Preparation of pressure sensitive adhesive dispersions from multi-stage emulsion polymerization for applications of protective films

A pressure-sensitive adhesive and emulsion polymerization technology, applied in the direction of adhesives, ester copolymer adhesives, non-polymer organic compound adhesives, etc. Combined force, the effect of reducing adhesive residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0057] 1. A method for preparing a pressure-sensitive adhesive dispersion, comprising:

[0058] 1) The first stage of emulsion polymerization, including

[0059] i) obtaining first-stage polymer particles in an aqueous medium from a first-stage monomer composition consisting of an ethylenically unsaturated monomer and at least one ethylenically unsaturated monomer containing a carboxylic acid group to forming a first stage dispersion wherein the carboxylic acid group-containing ethylenically unsaturated monomer is included in an amount of at least 1.0% by weight (preferably 10 to 30% by weight) of the first stage monomer composition;

[0060] ii) adding a chain transfer agent to the first-stage monomer composition, wherein the chain transfer agent is added in an amount in the range of 0.3-1.5% by weight, preferably 0.3-1.1% by weight, based on the first-stage monomer composition weighing scale;

[0061] iii) neutralizing the first stage dispersion with an aqueous alkaline so...

Embodiment 1

[0091] Example 1. Preparation and application of dispersion P01

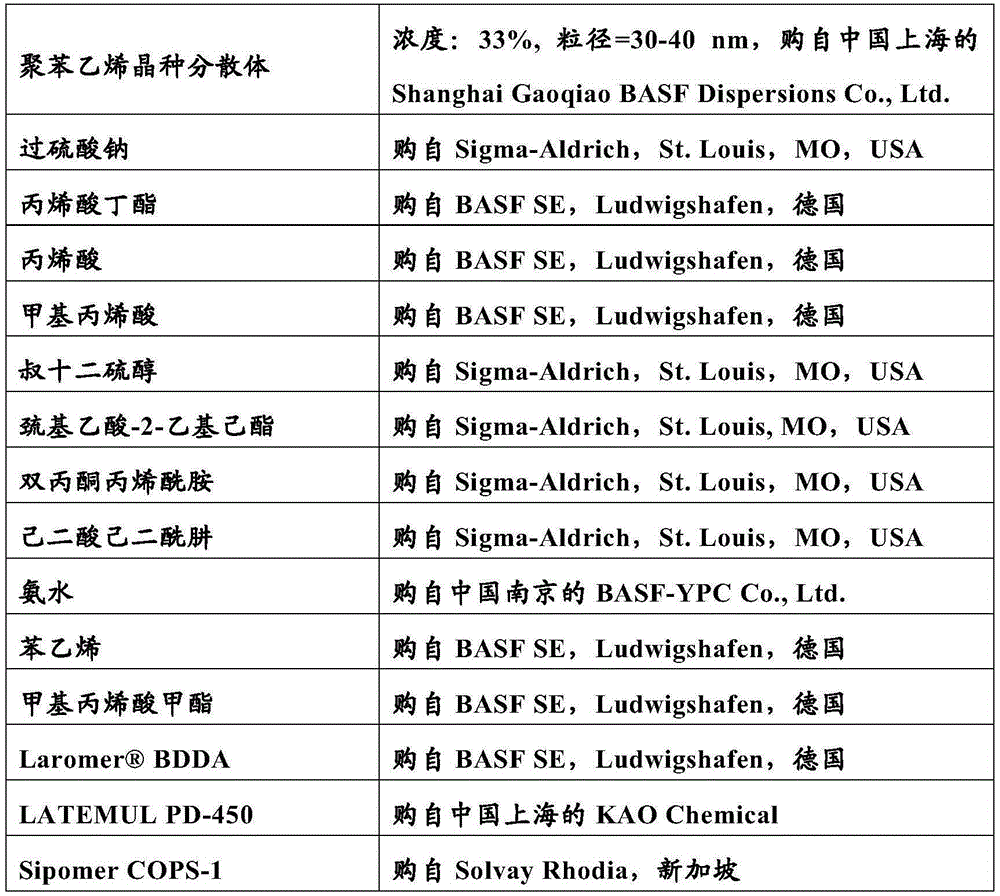

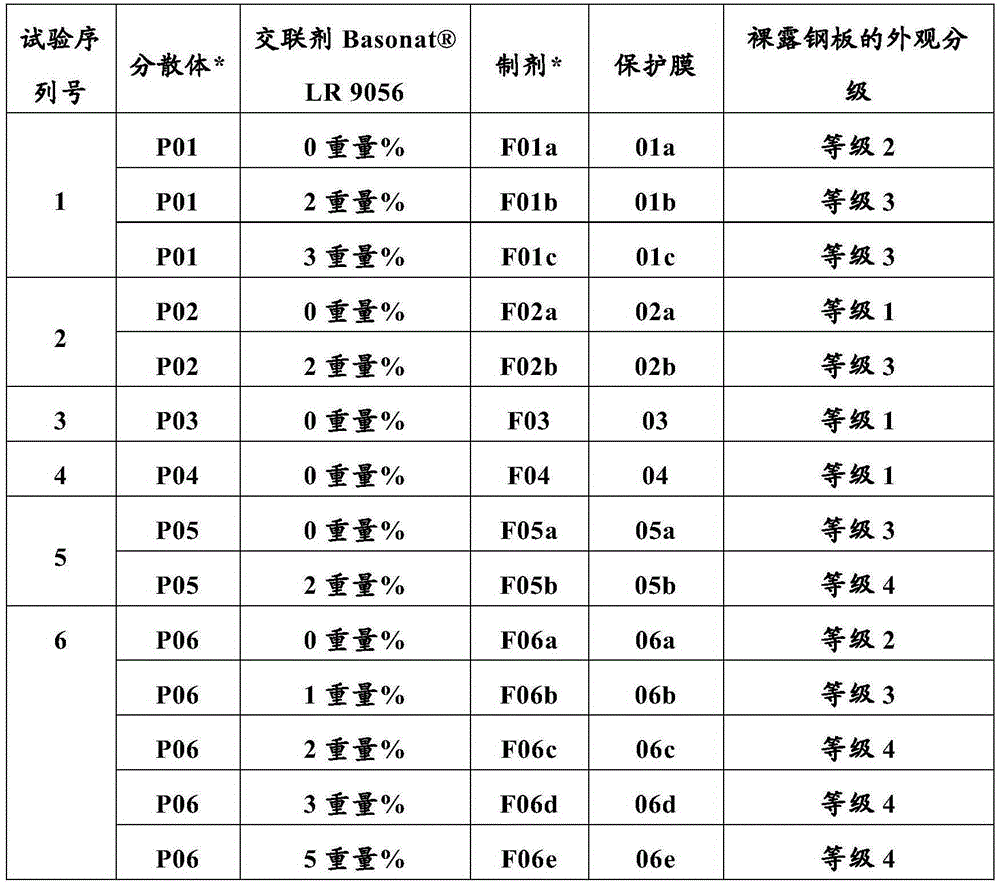

[0092]A polystyrene seed dispersion (4 g, 33% solids) was introduced into the polymerization vessel. The polystyrene seed dispersion was heated and sodium persulfate (SPS, 7%, 71 g) was added when the temperature reached 80°C. Afterwards, the addition of mixture 1 (consisting of 126 g butyl acrylate, 22 g acrylic acid, 1.3 g tert-dodecanethiol) was started. Aqueous ammonia (25%, 10.5 g) was added over 45 minutes after starting the addition of Mixture 1 30 minutes later. After the above steps are completed, start to add mixture 2 (by 716g butyl acrylate, 42g styrene, 84kg methyl methacrylate, 7.7g BDDA), and for 3 hours, sodium persulfate (7%, 71 g) and ammonia water (25%, 21 g) were added simultaneously.

[0093] After the above polymerization step, chemical deodorization starts. Sodium persulfate (7%, 22 g) and sodium bisulfite (1.5%, 50 g) were added to the polymerization vessel. Chemical deodorization f...

Embodiment 2

[0095] Example 2. Preparation and application of dispersion P02

[0096] Dispersion P02 was prepared according to the same procedure as in Example 1, except that the polystyrene seed dispersion was not included in the first charge to the polymerization vessel in the emulsion polymerization stage.

[0097] The obtained dispersion P02 had a solids content of 44.6%, a pH of 5.8 and a particle size of ~212 nm.

[0098] Dispersion P02 was neutralized to pH 7.4 with NaOH solution (8% by weight), then with 0.5% An aqueous solution of I-SC (50% by weight) was formulated to form Formulation F02a. Formulation F02a was mixed with 2% by weight The LR9056 was further mixed and stirred vigorously for 30 minutes to form Formulation F02b. Formulations F02a and F02b were each cast on a corona-treated polyethylene film and dried at 70°C for 3 minutes to form protective film 02a and protective film 02b. The dry weight of the adhesive layer obtained on the film was ~5 g / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com