Ice preventing and ice removing wind power blade and manufacturing method thereof

A technology for wind power blades and anti-icing, which is applied in wind power generation, wind power engines, and final product manufacturing. The production method is simple and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

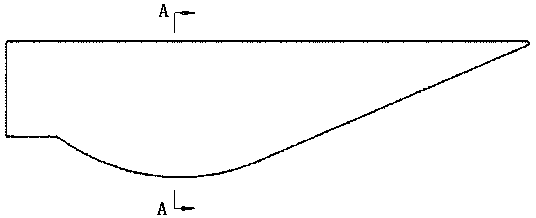

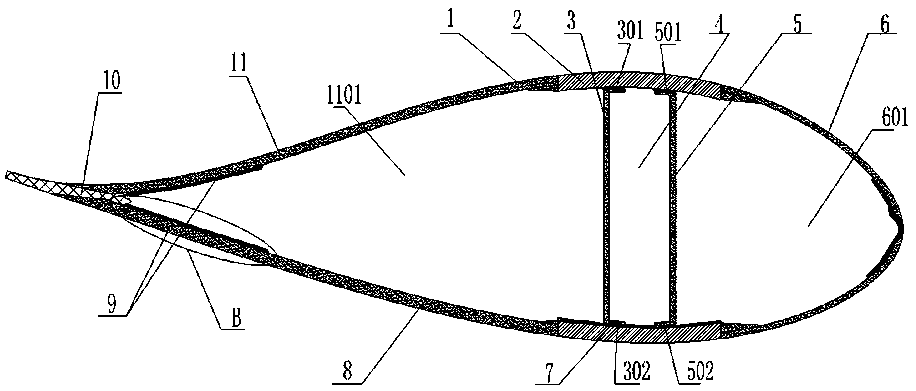

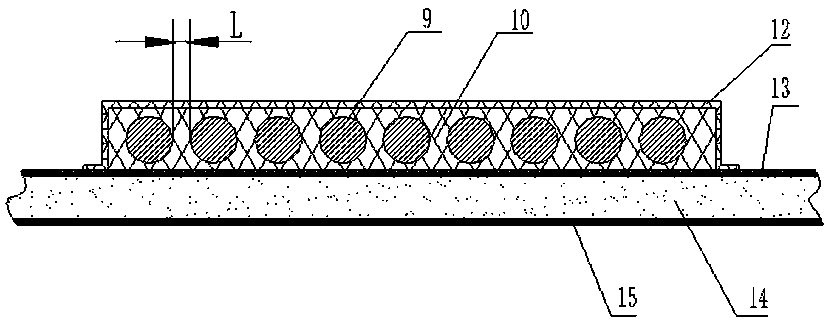

[0039] An anti-icing wind turbine blade, comprising a wind turbine blade body and a heating resistor 9 arranged on the inner wall of the wind turbine blade body, the wind turbine blade body includes an upper shell 1 and a lower shell 8 bonded together, the upper shell The body 1 and the lower shell 8 both include a glass fiber outer skin 15, an intermediate core material 14 and a glass fiber inner skin 13 from the outside to the inside. There are multiple horizontal slots and multiple vertical slots on the board surface, the multiple horizontal slots and the multiple vertical slots are intersecting and connected, and the heat conducting material 16 is arranged in the horizontal slots and the vertical slots.

[0040] The thermally conductive material 16 is preferably any one of carbon fiber or metal sheet with relatively high thermal conductivity. For example, the metal sheet can be selected from aluminum foil.

[0041] The heating resistor 9 includes a resistance wire bundle (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com