Surrounding rock support method adopting tensioning type pre-tightening anchor rod

A technology of surrounding rock support and pre-tightening force, which is applied to the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of high labor intensity of construction personnel, damage to the rod body, scrapping of the bolt, etc., and avoid the torque of the bolt Insufficient force, timely protection of the roof, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] The specific steps of the surrounding rock support method of the tensioning type pre-tightening force bolt are as follows:

[0027] a. Drill bolt installation holes: use blasting or fully mechanized excavator to break coal and gangue in the roadway. When the height of the roadway reaches the requirements of the roof bolt for construction, use the bolt drill rig to drill the bolt installation hole, and clean the remaining water and slag in the hole;

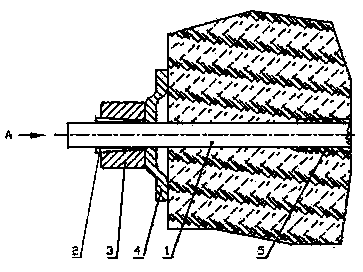

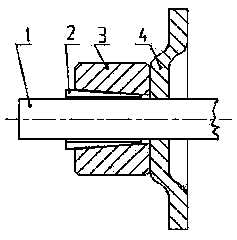

[0028] b. Initial installation of anchors and anchor locks: After the work of laying nets and installing reinforcement beams is completed, if figure 1 , figure 2 As shown, the anchoring agent 5 is first injected into the anchor rod installation hole, then the front end of the anchor rod 1 made of threaded steel is inserted into the anchor rod installation hole, and the anchor rod supporting plate 4 and the devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com