Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Fall in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

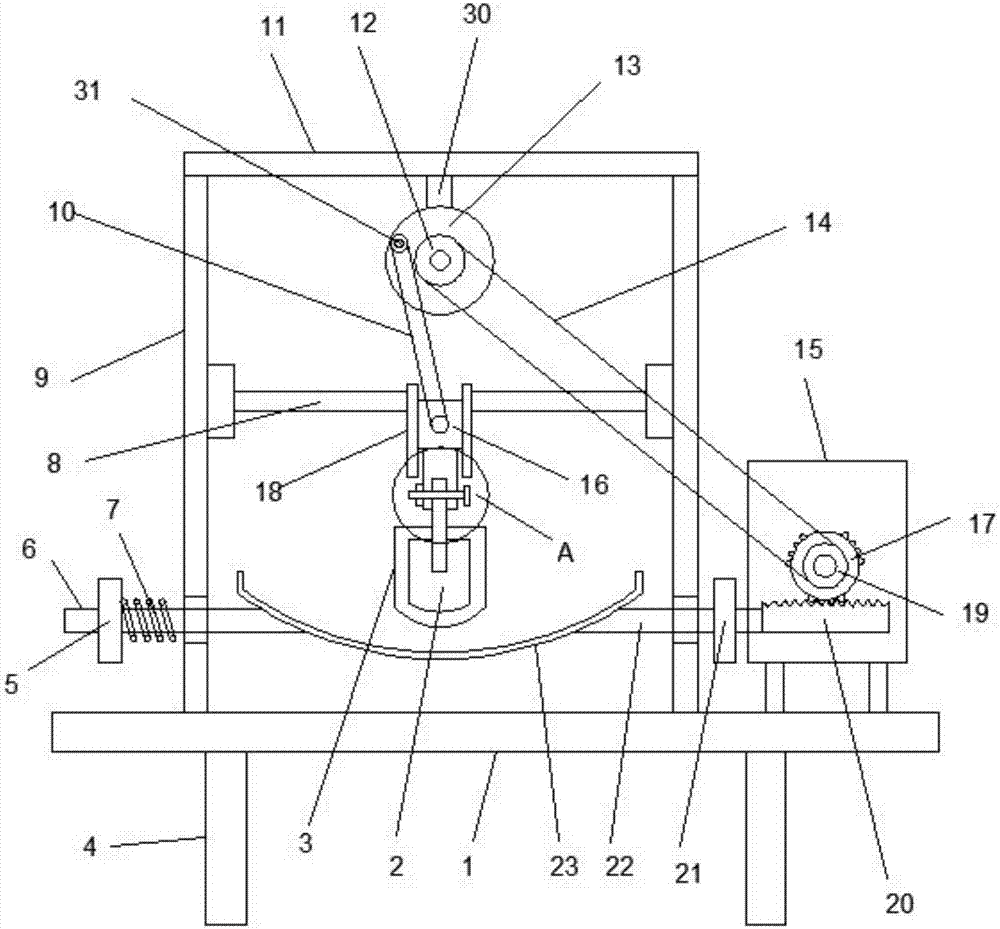

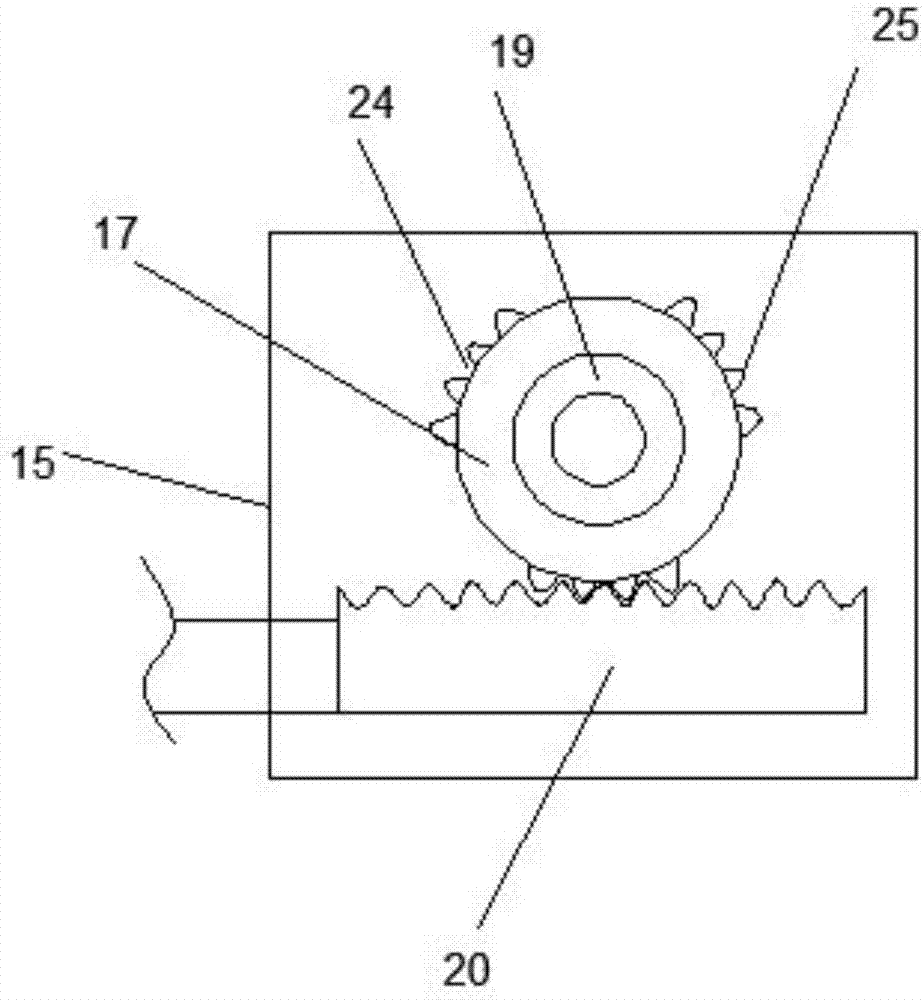

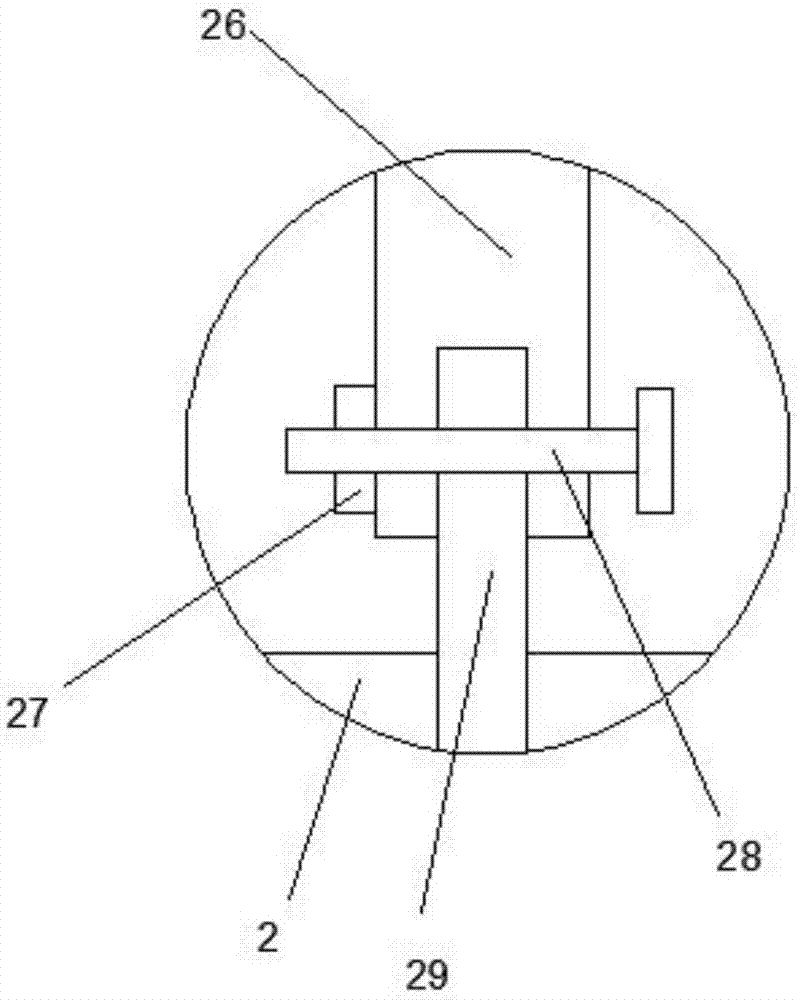

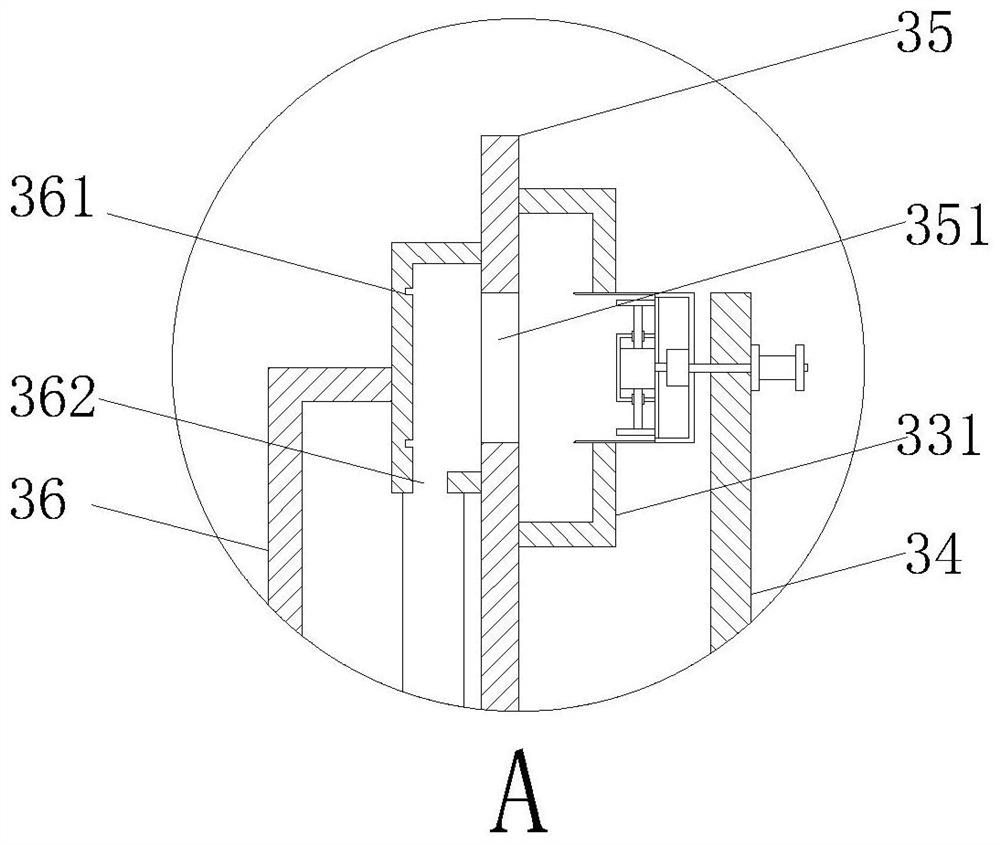

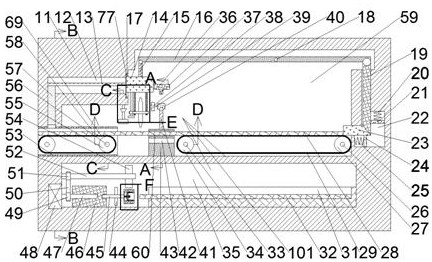

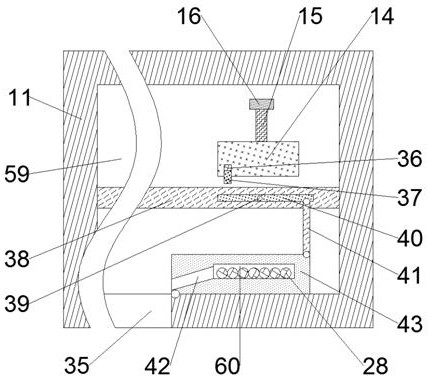

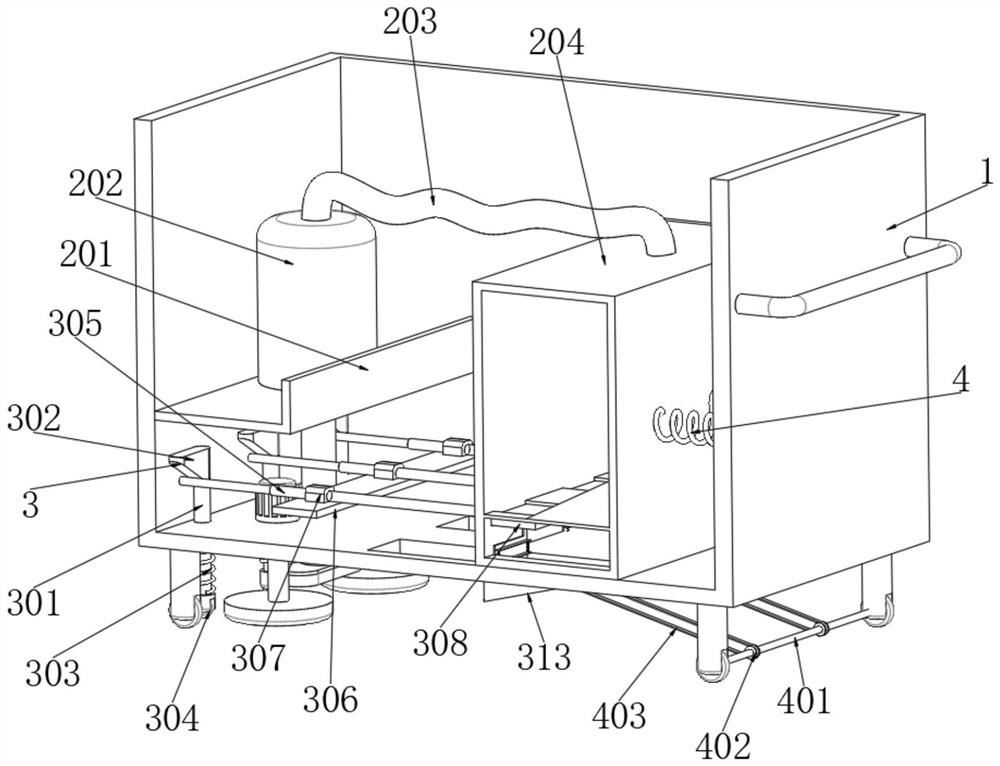

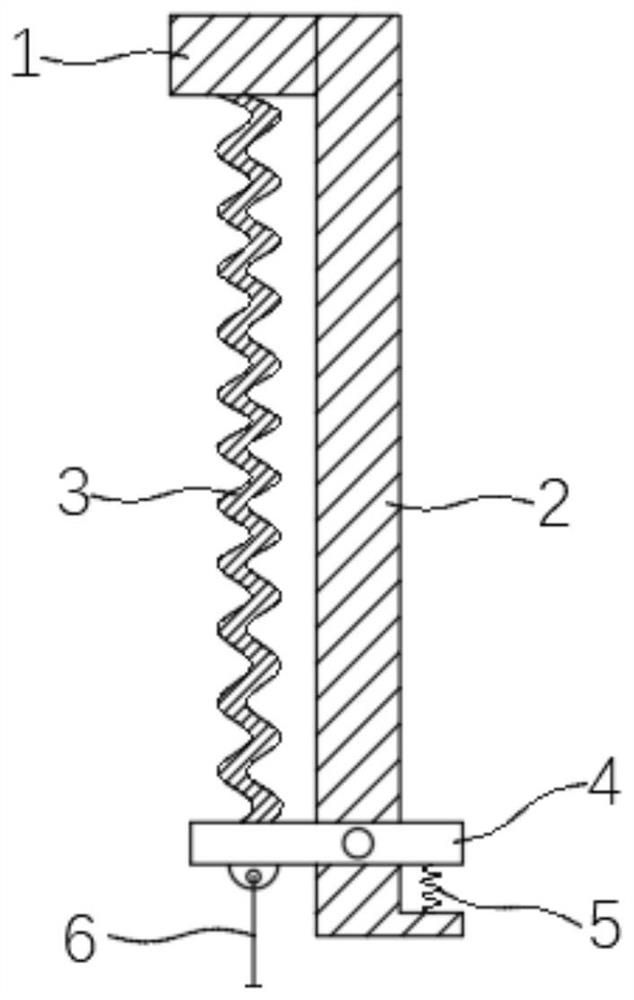

Quick medicine mashing device for Chinese pharmaceutical manufacturing

InactiveCN107008526AImprove the efficiency of pounding medicineImprove the quality of pounding medicineGrain treatmentsGear wheelReciprocating motion

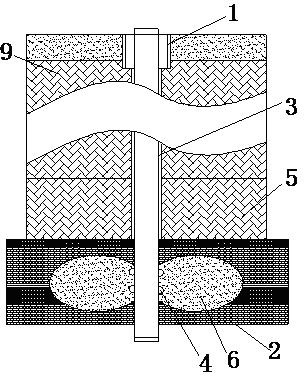

The invention discloses a rapid pounding device for traditional Chinese medicine, which comprises a support base and a drive box. Support columns are connected to both sides of the upper end of the support base. The upper end of the support column is connected to a top plate. The middle part is connected with a rotating wheel, and the front end of the middle part of the rotating wheel is connected with a connecting rod. The shaft position is connected with a driven pulley, the driven pulley is connected with a driving belt, the other end of the driving belt is connected with a driving pulley, the rear end of the driving pulley is connected with a rotating gear at the coaxial position, and the lower end of the rotating gear is meshed with a rack and a gear. The left end of the bar is connected with a right moving rod, the middle part of the right end of the right moving rod is connected with a right limit block, and the left end of the right moving rod is connected with a pounding medicine groove. The present invention realizes the up and down reciprocating motion of the tamping hammer and the left and right reciprocating motion of the ramming trough, greatly improving the ramming quality and ramming efficiency.

Owner:六安市我罗生工业设计有限公司

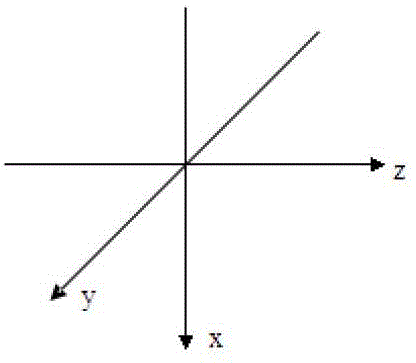

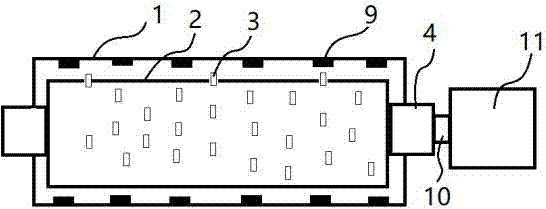

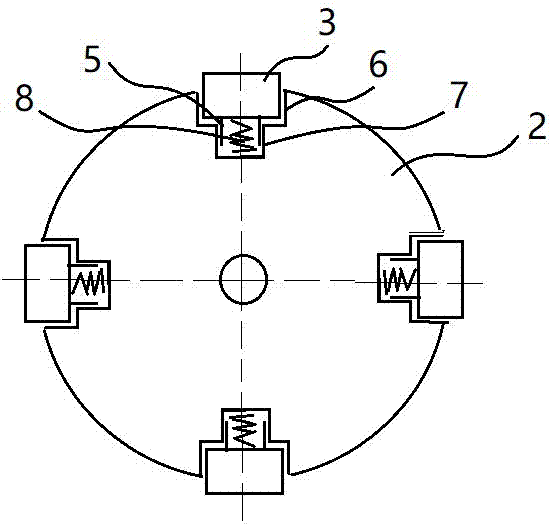

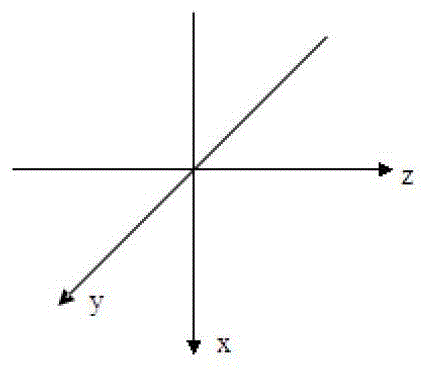

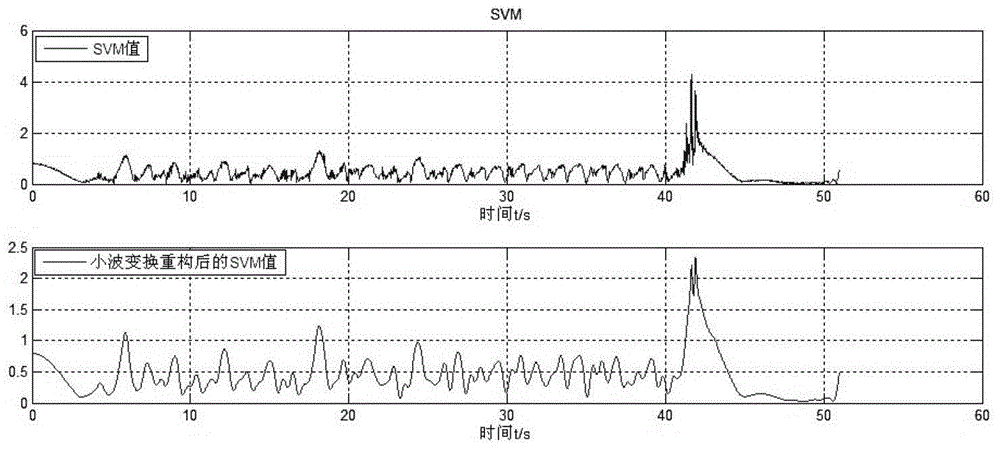

Tumble detection method for human body based on three-axis acceleration sensor

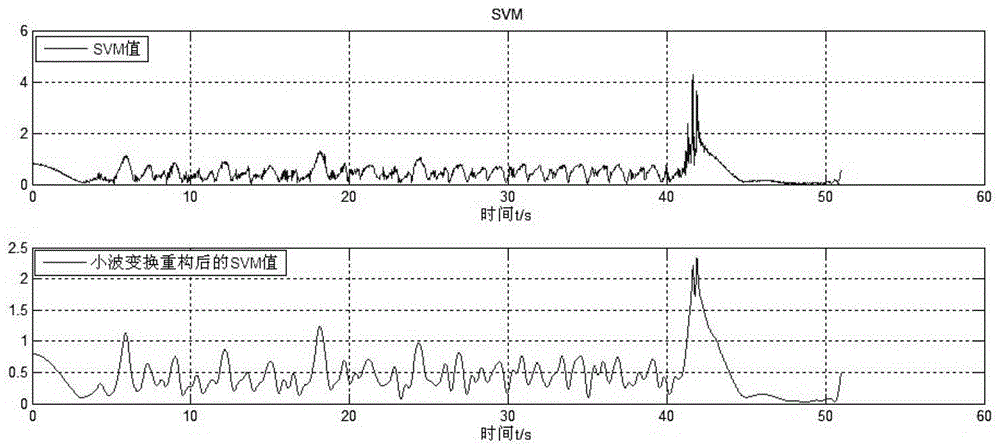

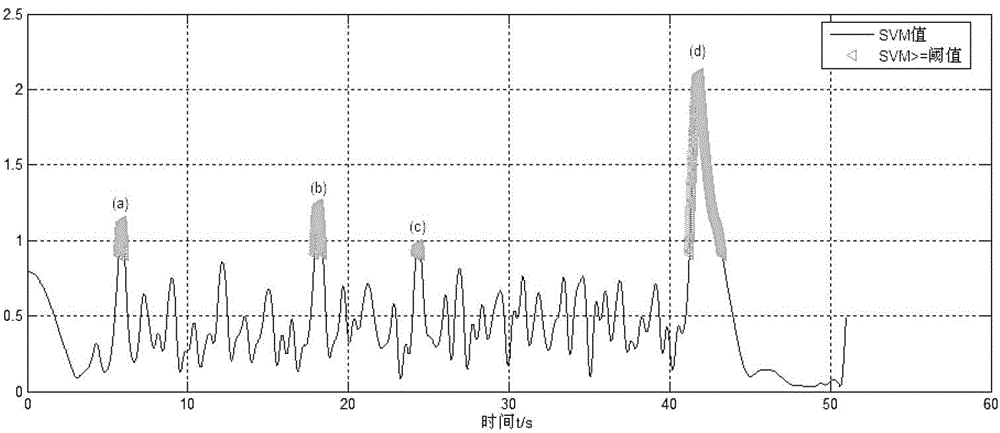

The invention discloses a tumble detection method for a human body based on a three-axis acceleration sensor, which acquires human body three-dimensional acceleration signals through the three-axis acceleration sensor. The method adopts the three-axis acceleration sensor to acquire the acceleration signals of the human body in three directions, adopts two characteristic quantities of SVM and SMA to detect the tumble of the human body. The method comprises the following particular steps: 1) acquiring acceleration data of the human body; 2) performing data preprocessing; 3) calculating SVM value; 4) performing SVM wavelet analysis; 5) detecting SVM detection, if the SVMs of a plurality of consecutively acquired sample points are larger than or equal to the threshold value th1, confirming the tumble of the human body initially, and entering step 6), otherwise, continuing step 5); 6) calculating SMA value, if the SMA is larger than or equal to the threshold value th2, entering step 7), otherwise, determining as suspicious tumble, returning to step 5); 7) if the SMAs of a plurality of consecutively acquired sample points is larger than or equal to the threshold value th2, confirming the occurrence of tumble finally and alarming, otherwise, determining as suspicious tumble, and returning to step 5).

Owner:SHANDONG NORMAL UNIV

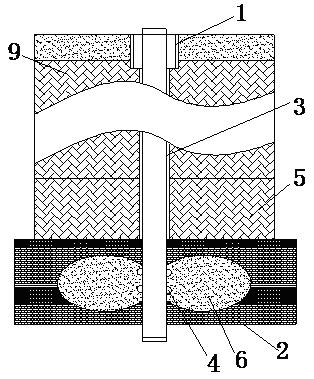

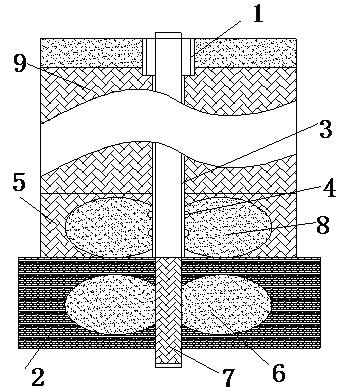

Method for preventing rock burst by adopting high-pressure fracturing

ActiveCN102536240AAvoid destructionRemove the threat of exploitationUnderground miningSurface miningHigh pressureRock burst

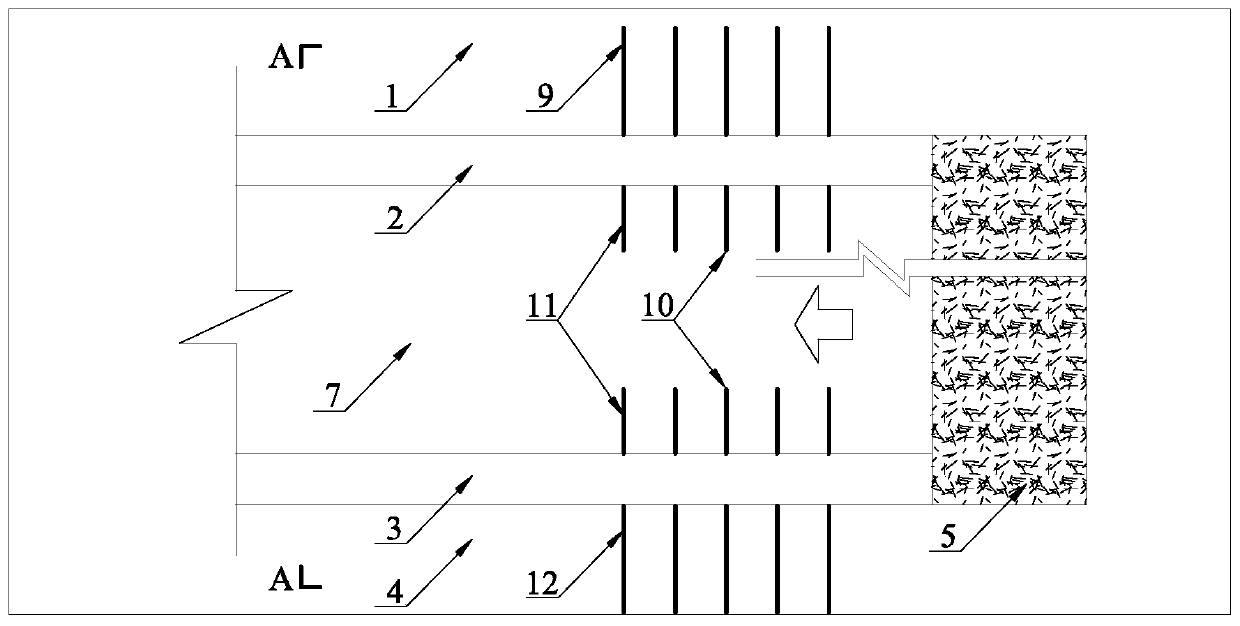

The invention belongs to the coal mining field, in particular to a method for preventing rock burst by adopting high-pressure fracturing, which adopts a high-pressure fracturing method to enable a coal seam roof to be fractured to realize pressure relief in a balanced manner and prevent rock burst. A drill hole, a sleeve and a jet orifice are directly distributed from the ground to a destination layer in a designed construction area, water is injected by high pressure, so that the coal seam roof generates a great amount of fractures to realize pressure relief in the balanced manner, and the fracture slots are communicated by fracturing, the original form of rocks is destroyed, and an original stress field is changed and destroyed, an overlying rock is subjected to caving timely along with the progress of a working surface during backstopping, a large-area hanging arch is no longer formed, the damage to a digging space due to caving caused by the large-area hanging arch can be effectively prevented, and threat of rock burst to mining is eliminated.

Owner:河南省煤层气开发利用有限公司

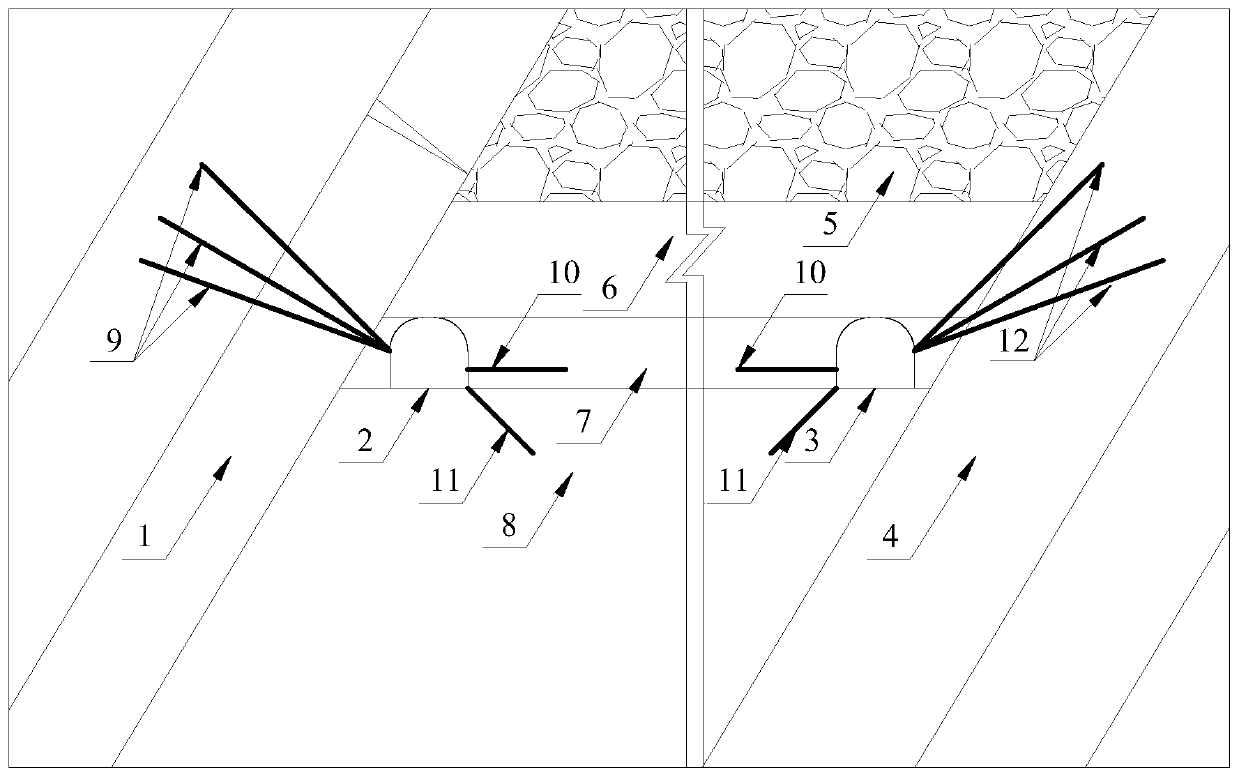

Method for preventing and treating impact mine pressure through high-dipping super-high-seam mining roadway combined pressure relief

InactiveCN110067558AReduce stress concentrationEliminate strong vibration disturbanceMining devicesDisloding machinesStress concentrationEngineering

The invention discloses a method for preventing and treating impact mine pressure through high-dipping super-high-seam mining roadway combined pressure relief. By implementing blasting pressure reliefon a roadway side and bottom corners, the stress concentration degree of a coal body around a roadway is decreased; and by implementing deep-hole blasting pre-cracking on a roof and floor rock stratum, a roof and floor can be collapsed in time along with working face coal caving, thus large-area roof and floor rock stratum suspension is prevented from being formed, the stress concentration degreeof roadway surrounding rock is decreased, meanwhile, strong vibration disturbance generated by sudden breaking of the roof and floor rock stratum is eliminated, and the risk that vibration induces the high-stress coal body around the roadway to generate the impact mine pressure dynamic disaster is reduced.

Owner:CHINA UNIV OF MINING & TECH +2

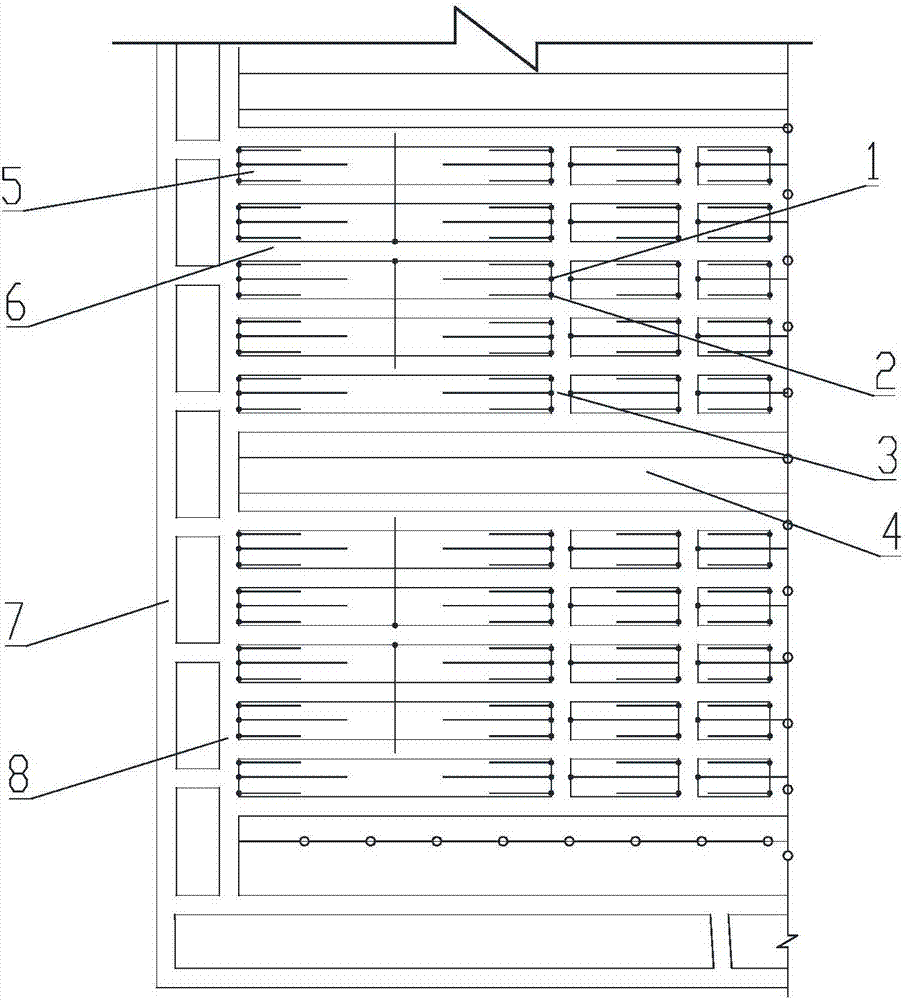

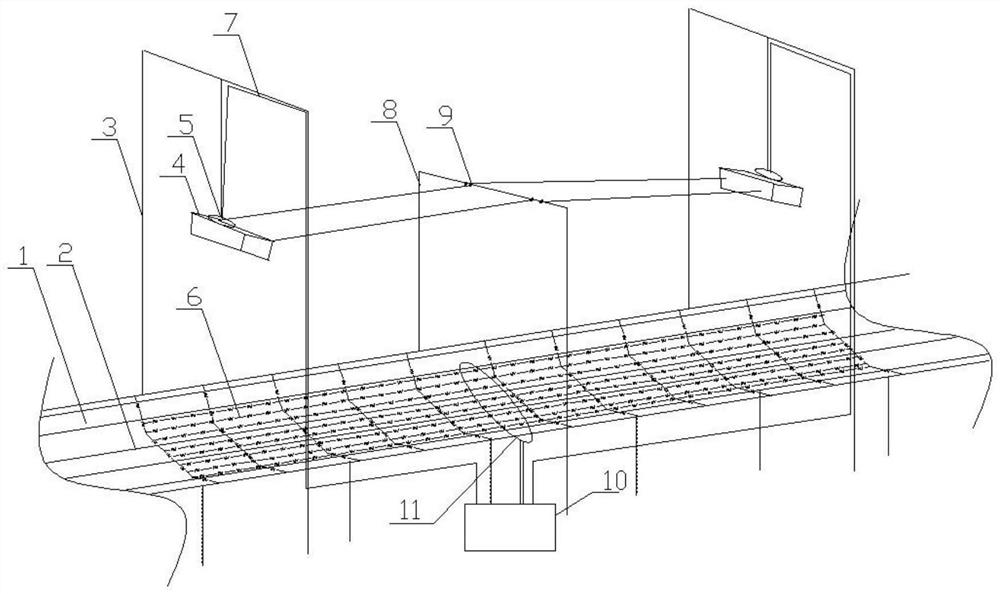

Wangeviry stope face roof hydraulic fracturing weakening method and device

InactiveCN107152279ADoes not affect normal recoveryFall in timeUnderground miningSurface miningHydraulic fracturingCoal pillar

The invention relates to the field of coal mining, and discloses a Wangeviry stope face roof hydraulic fracturing weakening method. The method comprises the following steps of S1, determining the structure parameters of a roof rock layer and a coal pillar of a stope face; S2, calculating the basic parameter of a hydraulic fracturing drill hole according to the structure parameters of the roof rock layer and the coal pillar; S3, according to the calculation result, drilling a horizontal fracturing drill hole in an inclined direction on the roof rock layer above the coal pillar from a connected roadway or a haulage drift or a section branch roadway; S4, performing hydraulic fracturing weakening treatment in the preset position on the hydraulic fracturing drill hole. The method provided by the invention has the advantages that the in-time safe caving of the roof rock layer in the stope process can be ensured; vicious accidents such as work face equipment damage and casualties due to hurricane and strong impact generated by one-step caving caused by the large-area suspended roof in a goaf can be avoided. The invention also discloses a Wangeviry stope face roof hydraulic fracturing weakening device.

Owner:TIANDI SCI & TECH CO LTD

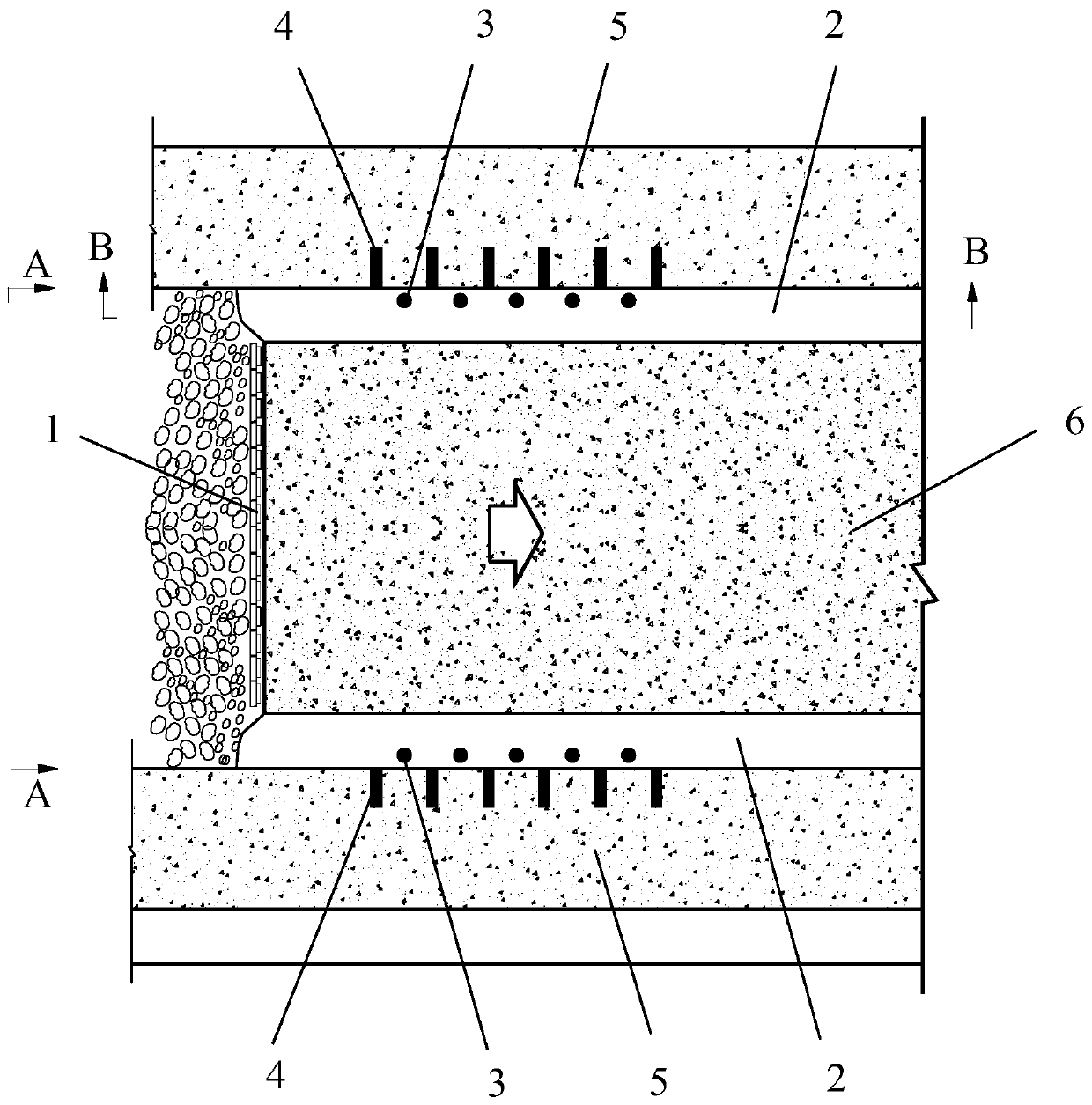

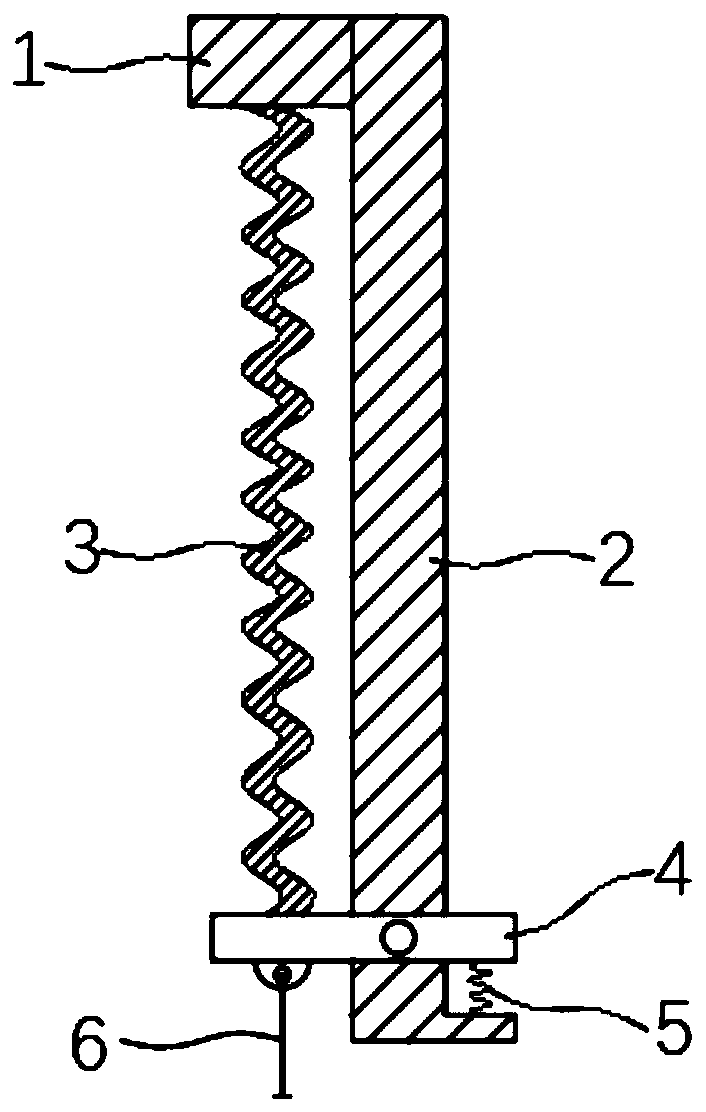

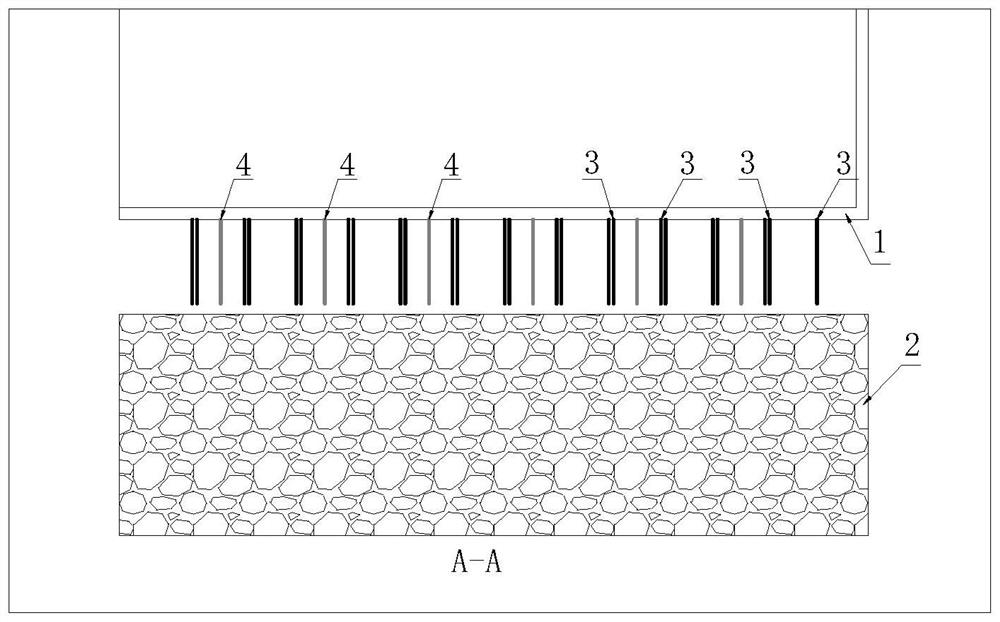

Surrounding rock support method adopting tensioning type pre-tightening anchor rod

InactiveCN104343460AQuick installationSimple manufacturing processAnchoring boltsSteel barEngineering

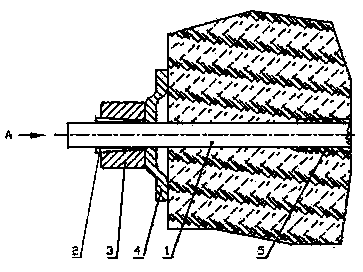

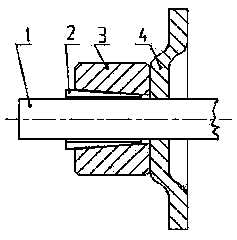

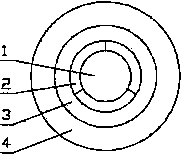

The invention discloses a surrounding rock support method adopting a tensioning type pre-tightening anchor rod. The method comprises the steps as follows: a tensioning machine is adopted to tension the anchor rod (1) and apply pre-tightening force to the anchor rod (1), and the anchor rod is locked by anchor rod locks such as an anchor rod support plate (4), an anchor ring (3) and a clamping piece (2). The method is applicable to the support way of reinforcing the surrounding rock of a roadway by mounting of various specifications of anchor rods with pre-tightening force, the used anchor rod is directly cut out from a reinforcing steel bar according to a required length, and the processing and manufacturing process of the anchor rod is simple; after the anchor rod stirs an anchoring agent (5), an anchor rod tray and the anchor rod locks can be directly pushed to the surrounding rock surface along the anchor rod, an anchor drilling machine can be withdrawn after the anchoring agent is solidified, and rapid mounting is realized while a top plate is protected in time; the conditions of insufficient anchor rod torque force due to human factors and torsion failure of the anchor rod due to overlarge torque force can be avoided, and the labor intensity of a construction worker can be reduced simultaneously; and besides, the pre-tightening force can be recovered by tensioning the faulty anchor rod again, the anchor rod cost can be reduced, and the anchor rod locks can be recovered and recycled.

Owner:XUZHOU MINING BUSINESS GROUP

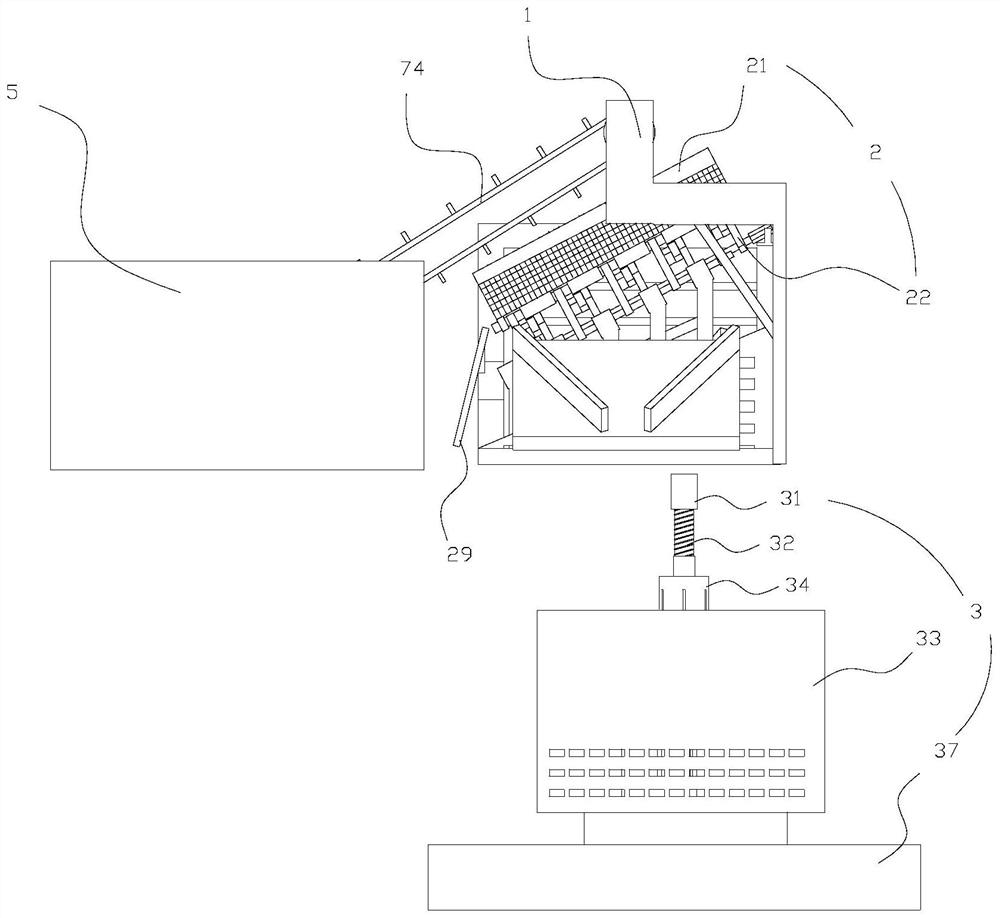

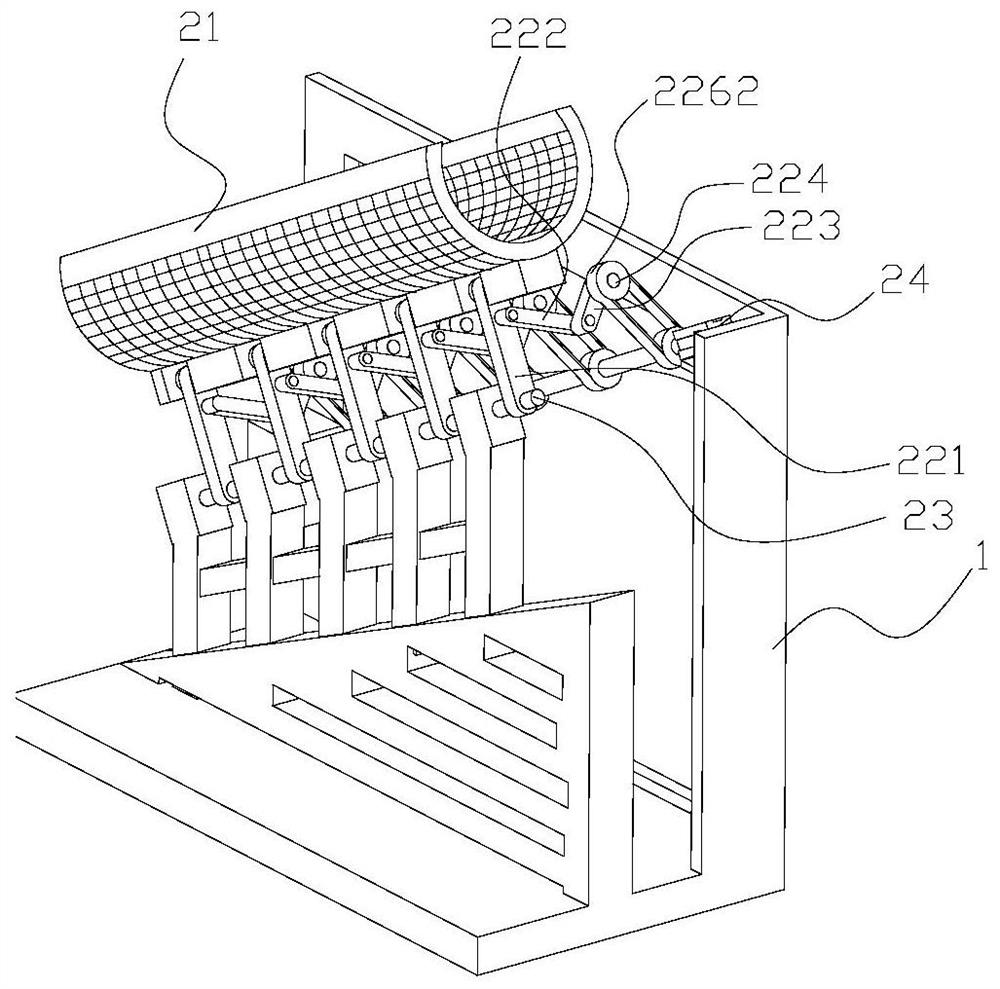

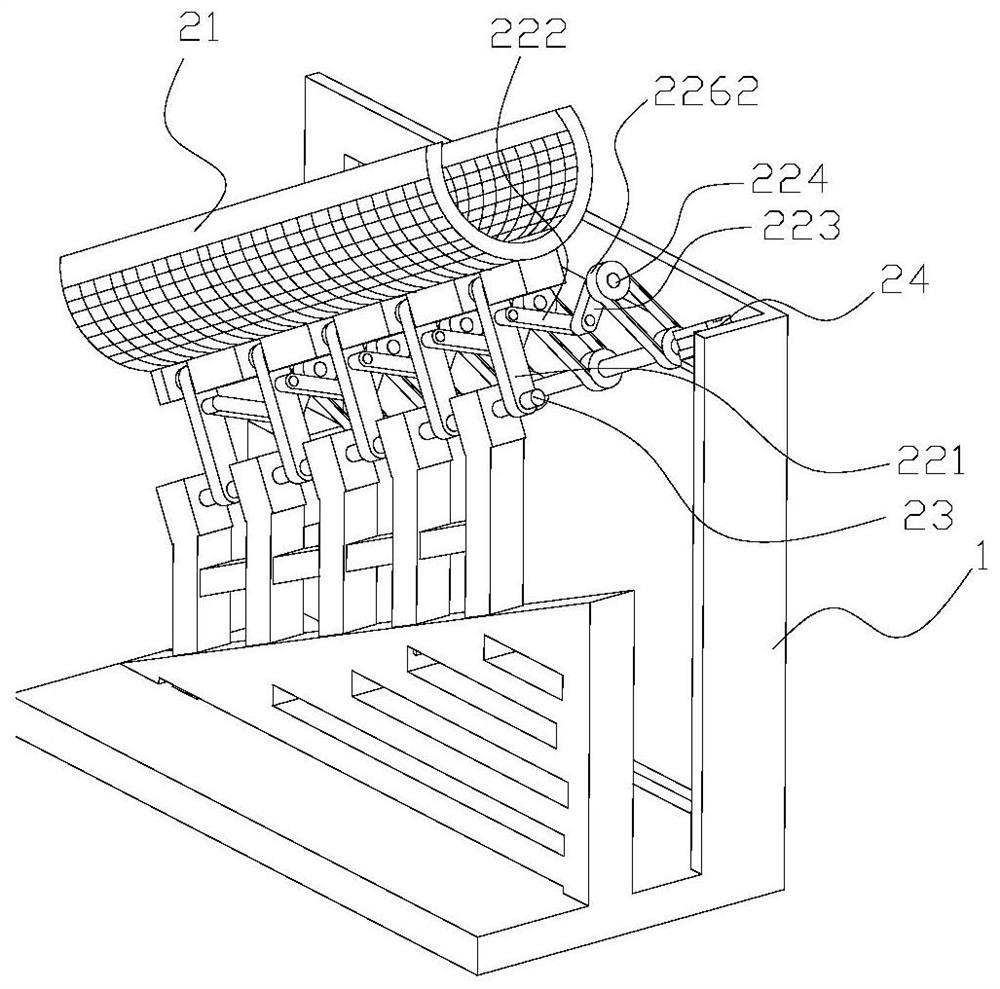

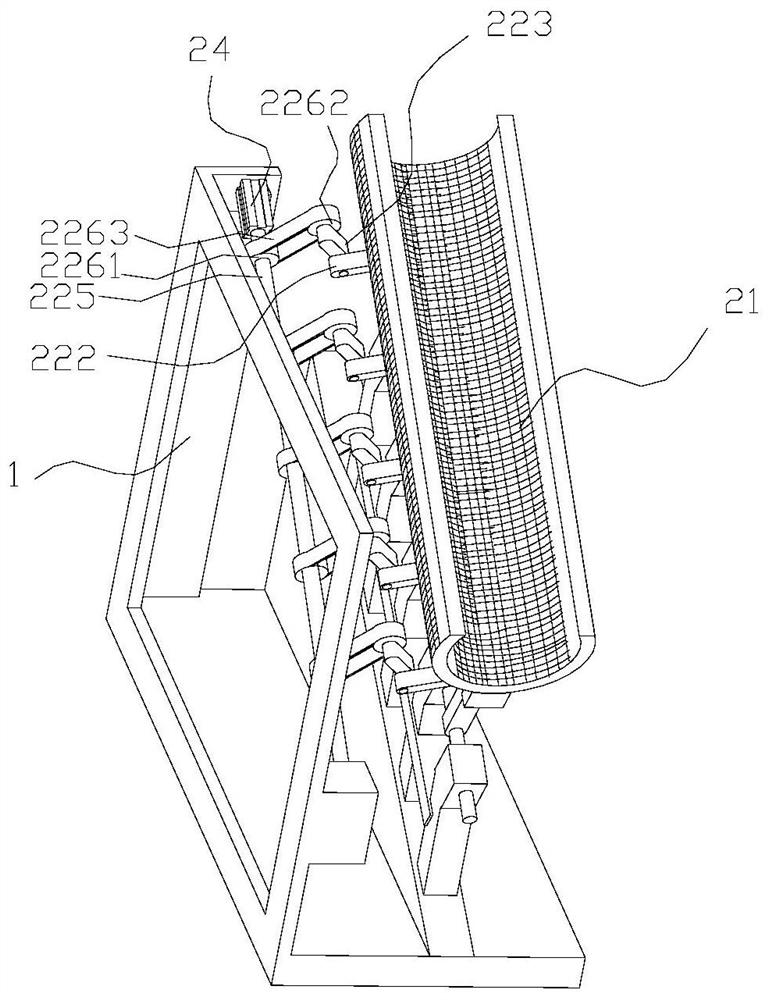

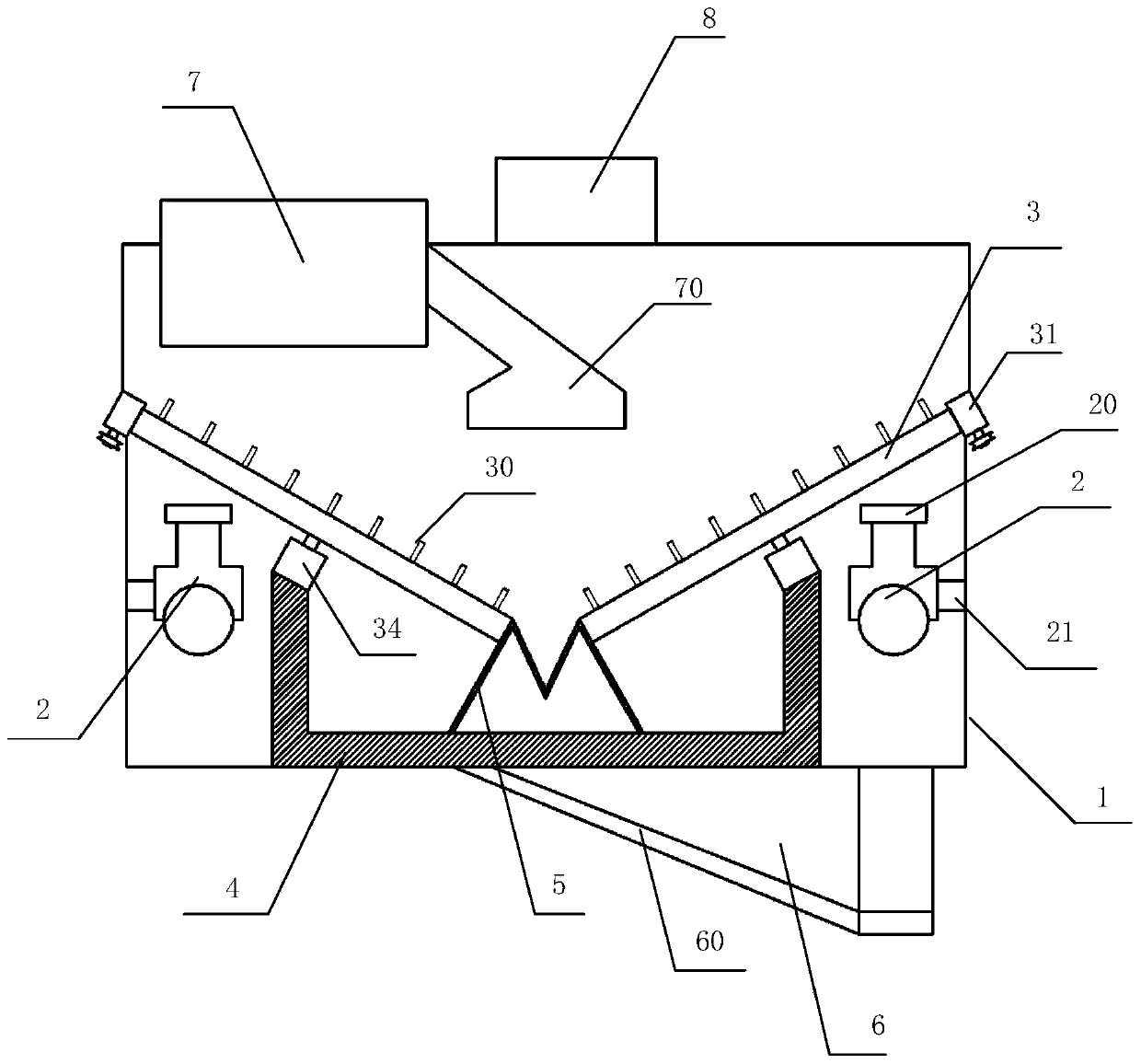

Multi-stage screening mechanism and concrete gravel screening device

The invention discloses a multi-stage screening mechanism for screening in a spatial position sequence. A primary screening device and a secondary screening device are sequentially arranged from top to bottom, a first driving motor is used for driving a swing mechanism to swing, and then an arc screen is driven to swing; materials screened by the arc screen can fall into the secondary screening device; an output shaft of a second driving motor is connected with the top of a connecting rod, and the bottom of the connecting rod extends downwards; a sleeve is arranged on the periphery of the connecting rod, and a gap exists between the sleeve and the connecting rod; a downward moving pressing piece can drive a movable block to slide downwards so that the other end of a second connecting rod can extend out of a through groove; a secondary screen is connected to the sleeve; the secondary screen comprises a bottom screen and a side screen, and the bottom screen and the side screen define a screen structure with an opening in the top and the periphery and the bottom connected; and the secondary screen can rotate relative to a chassis. The invention further discloses a concrete gravel screening device. The multi-stage screening mechanism and the concrete gravel screening device have the advantage of being high in screening efficiency.

Owner:郑州市金禄市政工程有限公司

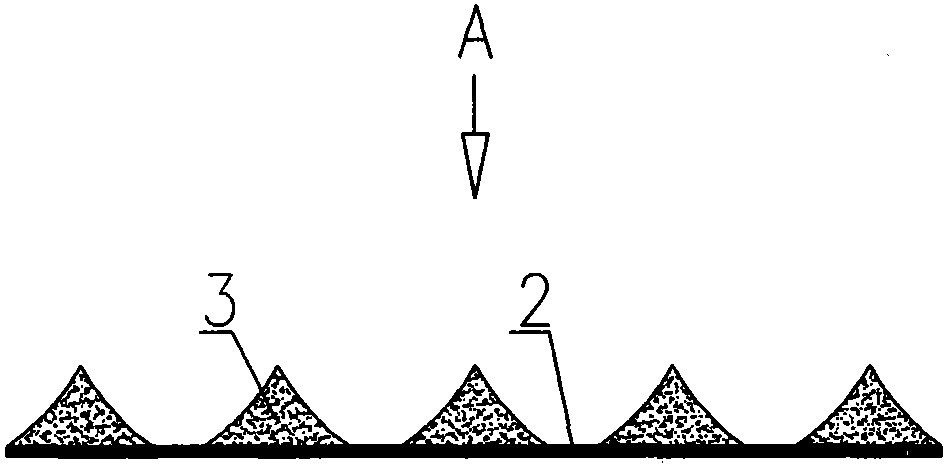

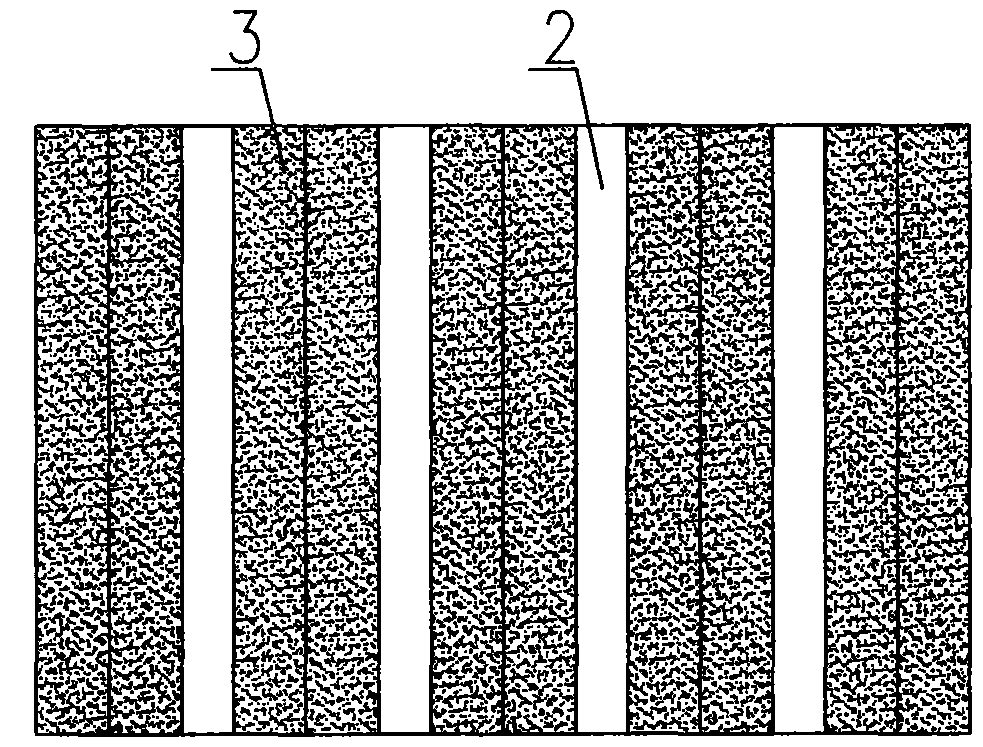

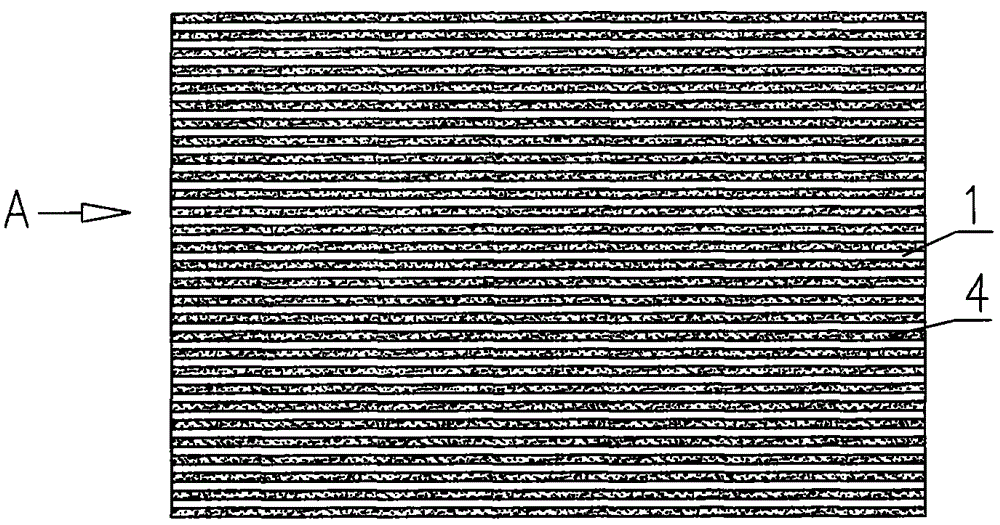

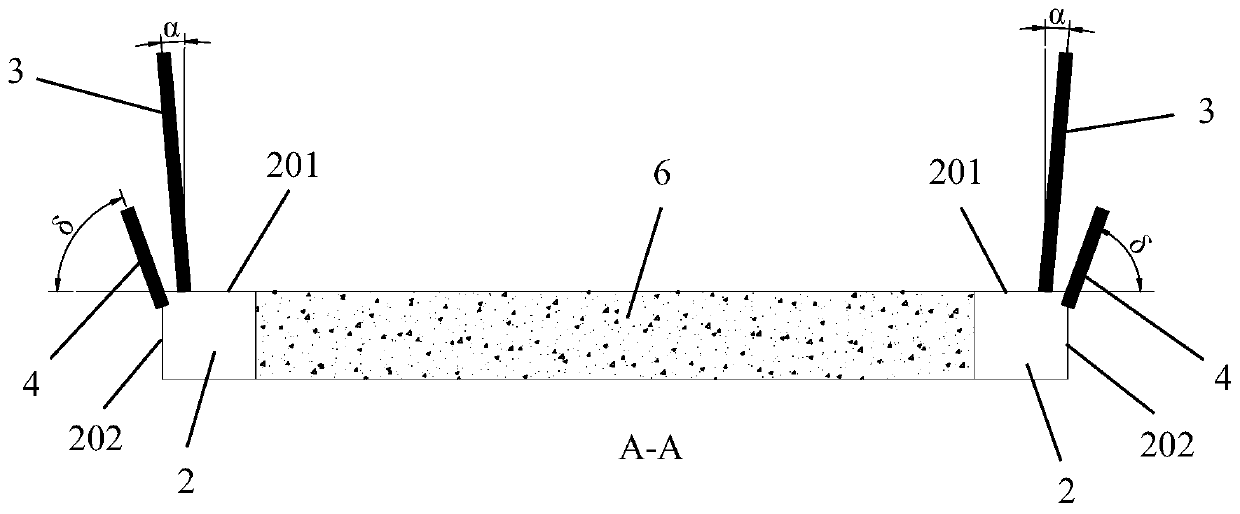

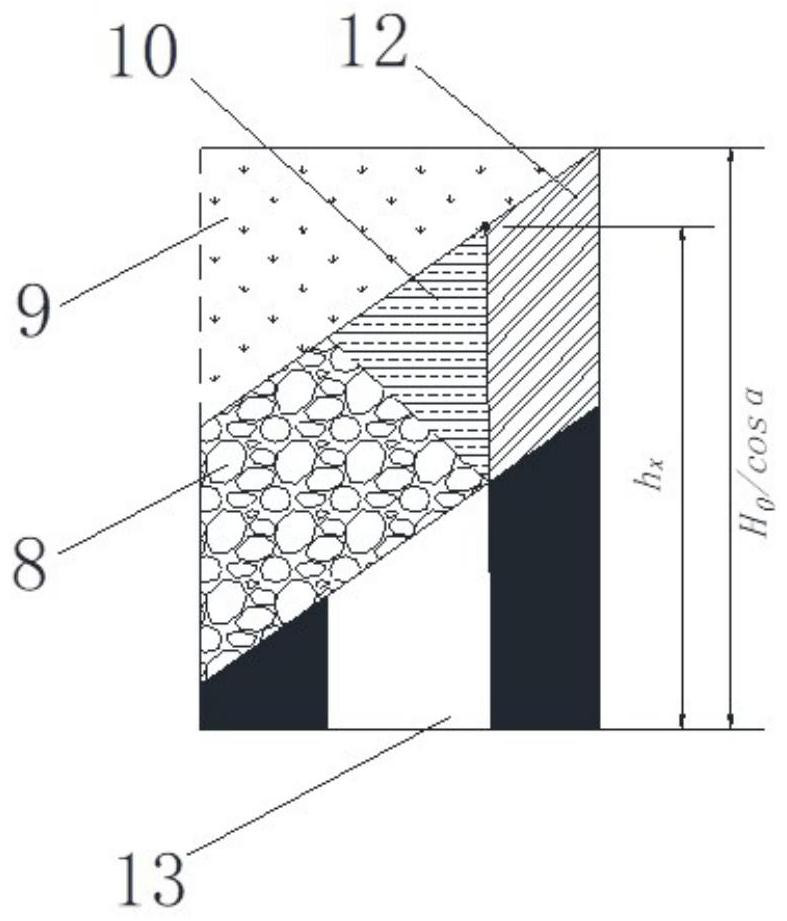

Method for adhering face brick of building

The invention provides a method for adhering wall bricks with relatively large specification and weight or vitreous bricks with extremely low water absorbing rate, and specifically provides a method for adhering a face brick of a building. The method comprises the steps of fully coating prepared adhering materials on a wall base layer (1); pressing the adhering materials on the rear surface of the face brick (2) into furrow shape, wherein each adhering material in the furrow shape is vertical to the ground; transversely combing the adhering materials on the wall base layer through a saw-tooth render to form an adhering material layer (4) of a strip-shaped structure through the adhering materials on the surface of the wall base layer; adhering and pressing the face brick of which the rear surface is provided with the furrow-shaped adhering material on the wall bas layer fully adhered with adhering material, wherein a transverse strip-shaped structural adhering material layer (4) and a vertical similar furrow shaped adhering material layer (3A) are arranged between the wall base layer (1) and the face brick (2). The method has the advantages that the adhering strength is improved, and the construction is convenient.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Multi-stage screening mechanism, concrete sand and gravel screening device

ActiveCN112246622BAvoid technical problems of poor swing stabilityGuaranteed stabilitySievingScreeningElectric machineryDrive motor

Owner:郑州市金禄市政工程有限公司

Surface treatment device for integrated circuit lead frame

ActiveCN114171487AEasy to processAvoid stickingSemiconductor/solid-state device detailsSolid-state devicesStructural engineeringLead frame

The invention relates to the technical field of lead frame surface treatment, in particular to an integrated circuit lead frame surface treatment device which comprises a shell, and spray washing mechanisms used for conducting spray washing on the surface of a lead frame are symmetrically arranged on the two sides of the shell. A conveying mechanism used for clamping a lead frame to move in the shell is arranged on the inner wall of the shell, a guide plate is fixed to the inner wall of the shell, the top face of the guide plate is inclined, a communicating groove is formed in the position, located at the lowest position of the guide plate, of the shell, and a draining box is fixed to the outer wall of the shell and communicates with the interior of the shell through the communicating groove. A filter opening is formed in the top surface of the guide plate close to the draining box, and a first filter screen is fixed in the filter opening; according to the scheme, liquid medicine is sprayed to the lead frame through the spray-washing mechanism, and the liquid medicine is filtered in time, so that impurities are prevented from adhering to the surface of the lead frame, and subsequent processing of the lead frame is facilitated.

Owner:天水华洋电子科技股份有限公司

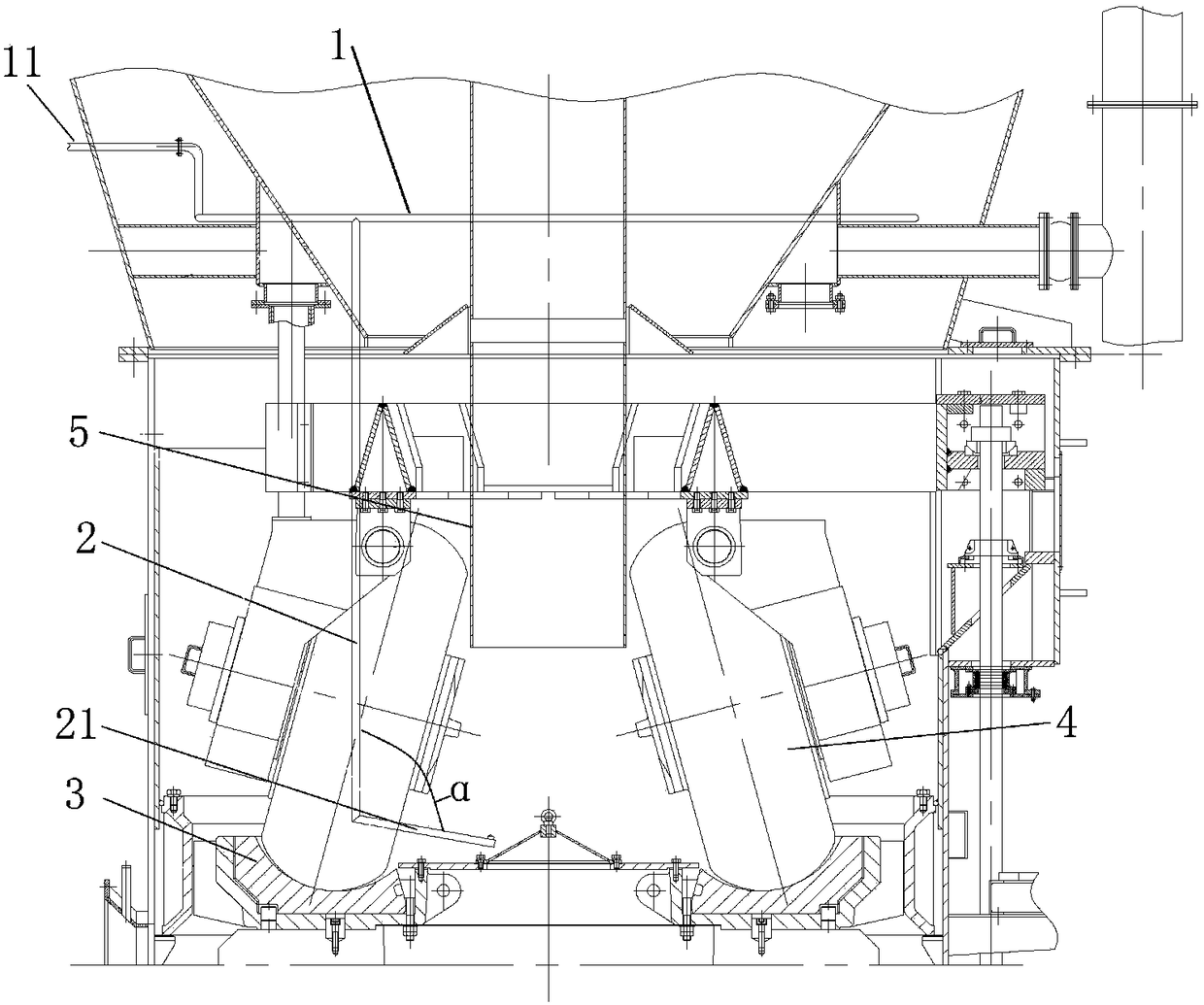

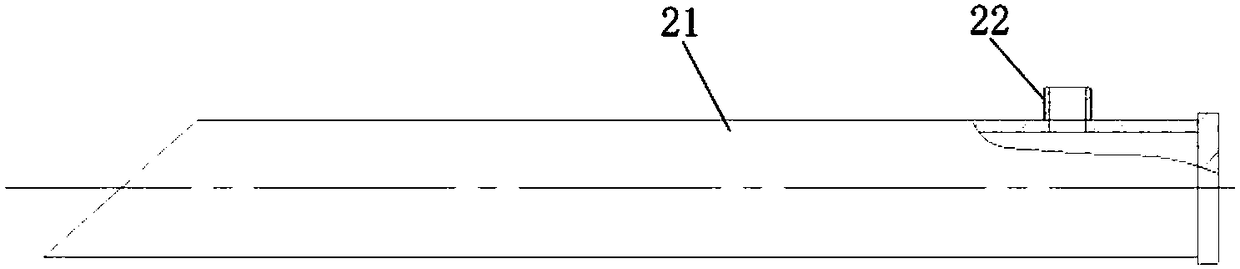

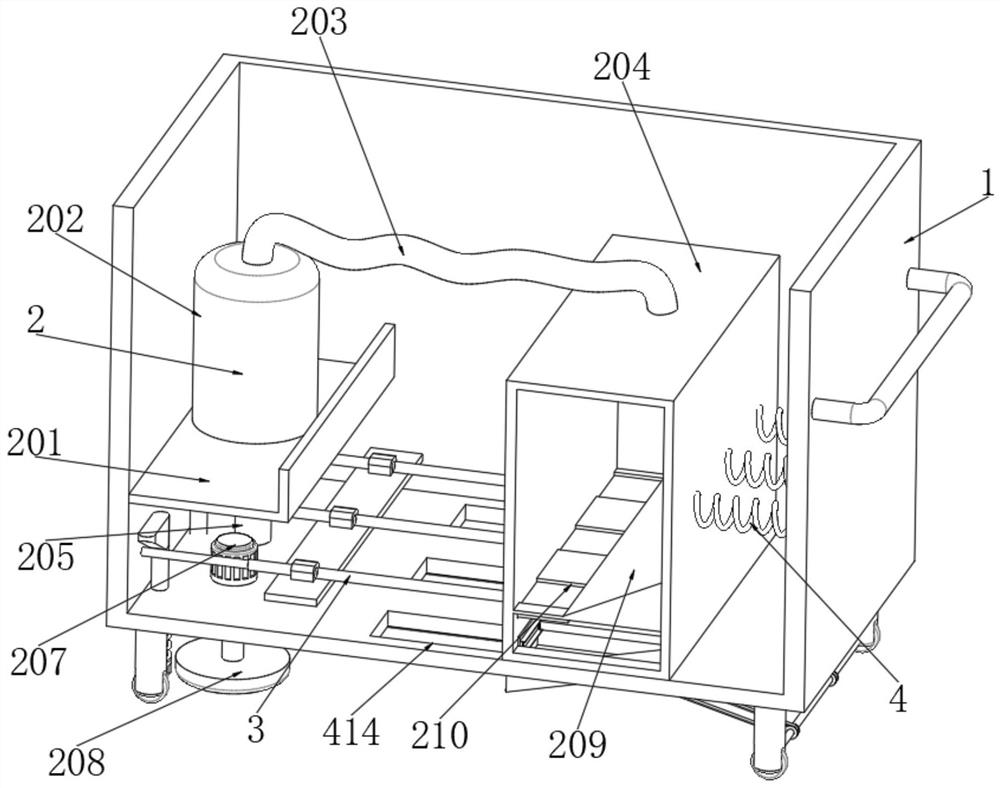

Flow field optimization device capable of improving capacity of coal mill

The invention relates to a flow field optimization device capable of improving the capacity of a coal mill. The flow field optimization device comprises an air inlet pipe and three air guide pipes, wherein an air inlet of the air inlet pipe stretches out of the coal mill and is externally connected with an air source; the coal mill is internally provided with three milling rollers which are uniformly distributed along the peripheral direction of a milling disc at intervals; a coal falling pipe of the coal mill is located above the middle part of the milling disc; the three air guide pipes areuniformly and vertically arranged above an edge of the milling disc at intervals along the peripheral direction respectively, and are located at the outer sides of the two adjacent milling rollers respectively; the upper ends of the air guide pipes are connected and communicated with the air inlet pipe respectively; a blowing air pipe, which obliquely extends toward the center of the milling disc,is arranged at the lower end of each air guide pipe; a plurality of air outlet holes, which are used for blowing air toward the milling disc, are formed in the lower parts of the blowing air pipes along the length direction; a spraying nozzle, which is used for blowing the air upward, is connected and communicated with the upper end of one end, far away from the corresponding air guide pipe, of each blowing air pipe. The flow field optimization device provided by the invention has the advantages that the structure design is simple and reasonable; ground coal powder and raw coal can be effectively separated in time, and the capacity of the coal mill is improved.

Owner:BEIJING SINO POWER RUNZE ENVIRONMENTAL PROTECTIONCO

Double-effect damage prevention roller treatment device

Owner:桐乡佳车科技股份有限公司

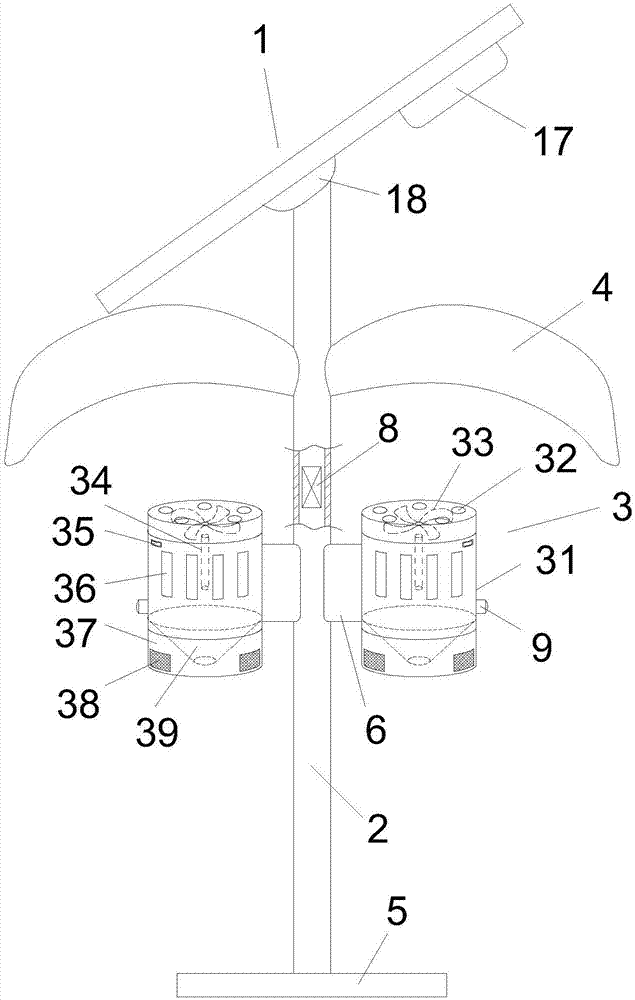

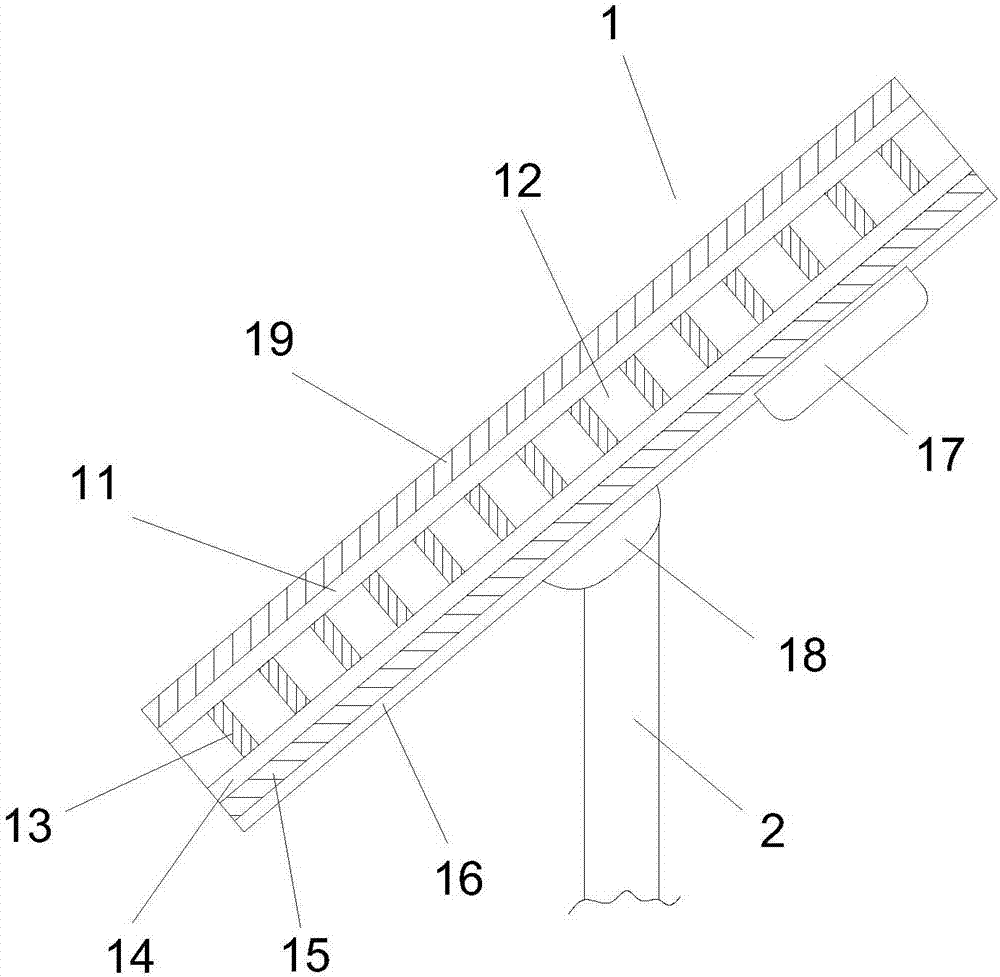

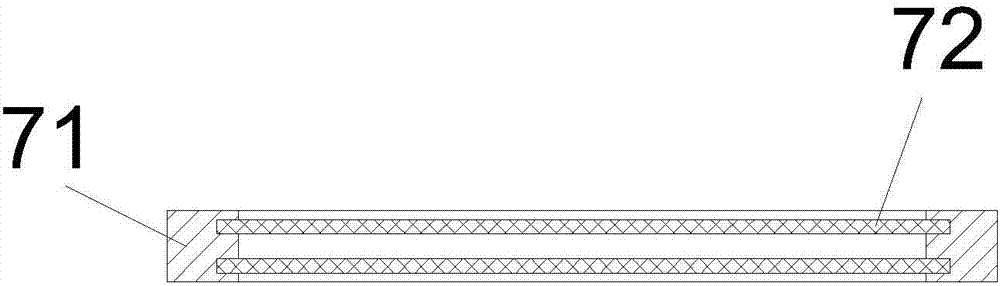

Solar energy high-efficient mosquito killer lamp

InactiveCN107318803AImprove utilization efficiencyEfficient killingInsect catchers and killersElectricityEngineering

The invention discloses a solar energy high-efficient mosquito killer lamp, which comprises a supporting rod, a solar energy panel component and a mosquito killer lamp component; the bottom part of the supporting rod is equipped and fixed with the solar energy panel component; a group of mosquito killer lamp component electrically connected with the solar energy panel component is fixed on the supporting rod through an installing base; the mosquito killer lamp component comprises a mosquito killing shell body; a venting hole is arranged on the top face of the mosquito killing shell body; the lower part of the venting hole is provided with a fan, and an UV lamp tube is arranged beneath the fan; a mosquito entering hole is arranged on the outer wall of the mosquito killing shell body, the lower end of the mosquito killing shell body is provided with a funnel type conical cover; the opening of the upper end of the conical cover is equipped with an electric shock component, and the electric shock component comprises an electric shock frame and two layers of electric shock wire meshes installed in the electric shock frame; two layers of electric shock wire meshes are connected with positive and negative output ends of the solar energy panel component. The solar energy high-efficient mosquito killer lamp is reasonable in structural design, high in solar energy utilization rate, and can completely kill the mosquito and effectively keep out wind and rain; therefore, the safety performance of using is high.

Owner:安徽亮亮电子科技有限公司

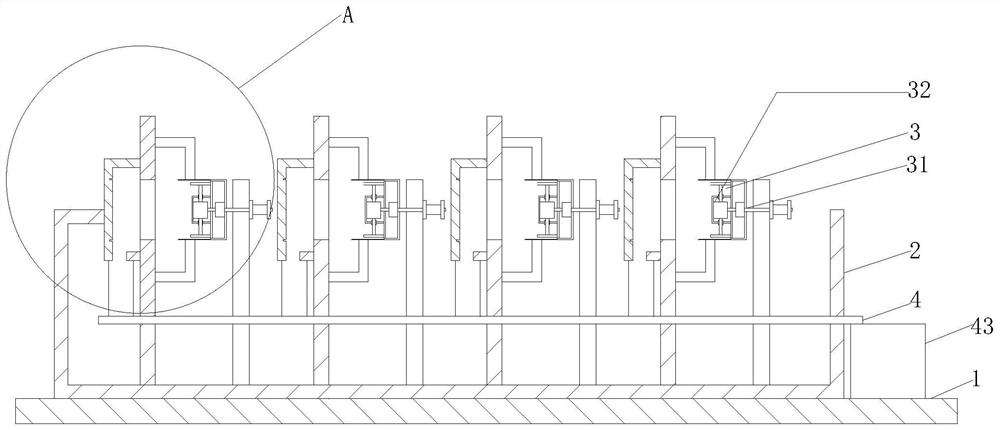

A kind of copper clad laminate die-cutting processing equipment and die-cutting processing technology

ActiveCN112077937BPrecise cuttingIncrease production capacityMetal working apparatusCircuit precursor manufactureMachine buildingIndustrial engineering

The invention provides a copper clad laminate die-cutting processing equipment and die-cutting processing technology, which relate to the field of mechanical manufacturing and processing, including a bottom plate, a support frame, a die-cutting device and a collecting device. production capacity, and at the same time, it can position the copper clad laminate to ensure the accuracy of the die cutting process of the copper clad laminate, avoid the offset of the copper clad laminate, and can automatically repair after the die cutting process, without secondary processing, which improves the product quality. production efficiency.

Owner:乐清市金泰铜业有限公司

Human fall detection method based on triaxial acceleration sensor

The invention discloses a tumble detection method for a human body based on a three-axis acceleration sensor, which acquires human body three-dimensional acceleration signals through the three-axis acceleration sensor. The method adopts the three-axis acceleration sensor to acquire the acceleration signals of the human body in three directions, adopts two characteristic quantities of SVM and SMA to detect the tumble of the human body. The method comprises the following particular steps: 1) acquiring acceleration data of the human body; 2) performing data preprocessing; 3) calculating SVM value; 4) performing SVM wavelet analysis; 5) detecting SVM detection, if the SVMs of a plurality of consecutively acquired sample points are larger than or equal to the threshold value th1, confirming the tumble of the human body initially, and entering step 6), otherwise, continuing step 5); 6) calculating SMA value, if the SMA is larger than or equal to the threshold value th2, entering step 7), otherwise, determining as suspicious tumble, returning to step 5); 7) if the SMAs of a plurality of consecutively acquired sample points is larger than or equal to the threshold value th2, confirming the occurrence of tumble finally and alarming, otherwise, determining as suspicious tumble, and returning to step 5).

Owner:SHANDONG NORMAL UNIV

Processing method of upper corner hanging arch on mine working face

InactiveCN111173514APreharvest stabilizationReduce areaMining devicesDisloding machinesMining engineeringStructural engineering

The invention relates to the technical field of mine construction, in particular to a processing method of an upper corner hanging arch on a mine working face. The processing method of the upper corner hanging arch on the mine working face comprises the steps that before advanced bearing pressure disturbance formed by working face stoping, two rows of drill holes are correspondingly formed in thepositions, on top plates of stoping roadways, on the two sides of the working face in advance; and high-pressure water is correspondingly injected into each drill hole to perform hydraulic fracturingon top covers, so that cracks are generated and extended on the top covers. According to the processing method of the upper corner hanging arch on the mine working face, the integrity of the top covers above a working face end head coal seam can be damaged, the strength of the top covers is reduced, the purpose of before-mining stability and post-mining timely falling of the upper corner hanging arch of a high gas mine working face is achieved, the upper corner hanging arch area of the stoping working face is obviously reduced, gas accumulation and overrun of the upper corner hanging arch of the working face is effectively prevented, and the safety is high.

Owner:TIANDI SCI & TECH CO LTD

Reinforcing steel bar shearing device capable of shearing efficiently and milling end face

InactiveCN111992643AAvoid millingAvoid cutting failureRevolution surface grinding machinesGrinding drivesGear wheelRebar

The invention discloses a reinforcing steel bar shearing device capable of shearing efficiently and milling an end face. The reinforcing steel bar shearing device comprises a shearing body, and a shearing cavity is formed in the shearing body. The reinforcing steel bar shearing device is mainly applied to shearing of the reinforcing steel bars in the industry, and in the shearing process, throughabutting of an abutting block and the to-be-sheared reinforcing steel bars, a to-be-sheared reinforcing steel bar can be cut by a cutting device through an abutting shearing mechanism, and meanwhile,the to-be-sheared reinforcing steel bar can be compressed through an abutting sliding rod to avoid cutting failure, the to-be-sheared reinforcing steel bar can fall into a containing cavity in time through abutting of an ejector block and an abutting lever after being sheared, and then the shearing work can be carried out in order; and meanwhile, the end face of the to-be-ground-and-milled reinforcing steel bar can be effectively ground and milled through a clamping mechanism, excessive grinding and milling of the to-be-ground-and-milled reinforcing steel bar can be avoided through a limitingclamping block, the to-be-ground-and-milled reinforcing steel bar can be clamped, and the clamping mechanism is meshed with a main transmission gear through movement of an auxiliary transmission gear,thereby rotating the clamping mechanism.

Owner:温州空云如电子科技有限公司

Novel road grinding machine

InactiveCN112746551AImprove cleanlinessEasy to recycleRoad cleaningRoads maintainenceStructural engineeringRoad surface

The invention relates to the technical field of road construction, and particularly relates to a novel road grinding machine which comprises a cart, a grinding mechanism, a filling mechanism and an adjusting mechanism. The inner side wall of the cart is fixedly connected with the grinding mechanism used for grinding a road surface and collecting dust. The filling mechanism used for filling a pavement foundation pit is fixedly connected to the inner side wall, close to the grinding mechanism, of the cart, and an adjusting mechanism used for adjusting the distance between the filling mechanism and front wheels of the cart is slidably connected to the bottom side wall of the cart. Protrusions on the road surface are polished through a polishing wheel, dust generated during polishing is collected through a dust collector, when pits exist in the road surface, a roller drives the filling mechanism to act, residues in a residue storage box can fall into the pits in the road surface, and therefore the pits can be conveniently buried; and through the arrangement of the adjusting mechanism, the residues in a funnel can fall into the pits on the road surface in time, and falling of the residues is avoided.

Owner:刘自保

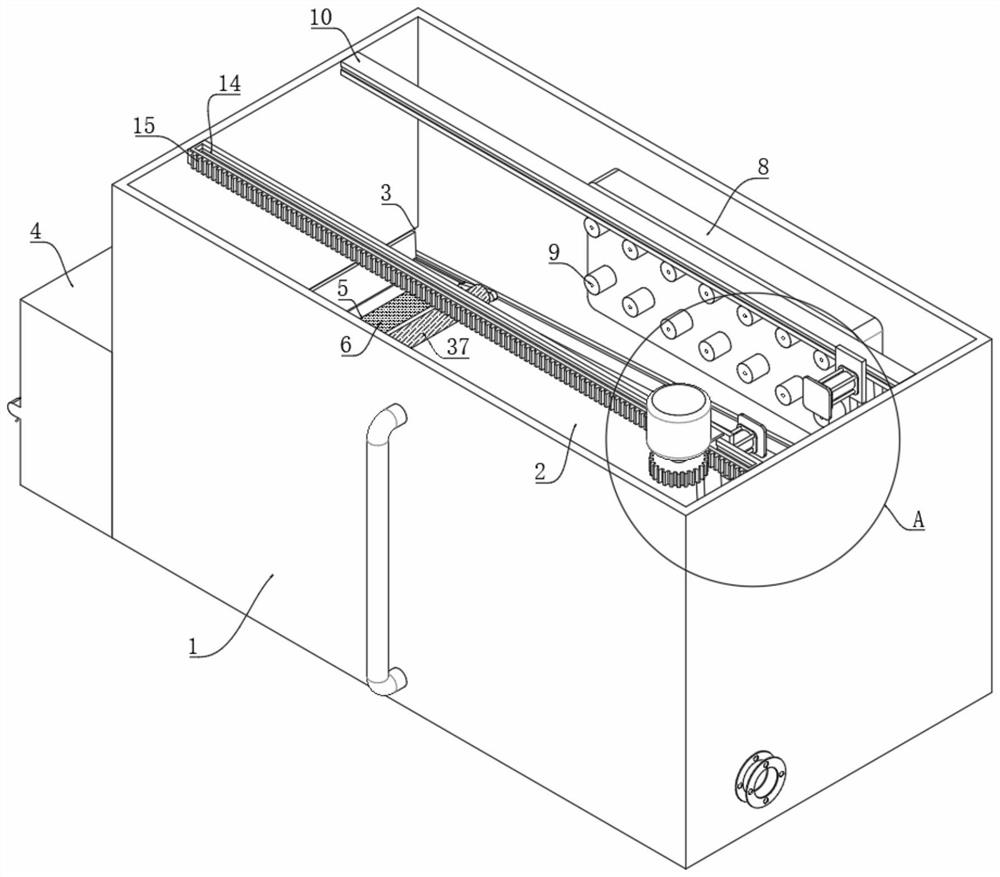

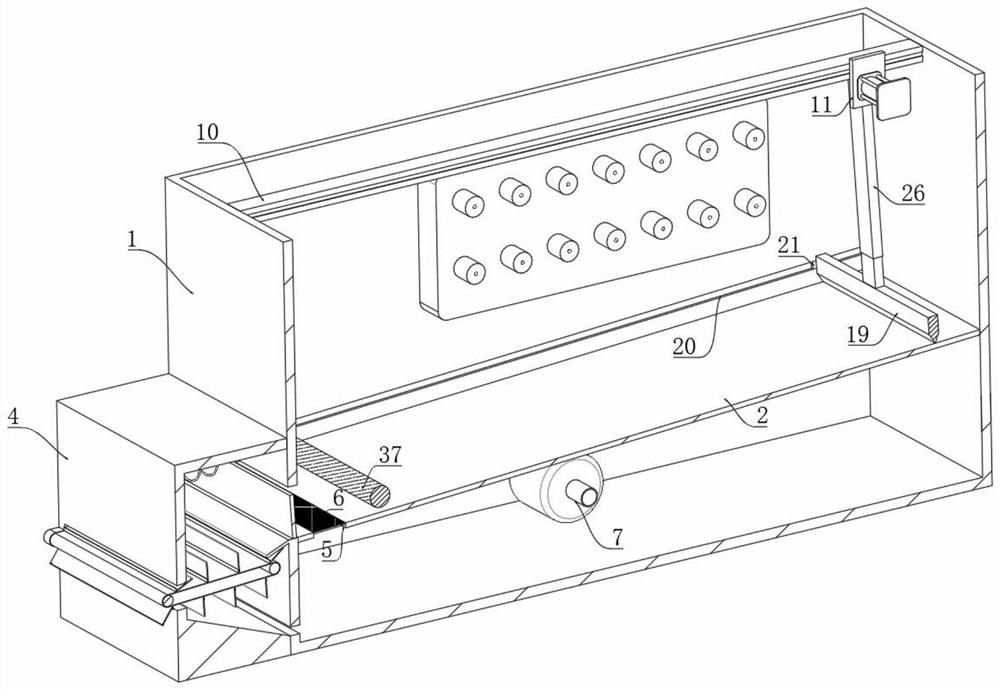

Gravity type roller crushing and separating machine

The invention relates to the technical field of crushing and separating machines, in particular to a gravity type roller crushing and separating machine. The crushing and separating machine is used for solving the problems that in the prior art, when finished products such as alloy balls are crushed, fine materials cannot be discharged in time, so that the product quality and the crushing efficiency are reduced. The crushing and separating machine comprises a right flange, wherein a mesh screen cylinder is mounted on the right flange, the other end of the mesh screen cylinder is connected witha left flange, a crushing mechanism located in the mesh screen cylinder is mounted between the left flange and the right flange, an outer cover assembly covering the mesh screen drum is mounted on asupport frame assembly, and a discharge groove is formed in the lower end of the outer cover assembly. According to the crushing and separating machine, the finished products such as the alloy balls are put into the mesh screen cylinder to be crushed, the crushed fine materials can be timely removed from the gap of the mesh screen cylinder due to the action of gravity and leaked out of the discharge groove, so that the fine materials do not need to be crushed again, and the quality and the crushing efficiency of the product can be improved.

Owner:ANXIN TUORI INFORMATION TECH CO LTD

Heating stove with fast ash falling function

InactiveCN106287825AAvoid wastingAvoid pollutionLighting and heating apparatusStove/ranges for heating waterCombustion chamberEngineering

The invention relates to a heating stove with a fast ash falling function. The heating stove with the fast ash falling function comprises a stove body; an upper stove chamber and a lower combustion chamber which communicate with each other are arranged inside the stove body; a cavity formed by the stove body, the stove chamber and the combustion chamber is a water chamber; a water inlet pipe is connected with the bottom of the stove body, and a water outlet pipe is connected with the upper portion of the stove body; a smoke outlet pipe communicating with the stove chamber is installed in the water outlet pipe; a stove bottom is connected with the bottom of the combustion chamber; the bottom of the combustion chamber is in a funnel shape; an ash outlet device is installed in the stove bottom; and the ash outlet device directly faces an outlet of the funnel type combustion chamber. The heating stove with the fast ash falling function has the advantages that the smoke outlet pipe is further installed in the water outlet pipe, and heat generated by burning fuel is utilized maximally, so that energy waste is avoided; and a lifting rod capable of rising and descending is adopted at the stove bottom, and it is ensured that ash in the combustion chamber falls into the stove bottom in time, so that blocking condition is avoided.

Owner:全爱军

Household environment-friendly bundled straw heating furnace

ActiveCN113154512ASimple structureReasonable designLighting and heating apparatusSpace heating and ventilation detailsParticulatesCombustion chamber

The invention discloses a household environment-friendly bundled straw heating furnace applied to the field of civil heating. The household environment-friendly bundled straw heating furnace comprises a stock bin, a combustion chamber and an ash chamber which are arranged in a furnace body from top to bottom, a feeder is arranged between the stock bin and the combustion chamber, and a fire grate is arranged between the combustion chamber and the ash chamber. A notch formed in the fire grate corresponds to a loosening claw on an ash removal loosening device below the fire grate, the ash removal loosening device is arranged in an ash removal blast chamber, the ash removal blast chamber is connected with an ash chamber below the ash removal blast chamber, and the ash chamber is connected with an ash removal opening. The household environment-friendly bundled straw heating furnace is reasonable in structure, novel in design and good in practicability, layered, slow, stable and sufficient combustion is achieved under the action of the feeder and the ash removal loosening device by taking bundled straw as fuel, the combustion has the characteristics of low nitrogen oxide and low carbon monoxide emission, two times of dust removal are integrated, and the emission of particulate matter in smoke is reduced to be low; and the heating furnace is high in heat efficiency, low in pollutant emission, capable of saving energy, environmentally friendly and worthy of being advocated.

Owner:刘庆超

Filtration device of air vent of green building

InactiveCN107441830AQuality improvementFall in timeGas treatmentDispersed particle filtrationLife qualityPhysical health

The invention discloses a filtration device of an air vent of a green building. The filtration device comprises an air vent, wherein a filtration device part is arranged on the inner side surface of the air vent; a mounting case is arranged on the lower surface of the air vent; a dust outlet is formed in the upper surface in the air vent and communicated with the mounting case; a sliding groove is formed in the side surface of the mounting case; a dust collection box is connected into the sliding groove in a sliding manner; a fixing plate is arranged on the side surface of the dust collection box; a handle is arranged on the side surface of the fixing plate; and antiskid stripes are arranged on the outer side surface of the handle. The filtration device of the air vent of the green building improves a filtration effect, can provide a good air environment indoors, improves life quality, and guarantees physical health of a consumer; impurities such as dust accumulated in the air vent can fall into the dust collection box through the dust outlet and are convenient to collect; the dust collection box slides in the sliding groove formed in the side surface of the mounting case; the dust in the dust collection box can be treated conveniently; and the indoor environment is not influenced.

Owner:ZHONGSHAN NUODUN SCI RES TECH SERVICE CO LTD

Garbage incineration device

The invention provides a garbage incineration device, and belongs to the field of garbage treatment equipment manufacturing. The garbage incineration device comprises a furnace body, wherein the furnace body is a closed cavity, a feed inlet and a smoke outlet are formed in the top of the furnace body, and a slag outlet is formed in the bottom of the furnace body; the furnace body is internally provided with a support frame and combustors, and the top of the support frame is provided with at least one rotatable ceramic combustion plate, the combustors are positioned below the ceramic combustionplate, and the rotation plane of the ceramic combustion plate are inclined to the horizontal plane; and a plurality of stirring rods are arranged on the ceramic combustion plate, each stirring rod isof a tubular structure, and two ends of the tubular structure are used for communicating the two ends of the ceramic combustion plate. According to the garbage incineration device, the ceramic combustion plate is arranged above the combustors, so that the materials on the combustion plate can be fully stirred, the feeding efficiency can be accelerated, the insufficiently burned ashes can be combusted again, and the sufficiency of combustion is improved.

Owner:NANNING UNIV

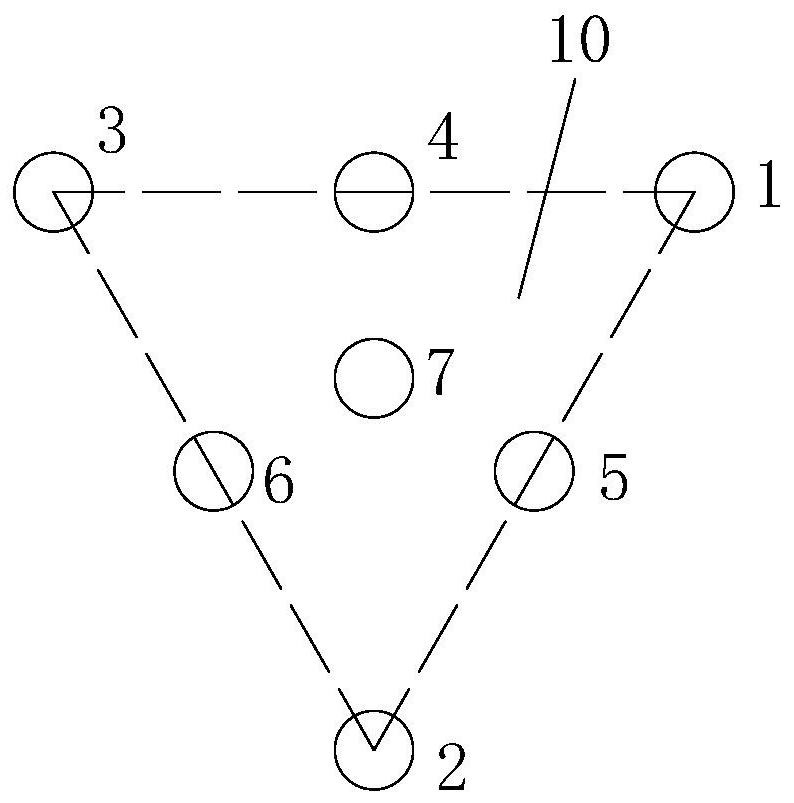

Method of Releasing the Stress of the Triangular Suspended Roof by Blasting the Island Body

ActiveCN111042815BEnsure safetyFall in timeDisloding machinesMaterial fill-upStress concentrationMining engineering

The invention discloses a method for blasting an island body to release the stress of a triangular suspended roof region. The method comprises the following blasting steps that firstly, drilling holesare distributed according to the area of the triangular suspended roof region, and the drilling holes at least comprise main drilling holes arranged in the three angular positions and the central position of the triangular suspended roof region respectively, and a plurality of adjusting drilling holes arranged in other positions in the triangular suspended roof region; secondly, carbon dioxide blasters are installed inside the main drilling holes, and the adjusting drilling holes are vacant inside to serve as free surface vacant holes; and finally, all the carbon dioxide blasters inside the main drilling holes are initiated. The method for blasting the island body to release the stress of the triangular suspended roof region is safe and reliable, is not influenced by gas accumulation in agoaf, and is particularly suitable for the application to a highly gassy mine, the blasting fragment size is not limited, construction is simple and convenient, the area of the triangular suspended roof region can be reduced effectively in time, stress concentration in the goaf is weakened or eliminated, a suspended roof in the goaf is timely stripped and collapsed, the goaf at the middle upper part is filled, and safe and smooth production of a working face is guaranteed.

Owner:CENT SOUTH UNIV

An automatic cold insulation window for indoor use

ActiveCN109965653BReduce exposurePrevent from being closedCurtain accessoriesSpecial door/window arrangementsLiquid stateEngineering

The invention discloses an automatic cold-insulation window for indoors, which comprises a frame, glass and a blocking cloth. A vertically arranged elastic hanger is fixedly connected, and the blocking cloth can be covered and stored on the elastic hanger. A through hole is opened in the middle of the bottom end of the frame, and a fixing member is arranged in the through hole. The invention utilizes the characteristic that the low-boiling point liquid is gaseous at normal temperature. In a closed volume, when the low-boiling point liquid changes from gaseous state to liquid state, negative pressure will occur, thereby realizing a self-triggering structure according to temperature. The outstanding feature of the present invention is that the power is provided by natural reaction, and the process is reversible, so that the cloth can be dropped in time when the temperature is lowered and there is no care.

Owner:周静

High-strength belt breakage protection device

PendingCN112124903APrevent free runPrevent the escapeConveyorsControl devices for conveyorsEngineeringPhysics

Owner:云南滇东雨汪能源有限公司

Automatic cold insulation window used indoors

ActiveCN109965653AFall in timeProcess reversibleCurtain accessoriesSpecial door/window arrangementsLiquid stateBoiling point

The invention discloses an indoor automatic cold insulation window. The window comprises a frame, glass and blocking cloth. The glass is arranged in the frame in a sealed mode. The top end of the blocking cloth is hung on the frame. The middle of the top end of the frame is fixedly connected with an elastic hanging piece which is vertically arranged. The blocking cloth can be shaded and containedon the elastic hanging piece. A through hole is formed in the middle of the bottom end of the frame. A fixing piece is arranged in the through hole. The characteristic that the low-boiling-point liquid is in the gas state at normal temperature is utilized. When the low-boiling-point liquid is converted from the gas state to the liquid state within a closed volume, the negative pressure is generated. After that, the self-triggering type structure according to the temperature is achieved. The nursing bed has the outstanding characteristics that power is provided through natural reaction. The process is reversible. The blocking cloth can fall off in time in the shortage condition of the nursing service in the temperature reduction state.

Owner:周静

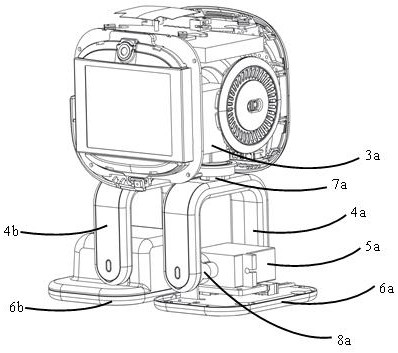

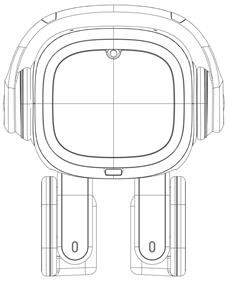

Fall detection method and fall protection method for foot type desktop pet robot

The invention relates to the technical field of robots, in particular to a falling detection method and a falling protection method for a foot type desktop pet robot. An acceleration sensor is arranged in the foot type desktop pet robot, when the robot falls, the acceleration sensor can detect falling, a foot steering engine of the robot executes falling protection action, a foot steering engine shaft is only subjected to radial force and not subjected to torque when the foot touches the ground, and therefore a steering engine gear is protected against damage, and the service life of the foot type desktop pet robot is prolonged. And the reliability and durability of the foot type tabletop pet robot are improved.

Owner:灵起科技(深圳)有限公司

Method for preventing rock burst by adopting high-pressure fracturing

ActiveCN102536240BDestroy the original formFall in timeUnderground miningSurface miningHigh pressureRock burst

The invention belongs to the coal mining field, in particular to a method for preventing rock burst by adopting high-pressure fracturing, which adopts a high-pressure fracturing method to enable a coal seam roof to be fractured to realize pressure relief in a balanced manner and prevent rock burst. A drill hole, a sleeve and a jet orifice are directly distributed from the ground to a destination layer in a designed construction area, water is injected by high pressure, so that the coal seam roof generates a great amount of fractures to realize pressure relief in the balanced manner, and the fracture slots are communicated by fracturing, the original form of rocks is destroyed, and an original stress field is changed and destroyed, an overlying rock is subjected to caving timely along with the progress of a working surface during backstopping, a large-area hanging arch is no longer formed, the damage to a digging space due to caving caused by the large-area hanging arch can be effectively prevented, and threat of rock burst to mining is eliminated.

Owner:河南省煤层气开发利用有限公司

Coal pillar type rock burst prevention and control method based on electric pulse

PendingCN114320293AFall in timeAvoid formingMining devicesDisloding machinesStress concentrationMining engineering

The invention provides a coal pillar type rock burst prevention and control method based on electric pulses, and relates to the technical field of mine safety production. According to the method, the stress concentration degree of the coal pillar is reduced from the goaf suspended roof fracturing and coal body weakening angles. A hydrofracture method is adopted to cut off a suspended and exposed top plate of the goaf, and the acting force of the suspended top of the goaf on the coal pillar is reduced. Meanwhile, an electric pulse presplitting method can be adopted for further presplitting and pressure relief of the concentrated stress area of the coal pillar, so that the concentrated stress is transferred to the deep area of the coal pillar, and the stress concentration degree of the surrounding rock of the roadway is reduced. The two methods act together to achieve the purpose of preventing and controlling the coal pillar type rock burst.

Owner:LIAONING TECHNICAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com