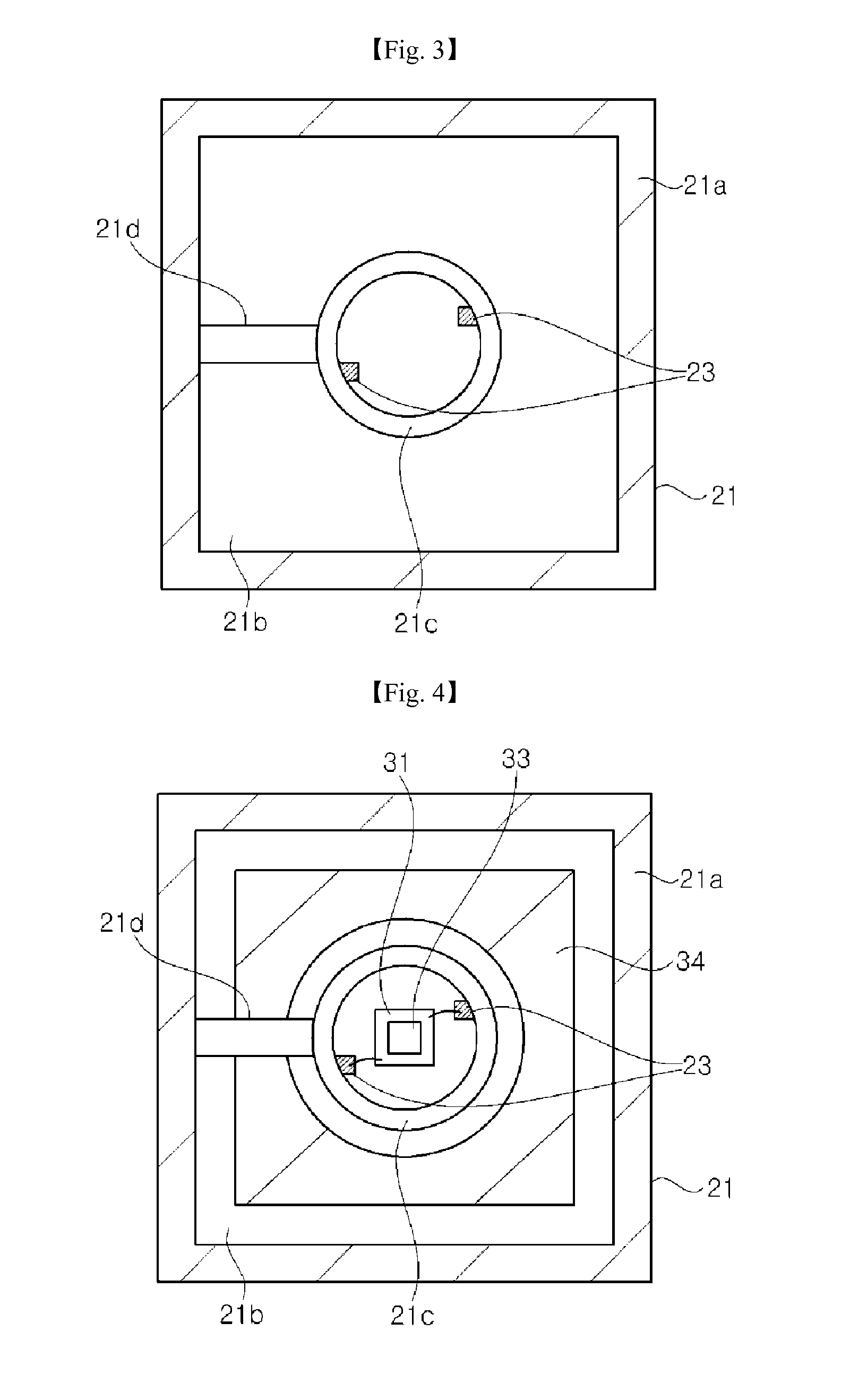

Light-emitting diode package and method for manufacturing same

ActiveUS20140284650A1Prevent separationAvoid bond failureSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

Disclosed are a light-emitting diode package and a method for manufacturing same. The method for manufacturing a light-emitting diode package comprises: preparing a package main body having a cavity and an air vent passageway which extends from the cavity; installing a light-emitting diode inside the cavity of the package main body; attaching a transparent member by means of an adhesive so as to cover the upper part of the cavity; and blocking the air vent passageway by forming a sealing member. As the air vent passageway is blocked after the transparent member is attached, the transparent member may be prevented from peeling off from the air pressure inside the cavity.

Owner:SEOUL VIOSYS CO LTD

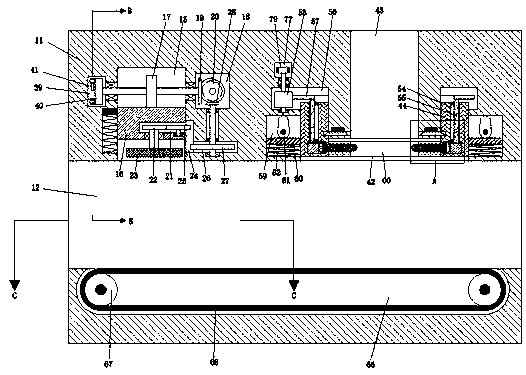

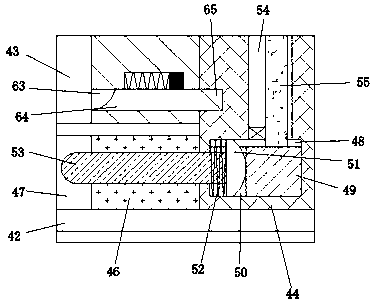

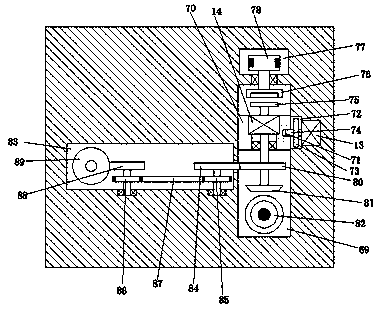

Method for ceramic bonding by utilizing ceramic ware bonding device

The invention discloses a method for ceramic bonding by utilizing a ceramic ware bonding device. The bonding device comprises a device body, a bonding cavity is formed in the device body, and a smearing device is arranged on the upper left portion in the bonding cavity; firstly, the smearing device clamps the front and back sides of ceramic, glue is smeared on and bonded to the upper end of the ceramic, and the bonding device is arranged on the upper right portion in the bonding cavity; materials needing to be bonded to the upper end of the ceramic are clamped through the bonding device and pressed to the glue for bonding, a conveying device is arranged on the lower side in the bonding cavity, and fixed point conveying is achieved through the conveying device; when the bonding device is utilized for ceramic bonfing, locating and clamping can be automatically conducted for bonding again, it is avoided that in the bonding process, due to position deflection, bonding fails, and materialsare wasted, and the work quality and efficiency are improved.

Owner:缙云新间新材料有限公司

PCB with soldering pad projections forming fillet solder joints and method of production thereof

ActiveUS8338715B2Avoid bond failureAvoid yield lossPrinted circuit assemblingFinal product manufactureEngineeringMethods of production

Owner:FUJITSU LTD

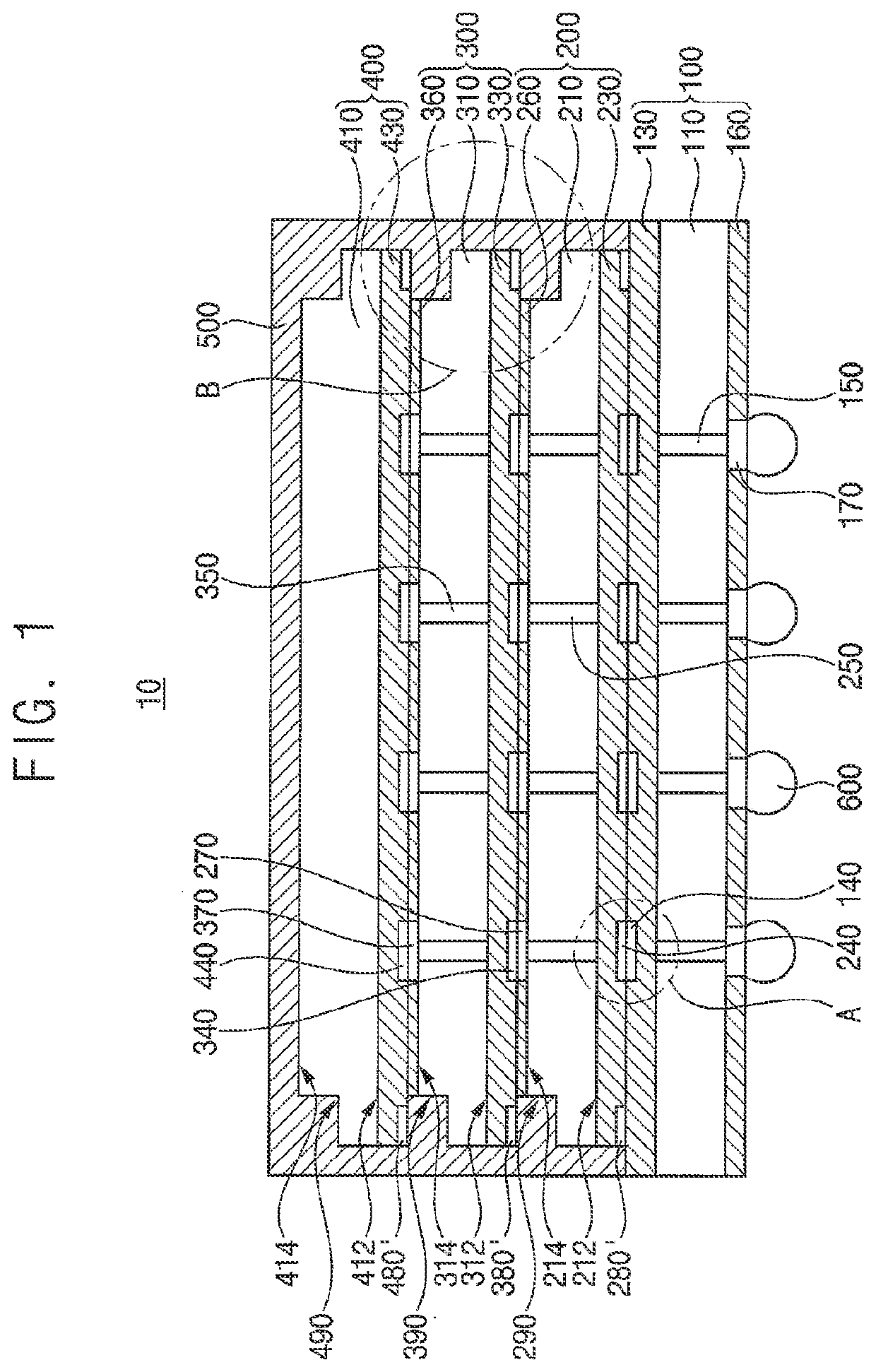

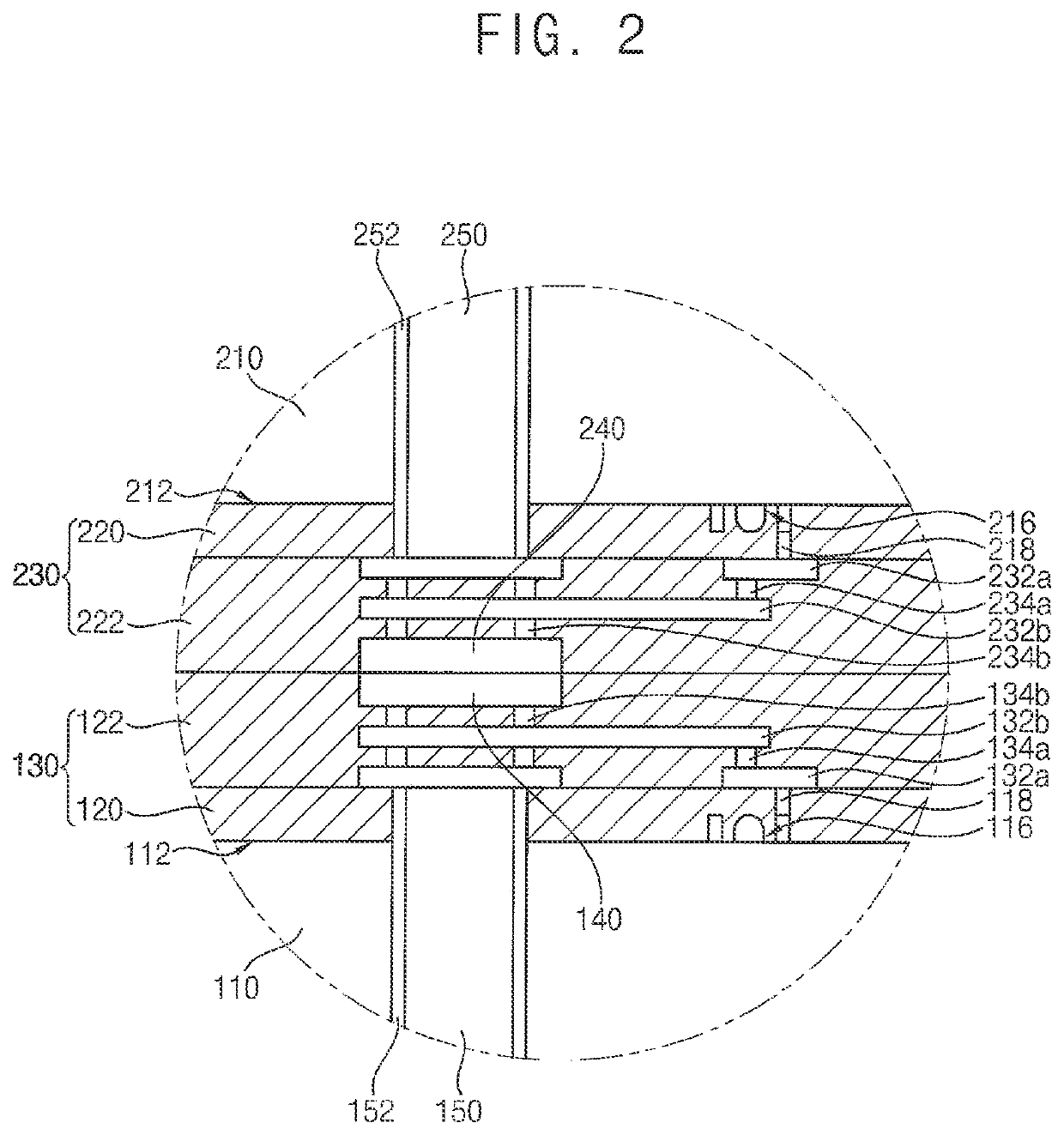

Semiconductor package and method of manufacturing the semiconductor package

PendingUS20220181299A1Improve processing yieldAvoid bond failureSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageSemiconductor chip

A semiconductor package includes a first semiconductor chip, a second semiconductor chip, a third semiconductor chip and a fourth semiconductor chip sequentially stacked on one another. The second semiconductor chip includes a second substrate and a second substrate recess formed in an edge of a backside surface of the second substrate. The third semiconductor chip includes a third substrate and a first metal residual material provided in a peripheral region of a front surface of the third substrate. When the second semiconductor chip and the third semiconductor chip are bonded to each other such that the front surface of the third substrate and the backside surface of the second substrate face each other, the first metal residual material is located in the second substrate recess. A first bonding pad on the backside surface of the second substrate and a second bonding pad on the front surface of the third substrate are bonded to each other.

Owner:SAMSUNG ELECTRONICS CO LTD

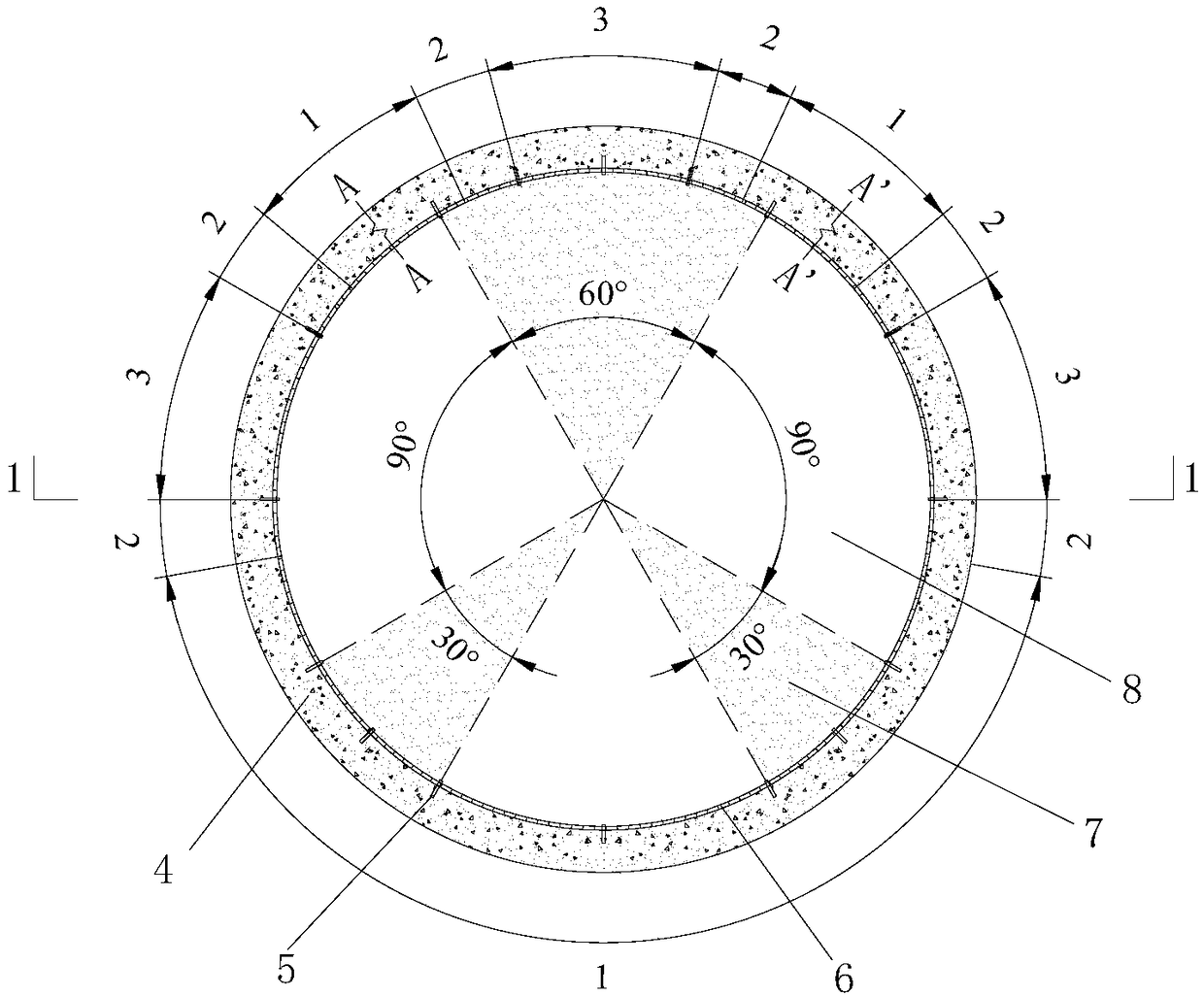

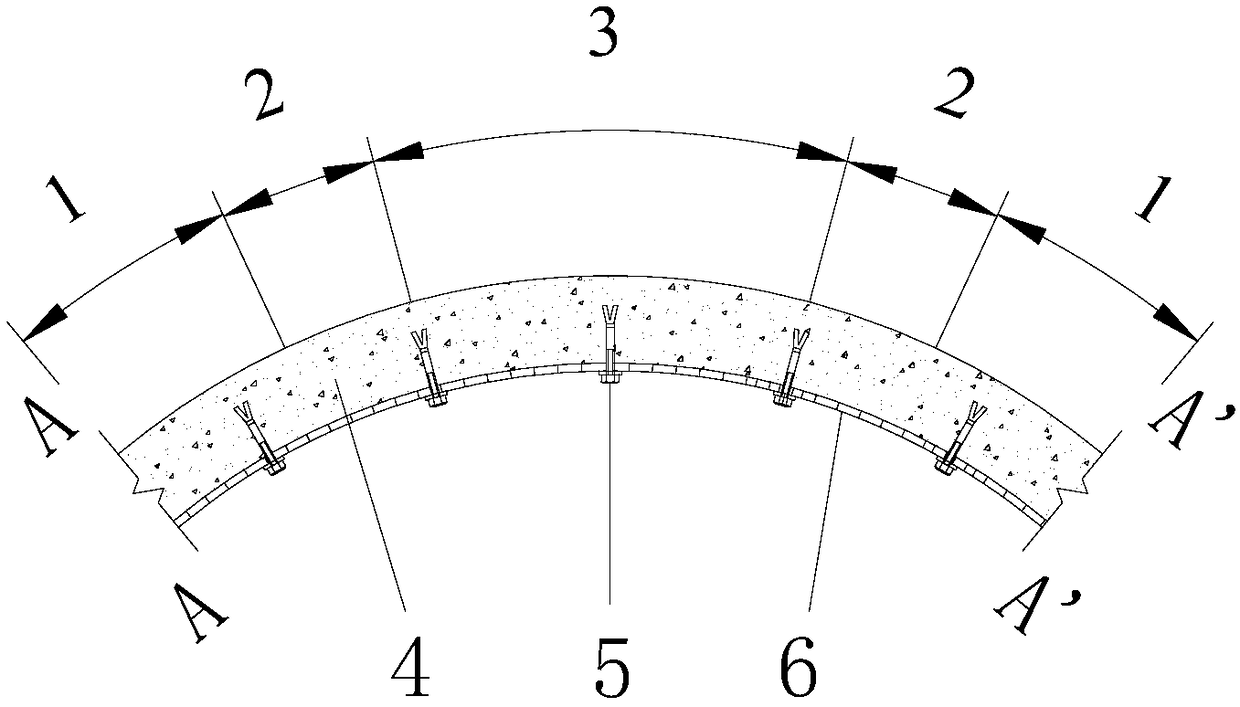

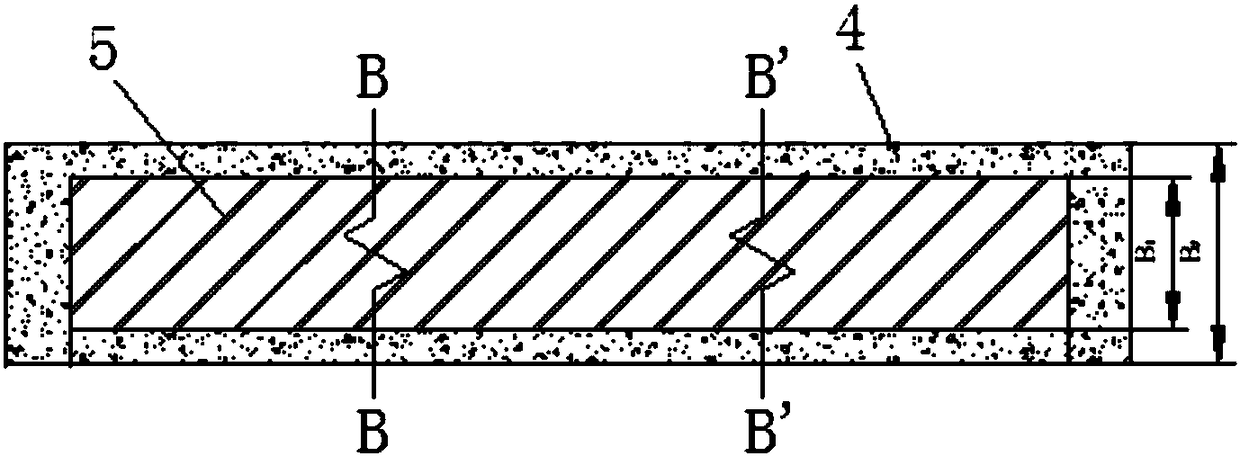

Shield tunnel segment variable thickness steel ring

PendingCN108386213AIncrease profitReduce construction costsUnderground chambersTunnel liningSheet steelMaterials science

The invention relates to a shield tunnel segment variable thickness steel ring. The shield tunnel segment variable thickness steel ring is formed by splicing steel sheets; starting from the right above of segments at 0 degree, the degree of the spliced steel sheets is increased clockwise, the areas between 345 degrees and 15 degrees, 60 degrees and 90 degrees, and 270 degrees and 300 degree of thesegments are special areas; areas on both sides of every special area within 10 degrees are gradient areas, and the other areas of the segments are common areas; the thickness of steel ring in the special areas is twice as much as that in the common areas. The shield tunnel segment variable thickness steel ring determine a reasonable and scientific reinforcing steel ring thickness, thereby improving the reinforcing effects and meanwhile reducing consumption of steel ring materials as well as the construction costs; the segments and the steel ring are anchored through expansion bolts, the areas clockwise between 330 degrees and 0 degree, 120 degrees and 150 degrees, and 210 degrees and 240 degrees of the segments serve as reinforced anchoring areas and areas outside the reinforced anchoring areas as common anchoring areas, the segments and the steel ring are anchored through the expansion bolts at an interval of 20 degrees in the reinforced anchoring areas and an interval of 30 degreesin the common anchoring areas, so that the tensile strength of the segments and the steel ring can be enhanced effectively.

Owner:TONGJI UNIV

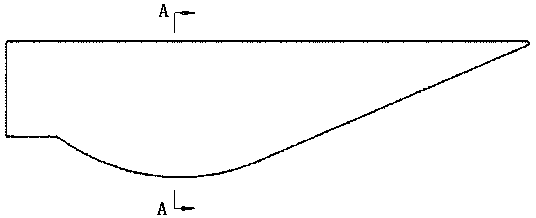

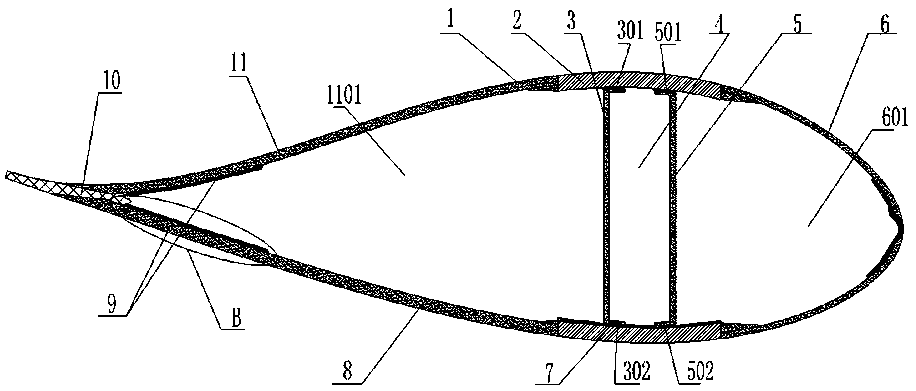

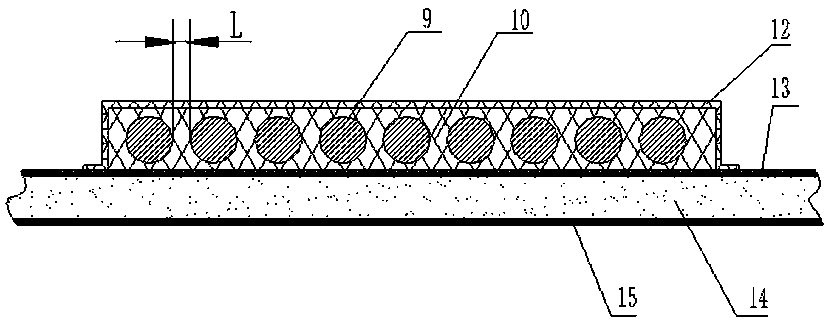

Ice preventing and ice removing wind power blade and manufacturing method thereof

ActiveCN107859603AImprove thermal conductivityAvoid lostFinal product manufactureHeater elementsGlass fiberElectricity

The invention provides an ice preventing and ice removing wind power blade and a manufacturing method thereof. By laying a heat conducting material layer high in heat conduction coefficient in a grooved middle core material to improve the heat conduction coefficient of a wind power blade body, heat generated by heating resistors can be fast transmitted to the outer surface of the wind power bladebody, and therefore energy needed for heating the wind power blade body can be reduced to be lowest, and the problems that because of internal heating in the prior art, the interior temperature of thewind power blade body is too high, the material performance loss of the wind power blade body is caused, and consequently the service life is shortened, and combustion of the wind power blade body iscaused are solved. The heating resistors are uniformly arranged in epoxy structural glue as an adhesion agent, primary packaging is performed when adhering is performed, a glass fiber protecting layer infiltrated by resin is arranged so that the service life of the heating resistors is prolonged, the application reliability of the ice preventing and ice removing wind power blade is guaranteed, and application and popularization value is great.

Owner:江苏双瑞风电叶片有限公司

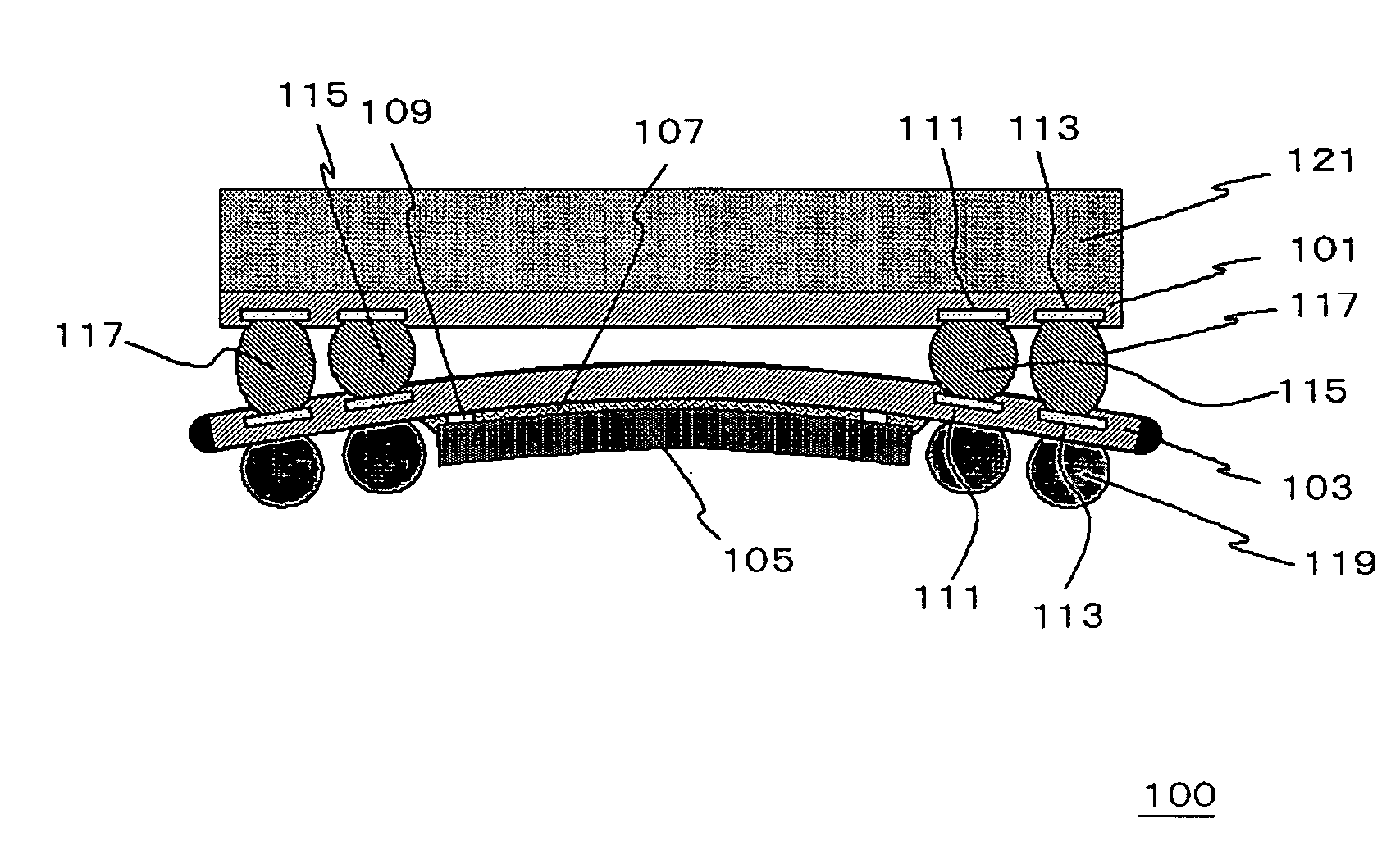

Substrate and semiconductor device

InactiveUS7759799B2Suppress bonding failureEasy to adjustFinal product manufactureSemiconductor/solid-state device detailsSemiconductorSemiconductor device

Aiming at adjusting the height of bump electrodes connected to lands on a substrate, a semiconductor device 100 has a first interconnect substrate 103 and a second interconnect substrate 101. On one surface of these substrates, first lands 111 and second lands 113 are provided. The plane geometry of the second lands 113 is a polygon characterized by the inscribed circle thereof having an area smaller than the area of the inscribed circle of the first land.

Owner:RENESAS ELECTRONICS CORP

Bonding apparatus

InactiveUS9711483B2Prevent short-circuitingImprove productivityPrinted circuit assemblingSemiconductor/solid-state device detailsElectrical and Electronics engineeringElectrode

A bonding apparatus bonds a plurality of device chips on a plurality of electrode pads that are provided to a surface of a substrate. The bonding apparatus includes a stage, a head unit, a head lifting mechanism, a head vibrator, a heater, and a bonding region observation component. The substrate is placed and supported on the stage. The head unit holds the device chips. The head lifting mechanism raises and lowers the head unit in an up and down direction relative to the stage. The head vibrator vibrate the head unit in the up and down direction. The heater heats a bonding paste that bonds the device chips and the electrode pads. The bonding region observation component observes a region that includes at least a peripheral part of the electrode pads.

Owner:TORAY ENG CO LTD

Anti-stick waterproof board and preparation method thereof

ActiveCN106700216AImprove adhesionImprove waterproof performanceUnderground chambersCoatingsPolymer scienceAntioxidant

The invention provides an anti-stick waterproof board with excellent water resistance. The anti-stick waterproof board consists of a base material layer, a self-adhesive layer and an isolating membrane layer which are sequentially compounded into a whole, wherein the self-adhesive layer is positioned between the base material layer and the isolating membrane layer; the isolating membrane layer does not need to be removed, and disappears after reacting with poured concrete; the self-adhesive layer has the thickness of 0.2-0.4mm, and is prepared from the following components in parts by weight: 2-10 parts of chlorobutyl rubber, 20-30 parts of high-molecular-weight butyl rubber with a viscosity average molecular weight of 400-500 thousands, 30-50 parts of medium-molecular-weight polyisobutylene with a viscosity average molecular weight of 50-100 thousands, 20-40 parts of low-molecular-weight polyisobutylene with a viscosity average molecular weight of 1000-3000, 0.5-10 parts of vinyl-terminated silicone rubber and 1-5 parts of an antioxidant; the vinyl-terminated silicone rubber is terminal vinyl silicone rubber and has a viscosity average molecular weight of 50-300 thousands, and the mole percent of vinyl is more than 1%. The invention also provides a preparation method of the anti-stick waterproof board.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

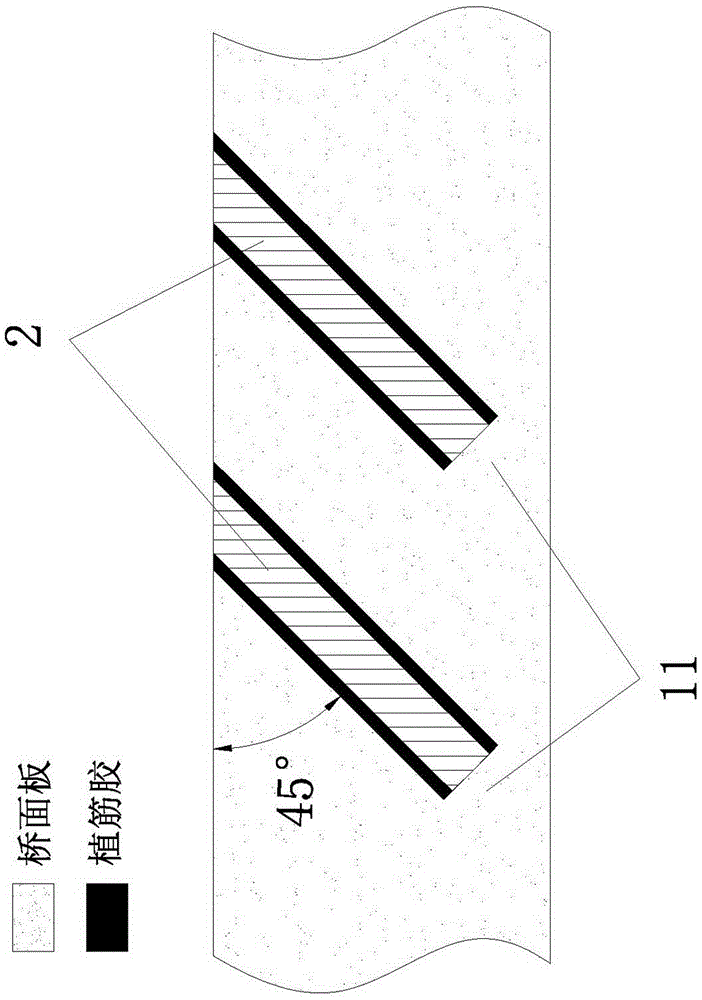

Bridge deck reinforcing structure and method

InactiveCN106168016AIncreased shear capacityImprove adhesionBridge structural detailsBridge erection/assemblySurface layerSurface mounting

The invention provides a bridge deck reinforcing method. The method comprises the steps of drilling, wherein reinforcing holes are drilled in the top surface and / or bottom surface of a bridge deck; glue filling, wherein the reinforcing holes are filled with steel bar embedding glue; steel bar distribution, wherein FRP bars are placed in the reinforcing holes. Compared with a surface bonding method in the prior art, the reinforcing method has the advantages that the FRP bars are protected and limited by a concrete structure of the bridge deck after being placed in the reinforcing holes without being affected by the external environment basically, so that FRP bar and concrete bonding property is improved and bonding failure caused by edge concrete cracking is effectively avoided. Compared with a surface-surface mounting method in the prior art, the reinforcing method has the advantage that reinforcement is conducted by drilling concrete and then placing the FRP bars in the drilled reinforcing holes instead of being conducted on the surface layer of concrete, so that damage to a concrete protection layer is avoided.

Owner:DONGGUAN UNIV OF TECH

Epoxy modified cement pavement antiskid wearing layer and construction method thereof

PendingCN113322743AGood structural transitionSmooth connectionIn situ pavingsFirming agentRoad surface

An epoxy modified cement pavement antiskid wearing layer comprises a water-borne epoxy resin bonding layer formed by spraying water-borne epoxy resin and a water-borne epoxy curing agent on a cement concrete pavement; an epoxy asphalt sealing layer, formed by sequentially spreading a first epoxy asphalt cementing material, a first aggregate and a second epoxy asphalt cementing material on the water-borne epoxy resin bonding layer, and having a first epoxy asphalt cementing material layer / first aggregate layer / second epoxy asphalt cementing material layer sandwich structure; wherein the first aggregate is limestone, diabase or basalt; a high-viscosity modified asphalt macadam sealing layer, formed by synchronously spreading high-viscosity modified asphalt and second aggregate on the epoxy asphalt sealing layer and rolling the epoxy asphalt sealing layer through a road roller, and the high-viscosity modified asphalt macadam sealing layer and the epoxy asphalt sealing layer being mutually embedded and extruded to form an integrated fusion structure; wherein the particle size of the second aggregate is not greater than that of the first aggregate, and the second aggregate is basalt or diabase; and an asphalt sealing layer, formed by spreading a sealing surface material on the high-viscosity modified asphalt macadam sealing layer.

Owner:CHONGQING SINCERE BOND PAVEMENT MATERIALS

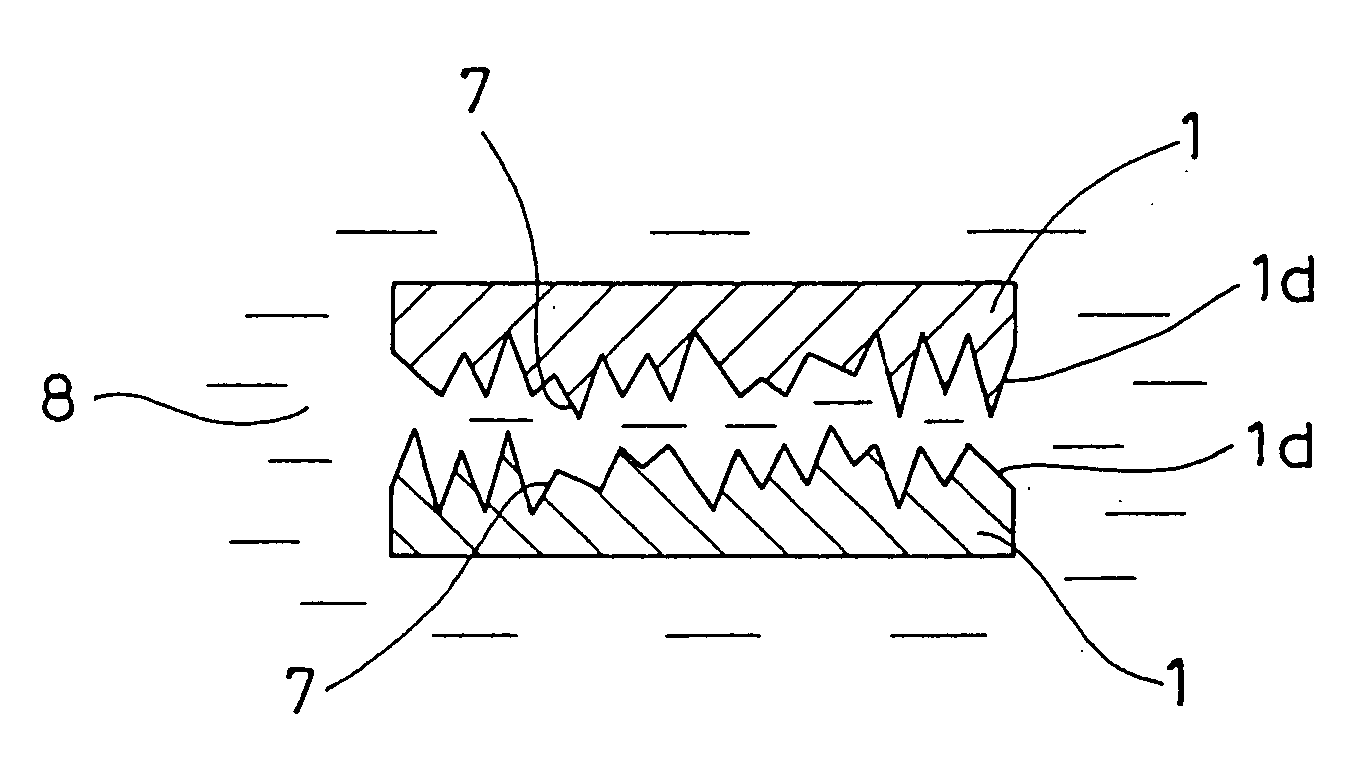

Metal part and surface treating method thereof

InactiveUS20060035104A1Increase surface areaImprove surface roughnessInsulating substrate metal adhesion improvementPerforating toolsMan-hourSurface roughness

In a metal part in which a rubber is adhered to a portion or the whole of a surface thereof, and a surface treating method of the metal part, in order to improve an adhesive property between the metal and the rubber, to make it easy to form a surface roughness in a specific portion of a metal part, and to achieve an improvement of working accuracy in the surface roughness, an improvement of mold maintenance property, a reduction of working cost, a reduction of man hour, and the like, a surface roughness for increasing an adhesive property between the metal and the rubber is formed in a portion of a surface of the metal part to which the rubber is adhered, and the surface roughness is transcribed from a mold for working the metal part to the metal part by previously providing with a surface roughness in the mold. A magnitude of the surface roughness is preferably set to be 10 μm or more and less than 60 μm.

Owner:NOK CORP

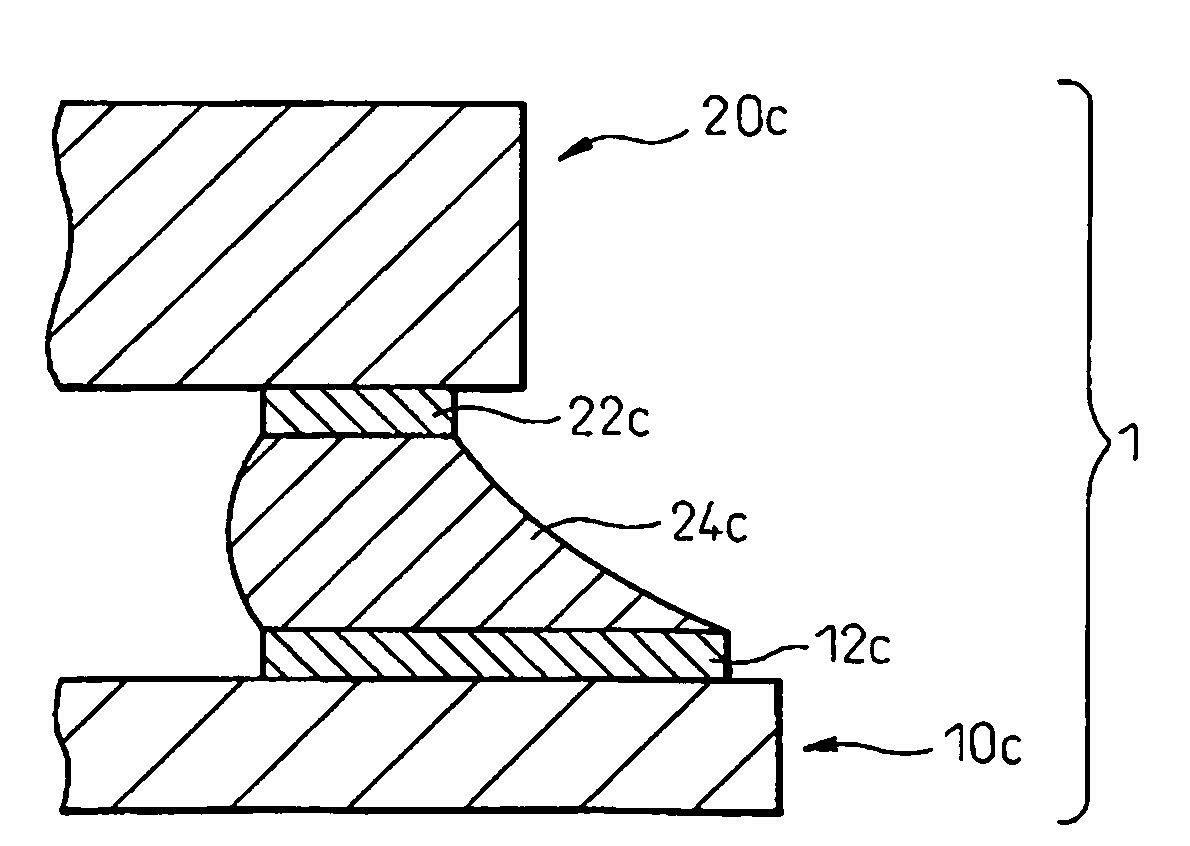

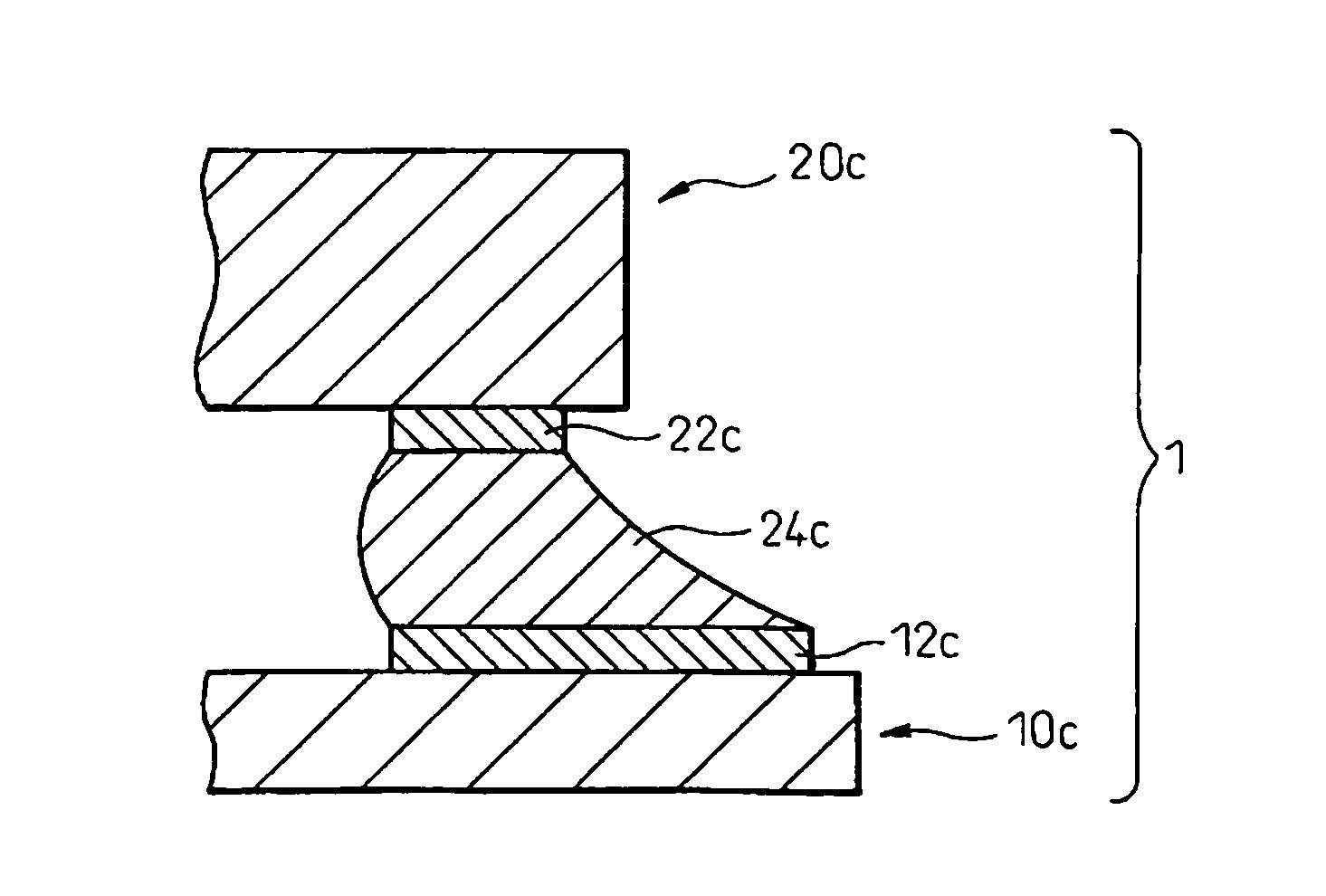

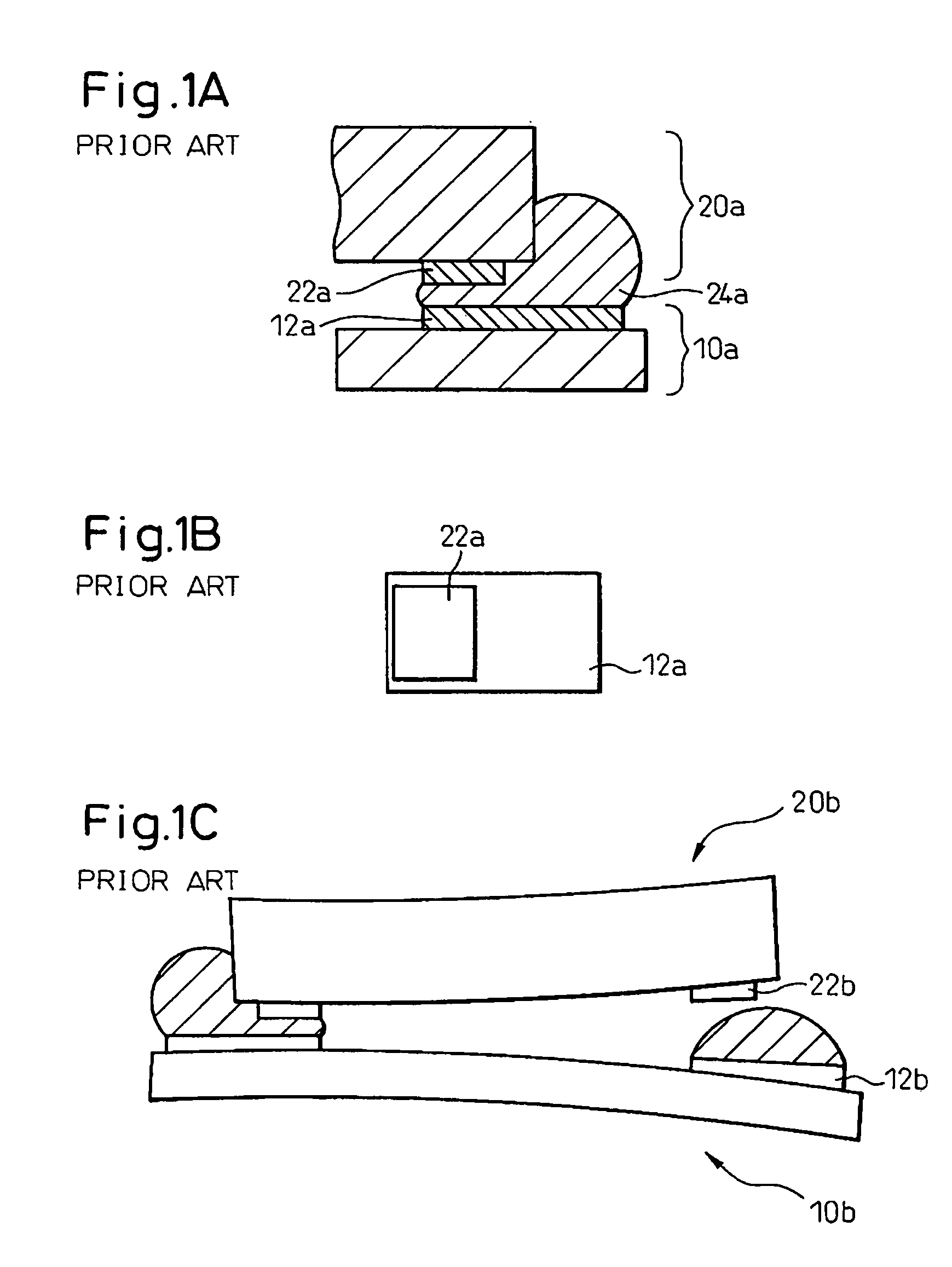

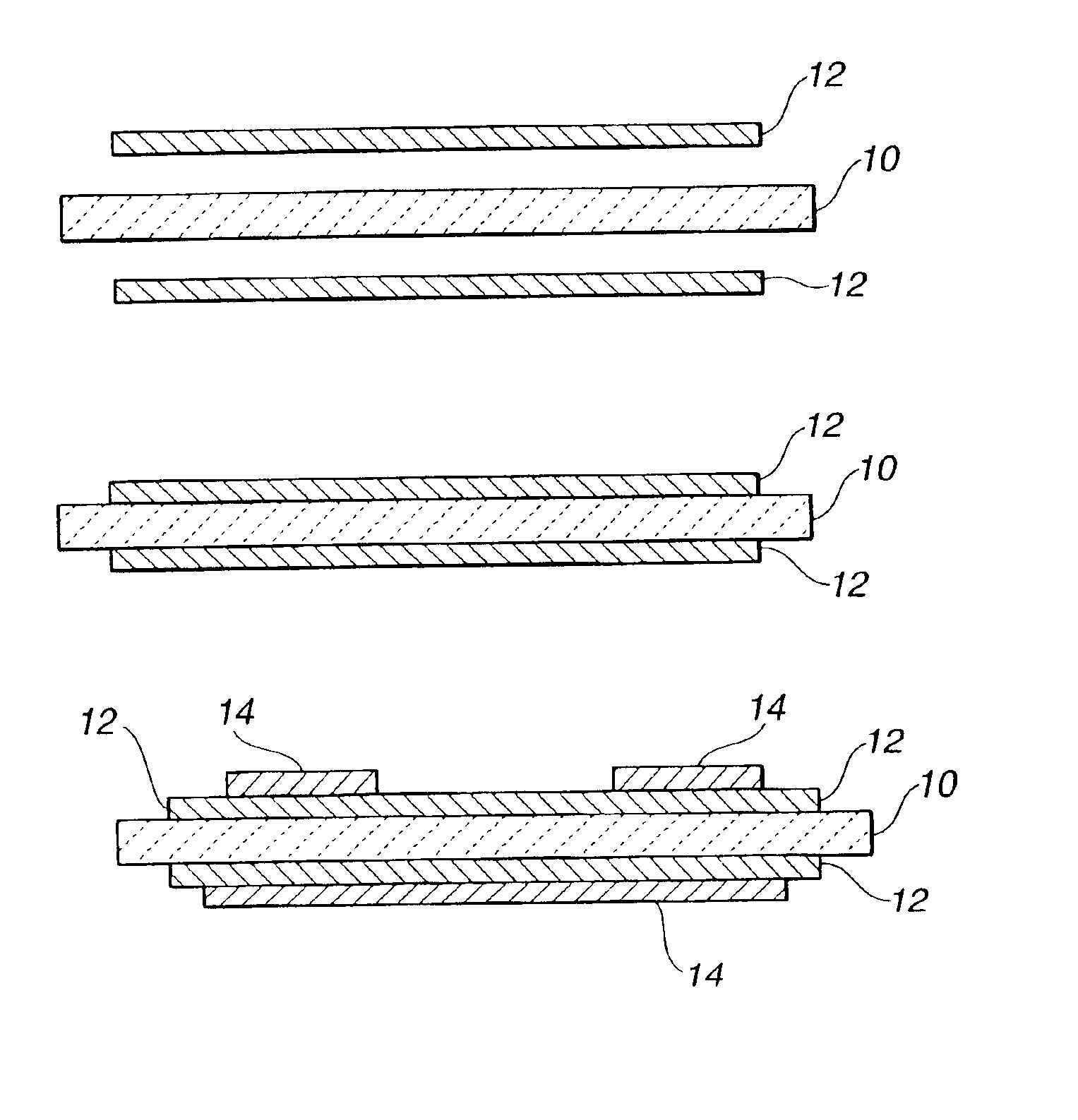

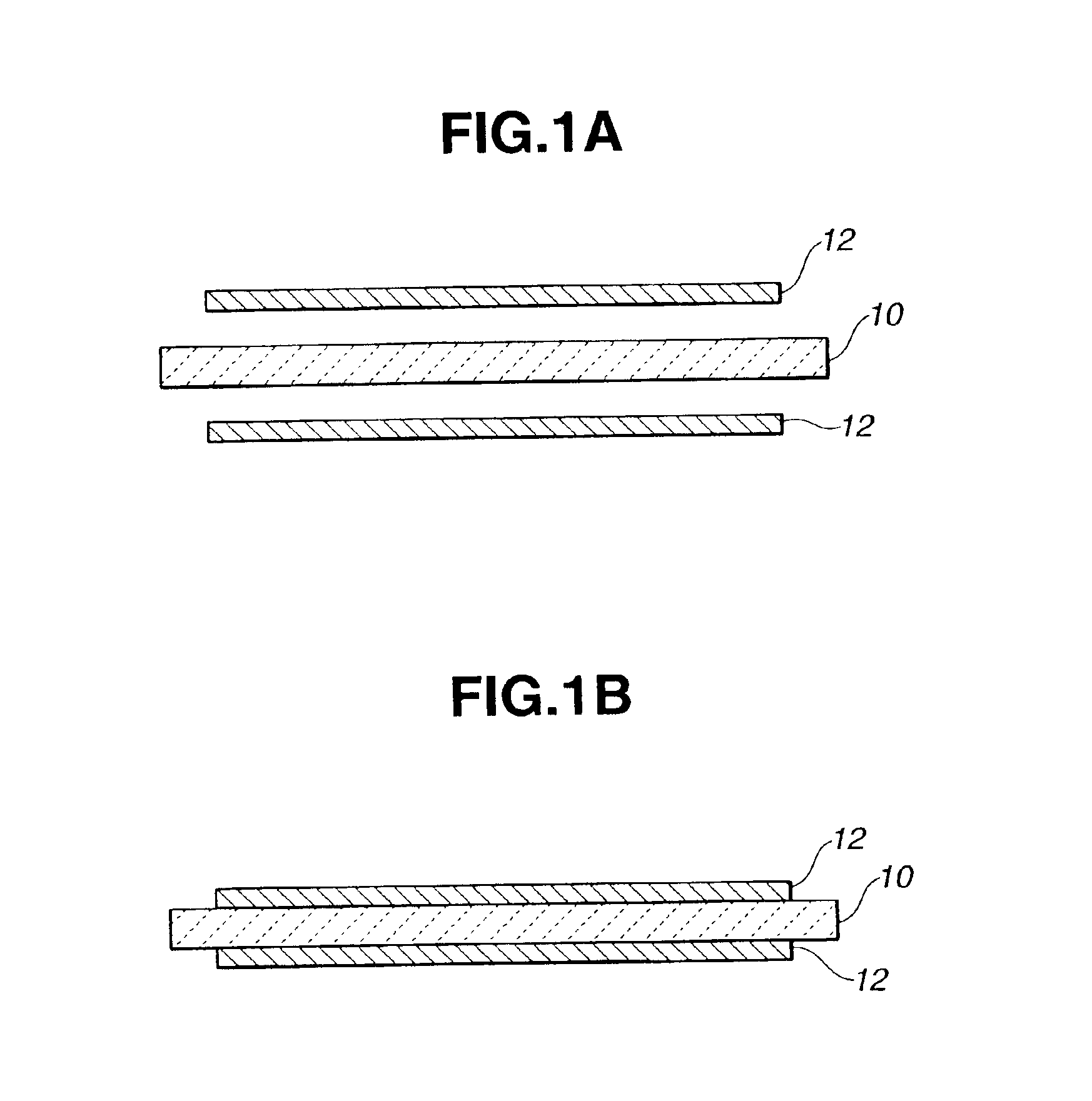

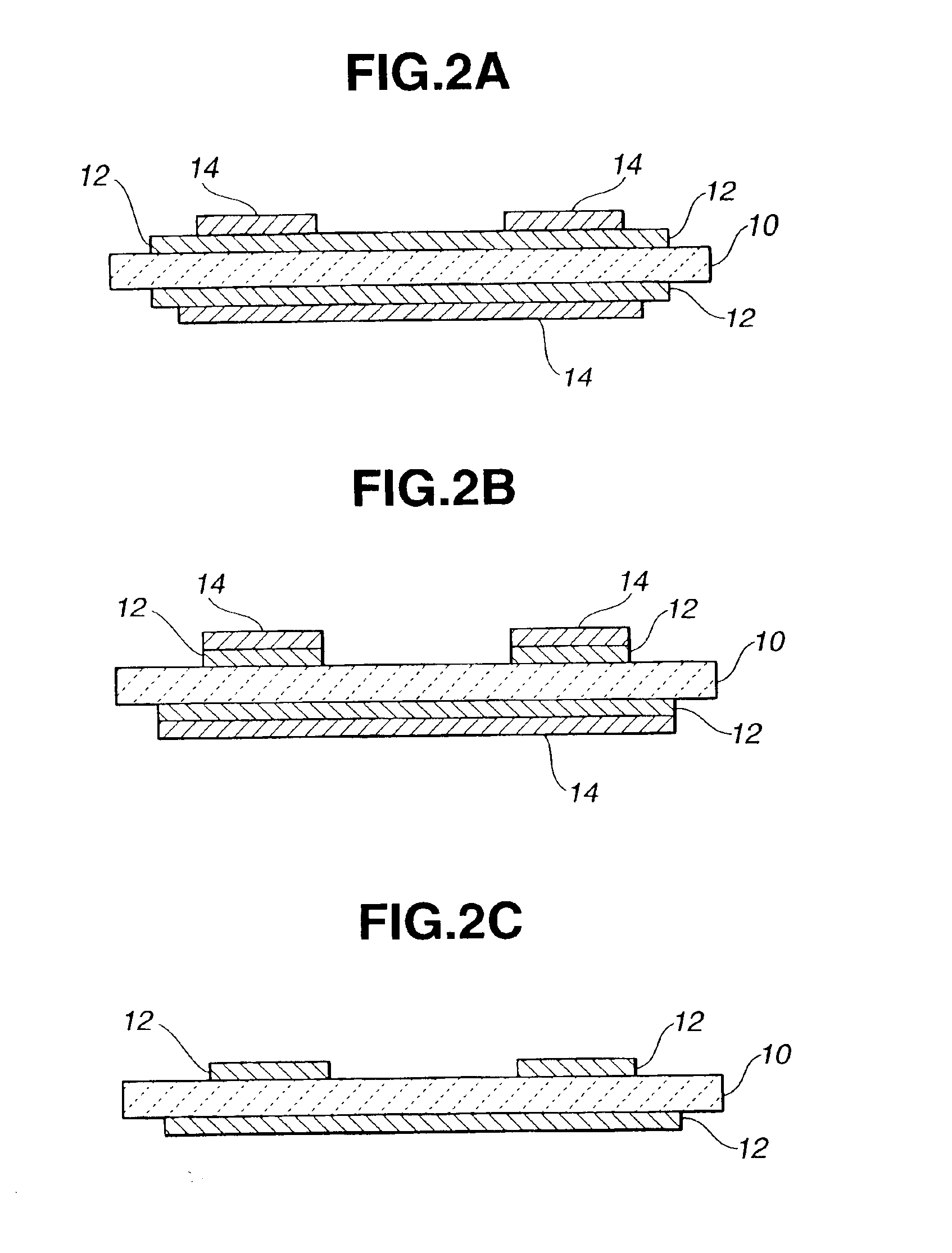

Metal/ceramic bonding article and method for producing same

InactiveUS6858151B2Reducing displacement failure of partImprove productivityDecorative surface effectsSemiconductor/solid-state device detailsResistProduction rate

There is provided a method for producing a metal / ceramic bonding article, the method including the steps of: bonding a metal plate 12 of an alloy containing copper and nickel directly to at least one side of a ceramic substrate 10; applying a resist 14 on a predetermined portion of the metal plate 12 to remove an undesired portion of the metal plate 12 by etching; and removing the resist 14 to form a pattern having a predetermined shape of the alloy on the ceramic substrate 10. According to this method, it is possible to reduce the displacement failure of parts to improve productivity and to prevent bonding failure during the mounting of a semiconductor device or the like thereon.

Owner:DOWA METALS & MINING CO LTD

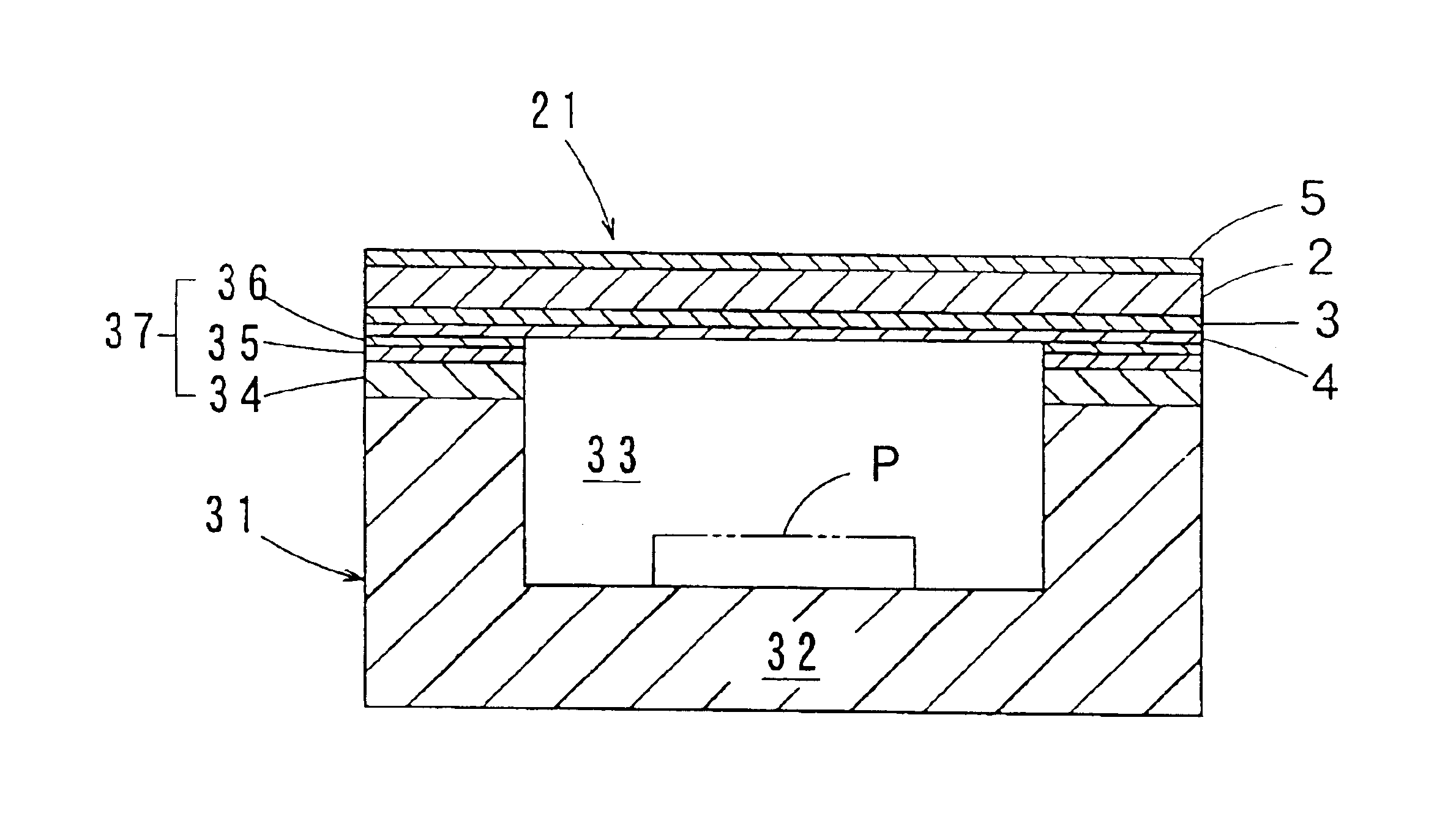

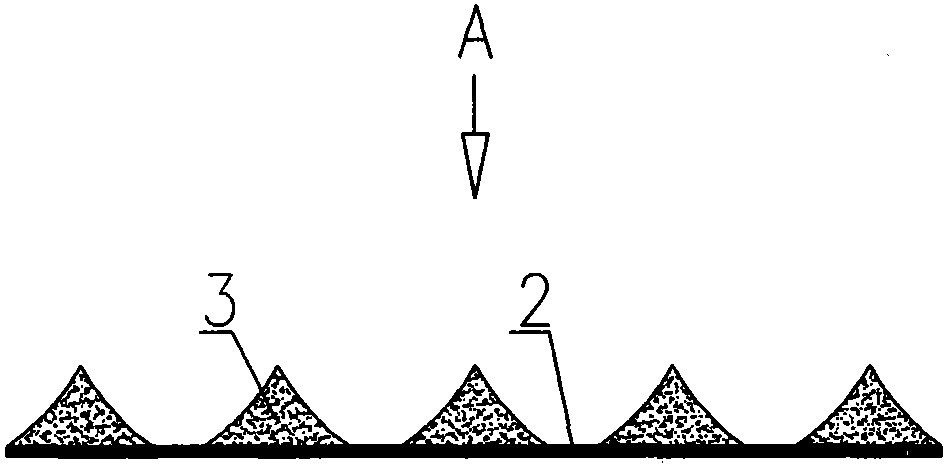

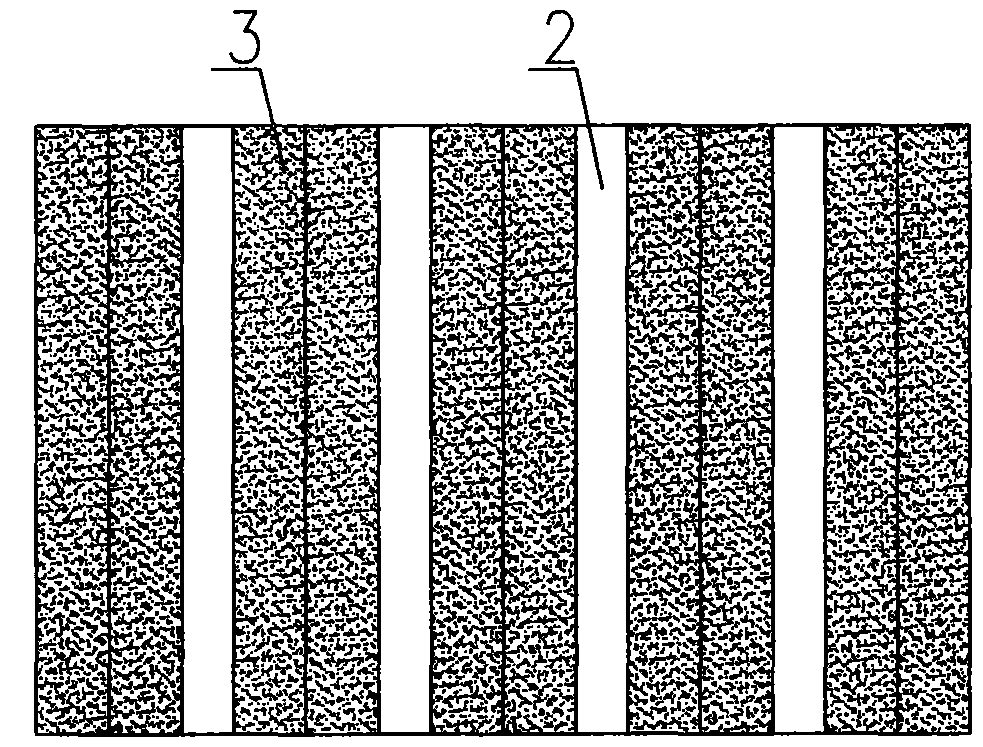

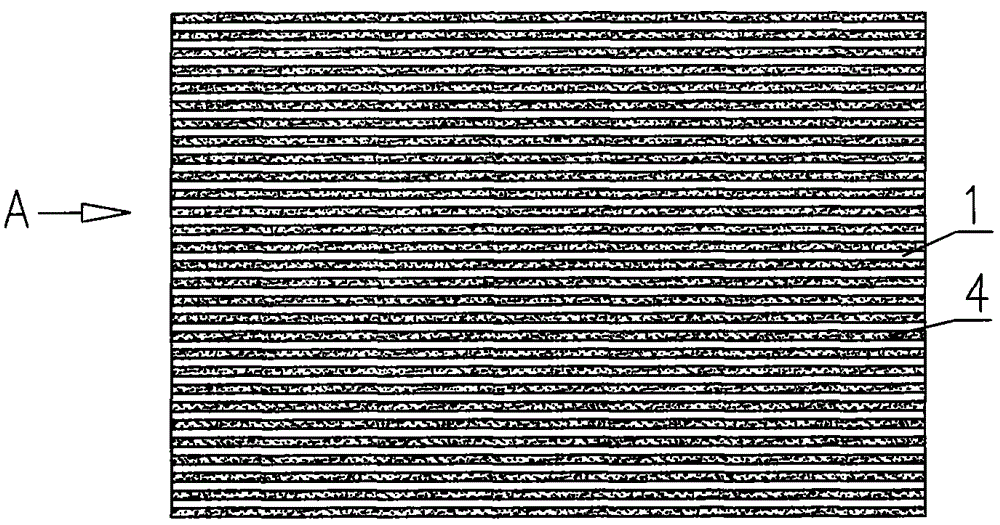

Package for electronic parts, lid thereof, material for the lid and method for producing the lid material

InactiveUS6921970B2Improve workabilityWell formedSemiconductor/solid-state device detailsSolid-state devicesBond propertiesAlloy

A lid material (1) according to the present invention comprises: a base layer (2) composed of a low thermal expansion metal; an intermediate metal layer (3) provided on one surface of the base layer (2) and composed of a low proof stress metal having a proof stress of not greater than 110 N / mm2; and a brazing material layer (4) provided on the intermediate metal layer (3) and composed of a silver brazing alloy mainly comprising silver. The intermediate metal layer (3) and the brazing material layer (4) are press- and diffusion-bonded to each other, and the brazing material layer (4) has a blistered area ratio of not greater than 0.5% as observed on an outer surface of the brazing material layer. The low proof stress metal is preferably oxygen-free copper. A lid produced from the lid material (1) exhibits an excellent bonding property when the lid is brazed to a case mainly composed of a ceramic material for an electronic component package. Further, the lid suppresses the breakage of the case, and ensures excellent brazing workability.

Owner:DAISHINKU CORP +1

Method for adhering face brick of building

The invention provides a method for adhering wall bricks with relatively large specification and weight or vitreous bricks with extremely low water absorbing rate, and specifically provides a method for adhering a face brick of a building. The method comprises the steps of fully coating prepared adhering materials on a wall base layer (1); pressing the adhering materials on the rear surface of the face brick (2) into furrow shape, wherein each adhering material in the furrow shape is vertical to the ground; transversely combing the adhering materials on the wall base layer through a saw-tooth render to form an adhering material layer (4) of a strip-shaped structure through the adhering materials on the surface of the wall base layer; adhering and pressing the face brick of which the rear surface is provided with the furrow-shaped adhering material on the wall bas layer fully adhered with adhering material, wherein a transverse strip-shaped structural adhering material layer (4) and a vertical similar furrow shaped adhering material layer (3A) are arranged between the wall base layer (1) and the face brick (2). The method has the advantages that the adhering strength is improved, and the construction is convenient.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com