Double-effect damage prevention roller treatment device

A processing device, anti-damage technology, used in grain processing and other directions to ensure a stable grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

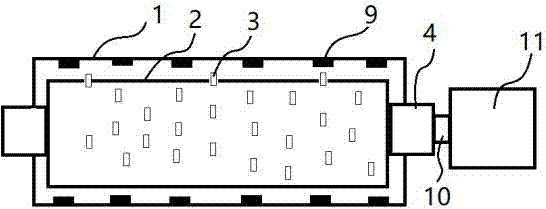

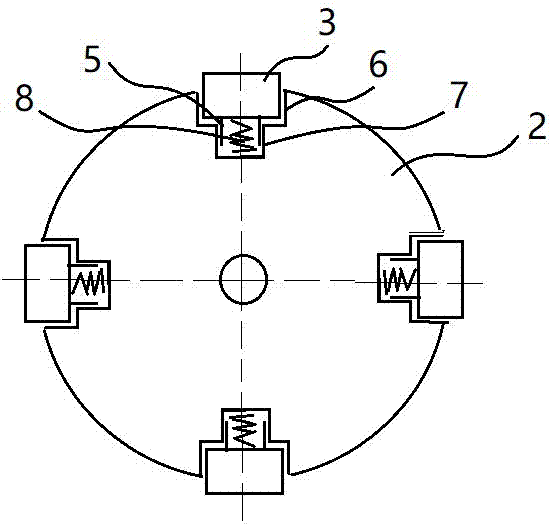

[0018] Such as Figure 1-2 As shown, a double-effect anti-damage drum processing device includes a drive mechanism 11, a speed reduction device 10 and a drum processing device; the drum processing device includes a drum peripheral processing side wall 1 and a processing drum 2, and the processing drum 2 is a cylinder Shaped solid drum, the central position of both sides of the processing drum 2 is provided with a drive shaft 4; the processing drum 2 is provided with several slotted holes, and the slotted holes include a first slotted hole section 6 and a second slotted hole section 7; 2 is provided with a number of roller teeth 3 corresponding to the slot holes, and the roller teeth 3 are all located in the slot holes on the corresponding processing drum 2, and the tooth top surface of the roller teeth 3 is higher than the outer edge of the slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com